1. Prepare pneumatic connection.

– Use O.D. pneumatic lines (e.g. plastic tubing PUN-8x1,25 from Festo): Supply

air (P) 8 mm; exhaust air (R) 10 mm.

– Cut tubing ends at right angles and without burrs. This avoids damage to

internal O-rings.

2. Connect the product to the ports P and R. To do this, insert the compressed air

tubing into the respective push-in fitting up to the stop.

3. Only in an unpressurised state: Check to ensure the tubing connector is securely

seated by pulling gently on the tube.

4. When using the optional connecting cable: Mount the cable connector and

protective conduit in accordance with the corresponding assembly instructions.

To loosen a tube

1. Press down on the disconnect ring (blue) of the push-in fitting and hold it down.

2. Carefully pull the tube out of the push-in fitting.

Cut off the damaged part before further use of the tube.

6 Commissioning

Caution

Uncontrolled movements of the actuator can cause damage.

Please note that when the compressed air supply is switched on and there is

no setpoint specification or no power supply, the drive will move to the safety

position (èChapter 3).

During initialisation, movement takes place to both end positions in successi

on, independently of the present setpoint value.

Note

To prevent the drive from moving to the safety position when switching on the

energy supply, switch it on in the following order:

1. Switch on the operating voltage supply.

2. Switch on the setpoint specification.

3. Switch on the compressed air supply.

Observe the operating conditions and comply with the permissible limit values

(èChapter 11).

First, select a slow travel speed. To do this, first close the flow control valves D2

and D4 completely. Then open the flow control valves D2 and D4 by two or three

turns.

After installation on initial start-up, always perform an initialisation of the drive.

Initialisation

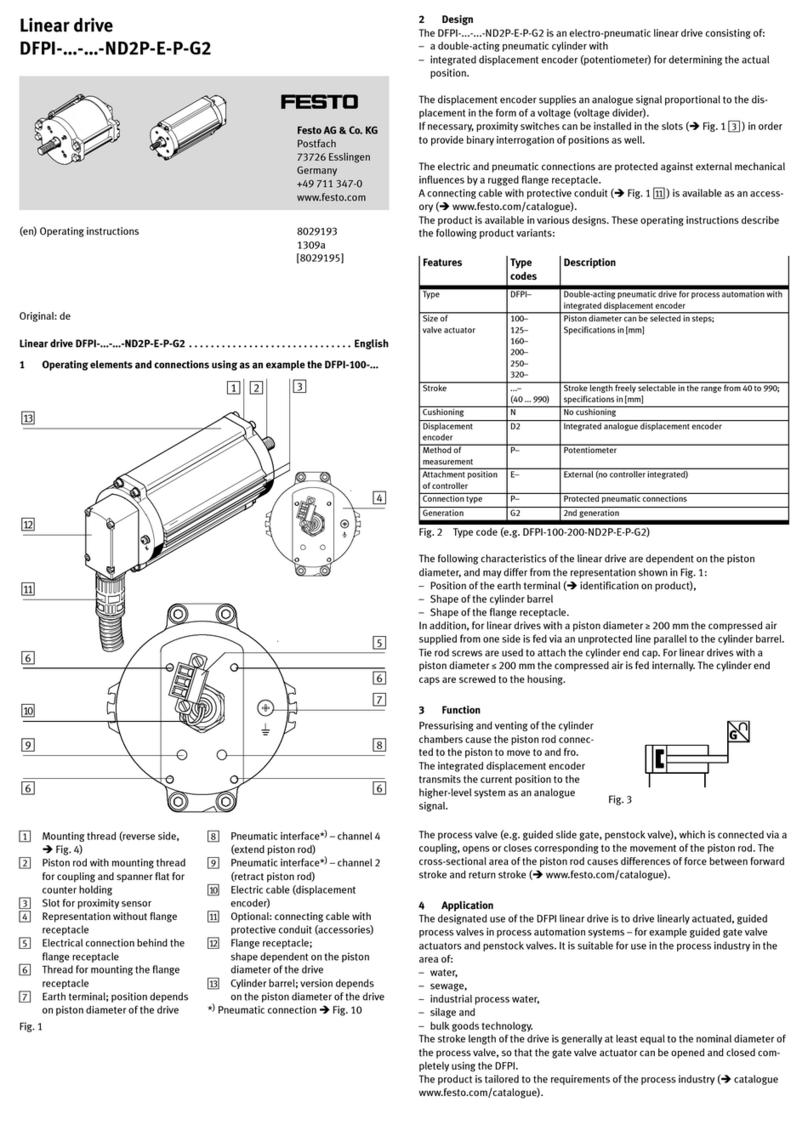

The linear drive is preinitialized before being shipped from the factory. The internal

positioner is then adjusted for travel without a load, without flow control, and for

use of the entire stroke length of the drive.

Analogue set

point

Setpoint position upon pre-initialisation from the factory

< 3.5 [mA] Safety position; advance piston rod (end position)

4 … < 4.2 [mA] Advance piston rod (end position) with maximum control force,

Seal closing function

4.2 … < 19.8 [mA] Intermediate position regulated 1)

19.8 … < 20.0 [mA] Retract piston rod (end position) with maximum control force,

Seal closing function

> 20.5 [mA] Safety position; advance piston rod (end position)

1) The setpoint characteristic curve is linear.

Fig. 8

A new initialisation process must be carried out in the following cases:

– On initial start-up after installation of the device

– After adjustment of flow control screws D2 and D4

– After changing the operating pressure

– After changing the process that influence the forces, e.g. at the slide gate, and

thus the process parameters

– After changing the stroke length used.

Initialization shifts the setpoint and actual characteristic curve corresponding to

the taught end positions. As a result, the relationship is determined between the

analogue setpoint value and the setpoint position as well as between the analogue

actual value and the actual position.

During initialisation the end positions of the product are approached automatic

ally. This teaches the positioner the available/used stroke length.

After successful initialization the linear drive is ready for operation.

Note

The initialisation procedure may take several minutes depending on the size of

the drive. During the initialisation procedure, a current value of 21.5 mA is

provided at the analogue output.

Note

Start initialisation of the drive from the safety position.

1. Switch on the operating voltage supply and setpoint input.

2. Switch on the compressed air supply. The drive moves to the specified setpoint

position.

3. Apply a signal (+24 V) at pin 5 for t > 1000 ms (èFig. 9 1) – e.g. by briefly

bridging pin 1 and pin 5. The initialisation procedure will then start

(èFig. 9 2).

During the initialisation procedure, a current value of 21.5 mA is provided at the

analogue output.

Fig. 9

2

3

1

1000 ms

4. When the initialisation procedure is complete, the DFPI is ready for operation

(èFig. 9, 3). It then travels to the specified setpoint position.

7 Operation

Warning

Fast moving parts can cause injury to people in the vicinity of the DFPI.

In the positioning range make sure that:

– Nobody can place his/her hand in the path of moving components (e.g. by

providing a protective guard).

– There are no foreign objects in the path of the moving components.

It should not be possible to touch the DFPI until the mass has come to a com

plete rest.

After the compressed air supply is switched on, the drive travels as follows:

– The drive moves to the safety position if the operating voltage supply or the

analogue setpoint are outside the permissible range.

– The drive moves to the specified analogue setpoint position if the operating

voltage supply is in the permissible range, depending on the end positions

taught during initialisation.

8 Maintenance and care

If used as intended, the product is maintenance-free.

9 Disassembly and repair

Warning

Danger of crushing! Uncontrolled advance of piston rod.

When the power supplies are switched off, if the compressed air supply is

switched off first and only after that the operating voltage supply, in case of error

(e.g. defective valve manifold) there may be continuous excess pressure in a

cylinder chamber. During dismantling the linear drive can then advance unexpec

tedly, thus crushing people's body parts.

Switch off the energy supplies in the following sequence to allow the in

tegrated valve block to vent the drive:

1. First switch off the operating voltage supply.

2. Only after that, switch off the compressed air supply.