www.venmar.ca S10ERVd150407

Residential Products Group, 550 Lemire Blvd., Drummondville, Qc, Canada J2C 7W9 - Tel.: 1-800-567-3855 Fax: 1-800-567-1715

Project: REMARKS

Location:

Part no.: 41700

Qty.:

Submitted by: Date:

VENMAR AVS S10 ERV ARCHITECTURAL SPECIFICATIONS

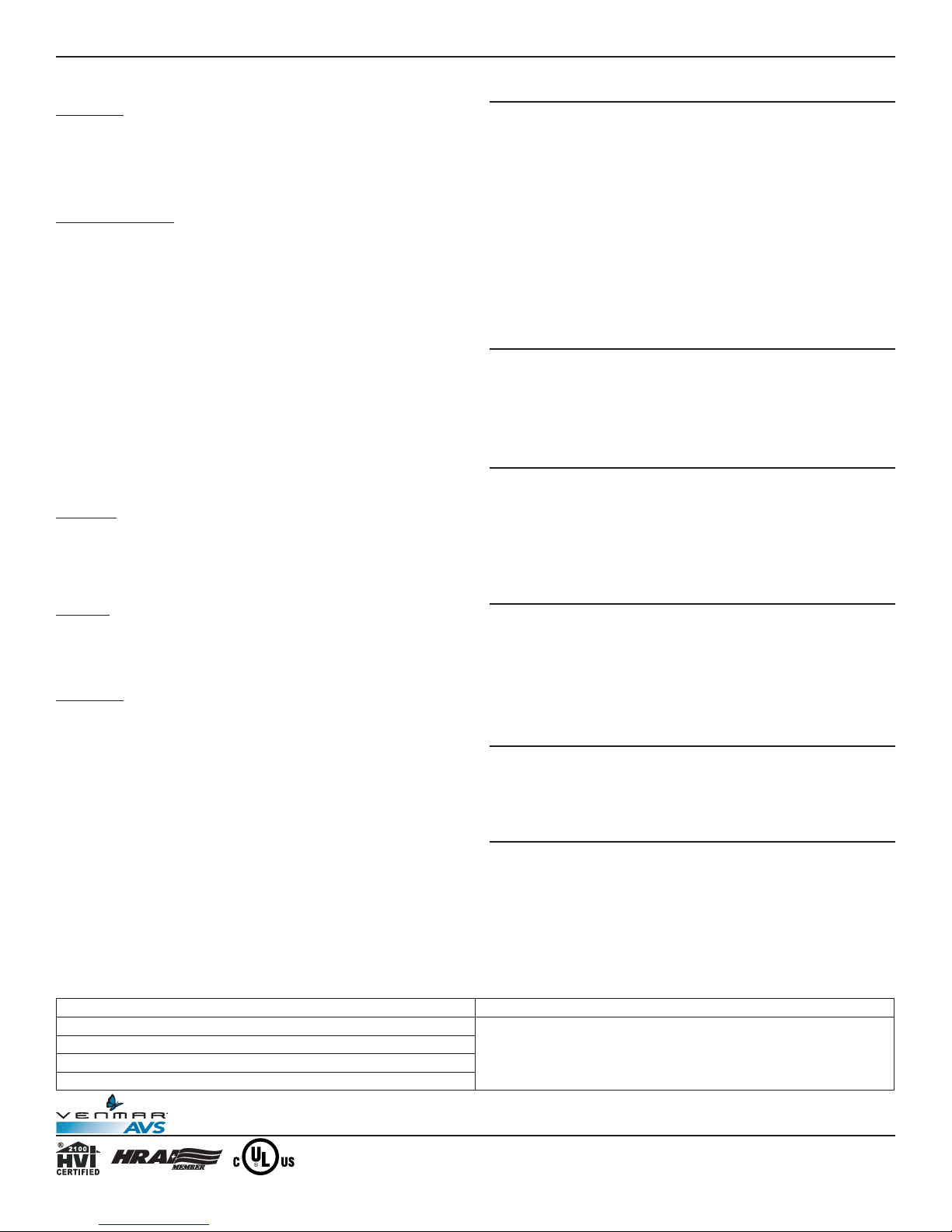

AIRFLOW

• High static pressure backward blowers shall perform a minimum of

68 CFM @ 1.0 in. w.g.

• Optional high speed: 85 CFM

• Optional low speed: 65 CFM

CONSTRUCTION

• Housing and door shall be made of 22 ga. galvanized steel

• Insulation shall be made of one-piece molded expanded polystyrene,

UL 94 HF-1 certied

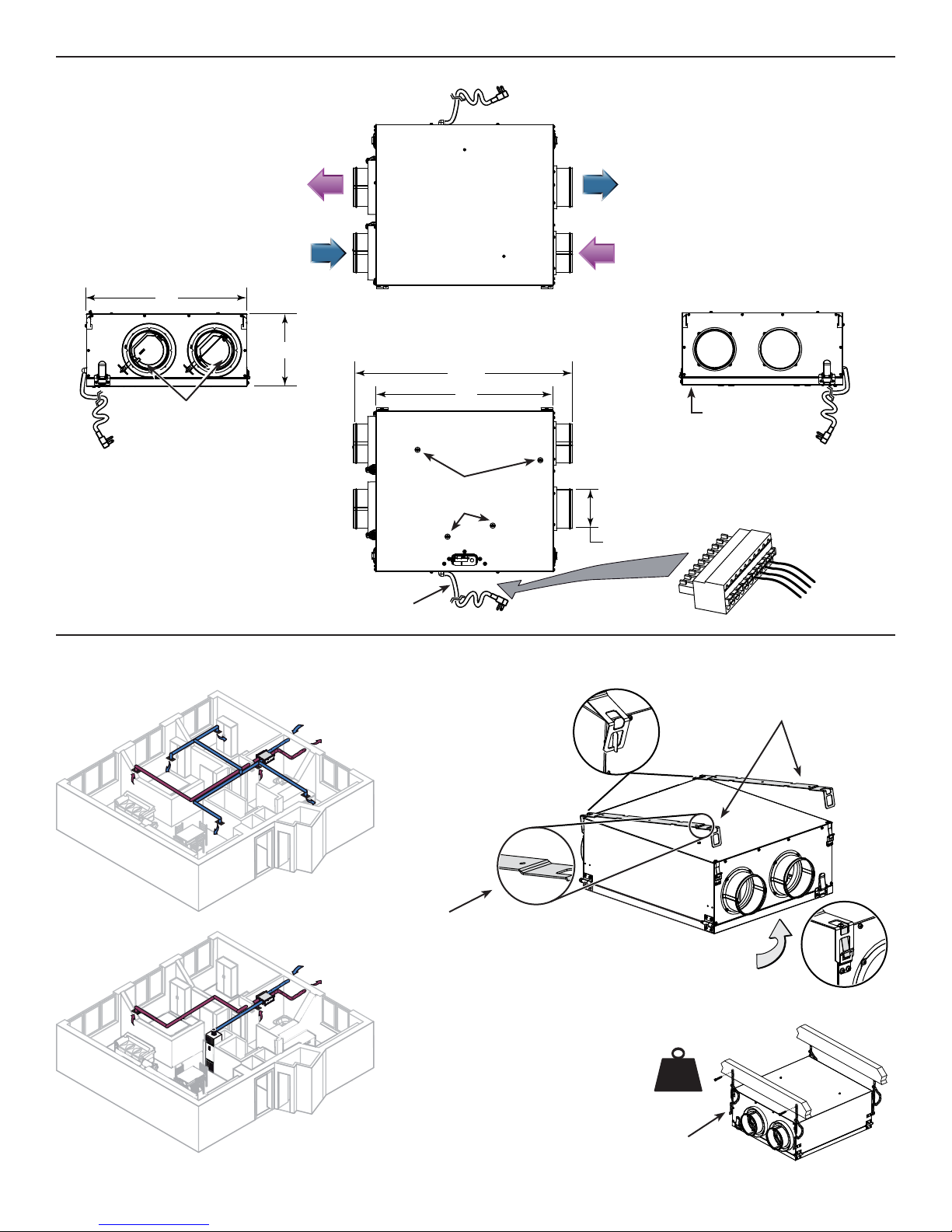

• 5" diameter ports shall be made of galvanized steel

• Door hinges and latches shall be made of steel

• Cold side ports shall have plastic ring to allow vapor barrier sealing

• Unit construction and components shall be UL and CSA certied

• Unit shall operate all year long without drain

• Weight shall not exceed 32 lb.

• Fresh air from outside and Exhaust air to outside ports shall be located

on same side

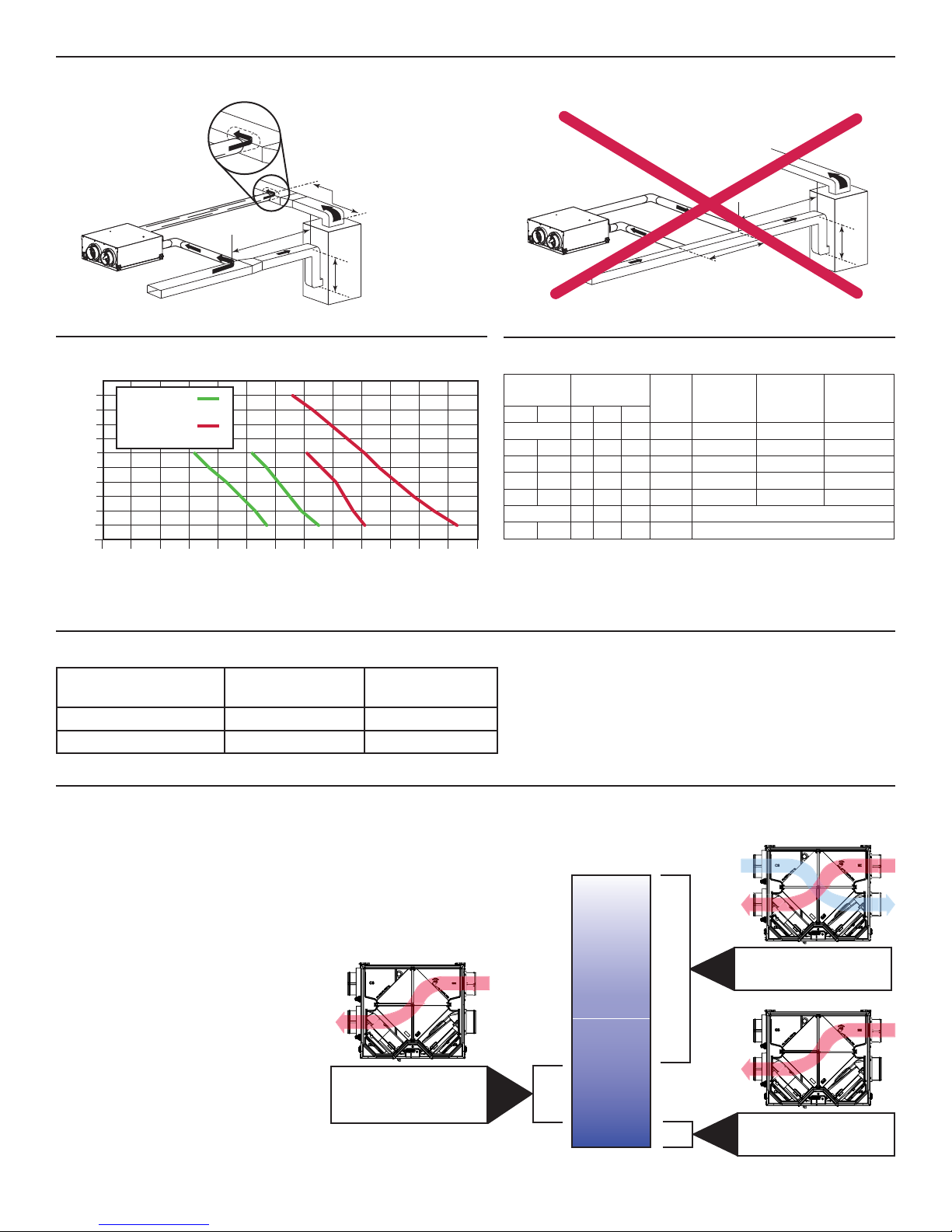

• Backdraft dampers shall be integrated in cold supply and cold

exhaust port

• ERV unit shall be HVI certied

MOTORS

• Unit shall have two high reliability, external rotor PSC motors, totally

enclosed and thermally protected

• The backward blowers shall support high static pressure environment

• The insulation class shall be B

FILTERS

• ERV unit shall have two washable 20 ppi reticulated polyester

urethane foam lters, UL 900 class 2 certied

• Optional MERV 7 lter kit shall be available, part no.: 21030

ERV CORE

• The ERV core shall be a crossow aluminum-polymerized paper core,

UL723 certied

• Hydroscopicpolymerexchangewaterbydirectvaportransfershalluse

molecular transport without the need of condensation

• The ERV core shall be constructed of alternate layers of corrugated

aluminum material and polymeric bactericide dessiccant

impregnated media; and shall not promote growth of mold or bacteria

• The ERV core design shall be made of rectangular utes to provide

very low pressure drop values

Controls

• Unit shall be equipped with an integrated push-button control for

Low or High speed operation

• Choice of low voltage main controls (not included) shall be

energized by ERV unit

• Optional low voltage auxiliary controls (not included) shall be

energized by ERV unit

• Removable terminal block shall be included for quicker low voltage

control connections

• A LED indicator shall indicate operating modes as well as error codes

• ERV unit shall be permanently energized, no control shall be installed

on power supply of unit

Air Flow Balancing

• Unit door shall be equipped with pressure taps as well as a

balancing chart to allow verication of balancing of the ERV unit

• Balancing dampers shall be integrated in cold supply and cold

exhaust ports

Defrost Cycles

• Unit operation shall include a choice of regular or extended defrost

cycles, according to climatic conditions

• Unit shall be equipped with Coldshield™ protection to stop air supply

in dwelling if air supply temperature drops below freezing point, due

to abnormal conditions.

Accoustic Noise Power

• The unit shall have a maximum acoustic noise power of 58.0 dBA

on low speed at 0.1 in. w.g. and 67.8 dBA on high speed at 0.4 in. w.g.,

measured at fresh air to building port.

• The unit shall have a maximum acoustic noise power of 49.4 dBA

on low speed at 0.1 in. w.g. and 58.3 dBA on high speed at 0.4 in. w.g.,

measured at exhaust air from building port.

Requirements and standards

• Shall be HVI certied as per CSA C439 Standards

• Shall comply with the UL 1812 requirements regulating

the installation of Energy Recovery Ventilators

• Shall comply with the CSA C22.2 no. 113 Standard

applicable to ventilators

• Shall comply with CSA C444 requirements regulating

the installation of Energy Recovery Ventilators

Warranty

Unit shall be protected by a 5-year warranty on parts only, with the

original proof of purchase.