2

General information

Safety ............................................................................................................................................................................................................3

Power supply .........................................................................................................................................................................................3

Introduction ..................................................................................................................................................................................................3

Documentation ......................................................................................................................................................................................3

Data plate ...............................................................................................................................................................................................4

App option

Nilan User App ..............................................................................................................................................................................................5

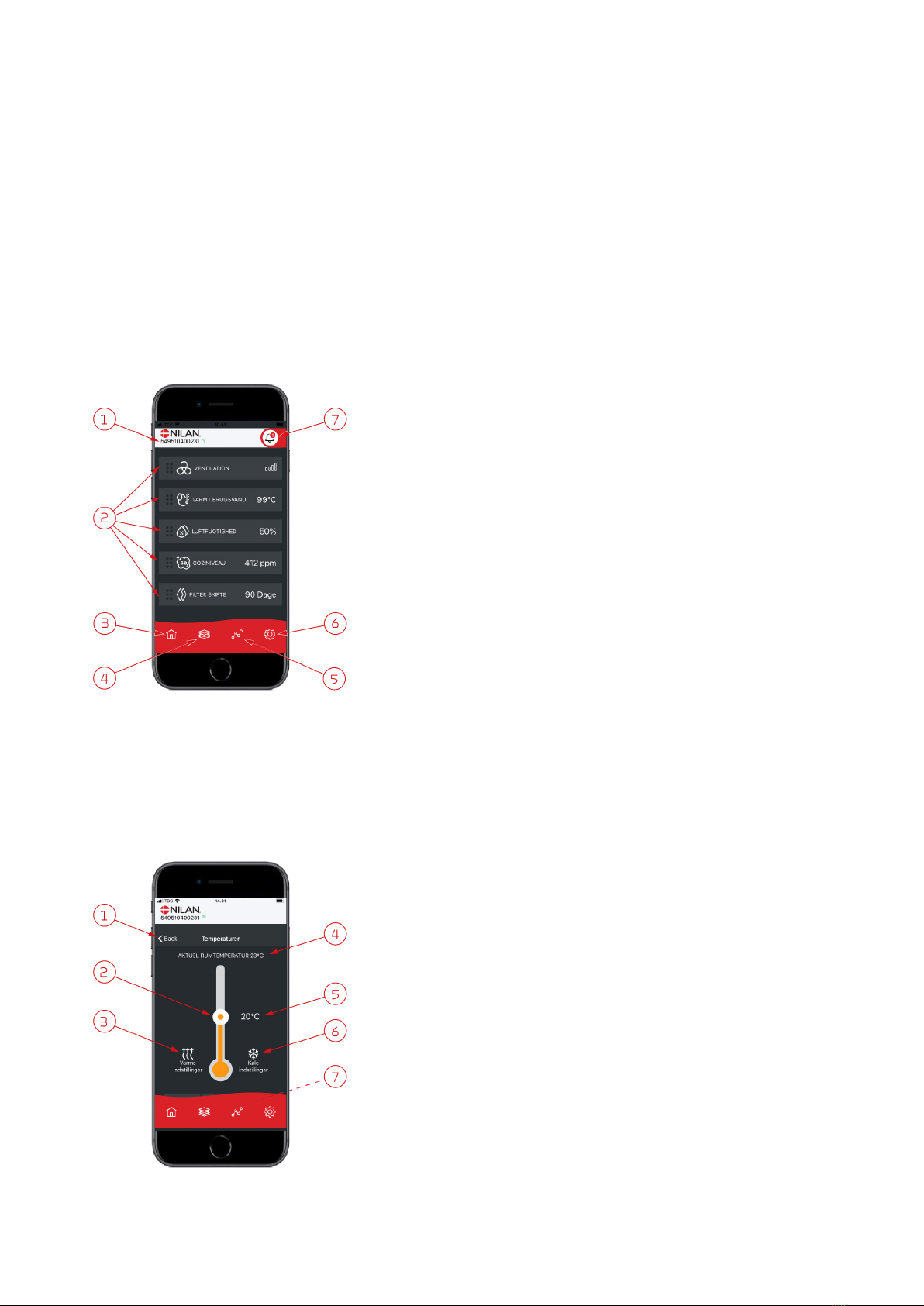

Introduction ...........................................................................................................................................................................................5

Explanation of main screen items ......................................................................................................................................................5

Temperature ..........................................................................................................................................................................................5

Ventilation ..............................................................................................................................................................................................6

Domestic hot water ..............................................................................................................................................................................6

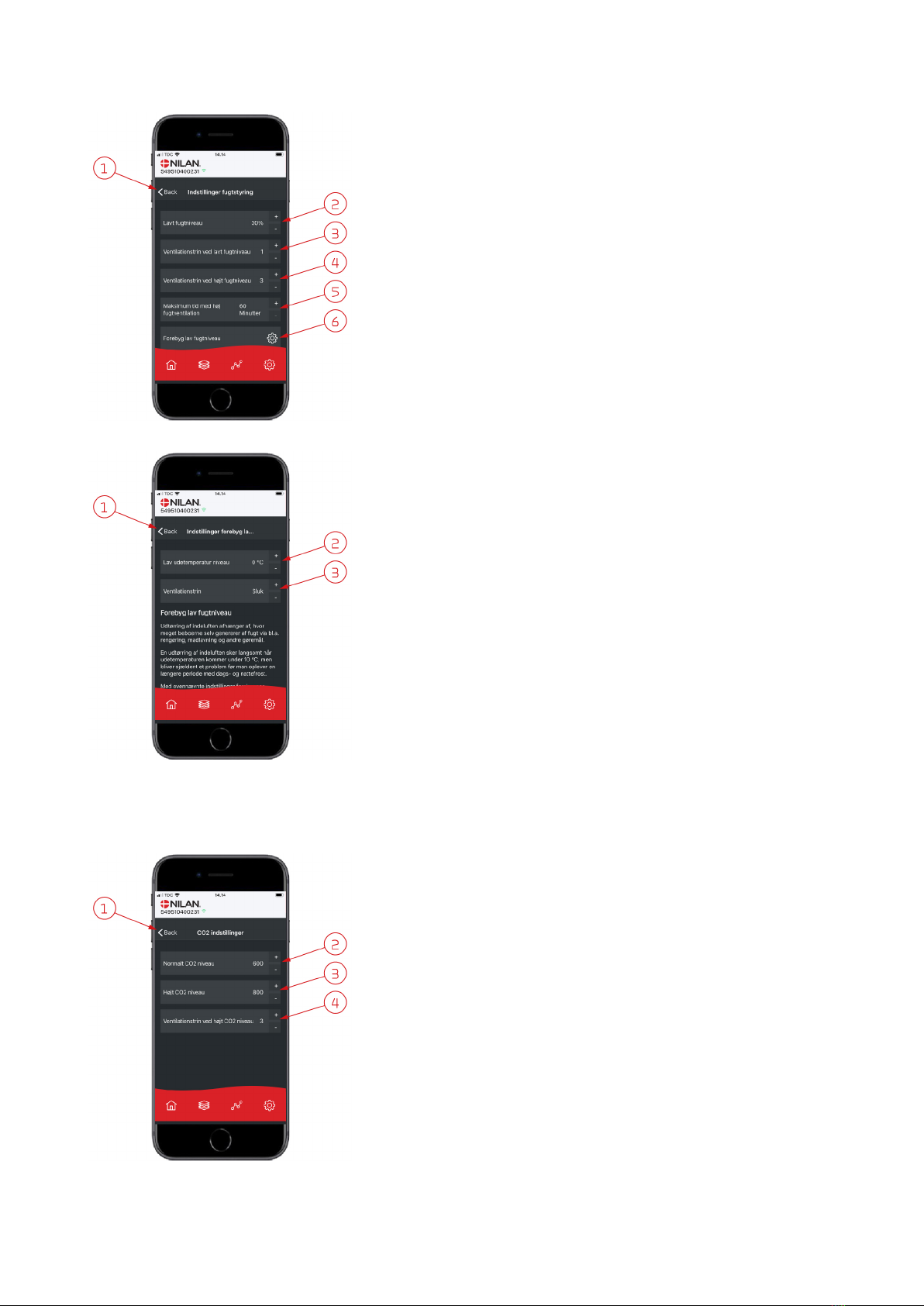

Air humidity ...........................................................................................................................................................................................7

CO2 settings ...........................................................................................................................................................................................7

Filter replacement ................................................................................................................................................................................8

Show data ...............................................................................................................................................................................................8

Trend curve ............................................................................................................................................................................................8

Control panel

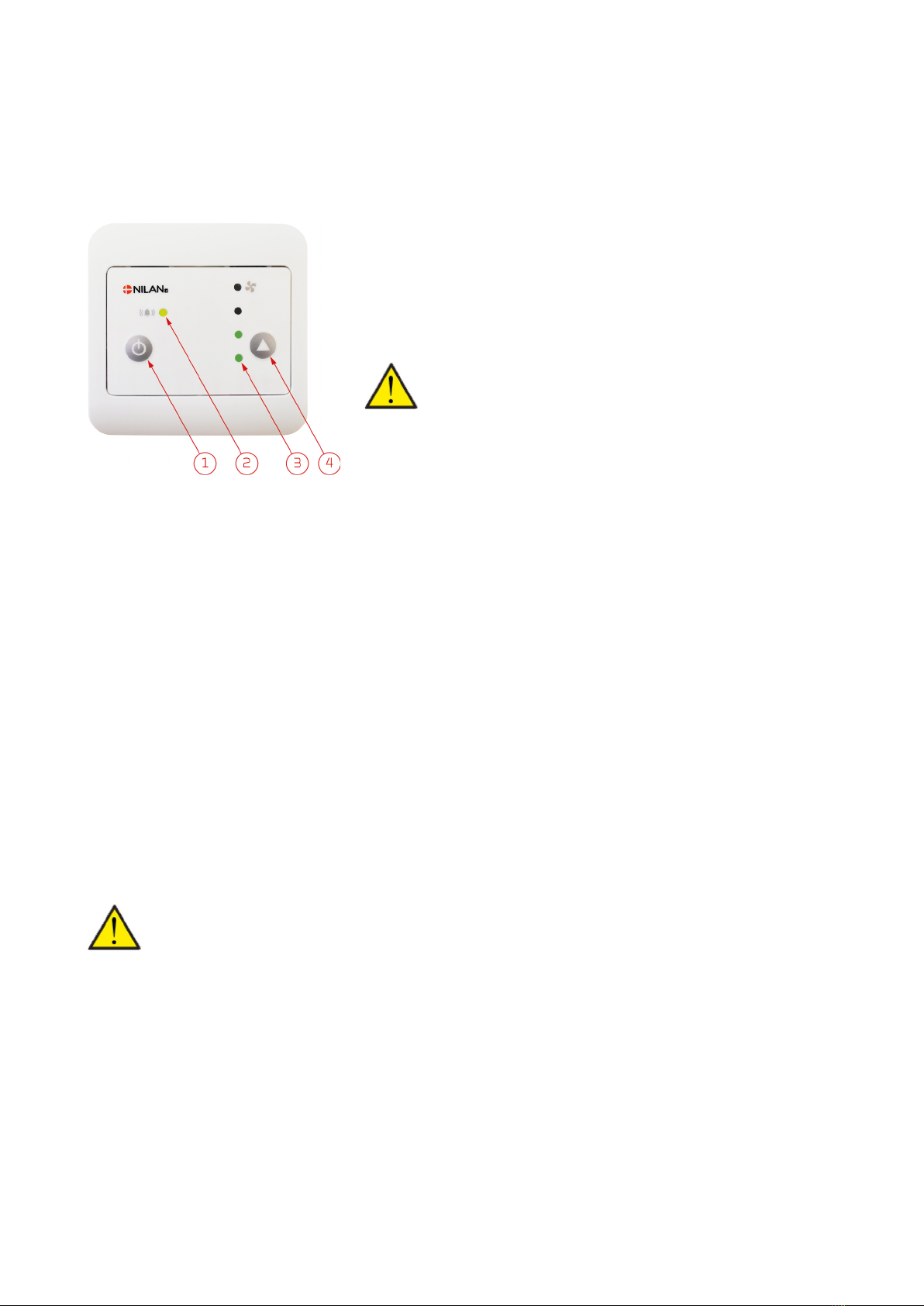

Control panel functions ..............................................................................................................................................................................9

Functional overview .............................................................................................................................................................................9

Fan speed level ......................................................................................................................................................................................9

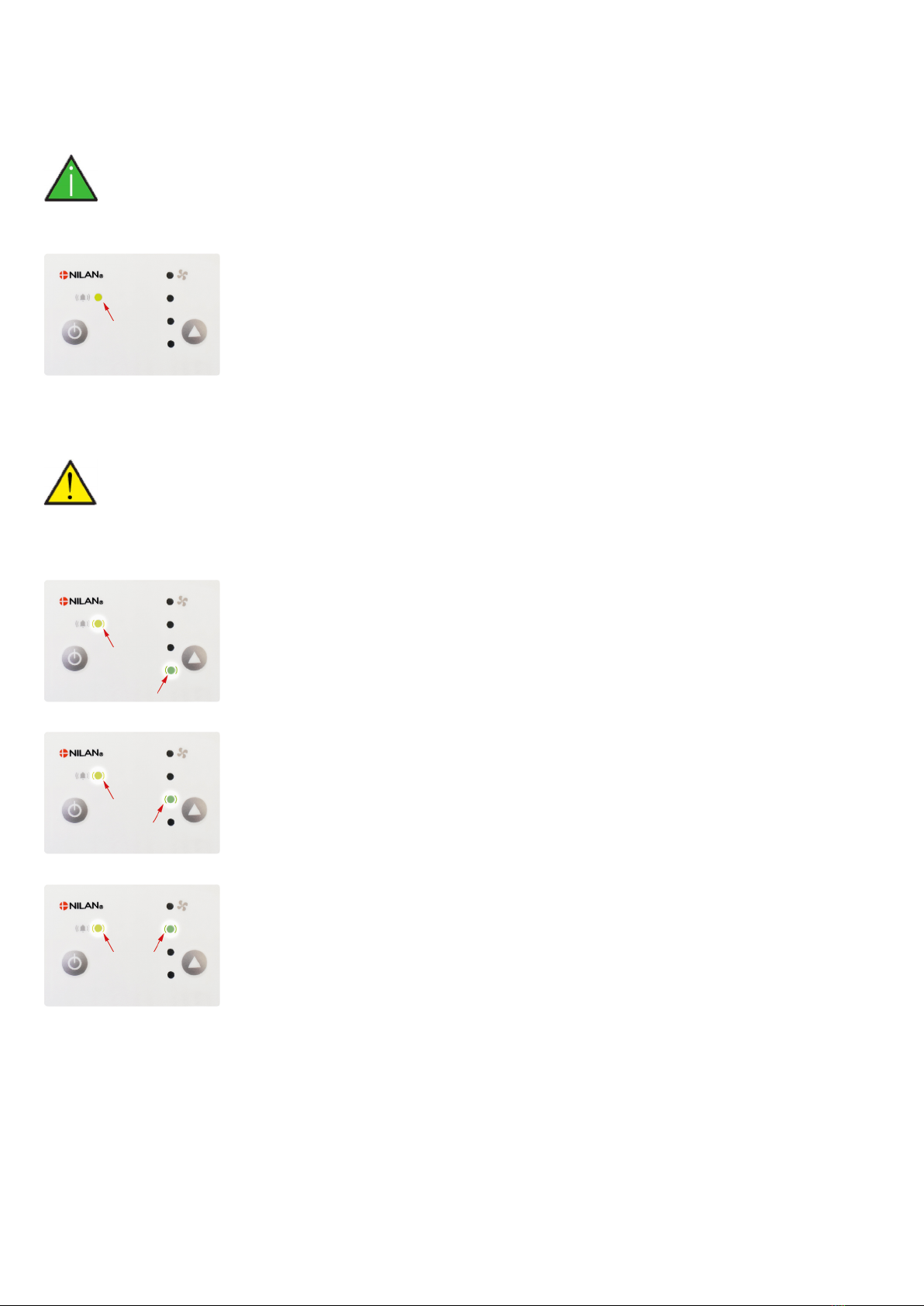

Warnings and alarms ......................................................................................................................................................................... 10

Damper test ........................................................................................................................................................................................ 11

Control panel locked .......................................................................................................................................................................... 11

Service and maintenance

Generally ............................................................................................................................................................................................. 12

Regular maintenance ............................................................................................................................................................................... 12

Filters ................................................................................................................................................................................................... 12

Illustration of filter change ............................................................................................................................................................... 13

Annual maintenance ................................................................................................................................................................................ 14

General cleaning ................................................................................................................................................................................. 14

Water trap ........................................................................................................................................................................................... 14

Heat exchanger .................................................................................................................................................................................. 15

Check air intake and discharge ........................................................................................................................................................ 15

Check ventilation ducts .................................................................................................................................................................... 15

Product data

EU/EC Declaration of Conformity ................................................................................................................................................... 16

Ecodesign data Comfort 250L ......................................................................................................................................................... 17

Ecodesign data Comfort 350L ......................................................................................................................................................... 18

............................................................................................................................................................................................................... 18

Disposal

The environment - part of the solution ................................................................................................................................................ 19

Ventilation unit ................................................................................................................................................................................... 19