Nippon Columbia Denon DP-11F Series User manual

DENON

SERVICE MANUAL

FULLY AUTOMATIC

DIRECT DRIVE TURNTABLE SYSTEM

MODEL DP-l IF SERIES

Hr Fr Component

U.S. and Canadian models do not include cartridge.

NIPPON COLUMBIA CO., LTD.

www.hifiengine.com

TABLE OF CONTENTS

FEATURES

SPECIFICATIONS. .....

BLOCK DIAGRAM

PART NAMES AND FUNCTION

EXPLANATION OF THE MICROPROCESSOR

ADJUSTMENT METHOD ....

PARTS LIST OF EXPLODED VIEW

EXPLODED VIEW OF MAIN PARTS

SCHEMATIC DIAGRAM

PRINTED CIRCUIT BOARD

CONNECTIONS OF P.C. BOARD

PARTS LIST OF P.C. BOARD.. ..

1

2

3

4

5'8

I -10

11

12

13

14

15

16

WARNING:

1. Component parts

Parts marked with A and/or shading in this service manual have special characteristics important to

safety. Be sure to use the specified parts for replacement.

2. Leakage current

Before returning the appliance to customer, test the leakage current when the power plug is connected.

Use a calibrated (with an error of not more than 5%) leakage current tester and measure the leakage

current from any exposed metal to the earth ground. Reverse the power plug polarity and test the above

again.

Any current measured MUST NOT EXCEED 0.5 miliamps. Corrective measure must be taken if it

exceeds the limit.

Silent, fully automatic operations with the use

of a microprocessor controlled contactless servo

tonearm.

An innovative microprocessor controlled, contactless servo

tonearm ensures safe, easy to use automatic operations with

little loss in sound quality.

Low mass straight arm

This arm is fully capable of maximizing the performance of

high compliance cartridges with outstanding tracing ability.

Even with the newest, high grade records, its tracing ability

is outstanding.

DENON Quartz

The turntable speed is controlled by the "DENON Ouartz"

which is the combination of the "High Precision Magnetic

Pulse Detection Method". the most sophisticated method

of FG detection, and the "Ouartz Lock".

-1-

www.hifiengine.com

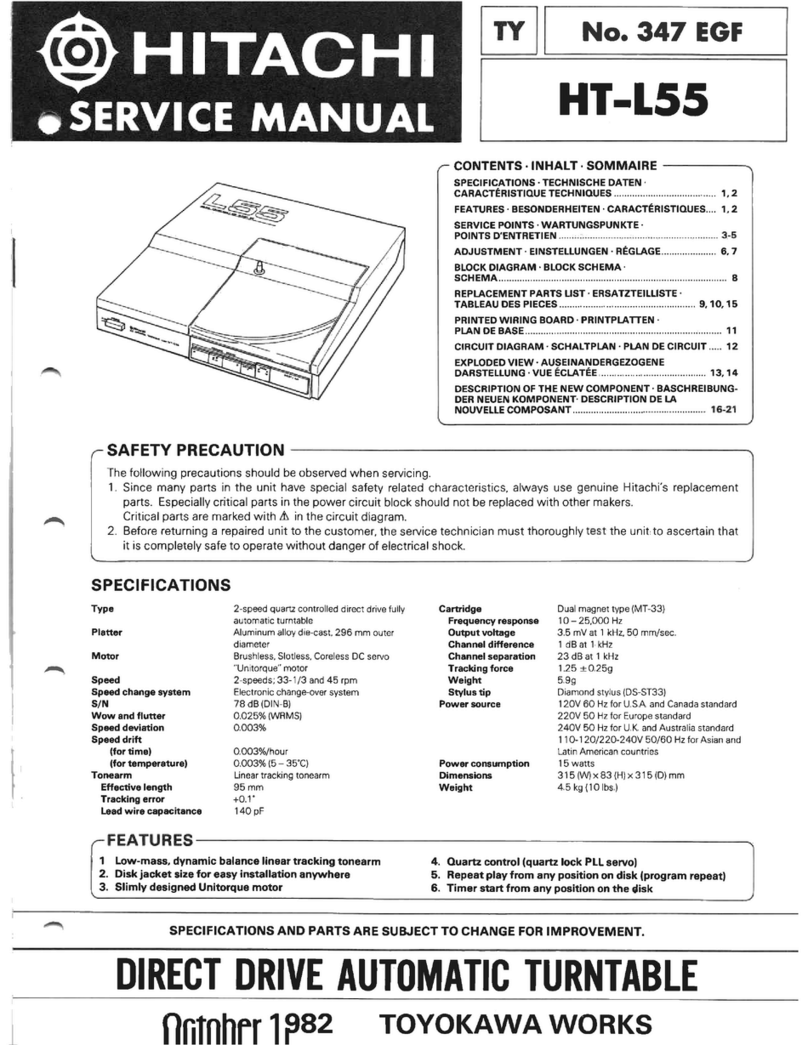

SPECIFICATIONS

Phonomotor section

Drive system: Servo controlled direct drive

Turntable speeds: 33-1/3,45 rpm

Wow & flutter: Below 0.02% wrms (servo system)

Below 0.037o wrms (JlS)

S/N ratio: Over 75 dB (D|N-B)

Rise time: Normal speed within 2 seconds (at 33-1 /3 rpm)

Platter: Aluminum die-cast;300 mm diameter

Motor: Linear drive motor

Speed control system: Speed servo by frequency detection, phase servo control

Speed deviation: Below 0.002%

Load characteristics: 0% (gO g stylus force; outermost groove)

General

Power supply: 50-60 Hz, Voltage is shown on rating label

Power consumption: 7 W

Dimensions: 100 x 365 x 335 mm (H x W x D)

Weight: Approximately 5 kg

Tonearm section

Arm type: Dynamically balance, semi-integrated straight arm

Effegtive length: 22O mm

Overhang: 16 mm

Tracking error: Within 3o

Automatic mechanism: Electronically controlled, fully automatic

Adjustable stylus force range: 0-3.0 g (1 scale=0.1 g)

Suitable cartridge weight range: Approximately 4.0-6.0 g (including screws, nuts)

Cartridge section (Only for those models with attached cartridge)

DL-60

Type: Moving magnet (MM)

Output voltage: 2.5 mV

Frequency response: 20-30 kHz

Stylus force: 1.810.3 g

Above specifications and outward appearance may be altered in future for improvement.

U.S. and Canadian models do not include cartridge.

-2-

www.hifiengine.com

Lock i

BLOCK DIAGRAM

Memorize

Reference voltage

F/V output

Start/stop command

ndication

/+* Rotation

control Power

amplifier

Speed selector

(33/451 o

Size sel ector

(30/1 7) o

Reference voltage

Memorize

Memorize

Memorize Compare/

amplify

Stop. cbntrol

Speed detection

Anti skate command

Anti skate.voltage

Rotation Power

control amPlifier

Power

amplif ier

Mid-point detection

Phonomotor

Vertical mot(

(Lifter motor

!c

o

E

E

o

o

c

3

o

E

l

E

il;l

Compare/

amplify Horizontal mol

Rotational speed detection

Magnetic polarity

dq!q9!',on _ ____?,

Magnetic polarity

detection

Motor-control

m icroprocessor

tR3T02

17130 Position

detebtion Reference voltage

Arm control

microprocessor

tR3TO3

Accela ration output

I

!o

o

o

E

c

o

N

'o

r

Rest/end detection

Speed detection

-3-

Note: -Ep inai"rt"s an analog switch

www.hifiengine.com

PART NAMES AND FUNCTION

Dust cover

Balance weight

Tonearm

REPEAT (Repeat switch)

When playing the records repeatedly, switch it on

(lamp lit).

@ eowen (Power switch)

This switch turns the power supply on (^l and off

(f ). When turning the power off, always return the

tonearm to the arm rest and hold it in place with the

clamp.

@ SlZe (Record size selector switchl

Set to the size of record to be played.

30 cm records

17 cm records

@ SfeeO (Speed selector switch)

Set to the desired record speed.

33-1/3 rpm records . . "33" (lamp lit)

4S rpm records . . . . "45" (lamp lit)

@ LOCK (Lock indicator)

When the power is turned on, the lamp will light up.

During play. the lamp will flicker until the proper

turntable speed is reached. Once the proper speed

is obtained, the lamp will, again. stay lit.

"30" (lamp lit)

"17" (lamp lit)

@ ARM LTFTER (Arm tifterswitch)

This switch is used to raise and lower the arm during

play or when playing the records manually. The lamp

is lit when arm is up.

START (Start switchl

Press this switch when starting the records auto-

matically.

@ STOP (Stop switch)

Press this switch when stopping the record during

play.

@ STYLUS FORCE (stytus force adjustment knob)

\

\\

-4-

This knob is used to adjust the stylus force.

www.hifiengine.com

EXPLANATION OF THE MICROPROCESSOR

. Motor Control lC . . . lR3T02 (at standard

revolution of 33 rpm)

The numbers on the left hand side indicates the terminal

number.

2. 4.5MHz OSC

3. 4.5MHz OSC

rpm selector

H: 45 rpm

L: 33 rpm

power source input

Vcc: 5V +0.5V

FG I bypass terminal

EG =%Ycc

FG I lowPass termini

FG I inverse input

The gain set element is connected.

E9l%Ycc

FG I non-inverse input

10mVpp - 1OOmVPP

E10 = %Ycc

ground terminal

F/V output

slower than normal revolution: 2 - 4.5V

normal revolution: i 2V

faster than normal revolution: O - 2V

9.

10.

14.

15.

4.

5.

6.

7.

16. r/v hold terminal

sJnre as terminal 15

17. F/V triangular wave

slorvtr than rtornral revolution

l_ i7. .1.tj/nLs

-l

ta1/1-I,,,

__I- >2v

normal revolution

faster than normal revolution

t I ; l.ttrnS

l*.1

t/v/1 A

ItllT-::\

I

v

8. FG I outPut

t l 7' l.8tt? S

r1 - --r--'

i t: r z

,t

lowpass terminal

t,/2yct, 2-1.5v

-5-

?\/

www.hifiengine.com

18. timing pulse width-set terminal

E18 = 0.6V

19. PD triangular wave

26. START/STOP terminat

H + START

L -+ STOP

28. Lock indicator

during lock (LED tit dimty)

69HZ

+4V

stop.. ... (LEDtit)

during transition . . (LED flashes)

+4v

.r 4.5rn s.

JLTL

20. sample pulse monitor.terminal

-:J! {_s

*lF ;

:'0.6 v

advance 0

21 PD hold terminal

slowphase:2-4V

normal phase: = 2V

advancedphase:1 -3V

22. PD output

same as terminal 21

Lock detector time set terminal

during lock: 0.6V

lock disengaged:0V

Revolution detector

during revolution: :--'....-,".-I + 4V

stop: 0V

Fou

. o.4ss , 2.2H2

m

23.

el

*':

25.

- 6,-

www.hifiengine.com

o Arm Control lC lR3T03

The numbers on the left side indicates the terminal number

of the lR3T03.

1. Accelaration inPut

Except for the matching range of the lead-in detector

(E7 < I t0.6V | ), it will recognize the situation and control

the accelaration during automatic tonearm operation.

2. Accelaration output

rt 5l tz.szv t0.1v I . . . open (will not control the ac-

celaration within the match-

ing range)

er 2lrz.sv10.1v | . . . . E2=t3.95V

-3.95V: will accelarate toward the inside from rest'

+3.95V: will accelarate toward rest from the inside'

3. UP/DOWN selection of the arm lifter

When E9 is H, the control output for lifting the arm will be

made at E3 = -Vcc.

When E9 is L, the control output for lowering the arm will

be made at E3 = +Vcc.

4. Detection of the rest Position

E4< -2.64V will be recognized as the arm being at rest'

5. Detection of the END Position

When E5 2 Z.Aqv, it will be recognized to be within the

END detection range.

E5 > 2.64V when the stylus tip nears the last sections of

the sound groove.

6. End control

Whithin the END detection range of 5 (above), (E5 >

2.64V}, the arm will be returned by the END control when

E6 > 0.23V.

E5 > 0.23V when the stylus tip moves into the lead-out

groove and the arm moves fast.

7. Matching input

E7 < | 10.6V lwill be recognized as the match range for

I ead-i n .

8. Drive output

Connect to GND.

9. UP control output

When the lifter is in the UP position during automatic arm

operations or when the UP signal is sent by pressing the arm

lifter button, pin 9 will be at H level.

EgH + 4V

E9L: OV

10. DOWN time constant

To ensure that the arm is lowered completely before pro-

ceeding to the next movement, a resistor between pins 9

and 10 and a capacitor on pin 10 has a preset discharge

time constant which is somewhat longer than the time

required for the arm to be lowered. Thus, when pin 9

becomes L (EgL : 0V), and the fixed amount of time

elapses. the arm will be recognized to be DOWN as soon as

E10 < 2V.

11. ANT (Anti-skating) control

When E10 < 2V, then El1 = -4V will be the control

output needed for the anti-skating to be engaged.

When E10 2 ZV, then E11 = +4V will be the control

output needed for the anti-skating to be disengaged.

12. Negative power source

Supplies -5V.

14. SUB (substratum)

To prevent any interference from the inner elements of the

LSl, the substratum terminal is connected to the unregu-

lated side of the negative power source, since it has the

lowest electric potential.

15. GND

Standard zero electric potential is the GND.

17. Return control

When the stop comrr'and is given, or when the repeat is

disengaged and the END is detected (EO > 0.23V), a con-

trol signal output (E17H > 4V) is mqde to return the arm

to rest.

E17H > 4V

E17L: release

18. Horizontal drive control

When the arm is in resting position, or when the arm

reaches the lead-in position during automatic play, and

comes into the matching range (E7 ( 1 tO.Ov | ), a control

signal output (E18H = 4V) is made to stop the horizontal

motion of the arm.

19. Initialset

This is the preparation time setting ierminal when the

power source is turned on. The resistor in the LSI and the

outer capacitor will set the charge time constant and carry

out the initial set.

-7 -

www.hifiengine.com

20. LCTD (Located) time constant

The LSI and its outer circuits will set the LCTD time

constant to improve the detection accuracy of the lead-in

position and the arm rest position.

E20H = 1.2V . A few moments after the arm reaches

the range of detection, in other words,

after the set LCTD time constant

elapses, it will become H level, where

it is memorized immediately and then

reset to the L level.

. Before and after detection, it will

become L level.

E20L = 0V

21. Turntable (T/T) Drive Control

E21L=0V . . . . . theturntablestops

E21H release . . . . theturntable rotates

(refer to the operational explanations for pin 22)

22. Turntable (T/T) Start Position

This terminal establishes the turntable start position. The

turntable will start when the arm separates from the arm

rest and pin 22 is released, under manual and auto modes.

23. Start

Will start automatically at the GND level.

24. Auto stop

Will stop automatically at the GND level.

25. Lifter

Will raise the lifter automatically at the GND level.

26. Repeat

Will engage the repeat automatically at the GND level.

27. UP SW

An UP time constant circuit is used so that when the lifter

is in the UP condition, this terminal is released and becomes

H level; and at other times, it becomes GND level.

With this unit, the arm will start to move approximately

two seconds after the UP command.

28. Positive power supply

Supplies +5V.

-8-

www.hifiengine.com

ADJUSTMENT METHOD

* Prepare a two-channel oscilloscope for the measuring

instrument.

r Adjusting the Phonomotor Section

* Measure, using the wrapping terminal number 8 of the

motor drive circuit board as the ground referent point when

adjusting the motor OP amp. voltage offset and the motor

torque.

VR2O3 (Motor torque adiustment)

VR2Ol (Motor offset adiustment)

VR202 (Motor offset adiustment)

VR204 (Motor torque adiustment)

TP203

TP2O4

Motor drive circuit board

Servo control circuit board

VR2 45rPm Lock adjustment

VR1 33rPm Lock adiustme

1. Adjusting the motor amp. offset voltage

1) Fix the tonearm to the arm rest and connect the oscil-

loscope to TP 203 and 2Q4 .

2l Rotating the turntable by hand, adjust the center of

amplitude at TP 203 1s Q 10'1V by turning VR 201 '

3) Following the preceding directions adiust to 0 t0'1V

byturningVR 2O2 forTP 2O4

2. Adjusting the motor torque

1 ) Leave the oscilloscope connections as they were for the

motor OP amp. voltage offset adjustments'

2l Take the turntable off the main body; move the tone-

arm close to the speed detection head and rotate the

phonomotor at a fast sPeed.

(Note) Be very cautious as not to damage the cartridge

during this Procedure.

3) For T.P. 2O3 , rotate VR 2O3 and adiust to

15VP-PtO.5V.

4l For T.P. 2O4, rotate VR 2O4 and adjust to

15VP-Pt0.5V.

3. Adjusting the head gap

Adjust, so that the gap between the turntable magnetic

coating surface and the detection head is 0.18 mm.

4. Lock adjustments for 45 rpm

From hereafter, the earth reference point of the measuring

instrument should be connected to T.P. 6 of the servo

control circuit board.

1) Connect the two-channel oscilloscope to T.P. 1 and

T.P. 2.

2l Set the speed selector to 45 rpm,

3) Take the arm off the arm rest and move it toward the

turntable to rotate the phonomotor.

4l Adjust VR2 so that the pulse from T.P. 1 is posi-

tioned to % the triangular wave length from f .P. 2 .

5.

1)

2l

Lock adjustments for 33 rpm

Connect the oscilloscope in the same manner as the

45 rpm lock adjustments. Set the speed selector to

33 rpm.

Adjust VR1 in the same manner as the lock adjust-

ments for 45 rpm.

aflovFPro5r

-9-

www.hifiengine.com

o Adjusting the Arm Control Section

Lead-in adiustment hole

VR5 (Stylus force adiustment)

VR3 (Horizontal offset adiustment)

1. Adjusting the horizontal OP amp. offsetvoltage

1) Fix the tonearm to the armrest and connect the oscil-

loscope to T. P. 3 .

2\ Set the lifter switch to the UP condition.

3) Turn VR3 and adjust to 0V10.01V.

2. Adjusting the lifter OP amp. offset voltagp

1) Fix the tonearm to the armrest and connect the oscil-

loscope to T. P. 4 .

2l Set the lifter switch to the DOWN condition.

3) Turn VR4 and adjust to -1V10.1V.

3. Adjusting the stylus force

1) Turn the power supply switch OFF.

2l Take the arm off the armrest. Rotate the balance

weight so that the tonearm becomes parallel to the

turntable surface when let go.

3) Return the arm to the armrest and turn the power'

supply switch ON.

4) Wait five seconds after the arm has lowered. Place the

cartridge stylus tip onto a stylus force guage and set

the stylus force adjustment knob to 1.5 g.

(Notel At this time, the stylus tip height should be

adjusted so that it is about the same height as during

play.

5) Turn VR5 and adjust, so that the stylus force guage

reads 1.5 g.

4. Adjusting the 30 cm lead-in position

1) Place a 30 cm record on the turntable and set the

record size selector switch to "30".

(Note) Keep the bottom cover closed.

Move the arm so that the stylus tip is at approximately

the 30 cm lead-in position. lnsert a small flat-headed

screwdriver into the lead-in adjustment hole; move the

arm back and forth and fit the screw driver into the

groove of the cam inside gently.

After turning the screwdriver, pull it out. Press the

start switch and adjust so that the stylus position stops

at the 30 cm lead-in position.

(Note) The 30 cm lead-in adjustments cannot be per-

formed unless the stylus tip position is approximately

in the 30 cm lead-in position. ln addition, if the screw-

driver is left inserted, the arm will not move.

5. Adjusting the 17 cm lead-in position

Adjust as necessary, such as when parts of the sensor sec-

tion have been replaced.

However, the following procedures should only be used

when a discrepancy is found for the 17 cm lead-in position,

after the 30 cm lead-in position has been adjusted.

1) Set the record size selector to 17 cm.

2l By continuously pressing the start switch, the arm will

move over and stop. At this time, check now many

millimeters, toward the inside or outside, the stylus tip

deviates from the required 17 cm lead-in position.

3) Take off the bottom cover of the cabinet and check the

adjustment scale position of the shutter. (One adjust-

ment scale corresponds to a stylus tip movement of

5 mm.)

4l Untighten the screw holding the sub shutter and place

a small screwdriver into the slot of the shutter. When

the stylus position is toward the inside, compared to

the required position, move the sub shutter toward the

right of the scale; when the stylus position is toward

the outside, move the sub shutter toward the left.

When completed, tentatively tighten the screw holding

the sub shutter.

5) After the adjustments are made, press the start switch

and check whether or not the stylus stops at the 1 7 cm

lead-in position.

6) lf the stylus stops at the required position, then tighten

the sub shutter screw.

Sub shutter

2l

3)

VR4 (Lifter of f set adiustment)

-10-

Adjustment scale sub shutter screw

www.hifiengine.com

PARTS LIST OF EXPLODED VIEW

Ref .

No. Part No. Part Name Remarks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

'16

17

18

19

20

21

22

aa

24

25

26

27

28

29

30

31

32

33

34

35

36

37

JO

39

40

41

42

43

44

45

46

47

48

49

50

51

52

58

59

473030601 2 |

4751005004 I

I

1048066018 |

4730306038 |

1058083104 I

421A21720g1

I

I

421 8288005 J

4628023009

5298006002

1468137103

401 8059007

31585451 13

3138003109

3 1 58705005

209825 1 005

4618113000

2224468004

47 12303017

4638225004

471 1 30301 8

4751003006

4438545104

4338172004

43381 77300

476 t 003009

3158451003

34 1 8025205

2398013105

4338181008

4744102037

4248019105

441 881 5003

4698008009

2228468004

4730304014

3939041 001

222A46800a

4 7 1 3808003

4 7 1 3806003

2178062101

473030901 9

wAo1074

4620027003

2339051 0b3

2339058006

23390501 01

441 8846001

441Aa14208

39 1 8423006

47000090 1 9

2228464004

211AO24002

1 1 28085003

2033642103

2062002031

20060 1 9307

2062024006

200603 1 026

20620 1 9008

3x1 2 CBRTS (1 )

4W

INSULATOR ASS'Y

3x1 2 CBRTS (1 )

BOTTOM COVER ASS'Y

RECORDED TURN TABLE

RUBBER SHEET

BUSH I NG

45 ADAPTOR

DUST COVER ASS'Y

HINGE

INCLUDED SCREW

ARM REST

CARTRIDGE GENE ASS'Y

MAIN BODY ASS'Y

TERMINAL WIRE

SPRING PLATE

OUTPUT P.C.B

3x6 CFS

SPR I NG

3x6 CPS

3W

COLLAR

SUB SHUTTER

SHUTTER

3E RING

FRICTION WASHER

MAGNET ASS'Y

COIL ASS'Y

YOKE (A} GENE ASS'Y

3x3 SS

ADJUST CAM

ARM PLATE

INSULATER MAT

CDS P.C.B

3x8 CBRTS (1)

LED

LED P.C.B

3x25 CBS

3x2O CPTS (1 )

MOTOR ASS'Y

3x16 CBRTS (1 )

WASHER

.FUBBER BUSH

POWER TRANS

POWER TRANS

POWER TRANS

WASHER

HEAD SUPPORT

MAGNETIC HEAD

3x6 CPSW

VOLUME HOLDER P.C.B

v16V1 5K8502

VOLUME KNOB

OUTPUT CORD ASS'Y

AC CORD

AS 3P AC CORD

AC CORD WITH LABEL

AC CORD WITH PLUG

AC CORD WITH PLUG

E1,EF,EG,EA,

EK,E1

LNS1RCP (HL)

BsBW. MBNi ll

SU5305

E 1 only

EU onlv

E2,EF,EG

EA

EK

E1

EU

Ref.

No. Part No. Part Name Remarks

63

64

65

66

1 038 1 96406

1038196422

222a46A0Oa

39391 40009

2129130008

CAB INET

CABINET

LED P.C.B

LED

PUSH SWITCH

LED

STOP KNOB

START KNOB

LIFTER KNOB

REPEAT KNOB

SPEED KNOB

SIZE KNOB

2.6x1 0CPTS(1)

PUSH SWITCH

KNOB

SERVO CONTROL UNIT

CONNECTOB

BODY CASE

BALANCE WEIGHT

ADJUST SCREW

SLIDE SWITCH

MOTOR DRIVE UNIT

E 1 only

G L-9PG24

PR-5524S-1

E1 only

67

68

69

70

71

72

73

74

15

76

7l

78

79

80

81

82

83

39391 53009

1 1 381401 03

1138139101

1 1 381 381 02

1 i38137103

1 138135105

1138136104

4730205016

21 291 80003

1138134009

KU0419

3168198000

3158693104

3 1 58695005

3 1 5870900 1

21 29 1 85008

KU0420

Bemark symbols in the parts list refer to the following countries and

a reas.

EA: Australia

EK: United Kingdom

EU: U.S.A. and Canada

E 1 : Multiple voltage model

E2: European continent

EF: French

EG: German

-11-

www.hifiengine.com

Fo

.b-o

$ o.1

VI

i9;

1.,'T I

a'

g

Y

I

F=o

Ge€(

QA'o

H

v

I

i,. /

@D

f --:-t-q34)

\_=.-_/

i

F--c

.-l

W*

I

@H,

\R $-6

Br\ {!>-a

) l;-bv.

0D)

-[

luQa

1) @€D

t:

(D<-?)

id.

i )-@

l--'\ ,/

16})

frY-

#

Bra

[-

a0)

b

@otto,*totttl F-e

1^

<AD

I

\@@

\\\

\

www.hifiengine.com

SCHEMATIC DIAGRAM

DPIIF

WIRING DIAGRAM

SPEED

tt/45

Rl4 6ak

STOP

STAR'I

REPEAT

Fig I OTHER

Europeon & Austrolion Models

;.;l

-tr*"."";;-l

rLow i

-l t'rcH I

__J

tNSIDE r DARK

IIOBIZONTAL MOTOI]

LINE VOLTAGE

Multi Voltoge Models

LI FTER

UP / DOWN

RECORO

SIZE

30/t7

KU -419

Note: o Resistance shall lte 'l /4W unless oth0rwise specilied and the unit

is !).

o The unit of capacitor is tF, P rs pF unless otherwise specif red.

o Parts marked wrth j are of rmportance rr rcsllcct to the safe-

ty. use the specified type wilhout fail.

The voltage values are measured ustng the circuit tester (DC

100 k5)/v)

This circurt dra.c;ram shows the basrc circuit. lt rs subJect lo

chanqe for the pupose of improvement.

D t-t5,2A,2t,23,24 ,301 ' tS2O?6

LED2 -7,PR55245'l

a

a

a

a

The anti-skating will be turned (

after the arm starts to go DOWN.

A "match" denotes the conditio

on the edge of a 3O or 1 7cm

"30" denotes a 30cm recored I

1 7cm record.

"33" denotes the record speed

4Srpm.

approximately five seconds

where the arm is positioned

played; "17" denotes a

33 1/3rpm; "45" denotes

I R 2Ol,2O3:zSC 2236 i^ioffi^G"7

--.-t I

HD/40668P vm

016- l9 : RvO6 t2u O.22A t2 a POWER

4 TRANS

555H2{33) lC I tR3fo2 F/v

. lAl'12y votoBCo\rRoLMrcRoPRocrssoq

4/w IL JUL P/D

33/45 rc, ru1!1,9 ^_ srqqr

F/v P/O MONITOR I,{ONJTER DETECTOR STOP

MATCHING TIME

CONSTANT

START SToP oOWN T/r r/T rNrlAL sET

TIME CONSTANT START/STOP

START POSiTION

lC 2 lR3ro3

ET ARM CONTROL MTCROPROCESSOR

TURN UP DETECTOR

HORI ZONTAL

KILLER

ACCELIN END DETECT9R ANTI, ACCELOUT

9

/30:-5v i

ltz,+q.evr

R,lo 22r I

L

HORIZONTAL lC3:lV5218L vro pOrrurOrreCtrOrul

..|.4?o IyPC324C

AC t20V

A 6oHz

Conodlon A U.S.A Models

See Fig I for oiher line Voltoqe -NJtt44556

pPC78lt405H !PC7905H

-

.ro\ )o\

ltll

##

ill|l u lJ ll

ta2 132

tr I our coM our

COM IN

ac |5v/230v

6OHz/5OHz

-13-

www.hifiengine.com

PRINTED CIRCUIT BOARD

KU.419 SERVO CONTROL UNIT

<o>

KU-420 MOTOR DRIVE UNIT

I

o

I

-o

n

N

n

--l

I

1

l

'l

o L--- ------- c

www.hifiengine.com

CONNECTIONS OF P. C. BOARD

lD PU ARll

SWLUS FORCE AOJ.

P. C. B.

KU- 420

aa

i-et-.l

[:lr-l

POTVER TRANS

lP-5

TP-6

TP{

TFE

TH

TFI

fP-7

TF8

KU-4 I I

l-ocK LEo P.c.B.

www.hifiengine.com

KU-419 SERVO CONTROL UNIT

Ref. No. Part No. Part Name R emarks

SEMICONDUCTOR GROUP

tc1

tc2

tc3

tq

tc5

rc6

tc7

tc8

tc9

TR1 ,2,"1O

TR4-9

TR3

D1-15, 20

21 ,23,24,

301

Dl6-19

TH1

LEDl

LED2-7

LED8,9

cDsl ,2

CD53

2630173004

26301 74003

26301 89001

2630146002

26301 98005

2630147001

2630 1 60004

2620276005

2620092001

2710102005

27301 98002

2740038000

2760049008

2760237001

276031 1008

39391 40009

39391 53009

3939041 001

39390ss001

3939053028

tR3T02

tR3T03

M5218L

p,PC324C

NJM4556

pPC78M05H

pPC79O5H

H D1 4066BP

M53205P

2SA1 015 (Yl

25C181 5 (Yl

2SD467 (Cl

ts2076

RVO6

THERMISTER

LED

LED

LED

cDs

CDS

TD5-C210D

GL.9PG24

PR-5524S-1

LN81 RCP(H L)

10-1sKe

RESISTOR GROUP

R30

R25

R15

R17

vRl ,2

VR3-5

VR6

2452195008

2452201002

2452207006

2452223006

EP-5462H15

21 16000073

2114024002

RN14K2E332G

R N1 4K2E562G

R N1 4K2E1 O3G

R N1 4K2E473G

SOLID VOLUME

vo8PB203

v1 6V1 5KB502

Metal Jilm

3.3K0 %W

5.6Ko %W

10Ko %W

47Ka %W

Variable resistor

22Ka

20Ko

5Ka

CAPAClTOR GROUP

c33,54

c27

c32,46

c4

c11,31,36,

38-40,50,

51 ,60

c9, 10

c57

c58

c2,53

c20

c8,30,41 ,

42,45,34

c12,21 ,

35,37,49

u4

u3

c24

c61

cl.3,5,18

c16

2s3 1 055069

253 1 008003

2531004007

25s 1 008003

2531027000

253361 9005

2533657009

25s3662007

253363 7003

2544129005

2544132005

25441 36001

2542037005

2542038004

2544140000

2544044009

2544119905

2554194017

cK45B1 H1 01 K

cK45B1 h472K

cK45B1 H102K

cK45B1H472K

cK45F1 H1 042

cD45SL1 H470J

cc45sL1 H101K

cc45sL1 H271 K

cc45sL1 H271 J

CE04W1A470=

CE04WlCl00=

CE04W1Cl01 =

CE02W1 E1 02=

CEO2W1E222=

CE04W1VR7=

cE04w1 H010

CE04W1 H010=

cog3P1 H473J

Ceramic

100PF 50V

0.0047pF50v

0.001pF 50V

0.0047prF50v

0.1pF 50V

47PF sOV

100PF 50V

270PF 50V

270PF 50V

Electrolitic

47p,F 10V

10pF 16V

100pF 16V

1000pF 25V

22OOpF 25v

4.7yF 35V

l trF 50V

1pF 50V

Film

0.047pF 5OV

PARTS LIST OF P. C. BOARD

KU.42O MOTOR DRIVE UNIT

Ref. No. Part No, Part Name Remarks

OTHER PARTS GROUP

SW1-6

2228r''68008

21 291 30008

2 1 291 80003

3998025000

4178028101

4450033005

SERVO CONTROL

P.C.B.

PUSH SWITCH

PUSH SWITCH POWER SW

CRYSTAL 4.5 MHZ

HEAT SINK

WIRE CLAMP BAND

Ref . No. Part No. Part Name Remarks

SEMICONDUCTOR GROUP

1c201

TR202,204

TR201,203

H-A, H.B

TH1 ,2

26301 89001

2710105002

2730201009

27603030 1 6

276031 1 008

M521 8L

254966 (Yl

2SC2236 (Y)

H L-300C

THERMISTEB TD5{210D

RESISTOR GROUP

v203,204

v201 ,202 21 16000031

21'16000073 vo8PB1 02

vo8PB203

CAPACITOR GROUP

c202

c201

c203,204

2544034006

2544140000

255 1 076002

CEO4W1 V4R7

CE04W1 V4R7=

co93M1 H223K

OTHER PARTS GROUP

2224477002

2050 1 34908

2090047903

MOTOR DRIVE P,C.B.

IM TERMINAL PIN

0.6 JUMPER WIRE

CARTONE CASE GROUP

Ref.

No. Part No. Part Name Remarks

501822A222

5028060001

5058092023

505801 701 1

5058006006

5058023018

CARTON CASE ASS'Y

PACKING ASS'Y

LAMINATE ENVELOPE

ENVELOPE

ENVELOPE

ENVELOPE

60x260x0.03

60x100x0.03

350x640x0.05

ACCESSORIES GROUP

Ref.

No. Part No. Part Name Remarks

5298006002

421 8288005

51 18208003

5118211003

511821?0,02

3 1 58547001

3158752003

2033667007

45 ADAPTOR

RUBBER SHEET

INSTRUCTION MANUAL

INSTRUCTION MANUAL

INSTRUCTION MANUAL

SHELL ACCESORIES ASS

ALIGNMENT PLATE

PLUG ADAPTOR

E2, EA, EK,

E1, EU

EF

EG

EU

E1

. The carbon res istors rated at %W are not listed hersin.

-16-

www.hifiengine.com

Table of contents

Other Nippon Columbia Turntable manuals