2

Contents EN

1. Preface ........................................................... 3

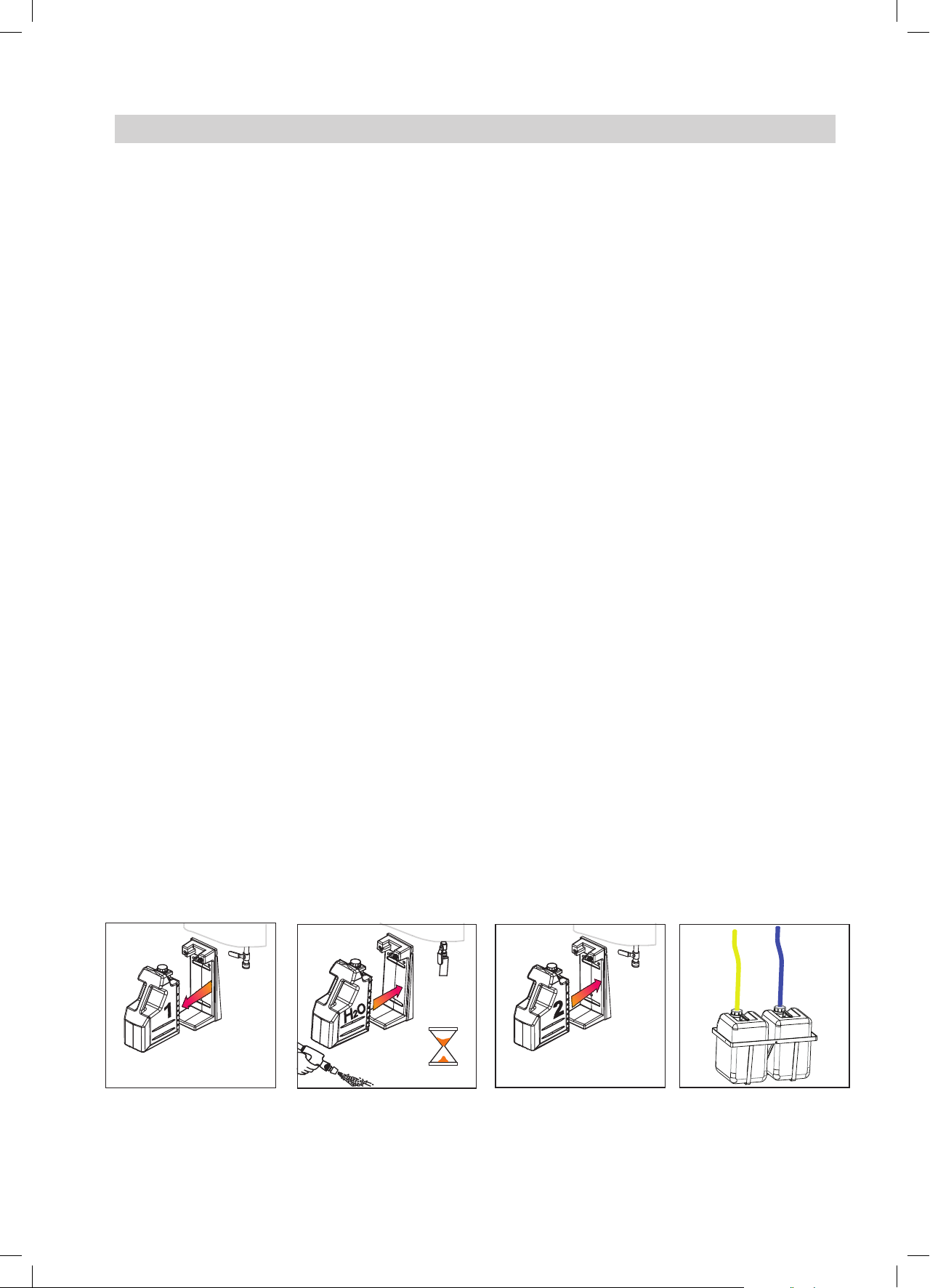

2. Connections to Low Pressure System................ 4

2.0 Directions for Mounting................................ 4

2.1 Water Connection ........................................ 4

2.2 Compressed-Air Connection........................ 4

2.3 Connection of Detergents ............................ 4

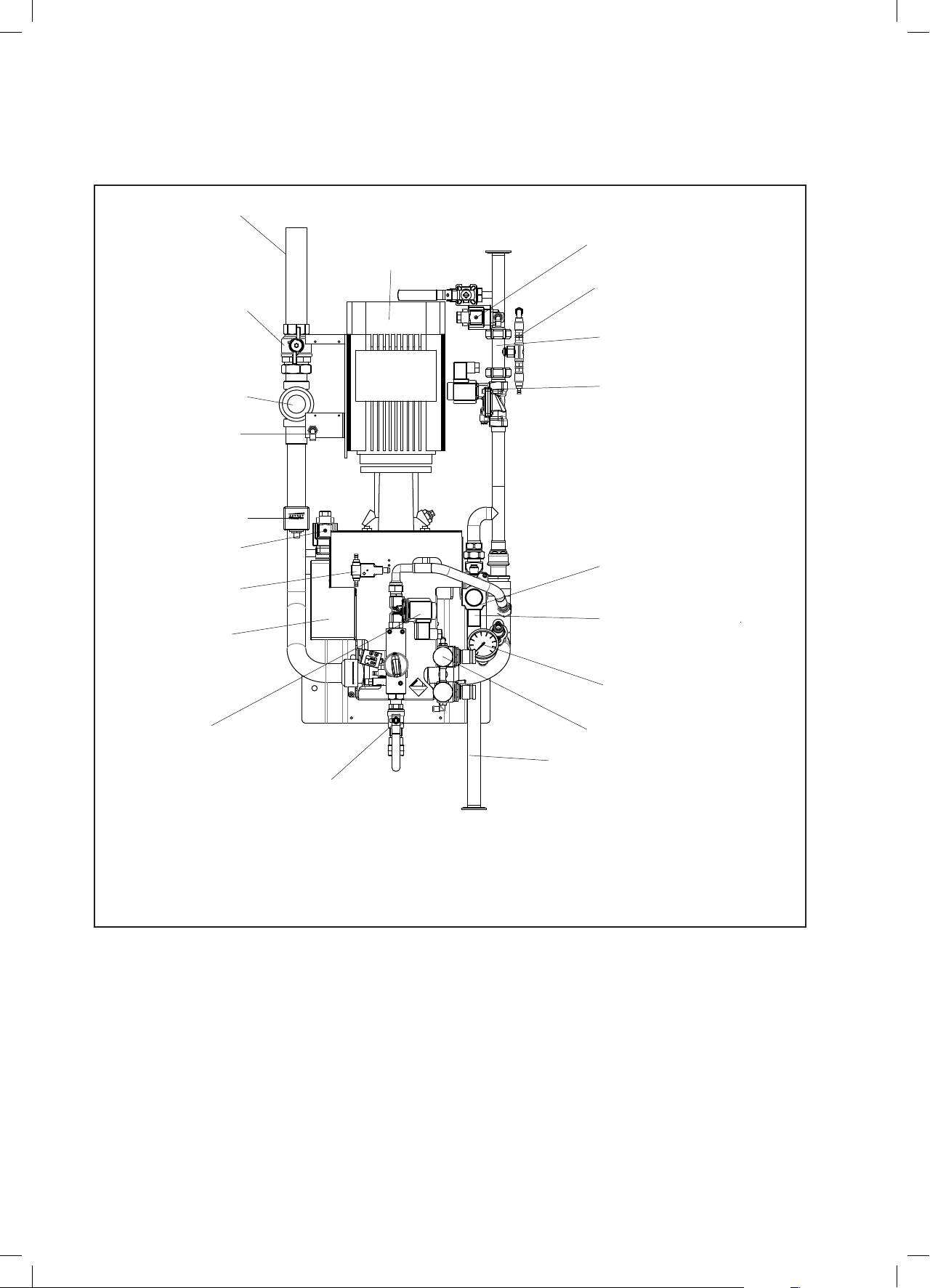

2.4 Layout Drawing............................................ 5

3. Directions before Operation.................................8

3.0 Automatic Cleaning...................................... 8

3.1 Function of User Pack System (accessory). 8

3.2 Bleeding the pump.........................................8

4. Manual Cleaning................................................. 9

4.0 Principle of the Injector System, Satellite .... 9

4.0.1 Functional principle of rinsing ............ 9

4.0.2 Functional principle of foaming.......... 9

4.1 Nozzle- and Handle Position ....................... 9

5. Security Devices............................................... 10

6. Regular Control and Service ............................ 10

7. Trouble shooting and Remedy.......................... 11

8. Flow Diagram ................................................... 13

8.1 Electric Diagram...........................................16

............................................ 17

10. Technical Data .................................................. 18

11. Guarantee......................................................... 19

12. Manufacturer ................................................... 19

Sparepart list............................................................79

Table des matières FR

1. Préface ......................................................... 44

2. Raccordement au circuit de basse pression..... 45

2.0 Instructions de montage ............................ 45

2.1 Raccordement de l’eau.............................. 45

2.2 Branchement d’air comprimé..................... 45

2.3 Alimentation en produits de nettoyage ...... 45

2.4 Dessin de disposition................................. 46

3. A lire avant l’utilisation ...................................... 49

3.0 Nettoyage automatique.............................. 49

3.1 Fonctionnement du système User Pack

(accessoire) ............................................... 49

3.2 Purge de la pompe........................................49

4. Nettoyage manuel ............................................ 50

4.0 Principe du système d’injecteur, satellite ... 50

4.0.1 Fonctionnement du rinçage ............. 50

4.0.2 Fonctionnement du moussage ........ 50

4.1 Positions des buses et de la poignée ........ 50

5. Dispositifs de sécurité....................................... 51

6. Révision et entretien réguliers .......................... 51

7. Diagnostic et résolution des pannes................. 52

8. Diagramme de fonctionnement ........................ 54

9. Plaque signalétique .......................................... 58

10. Données techniques......................................... 59

11. Garantie ......................................................... 60

12. Fabricant ......................................................... 60

Sparepart list............................................................79

Indice ES

1. Introducción ...................................................... 62

2. Conexiones al sistema de baja presión............ 63

2.0 Instrucciones de montaje........................... 63

2.1 Alimentación de agua ................................ 63

2.2 Alimentación de aire comprimido............... 63

2.3 Alimentación de detergentes ..................... 63

2.4 Diagrama ................................................... 64

3. Instrucciones previas al uso ............................. 67

3.0 Limpieza automática.................................. 67

3.1 Función del sistema User Pack

(accesorio) ................................................. 67

3.2 Purge de la Bomba.....................................67

4. Limpieza manual .............................................. 68

4.0 Principio del sistema inyector, Satélite ...... 68

4.0.1 Principio de operación durante el

enjuague.......................................... 68

4.0.2 Principio de operación durante el

espumado........................................ 68

4.1 Posición de la boquilla y del mango .......... 68

5. Dispositivos de seguridad................................. 69

6. Control periódico y mantenimiento ................... 69

7. Localización y reparación de averías ............... 70

............................................. 72

...................................... 76

10. Datos técnicos .................................................. 77

11. Garantía ......................................................... 78

12. Fabricante ........................................................ 78

Sparepart list............................................................79

Inhaltsverzeichnis DE

1. Vorwort ......................................................... 26

2. Anschluss an die Niederdruckanlage ............... 27

2.0 Montage der Anlage................................... 27

2.1 Wasseranschluss.............................................. 27

2.2 Druckluftanschluss..................................... 27

2.3 Reinigungsmittelanschluss ........................ 27

2.4 Übersichtszeichnung ................................. 28

3. Anleitung vor Inbetriebnahme........................... 31

3.0 Automatische Reinigung............................ 31

3.1 Kanisterhaltersystem (Zubehör) ................ 31

3.2 Entlüften der Pumpe...................................31

4. Manuelle Reinigung.......................................... 32

4.0 Prinzip des Kanisterhaltersystems,

Satellit ........................................................ 32

4.0.1 Spülen Prinzip.................................. 32

4.0.2 Schaum Prinzip................................ 32

.................... 32

5. Sicherheitseinrichtungen .................................. 33

6. Regelmäßige Wartungsarbeiten

und Prüfungen .................................................. 33

7. Betriebsstörungen und Abhilfe.......................... 34

8. Strömungsdiagramm ........................................ 36

9. Typenschild....................................................... 40

10. Technische Daten ............................................. 41

11. Garantiebedingungen ....................................... 42

12. Hersteller ......................................................... 42

Sparepart list............................................................79