Nietz ESD2 Installation and operation manual

ESD2

USER MANUALS

VARIABLE SPEED DRIVES

First of all, thank you for purchasing series frequency converters of our company!

PREFACE

Notes:

CONTENTS

Chapter 1 Introduction of Frequency Conversion ...........................................................1-2

1.1 Name of each part of frequency converter ..................................................................1

1.2 Inverter Model and Technical Data .................................................................................2

1.3 Technical Features of Frequency Converter .................................................................2

1.4 Installation Dimensions of Frequency Converter ......................................................2

Chapter 2 Description of Control Loop

2.1 Control Loop Wiring Diagram ..........................................................................................3

2.2 Control Terminals and Function Description...............................................................................................................4

.................................................................................3-4

Chapter 3 Key Description

3.1 Introduction to Operation and Display Interface ......................................................5

3.2 Description of Function Indicator ...................................................................................5

..........................................................................................................5-6

3.3 Key Function Description ...................................................................................................6

6.1 RTU Mode and Format

6.1. 1 Format per byte in RTU mode .............................................................................18

6.1. 2 RTU data frame sequence diagram ...................................................................18

......................................................................................................18

6.2 Description of Read-Write Function Code ................................................................18

6.3 Description of parameter address of communication protocol ..................18-21

6.4 03Read Function Mode ..............................................................................................20-21

6.5 Write Function Mode ........................................................................................................21

Chapter 4 Function Parameter Table ....................................................................................7-16

2.3 Terminal Screen Printing

2.3.1 Screen printing of external control terminals ..................................................4

2.3.2 Screen printing of power board terminals ........................................................4

...................................................................................................4

Chapter 5 Error Codes ...................................................................................................................17

Chapter 7 Warranty Agreement .................................................................................................22

Chapter 8 Product Warranty Card .............................................................................................23

Chapter 6 Communication Protocol ..............................18-21

(the following data are all hexadecimal)

series frequency converter is a simple and smart frequency converter, which can control AC asynchronous

motor by V/F, and is suitable for simple places such as assembly line and fan. This manual introducesthe configuration

function and usage of series frequency converters.

Please understand the safety precautions before using this product. When using for the first time (installation,

operation, maintenance, inspection, etc.)

Please read this manual before series frequency converters. Equipment supporting manufacturers please send

this manual to the end user along with it for subsequent reference.

In order to illustrate the details of the product, the legends in this manual sometimes show the state of

removing the housing or safety cover.

When using this product, please be sure to install the shell or cover as required, and operate according

to the instructions.

The legend in this instruction manual is for illustration only and may differ from the product you ordered.

Due to product upgrade or specification change, and in order to improve the convenience and accuracy

of the manual, the contents of this manual will be changed in time.

If you need to order the instruction manual due to damage or loss, please contact our regional agents

or contact our customer service center directly

ESD2

ESD2 it

ESD2

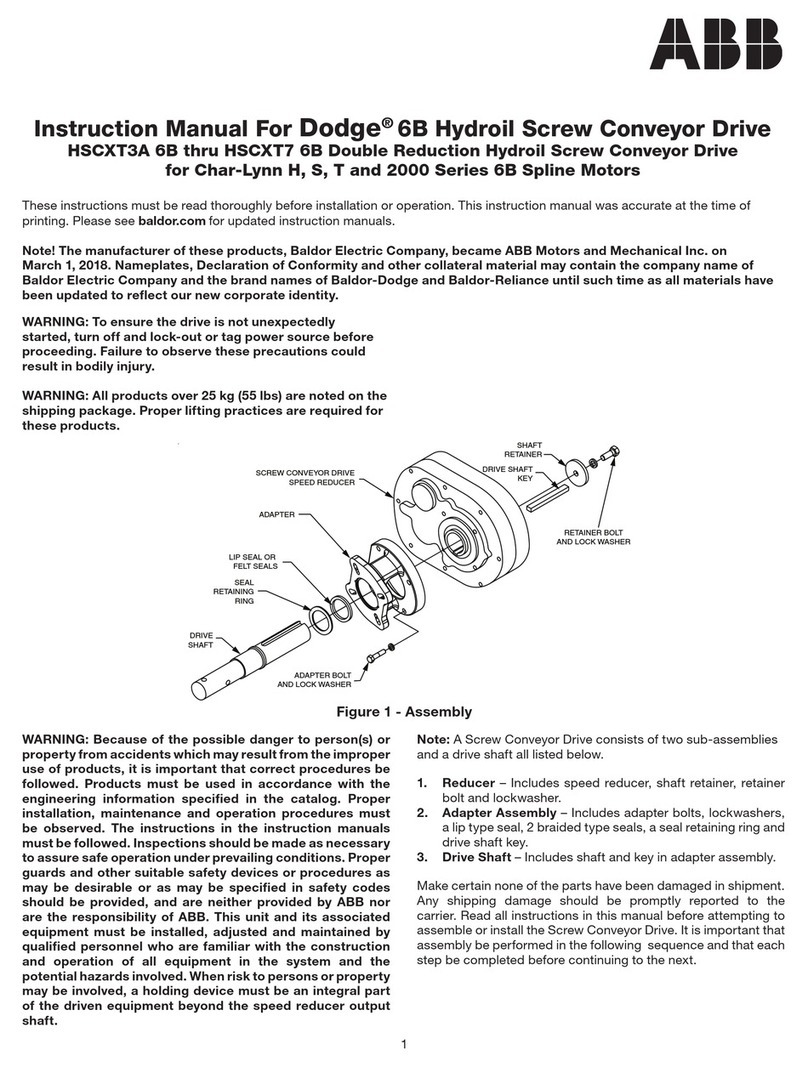

1.1 Name of each part of frequency converter

Chapter 1 Introduction of Frequency Conversion

1.2 Inverter Model and Technical Data

1.3 Technical Features of Frequency C onve r te r

◎ The output frequency range is 0-300 Hz;

◎ The op eration panel has its own s peed re gulating poten tiometer ;

◎ Built-in P I D regu lator c an real ize c losed-lo op regu lation;

◎ Built-in P I D regu lator c an real ize c losed-lo op regu lation;

◎ Multifun ctional open c ollector output;

◎ Suppor t an alog input 0-5 V;

◎ The V/ F cur ve function can be set a rbitrar ily to meet t he requ irements of speci al occ asions;

◎ Use th e Shif t key to view real-tim e param eters,

◎ Adopt a new g enerati on I P M module with co mplete protection functions ;

1.4 Inst allatio n Dimen sions of Freq uency C onverter

-1- -2-

Signal terminal

Main terminal

Plastic casing

Panel sticker

Potentiometer

Fan

Figure1-1

Table 1-1 Frequency Converter Model and Technical Data

Inver ter Model

Single phase power supply:200~240VAC,50/60Hz

Power supply capacity

K VA

Input Current

A

Output Current

A

Adaptive motor

K W

3 . 0 2 .3 1 . 6 0 .2

3 . 8 3 . 2 2 . 1 0 .4

5.6 4 .0 3 .7 0 .7 5

9.9 8 .3 5 .5 1 .1

160mm

102mm

89,5mm

Hole spacing L:80mm

2- 4,5mm

series frequency converter has convenient speed regulation, good hand feeling of potentiometer

knob, optimized structure, forced air cooling, strong electromagnetic compatibility, complete parameter

functions, instrument installation, external operation panel, large low frequency torque, optimized P W M

complete protection function and fast response.

W:53mm

ESD2

ESD2-0R2G1; 0.2kw

ESD2-0R4G1; 0.4kw

ESD2-0R7G1; 0.75kw

ESD2-1R1G1; 1.1kw

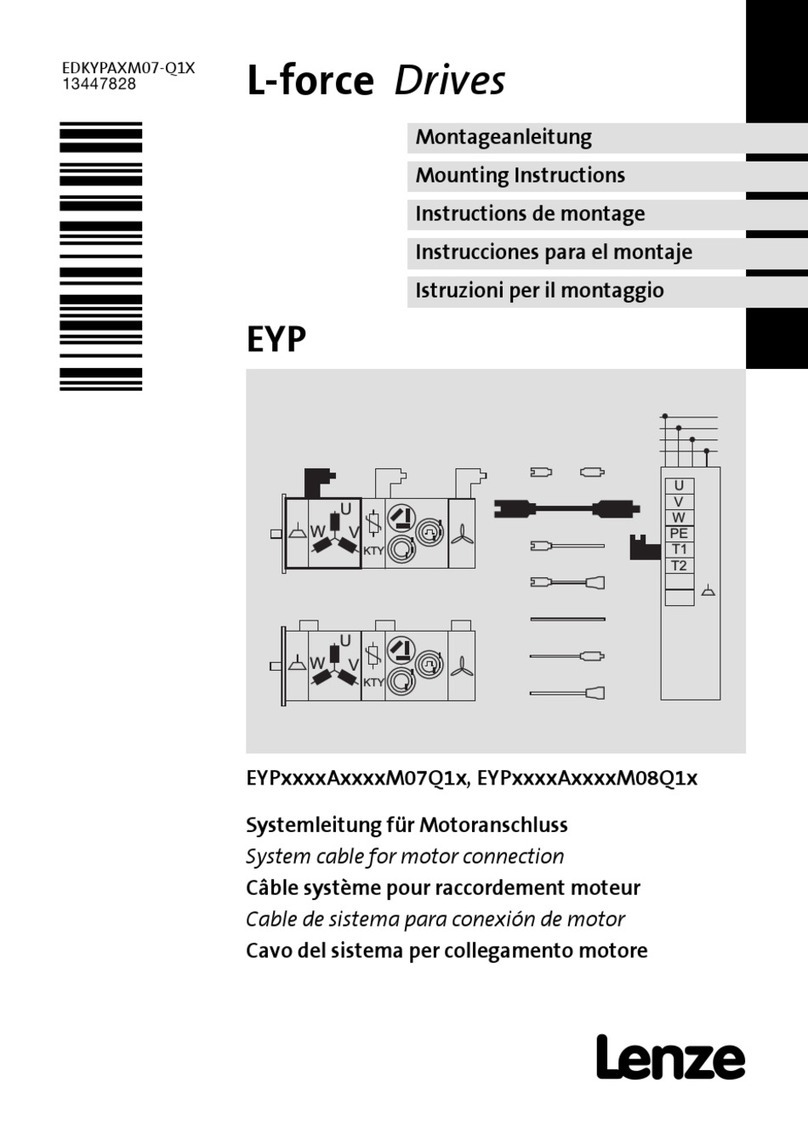

2.1 Con trol Loop Wiring Diagram

2.2 Control Terminals a nd Func ti on Description

Chapter 2 Description of Control Loop

-4--3-

Table2-1 -2 Control Loop Terminal Description

C a t e g o r y Funct ion Descri ption Specifications

Terminal Symbol

Power interface + 5V Analog Input Terminal Power

Supply

+5 V

+ 2 4 V

C O M

+2 4 VDigital signal input terminal

power supply

Analog, Digital, + 5V and + 24V

Ground Reference

Maximum output 100mA

Maximum output 20mA

Analog quantity and digital

quantity share land

A I AI only receives voltage quantity input

(reference ground: COM) INPUT, input voltage range:

0 ~ 5V

Analog Input

X 1

Multifunction Input

X 2

X 3

X 4

X 5

Y 1

Multifunctional programmable

open collector output,

programmable The process is

defined as a switching value

output terminal with multiple

functions, Common side: COM

OUTPUT, maximum load

currentNo more than 50mA.

Digital Output

X 1

X (X1, X2, X3, X4, X5) to COM

Active when intermittent shorting

(Common side: COM)

INPUT, 0-10V level signal,

Active low, 5mA.

A + Rs485 Signal + Terminal Standard Rs485

communication

interface

Communication

Interface A - Rs485 Signal-Terminal

Figure2-1

Table 2-1 Inverter Main Circuit Description

Terminal marking N a m e D e s c r i p t i o n

L 1、NSingle-phase power

supply input Single phase2 2 0 VAC power connection point

U、V、WFrequency converter output Connect three-phase AC motor

Grounding terminal

2.3.1 Screen printing of external control terminals

+5V COM AI A+A- X1 X2 X3 X4 COM +24V Y1

2.3.2 Screen printing of power board terminals

L1 L2 G U V W

2 . 3 Ter mi n a l S c r ee n P r i n ti n g

Grounding terminal

Multi-function

terminal input

1ph 220v power

supply input 50/60HZ three phase

asynchronous motor

analog input

Modbus,this

function can not use

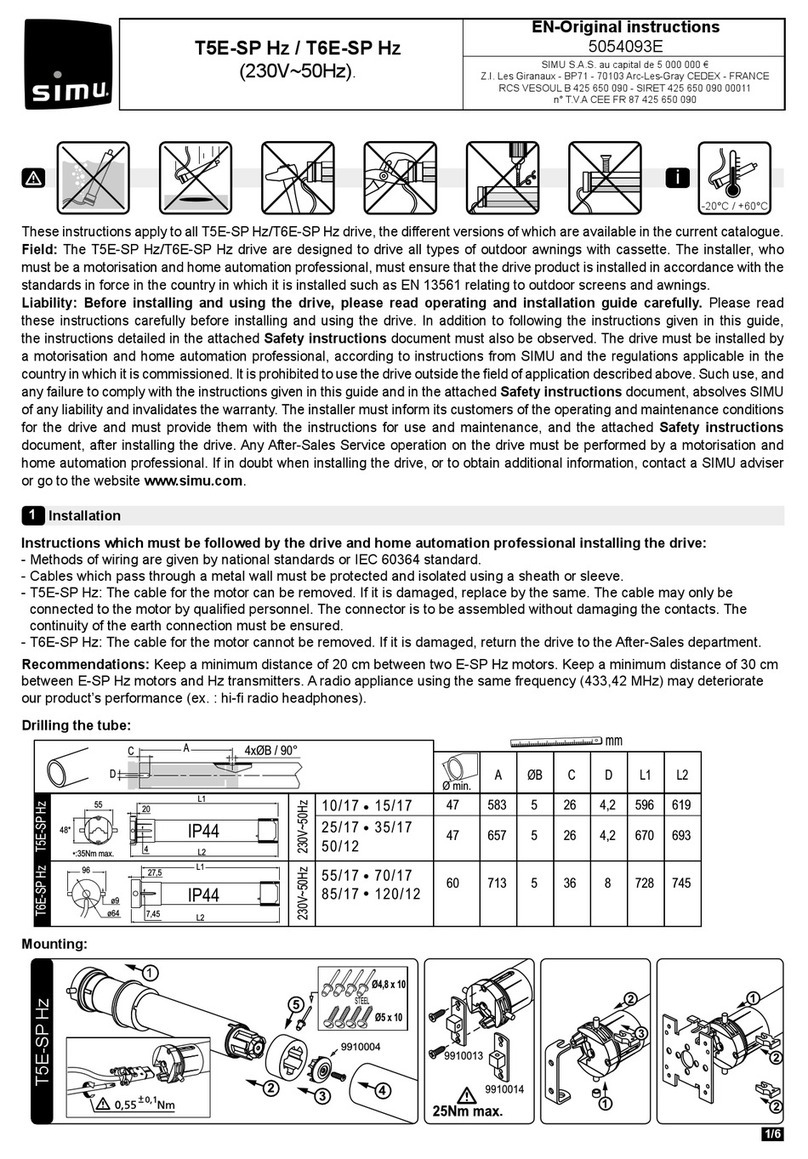

3.1 Introduction to Operation and Display Interface

3.3 Key Function Description

Chapter 3 Key Description

3.2 Description of Function Indicator

-5- -6-

Operating keys

Function indicator light

Speed regulating

potentiometer

Data Display

图3-1

Table 3-1 indicator function list

Name escription

Status indicator

F W D

R E V Reverse running indicator The light is on to indicate that the

frequency converter is in reverse operation

ALM Fault indicator lamp When the frequency converter is in a

fault state, the lamp lights up and goes out in a normal state

Unit indicator

H z Frequency unit

AUnit of current

VVoltage unit

Digital tube display 8Paragraph4BitsLEDDisplay, display frequency, current,

voltage and other information

Analog potentiometer Panel potentiometer regulates frequency

Table 3-1 Key Function Description

N a m e D e s c r i p t i o n

PRG Function Settings Enter Key, Exit Key

FUNC Ink key

ENTER Setting Parameter Confirmation

》》

Under the shutdown display interface and the operation display interface, you

can move right to cycle and select display parameters; When modifying

parameters,You can select the modification bit of the parameter

△Up key, data setting up key

▽Down key, data setting down key

RUN In keyboard operation mode, used for patrol operation

STOP

When running, this key can be used to stop the running operation; In case

of fault alarm state, the control mode can be used in many control modes

Press the key to reset the operation

Forward rotation operation indicator The light is on to indicat

that the frequency converter is in a forward running state

Chapte r 4 Function Parameter Table

The symbols in the menu are described as follows

Indicates the parameter that can be modified in any state;

Indicates the parameter that cannot be modified in the running state;

Indicates that the parameter is actually detected and cannot be modified;

Indicates that the parameter is "Manufacturer Parameter" and can only be

modified by the manufacturer. Modification is prohibited by the user.

×:

○:

◆:

◇:

Function

Code N a m e C o n t e n t S e t R a n g e Facto r y

Sett ings Change

F 0 Group-Basic Operating Parameters

F0.00

0: vector control

1: Reserved

2: V/F Control Note:

This parameter cannot be initialized

please modify it manually

Motor control mode 0~2 2×

F0.01

0: Operation Panel Run Command Channel

1: Terminal Operation Command Channel

2: communication run command channel

Command

Source Selection 0~2 0 ○

F0.02

0: given number 1 (preset frequency F0.03,

operation panel key ▲、▼can be modified)

1: The number is given 2 (preset frequency

F0.03, terminal UP/DOWN can be

modified)

2: AI1 analog (0 ~ 20mA/0 ~ 5V)

3: Reservation

: panel potentiometer

5: Reserved

6: Multi-speed

7: Reserved

8: PID

9: given communication

Main Frequency

Source X Selection 0~9 4 ○

F0.03 The set value is a given initial value

of the frequency number

Preset frequency 0.00 ~ upper limit

frequency 50.00 ○

F0.04 0: In the same direction

1: Opposite direction 0~1 0

Running direction ×

F0.05

The maximum output frequency is

the highest frequency allowed by

the frequency converter and is the

reference for acceleration and

deceleration setting.

MAX{50.00,

F0.06】}

~ 300.00

50

Maximum Frequency ×

F0.06 The operating frequency cannot

exceed this frequency

Lower limit frequency

"F0.07"~

Maximum frequency

"F0.05"

50.00

Upper limi t

freq uency ×

F0.07 The operating frequency cannot be

lower than this frequency

0.00 ~ upper

limit frequency

"F0.06" 0.00

Lower limit

frequency ×

F0.08

For occasions requiring silent

operation, appropriate mention

can be made The high carrier

frequency meets the requirements,

but the carrier frequency is increased

The rate will increase the calorific

value of the frequency converter.

Carrier frequency

2.0~16.0KHz

0.05~4.0KW

6.0KHz

5.5~11.0KW

4.5KHz

15.0~30.0KW

3.0KHz

○

F0.09

The frequency converter accelerates

from zero frequency to the maximum

output frequency Take time

Acceleration time 0.1~6000.0S

0.05~4.0KW

7.5S

5.5~11.0KW

15.0S

15.0~30.0KW

30.0S

○

F0.10

The frequency converter decelerates

from the maximum output frequency

to the zero frequency station Take time

Deceleration time ○

F0.11 0:Operating Frequency

1:Set Frequency

Runtime frequency

instruction

UP/DOWN Benchmar 0~1 0×

F 1 G r o u p - M o to r P a r a m e t e r s

F0.09

F0.10

Setting motor parameters

减速时间 ○

F1.00 Motor rated power

Rated voltage of motor

Motor rated current

Motor rated frequency

Rated speed of motor

F1.01

F1.02

F1.03

F1.04

0.05~99.99KW

0~999V

0.1~600.00A

0.01Hz~

maximum frequency

0~60000RFM

50.00

×

×

×

×

×

F1.05 Stator resistance of

asynchronous motor 0.001~20.000Ω ×

Setting stator resistance of

asynchronous motor

F1.06 No-load current of

asynchronous motor 0.1 ~ rated current

of motor ×

Setting no-load current of

asynchronous motor

F 2 G roup Auxiliar y Operation Parameters

10.00

F2.00 Inching operation

frequency setting ○

Set inching forward rotation operating

frequency

F2.01 Inching acceleration

time setting

0.1~6000.0S

0.05~4.0KW

7.5S

5.5~11.0KW

15.0S

15.0~30.0KW

30.0S

○

Set inching acceleration time

F2.02 Setting of inching

deceleration time ○

0

F2.03 Shutdown mode 0~1 ×

0: Slow down and stop 1: Free shutdown

F2.04

F2.05

F2.06

F2.07

Start frequency of

shutdown DC braking

Stop DC Braking

Waiting Time

Stop DC brake voltage

0.00 ~ upper limit

frequency

0.0~6000.0s

0.0 ~ 50.0% *

motorRated voltage

0.0~100.0s

0.00

0.0

0.0

0.0%

○

○

○

○

-8--7-

Function

Code N a m e C o n t e n t S e t R a n g e Facto r y

Sett ings Change

Model Setting

Model Setting

Model Setting

Model Setting

Model Setting

Model Setting

Model Setting

Model Setting

Model Setting

Set inching deceleration time

Model Setting

Model Setting

0.00 ~ upper limit

frequency

Stop DC braking time

output

frequency

Output current

(effec tive value)

run comma nd

Start Fre quency of stop braking

stop brak ing waiting time

DC Brakin g capacity

stop brak ing time

F2.08 Set hopping frequency, hopping

frequency range

Hopping frequency 0.00 ○

F2.09 Hop frequency range

0.00~Upper limit

frequency

0.00 ○

F2.10 Torque lift setting The amount of manual torque increase,

which is set relative to the Percentage of

motor rated voltage. 0.0~30.0%Model

Settings ×

F2.11 Torque lift cutoff

frequency 0.00~Motor rated frequency.。15.00 ×

F2.12

The set frequency is below

the lower limit frequency

Rate-time action

0: Operate at the lower frequency limit

1:Zero frequency operation

2: Shutdown

0~20×

F2.13 FDTHorizontal Setting 10.00 ○

F2.14 FDTHysteresis value 1.00 ○

F2.15 Frequency arrival

FARDetectionWidth

Positive and negative detection width of

output frequency at set frequency

Internal and Terminal Output Valid

Signal (Low level). 5.00 ○

F2.16 Multi-speed

frequency 0 5.00 ○

F2.17 10.00 ○

F2.18 15.00 ○

F2.19 20.00 ○

F2.20 25.00 ○

F2.21 37.50 ○

F2.22 50.00 ○

F2.23 0.00 ○

F2.24 0○

F2.25 Shutdown Monitoring

Parameter Item

Selection

0~31

1○

By cha nging the setting value of the

func tion code, it can be changed

Moni toring items in the main

moni toring interface, such as

sett ing4, I.e., select the output

curr entD-04The default display item

n the ma in monitoring interface is the

curr ent output current value

0~31

F2.26 Display Mode

LED Bits: Adjust the frequency, PID Display

selection for given amount

0: Display frequency, PID Quantity given

1: Show only status monitoring parameters

LED Ten: Reserved

LED Hundred: Reserved

LED Thousands: Reserved

0-0001H 0○

F2.27 0: Invalid 1: Effective 0~10○

F2.28

In case of motor oscillation, set F2.28 to select

effective, turn on the oscillation suppression

function, and then adjust by setting the

oscillation suppression coefficient. Generally,

The oscillation amplitude is large, and the

oscillation suppression coefficient is increased

by F2.29

0~1000 100 ○

F2.29 Cooling Fan Control

0: Automatic control mode

1: The power-on process runs all the time

2. Fan action with temperature higher

than 50 ℃The fan does not operate

below 45 ℃.

0~20○

F2.30 PWM Mode Selection

0: full frequency seven segments

1: Full-frequency five-band

2: 7 to 5

0~20×

F2.31 AVR Functions

0: Invalid

1: The whole process is effective

2: Invalid only when decelerating

0~22×

F2.32 Parameter

Initialization

0: No action

1: All user parameters are restored to

factory settings

2: clear fault record

0~20×

F G r o u p 3 - I n p u t / O u t p u t Te r m i n a l s

0: The control end is idle

1: Forward Rotation Control (FWD)

2: Inversion Control (REV)

3: Three-wire operation control

4: Forward rotation inching control

5: Reverse inching control

6: frequency increment instruction (UP)

7: Frequency Decrease Command

(DOWN)

8: Free shutdown control

9: External Reset Signal Input (RST)

10: Reserved

11: External Fault Normally Open Input

: Multi-speed selection S1

: multi-speed selection S2

: multi-speed selection S3

15-17: retain

: frequency source switch

19: UP/DOWN frequency clear

20: run command channel force to

terminal

21: Acceleration and deceleration are

prohibited

22: to 47: retain

48: external shutdown signal input (STOP)

49: Stop DC Brake Command

50: Reserved

51: run command channel force to

communication

52-61: retain

F3.00 Input Terminal X1

Function 0~51 1×

F3-01 0~51 2×

F3.02 0~51 0×

F3.03 0~51 0×

F3.04~

F3.05 Reservation —— — ◆

F3.06 FWD/REV Terminal

Control Mode

0: 2-wire control mode 1

1: 2-wire control mode 2

2: 3-wire control mode 1

3: 3-wire control mode 2

0~3 0 ×

-10-

-9-

Function

Code N a m e C o n t e n t S e t R a n g e Facto r y

Sett ings Change

Function

Code N a m e C o n t e n t S e t R a n g e Facto r y

Sett ings Change

0.00~Upper limit

frequency

0.00~Motor rated

frequency.。

0.00 Hz~Upper limit

frequency

0.00 Hz~Upper limit

frequency

0.00~Upper limit

frequency

-Upper limit frequency

~ up Limited frequency

-Upper limit frequency

~ up Limited frequency

-Upper limit frequency

~ up Limited frequency

-Upper limit frequency

~ up Limited frequency

-Upper limit frequency

~ up Limited frequency

-Upper limit frequency

~ up Limited frequency

-Upper limit frequency

~ up Limited frequency

-Upper limit frequency

~ up Limited frequency

Multi-speed

frequency 1

Multi-speed

frequency 2

Multi-speed

frequency 3

Multi-speed

frequency 4

Multi-speed

frequency 5

Multi-speed

frequency 6

Multi-speed

frequency 7

Set multi-speed frequency 0

Set multi-speed frequency 1

Set multi-speed frequency 2

Set multi-speed frequency 3

Set multi-speed frequency 4

Set multi-speed frequency 5

Set multi-speed frequency 6

Set multi-speed frequency 7

Operation Monitoring

Parameter Item

Selection

Oscillation suppression

selection

Oscillation suppression

coefficient

Input Terminal X2

Function

Input Terminal X3

Function

Input Terminal X3

Function

FDT Horizontal set value FDT lagged value

time

time

F3.07 Terminal function

detection selection

at power-up 0~1 0○

0: Terminal Run command invalid on power-up

1: Terminal Run Command Valid on Power-on

F3.08

UF/DOWN Terminal

Frequency

Modification Rate 0.01~50.00Hz/S 1.00 ○

This function code is to set the frequency

modification rate when the UP/DOWN

terminal sets the frequency, that is, the

UP/DOWN terminal is shorted to the

COM terminal by 1The magnitude of the

frequency change in seconds.

F3.09 Input Terminal Valid

Logic Setting (X1-X4) 0000~1111 ○

LED bits: X1 logic select

LED ten bits: X2 logic select

LED hundred bits: X3 logic select

LED thousand bits: X4 logic select

0 indicates positive logic, i.e. the connection

between the Xi terminal and the common

terminal is valid, and the disconnection is

invalid

1: Indicates inverse logic, that is, the

communication between the Xi terminal and

the common terminal is invalid, and the

disconnection is valid

0

F3.10 Reservation — — — ◆

F3.11 Ai1 Input Lower Limit

Set AI1 Lower Limit

0.00V/0.00mA~

5.00V/20.00mA 0.00 ○

F3.12 Ai1 Lower Limit

Corresponding Setting

The lower limit of AI1 is set to correspond to

the setting, which corresponds to

Percentage of upper limit frequency

-100.0%~100.0% 0.0% ○

F3.13 Ai1 Input Upper Limit

Set AI1 upper limit

0.00V/0.00mA~

5.00V/20.00mA 5.00 ○

F3.14 Ai1 Upper Limit

Corresponding Setting

Set the AI1 upper limit corresponding

setting, which corresponds to

Percentage of upper limit frequency

-100.0%~100.0% 100.0% ○

F3.15 Ai1 Analog Input Signal

FilteringWave time

constant

This parameter is used where the AI1 input

signal is filtered Reason, in order to

eliminate the influence of interference.

0.1~5.0s 0.1s ○

F3.16~

F3.20

—

——◆

F3.21 Open Collector Output

Terminal Y Setting 0~18 2×

F3.22

0: Idle

1: Frequency converter in operation

2: Frequency Converter Fault

3: Frequency/Speed Level Detection

Signal (FDT)

4: Frequency/Speed Arrival Signal (FAR)

5: The frequency converter is running at

zero speed

6: Frequency converter overload pre-alarm

7: The frequency converter is ready for

operation

8: Output frequency reaches upper limit

9: Output frequency reaches lower limit

10: Communication Settings

11: Alarm Output (Continue)

12: external failure shutdown

12 to 18: retain

——◆

——◆

F3.23

Delay from the change of the state of the

switching value output terminal Y to the

change of the output

Y Output Delay Time

F3.24

F3.25 Y OFF Delay Time

0.0~255.0s

0.0~255.0s

0.0

0.0

×

×

F3.16~

F3.20

—

——◆

F 4 G r o u p - P ro t e c t i o n P a r a m e t e r s

F4.00 Voltage limiting factor 0: off, 1 to 101 20

This parameter is used to adjust the ability

of the frequency converter to suppress

overvoltage during deceleration.

Encountered the motor coefficient setting

101 with large inertia

×

F4.01 Overvoltage limit level 350~600/400

~850V 370/700V

The overvoltage limit level defines the time

of overvoltage stall protection Operating

voltage of ×

F4.02 Accelerating current

limiting coefficient 0: off, 1-100

This parameter is used to adjust the frequency

converter during acceleration

Ability to suppress overcurrent ×

20

F4.03 Accelerating current

clipping level 50%~250% 160%

The current limiting level defines the

current threshold for automatic current

limiting, and its set value is the percentage

relative to the rated current of the

frequency converter.

×

F4.04 Fault automatic

reset times 0~10 0

When the number of obstacle resets is

set to 0, there is no automatic reset

function, only manual reset, and 10

means that the number of times is not

limited, i.e. countless times.

×

F4.05

Automatic fault

reset interval

Time 0.5~25.0s

Set Automatic Failure Reset Interval ×

3.0s

F4.06 Output phase-out

protection coefficient 0.0~20.00

Setting Input Phase Default

Protection Factor 10.00 ○

F4.07 Constant speed

current limiting

coefficient

0:off,1~5000

This parameter is used to adjust the ability

of frequency converter to suppress

overcurrent in constant speed process. ×

0

F4.08 Undervoltage

protection level

50~280/50

~480V

This function code specifies the allowable

lower limit voltage of DC bus when the

frequency converter works normally. ×

180/360V

F4.09

Overload pre-alarm

level of frequency

converter 0~150% 0~150%

The current threshold of overload

pre-alarm action of frequency converter

is set as a percentage relative to the

rated current of frequency converter.

○

F4.10

Overload Prealarm

Delay of Frequency

Converter

0.0~15.0s 5.0s

The delay time between the output current

of the frequency converter continuously

exceeding the amplitude of the overload

pre-alarm level (F4.09) and the output of the

overload pre-alarm signal.

×

G r o u p F 5 - P I D c o n t r o l p a r a m e t e r s

F5.00 PID given quantity

input channel

0~8 7

0: given by number

The PID assign amount is given by a number

and set by that function code F5.01

1: AI1

2-6: retain

7: given pressure (MPa, Kg)

8: panel potentiometer

○

F5.01 Set a given number 0.0~100.0% 50.0%

Use the operating keyboard to set the given

amount of PID control. This function is valid

only when the PID given channel selection

number is given (F5.00 is 0 or 8). If

F5.00 is 8, use as pressureGiven the force,

this parameter is consistent with the unit

of F5.04.

○

F5.02 PID Feedback Input

Channel 0~1 0

0AI1

1:Reserved ○

-12--11-

Function

Code N a m e C o n t e n t S e t R a n g e Facto r y

Sett ings Change

Function

Code N a m e C o n t e n t S e t R a n g e Facto r y

Sett ings Change

Reservation

Reservation

Reservation

Reservation

F5.03

PIDRegulation

characteristic 0~1 0

0: Positive effect

When the feedback signal is greater

thanPIDThe given quantity and requirement

of Inverter Output Frequency Decreases

(i. e., reduce that feedback signal).

1Negative effects

When the feedback signal is greater than

PIDThe given quantity and requirement of

Inverter Output Frequency Rise

(i. e., reduce that feedback signal).

○

F5.04 Sensor range 0.0~6000.0

(MPa、Kg) 10.0

0.0~6000.0(MPa、Kg) ○

PIDThe speed of adjustment is increased

by proportion The two parameters of

benefit and integration time should be set to

For fast adjustment speed, it is necessary

to increase proportional gain and decrease

Small integration time requires slow

adjustment speed and needs to be reduced

Small proportional gain increases integration

time. General sentiment In this case, the

differential time is not set.

F5.05 Proportional gainKp1 0.01~10.00 2.00 ○

F5.06 Integration timeTi1 0.00~10.00s 0.10s ○

F5.07 PIDSleep selection 0~1 1

0: Invalid

1: Normal sleep

This method needs to be setF5.08~F5.

11Such as specific

Parameters.

○

F5.08 Sleep threshold

coefficient 0.0~150.0% 100.0%

If the actual feedback value is greater than

the set value, and And the frequency output

by the frequency converter reaches the

lower limit frequency When the frequency

converter passes byF5.10Defined After

delaying the waiting time, enter the sleep state

(i.e. running at zero speed); The value isPID

Percentage of the setpoint.

○

F5.09 Allen Su threshold

coefficient 0.0~150.0% 90.0%

If the actual feedback value is less than the

set value Inverter PassF5.11After the defined

delay waiting time, get out of sleep and

start working;

The value isPIDPercentage of the setpoint

○

F5.10 Sleep delay time 0.0~6000.0s 100.0s

Set sleep delay time ○

F5.11 Allen Su delay time 0.0~6000.0s 1.0s

Set awakening delay time ○

F5.12 PIDSleep frequency 0.00 Hz~ Upper limit

frequency 20.00

SettingsPIDSleep frequency ×

F5.13 PIDPressure given 0~10.0 5.0

F5.00=7Time asPIDSetting quantity ○

F 6G ro u p- R S 4 8 5 C om m un i ca t io n Pa ra m et e rs

F6.00 Protocol Selection 0~1 1

0:CompatibleMD380Agreement

1: Compatible with DeltaMAgreement ○

F6.01 Communication baud

rate setting 0~7 5

0~4:Reservation 5:9600BPS

6: Reserved 7: Reserved ×

F6.02 Data Format 0~2 0

0: No verification (N,8,2)For RTU

1: even check (E,8,1)For RTU

2: odd check (0,8,1)For RTU ×

F6.03 Local Address 0~247 1

Set the local address

0Is the broadcast address ×

F6.04

Communication

Timeout Detection

Time

0.1~100.0s 10.0s

If this machine exceeds the time defined by

this function code During the interval, the

correct data signal was not received, Then

the machine thinks that the communication is

out of order, and the frequency converter It will

be determined according to the setting of

communication failure action mode Whether to

protect or maintain the current operation; This

value setting For0.0When, don't do itRS485

Communication timeout detected.。

×

F6.05 Propor tional linkage

coefficient

0.01~10.00 1.00

This function code is used to set the frequency

converter as a slave PassRS485Weight of

frequency instruction received by interface

Coefficient, the actual operating frequency of

this machine is equal to the local work Energy

code value multiplied byPassRS485Received

by the interface Frequency setting command

value. In linkage control, this The function

code can set the operating frequency of multip

le frequency convertersThe proportion of.

○

-14-

-13-

Function

Code N a m e C o n t e n t S e t R a n g e Facto r y

Sett ings Change

Function

Code N a m e C o n t e n t S e t R a n g e Facto r y

Sett ings Change

Monitoring Parameters

G r o u p D - M o ni t o r i ng P a r a m e te r G r o u p an d Fa u l t Re c o rd

d-00 0.00 ~ Max Output FrequencyOutput Frequency 0.01Hz 0◆

d-01 0.00 ~ Max Output FrequencySet Frequency 0.01Hz 0◆

d-02 0~999VOutput Voltage 1V 0◆

d-03 0~999VBus Vol tage (V) 1V 0◆

d-04 0.0~6000.0AOutput Current 0.1A 0◆

d-05 0~36000(RPM/min)Motor speed (RPM/min) 10◆

d-06 0.00V/0.00mA~10.00V/20.00mAAnalog Input AI1 (V/mA) 0.01 0◆

d-07 0.00~10.00V

Analog Input AI2 (V)

(Reserved) 0.01V 0◆

d-08 0.00~10.00V

Analog Output AO1 (V/

MA) (Reserved) 0.01V 0◆

d-09 0~60.00KHz

Pulse Input Frequency

(Khz) (Reserved) 0.01KHz 0KHz ◆

d-10 0.00~10.00VPID Setpoint (V) 0.01V 0.00 ◆

d-11 0.00~10.00VPID Feedback (V) 0.01V 0.00 ◆

d-12 0~65535

Current Count Value

(Reserved) 10◆

d-13 0~65535S

Current Timing Value (S)

(Reserved) 1S 0◆

d-14

0 ~ FH

Note: When expanded into binary, it means

from high to low

Sub-X4/X3/X2/X

Input Terminal Status 10◆

d-15

0 ~ 1H

Note: 1 indicates that output terminal Y

is active

Output Terminal Status 10◆

d-16 0.0℃~+110.0℃

Module temperature ℃ 0.1℃ 0◆

d-17

0 ~ FFFFH

BIT0: Run/Stop BIT1: Forward/Reverse

BIT2: Inching

BIT3: DC braking

BIT4: Reserved

BIT5: Overvoltage Limit

BIT6: Constant Speed Down

BIT7: Overcurrent Limit

BIT8 ~ 9: 00-Zero Speed/01-Acceleration/10

-Deceleration/11-Uniform

BIT10: Overload Prealarm

BIT11: Reserved

BIT12 ~ 13 Operation Command

Channel: 00-Panel/01-Terminal

/10-Reserved

BIT14 ~ 15 Bus Voltage Status: 00-Normal

/01-Low Voltage Protection/

10-Overpressure Protection

Operating state of

frequency converter

10◆

d-18 0~65535h

Accumulation of inverter

operation Time (h) 10

d-19 2019~2039

Software Upgrade

Date (Year) 10

d-20 0~1231

Software Upgrade

Date(Month,Day) 10

d-21 —

Reservation —0

d-22 0~21

Type of third failure 10

d-23 0~21

Second Failure Type 10

d-24 0~21

Latest Failure Type 10

d-25 0.00~Upper limit frequency

Operating Frequency

at Current Failure 0.01Hz 0

d-26 0.0~6553.5A

Output Current at

Current Fault 0.1A 0

d-27 0~999V

Bus voltage at current

fault 1V 0

d-28 0.0℃~+110.0℃

Module temperature

at current faultC℃ 0.1℃ 0

d-29

Inverter status at current fault0~FFFFH

BIT0: Run/Shutdown

BIT1: Forward rotation/Reverse

BIT2: inching

BIT3: DC brake

BIT4: Reserved

BIT5: PassVoltage limit

BIT6: Constant speed frequency reduction

BIT7Overcurrent Limit

BIT8 ~ 9:00-Zero speed/01-Accelerate/

10-Deceleration/11-Uniform velocity

BIT10: Overload pre-alarm

BIT11: Reserved

BIT 12 ~ 13Run command channel:00-Panel/01-

Terminal/10-Reservation

BIT 14 ~ 15Bus voltage state:00-Normal/01-

Low voltage protection/10-Overpressure protection

normal/01-Low voltage protection

/10-Overpressure protection

Inverter status at

current fault 10

d-30 0.0~100.0(bar/Kg)

PIDPressure setting 0.1 0

d-31 0.0~100.0(bar/Kg)

PIDPressure feedback 0.1 0

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

-16--15-

Function

Code N a m e S e t R a n g e M i n i m u m u n i t Facto r y

Sett ings Change

Function

Code N a m e S e t R a n g e M i n i m u m u n i t Facto r y

Sett ings Change

C h a p t e r 5 E r r o r C o d e s

-18-

-17-

F a u l t c o d e

F a u l t C o d e

N a m e

E r r 0 1 Power M o d u le Fail u r e

E r r 0 2 Overc urrent in accelerate d oper a tion

E r r 0 3 Overcurren t in dec e leratio n ope ration

E r r 0 4

E r r 0 5

E r r 0 6

E r r 0 7

E r r 0 8

E r r 0 9

E r r 1 0

E r r 1 1

E r r 1 2

E r r 1 3

E r r 1 4

E r r 1 5

E r r 1 6

E r r 1 7

E r r 1 8

E r r 1 9

E r r 2 1

6.1. 1 Format per byte in RTU mode

Chapter 6 Communication Protocol

(the following data are all hexadecimal)

6.1. 2 RTU data fra me sequence diagram

When the controller communicates on Modbus bus in RTU mode, every 8-bit byte in the information

is divided into 2 4-bit hexadecimal characters. The main advantage of this mode is that the density of

characters transmitted is higher than that of ASCII mode at the same baud rate, and each information

must be continuously transmitted.

Coding system: 8-bit binary, hexadecimal 0-9, A-F.

Data bit: 1 bit start bit, 8 bits of data (low bit first sent),

stop bit occupies 1 bit, parity bit can be selected.

(Refer to RTU data frame as sequence diagram)

Error Check Area: Cyclic Redundancy Check (CRC)

with parity

St a r t 1 2 3 4 5 6 7 8 Par St o p

without parity

St a r t 1 2 3 4 5 6 7 8 St o p

6.2 Des cr iption of Read-Write F unction Code

Funct i o n Code F u n ction Descripti o n

03

06

Read Register

Write register

6.3 Description of parameter address of communication protocol

Communication

Control Command

0001H:Shutdown

R/W

2000H

0012H:Forward rotation operation

0013H:Forward rotation inching operation

0022H:Reverse operation

0023H:Reverse inching operation

W

Communication set

frequency address 2001H

The set frequency range of communication

is-10000 ~10000.

Note: The communication set frequency is

relative to the most

Percentage of large frequencies, ranging

from-100. 00%~ 100.00%).

W

Communication

Control Command 2002H 0001H: External fault input

0002H: Fault reset W

Read Run/Shutdown

Parameter Description

2102H Set frequency (two decimal places) R

R

R

R

2103H Output Frequency (2 Decimal)

2104H Output Current (1 Decimal)

2105H Bus Voltage (1 Decimal)

6.1 RTU Mode and Format

Overcur re n t in u n iform operation

Overvoltag e in acceler a ted o peration

Over volta ge i n dec elerati o n op eration

Over voltage in u n i form o perati o

Overvoltag e duri n g shu tdown

Under volt a ge i n op eration

Frequen c y conver ter o v e rload

Motor over l oad

Re ser vation

Out-of-ph a s e on o utput side

Radiat or ov e rheating

Exte rnal Device Failure

R S 4 8 5 C o m munica t i o n f a i l ure

Res e r va t io n

Current Sense Fau lt

C P U Fa i lure

E E P R O M Reading and writi ng e rrors

function instruction data meaning instruction

address definition

function instruction data meaning instruction

address definition R/W

R

2106H Output Voltage (1 Decimal)

Read Run/Shutdown

Parameter Description

2107H R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

2108H

2109H

210AH

210CH

210DH

210EH

210FH

2110H

2111H

Analog InputAI(two decimal places)

Reser vation

Motor speed

210BH

2112H

2113H

2114H

2115H

2116H

2101H R

Inverter Temperature (1 Decimal)

PIDFeedback value (two decimal places)

PIDSet value (two decimal places)

Current Failure

Input Terminal Status

BIT0: Run/Shutdown

BIT1: Forward rotation/Reverse

BIT2: inchingBIT3: DC brake

BIT4: ReservedBIT5: Overvoltage Limit

BIT6: Constant speed frequency reduction

BIT7Overcurrent Limit

BIT8 ~ 9:00-Zero speed/01-Accelerate

/10-Deceleration/11-Uniform velocity

BIT10: Overload pre-alarmBIT11: Reserved

BIT 12 ~ 13Run command channel:00-Panel

/01-Terminal/10-Communication

BIT 14 ~ 15Bus voltage state:00-Normal

/01-Low voltage protection

/10-Overpressure protection

BIT0: RunBIT1: Shutdown

BIT2: inching

BIT3: Forward rotation

BIT4: Reverse

BIT5~BIT7: Reserved

BIT8: given communication

BIT9: Analog Signal Input

BIT10: Communication Run

Command Channel

BIT11: Parameter Lock

BIT12: Running

BIT13: a little move command

BIT14~BIT15: Reser ved

-19- -20-

R/W

R

2100H

Read out trouble

code description

00: No exception

01: Module Failure

02: overvoltage

03: Temperature fault

04: Frequency conver ter overload

05: Motor overload

06: External fault

07 ~ 09: Reserved

10: overcurrent dure acceleration

11: overcurrent dure deceleration

12: over-current in constant speed

13: Reser ved

14: undervoltage

6.4 03Read Function Mode

Inquir y information frame format:

Address 01H

Function 03H

Starting data address 21H

02H

00H

02H

Data(2Byte)

CRC CHK Low

CRC CHK High

6FH

F7H

Data analysis of this section: 01H is the address of the frequency converter

03H is read function code

2102H is the start address

0002H is the number of read addresses, and 2102H and 2103H F76FH are 16-bit CRC validation codes

Response information frame format:

Address 01H

Function 03H

Data1[2Byte] 17H

70H

00H

00H

CRC CHK Low

CRC CHK High

FEH

5CH

DataNum*2 04H

Data2[2Byte]

Reser vation

Reser vation

Reser vation

Reser vation

Reser vation

Reser vation

Input Terminal Status

function instruction data meaning instruction

address definition

Analysis of this data:

01H is the address of the inverter

03H is read function code

04H is the product of read entries * 2

1770H is read 2102H (set frequency) data

0000H is reading data of 2103H (output frequency

5CFEH is a 16-bit CRC check code

Address 01H

Function 06H

Starting data address 20H

00H

00H

01H

Data(2Byte)

CRC CHK Low

CRC CHK High

43H

CAH

Inquir y information frame format:

Analysis of this data:

01H is the address of the inverter

06H is write function code

2000H is the control command address

0001H is the shutdown command

43CAH is a 16-bit CRC validation code

Address 01H

Function 06H

Starting data address 20H

00H

00H

01H

Number of Data(Byte)

CRC CHK Low

CRC CHK High

43H

CAH

Response information frame format:

Analysis of this data: If the setting is correct, the same input data will be returned.

6 . 5 Wr i t e Fu n c t i o n M o d e

-21- -22-

Chapter 7 Warranty Agreement

1. This product will be guaranteed for 18 months (except for exported/non-standard machine products)

under normal use environment (without moisture and dust) from the date of purchase by the user from the

manufacturer.

2. This product will enjoy paid lifelong service from the date when the user purchases it from the

manufacturer.

3. During the warranty period, a certain maintenance fee will be charged for damage caused by the

following reasons:

a. Machine damage caused by errors in use and unauthorized maintenance and renovation;

b. Do not operate correctly according to the procedures listed in the "Product Manual" provided by our

company;

c. Product damage caused by force majeure such as earthquake, fire, feng shui disaster, lightning strike,

abnormal voltage or other natural disasters;

d. Product damage caused by improper selection of transportation mode or invasion of other external

forces during transportation after the user purchases the product;

e. Failures and damages caused by obstacles other than machines (such as external equipment factors);

4. The manufacturer has the right not to provide warranty service under the following circumstances: a.

When the user fails to pay off the purchase price according to the Purchase and Sale Contract signed by

both parties;

b. The user intentionally conceals the bad use of the product during installation, wiring, operation,

maintenance or other processes from the manufacturer's after-sales service provider.

5. If you have any problems during use, please contact our agent or our company in time.

Chapter 8 Product Warranty Card

U n i t A dd r e ss :

:

Compan y Name:

:

Customer

Name

Pos ta l Cod e:

:

Contact:

:

Contact number:

:

Product

Information

P a r t N o . :

:

Body bar code (pasted here):

D e a l e r N a m e :

Maintenance time and content:

Fault

Information

Re p a i r m a n:

-23-

Table of contents