NIKA NL-UHV / DX3 User manual

Nikalyte Ltd, 77 Heyford Park, Heyford Park Innovation Centre, Upper Heyford,

OX25 5HD, UK +44 (0)1869 238042. www.nikalyte.com 2

Contents

Safety Precautions ........................................................................................................ 3

Symbols:................................................................................................................... 3

Health and Safety –General Information ........................................................................ 3

Introduction ................................................................................................................. 4

Installation ................................................................................................................... 5

Operation..................................................................................................................... 5

NL-DX3 Sputter Head Targets..................................................................................... 5

Magnetron Target Installation..................................................................................... 6

Plasma Preventers .................................................................................................. 8

Start-up .................................................................................................................... 9

Striking a plasma ....................................................................................................... 9

Nanoparticle Generation ...............................................................................................10

Introduction .............................................................................................................10

Nanoparticle size variation.........................................................................................12

Indicative data .........................................................................................................13

Shut-down ...............................................................................................................16

Maintenance................................................................................................................16

Changing the Primary Orifice ..................................................................................19

Cleaning ..................................................................................................................19

Consumables ...............................................................................................................20

Troubleshooting...........................................................................................................20

Unable to strike a plasma ..........................................................................................20

The deposition rate is low or dropping........................................................................21

No Nanoparticles produced........................................................................................22

Source Materials .......................................................................................................23

Contacting us ..............................................................................................................23

Nikalyte Ltd, 77 Heyford Park, Heyford Park Innovation Centre, Upper Heyford,

OX25 5HD, UK +44 (0)1869 238042. www.nikalyte.com 3

Safety Precautions

Please read the following instructions carefully before installing the NL-DX3 and refer to them

as needed to ensure the continued safe operation.

Symbols:

= High Voltage

= Warning

= Information / Tip

Follow all warnings and instructions marked on or supplied with the product. Failure to

observe these precautions could lead to personal injury or death and/or damage to the

equipment.

Health and Safety –General Information

When connected to its power supply, the sputter source is supplied with potentially

lethal currents at very high voltages. The source should always be disconnected

from its supply during maintenance.

Nikalyte Ltd, 77 Heyford Park, Heyford Park Innovation Centre, Upper Heyford,

OX25 5HD, UK +44 (0)1869 238042. www.nikalyte.com 4

The toxicity of nanoparticles has not been determined in many cases and

consequently care should be taken when opening the vacuum system. Always use

gloves and the use of a fine-filter mask is also highly recommended as an absolute minimum.

Please note that some materials will burn if you use an IPA wipe for cleaning. Such

materials are Platinum, Hafnium and Iron. For cleaning systems which contain

these materials, use lint free wipes with a few drops of DI water and immediately drop the

used wipes into a bucket of water. This will render the materials safe.

Introduction

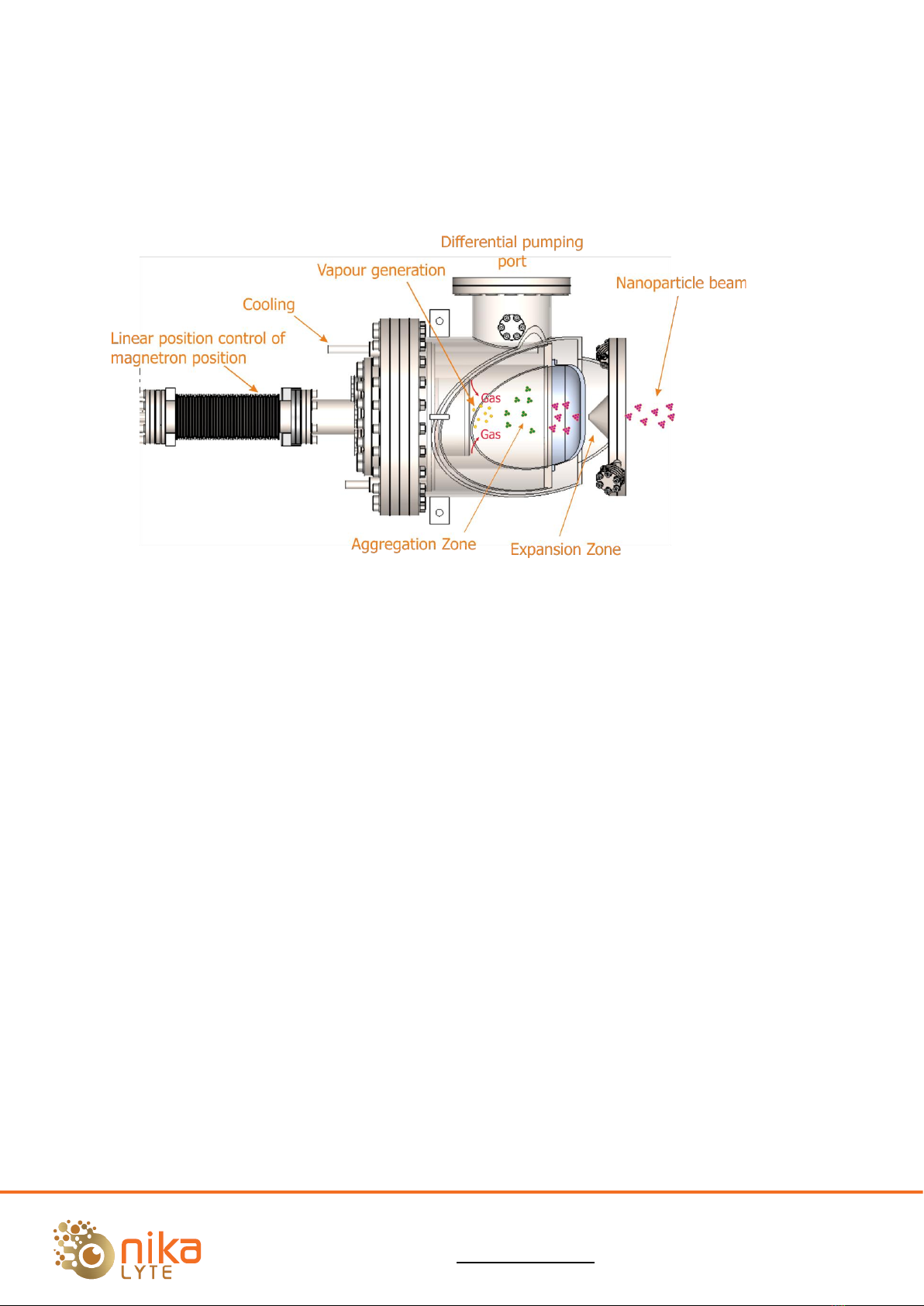

The NL-UHV nanoparticle source consists of a UHV compatible vacuum envelope which houses

a range of sputter sources specifically designed to work together to generate nanoparticles of

many types of materials.

The sources that are compatible with the NL-UHV include a single 1” source (NL-D1), a single

2” source (NL-D2), a single 3” source (NL-D3) and a triple 1” source (NL-DX3). This manual

covers the operation of the NL-UHV in combination with the NL-DX3.

Each individual sputter source is known as and will be referred to here as a

magnetron

.

Extreme caution is required when working with the magnetron power supplies. Do

not switch them on unless all leads are connected and shielded. All supplies, cables

and equipment must be suitably earthed.

Nanoparticles are formed when the magnetron(s) are running and sputtering material under

a range of conditions. The user can control several parameters to control the formation and

size of the nanoparticles. These parameters include gas flow (usually argon) over the

magnetron(s), a separate ‘carrier’ gas flow (usually helium), plasma power, magnetron to

Nikalyte Ltd, 77 Heyford Park, Heyford Park Innovation Centre, Upper Heyford,

OX25 5HD, UK +44 (0)1869 238042. www.nikalyte.com 5

aperture distance, and aperture size. The magnetron(s) are typically powered by 630V, dc

supplies, but in addition pulsed DC supplies can be used.

The NL-UHV produces nanoparticles by two main processes; 1) generation of atomic and

molecular species by magnetron sputtering and 2) subsequent generation of nanoparticles by

condensation in an aggregation zone. The NL-UHV consists of two zones, the Aggregation

zone and the Expansion zone with apertures between. The Expansion zone is differentially

pumped by a 300 l/s turbo pump.

Installation

For detailed information on the installation and the services required, please see the

accompanying document NL-Dxx & NL- QMS Installation.

Operation

NL-DX3 Sputter Head Targets

Table of contents