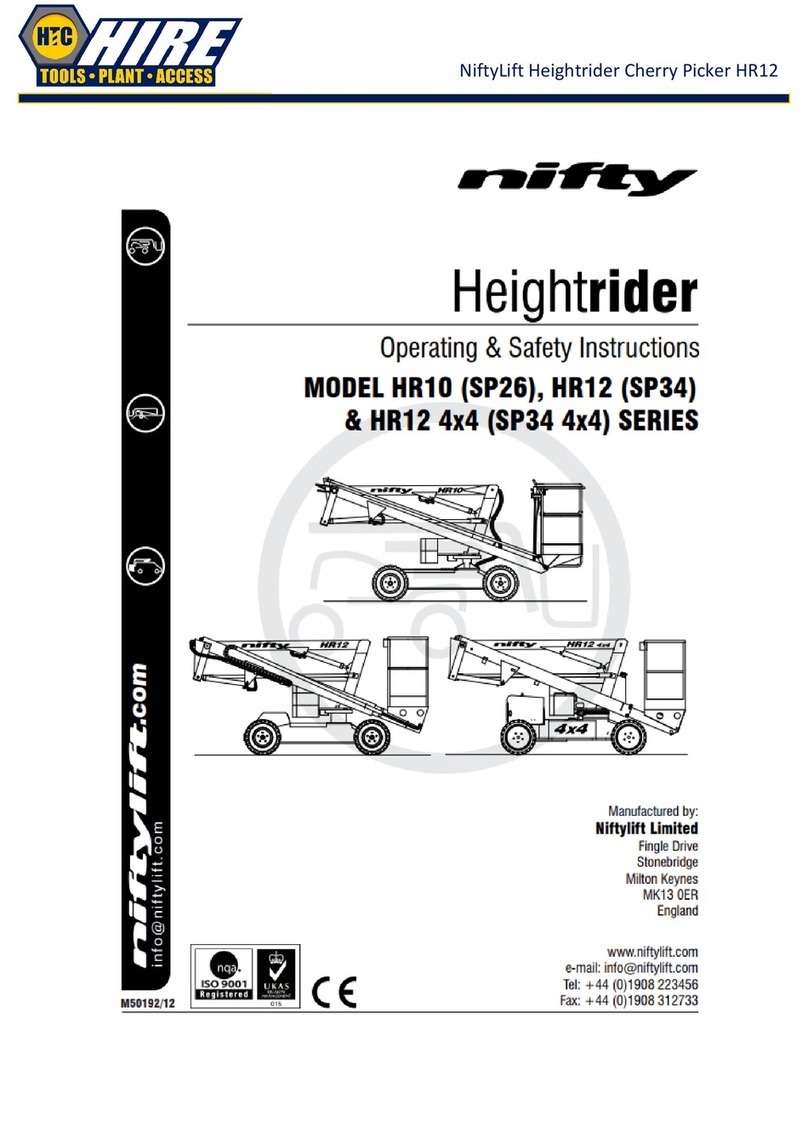

Height Rider/SP Series

Operating & Safety Instructions

English/USA –07/17

Original instructions

2Safety

2.1 MANDATORY PRECAUTIONS

When operating the Niftylift, your safety is of utmost concern. In order to fully appreciate all aspects of

the machine’s operation it should be ensured that each operator has READ and fully UNDERSTOOD the

relevant manual covering machine use, maintenance and servicing. If any doubts exist concerning any

points covered in this manual, contact your local dealer or Niftylift Ltd.

Before using any Niftylift, thoroughly inspect the machine for damage or deformation to all major

components. Likewise, check the control systems for hydraulic leaks, damaged hoses, cable faults or

loose covers to electrical components. At no time should damaged or faulty equipment be used -

Correct all defects before putting the platform to work. If in doubt, contact your local dealer or Niftylift

Ltd (see front cover for address).

THE MANUFACTURER HAS NO DIRECT CONTROL OVER THE MACHINE

APPLICATION AND USE. THEREFORE CONFORMITY WITH GOOD SAFETY

PRACTICES IS THE RESPONSIBILITY OF THE USER AND HIS OPERATING

PERSONNEL. FAILURE TO UNDERSTAND AND FOLLOW ALL SAFETY RULES

COULD RESULT IN SERIOUS INJURY OR DEATH.

2.1.1 Only trained persons are permitted to operate the Niftylift.

2.1.2 Always operate the Niftylift in accordance with these model-specific Operating & Safety Instructions.

2.1.3 Before use each day and at the beginning of each shift the Niftylift shall be given a visual inspection

and functional test including, but not limited to, operating and emergency controls, safety devices,

personal protective clothing, including fall protection, air, hydraulic and fuel system leaks, cables and

wiring harness, loose or missing parts, tyres and wheels, placards, warnings, control markings and

Operating and Safety Manuals, guards and guard rail systems and all other items specified by the

manufacturer.

2.1.4 Any problems or malfunctions that affect operational safety must be repaired prior to use of the

platform, with specific regard to any safety components refer to the Parts Manual for part numbers and

details. If in doubt, contact Niftylift Ltd (Details on page 3). Ensure wheels are chocked before

carrying out any maintenance that involves gearbox disengagement as described in

Section 4.7.2

2.1.5 Always ensure that all warning labels, instructions, placards, control markings and Operating & Safety

Manuals are intact and clearly legible. If replacements are required contact your local dealer or Niftylift.

Always obey the safety and operating instructions on labels.

2.1.6 Do not alter, modify, or disable in any way the controls, safety devices, interlocks, or any other part of

the machine.

2.1.7 The user must ensure that, prior to and during use, the working area and transport route is free from

possible hazards such as, but not limited to, uneven ground drop-offs, holes, bumps, obstructions,

debris, floor and overhead obstructions, high voltage conductors, wind and weather, unauthorised

persons and any other possibly hazardous conditions.