Nittan Evolution EV-UV User manual

NITTAN (UK) LTD. Hipley Street, Old Woking, Surrey, England, GU22 9LQ. UK

Tel: +44 (0) 1483 769555 • Fax: +44 (0) 1483 756686

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution • EV-UV • analogue addressable ultraviolet flame sensor instruction manual

EV-UV

analogue

addressable

ultraviolet flame

sensor

instruction manual

Quality System Certificate No. 041

Assessed to BS EN ISO 9001:2000

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

evolution.....

The EV-UV analogue addressable flame sensor forms part of a range

of analogue addressable fire sensors from Nittan (UK) Ltd called

evolution.

The EV-UV together with the EV-PH, EV-H, EV-P and EV-DP are all

elegantly designed, low profile fire sensors which are aesthetically

pleasing, thus enabling them to blend unobtrusively into modern

working environments.

The evolution analogue addressable range all feature the very latest

technological advancements such as ASIC design, increasing

reliability and performance.

evolution.....

2

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

Section 1 - INTRODUCTION

The EV-UV is an attractively-styled, low profile ultraviolet flame

sensor for use with Nittan 'evolution' protocol control panels.

The EV-UV utilises the ultraviolet light detection method.

EV-UV features:

• Ultraviolet sensor, detecting ultraviolet light emitted

by flames

• Low profile, stylish appearance

• Supplied with protective dust cover,(remove

during commissioning)

• Low monitoring current

• Remote indicator output

• Non-polarised terminals

• Compatible with UB-4-EV and STB-4SE-EV bases

Section 2 - SENSOR MODELS

The EV-UV ultraviolet flame sensor has two terminals for

connection onto the two wire loop. The remaining terminal

provides a switched current sink function which operates when the

detector goes into alarm condition, suitable for the operation of an

auxiliary function such as a remote indicator. Terminal 3 (RIL) is

limited to 3mA.

Section 3 - BASE MODELS

A variety of bases are available for use with the EV-UV sensor. It is

important to use the correct base for each application. The

available base models are:

i) UB-4-EV base: For standard use with EV-UV series ultraviolet

flame sensor.

ii) UB-4SE-EV base: Similar to UB-4-EV base, except deeper.

CONTENTS:-

Section 1

Introduction Page 3

Section 2

Sensor models Page 3

Section 3

Base Models Page 3

Section 4

Location Page 4

Section 5

Installation Page 4

Section 6

Maintenance & Page 5-6

Cleaning

Section 7

Specifications Page 7

Section 8

Environmental

Parameters: Page 7

- Temperature Page 7

- Humidity Page 7

Section 9

EMC Page 7

Section 10

Connections Page 8

Section 11

Dimensions Page 8

Section 12

Area Coverage Page 9-10

Section 13

Disposal Page 11

Section 14

ROHS Compliance

Statement Page 11

Section 15

Flameproof

Housing Page 12

3

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

4

Section 4 - LOCATION

Note: Use correct sensitivity position. See Section 12 on page 5 for

more details on positioning.

i) Determine suitable mounting location according to supervision

angle, and effective detection range.

ii) Avoid mounting at such angles that two detectors supervise each

others protected area unnecessarily.

iii) Avoid mounting around openings for ventilation because of dust

and dirt contamination.

iv) Avoid mounting in such as way as the sensor covers external

doors or windows, as ultraviolet light may enter the range of the

detector and cause false alarms.

v) Avoid mounting in areas such as workshops in case of false alarm

from welding etc. If this is unavoidable the source should be

shielded with plain glass.

vi) In the case of supervising certain obstructions ensure there are no

dead areas.

Section 5 - INSTALLATION

In normal use, the EV-UV sensor will be installed at ceiling level,

however it is permissable to mount the sensor at an angle (See

Section 12 for details). Pass the field wiring through the cable hole

in the centre and from the rear of the base. Offer up and affix the

base to the ceiling or conduit fitting with screws via the base

mounting holes. Consider visibility of the sensor's integral LED alarm

indicator when mounting the base. Connect the field wiring to the

base terminals, as detailed on page 8 making sure the wiring does

not obstruct fitting of the detector head. Fit the sensor head by

inserting it into the base and turning clockwise until the lugs align

with the base.

Note: The address must be set before the sensor is fitted into place.

Keep the plastic dust cover supplied over the sensor until the system

is fitted to prevent the quartz window from becoming scratched.

NOTE: THE PLASTIC DUST COVER MUST BE RE- MOVED FROM THE

SENSOR IN ORDER FOR THE SENSOR TO FUNCTION CORRECTLY.

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

Section 6 - MAINTENANCE

AND CLEANING

Maintenance:

The EV-UV detector is a high quality product engineered for

reliability. If proper preventative maintenance is not carried out,

there is a likelihood of malfunction, including false alarms.

Servicing:

Servicing of the system should be carried out in accordance with

the requirements of BS 5839 Part 1, Fire Detection and Alarm

Systems for Buildings: Code of Practice for System Design,

Installation and Servicing.

The maintenance procedures described below should be conducted

with the following frequency:

One month after installation: Routine Inspection and every 3

months after:

Every 6 months: Operational Test.

Every 12 months: Functional Test and Clean.

All above frequencies of maintenance are dependent on

ambient conditions.

Routine Inspection

i) Ensure the sensor head is secure and undamaged.

ii) Ensure the surface of the sensor’s outer cover is clean. If

there are deposits due to the presence of oil vapour, dust

etc, then the sensor should be cleaned in accordance with

the cleaning instructions detailed later in this manual. It

may be advisable to ensure that such cleaning is conducted

regularly in the future.

iii)Ensure no equipment which may emit ultraviolet light has

been installed in the vicinity of the detector since the last

routine inspection. If such equipment has been installed,

then you should notify the Fire Safety Officer or other

competent authority that its presence may cause

false alarms.

5

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

6

Operational Test

The purpose of the Operational Test is to confirm the sensor’s correct

operation in response to a smoke condition.

Note: When carrying out site testing of Analogue Addressable

Evolution detectors, the CIE shall be set to test mode prior to

beginning the tests.

i) Take any necessary precautions at the control panel to limit the

sounding of the alarm sounders/bells and any fire service

summoning device.

ii) Introduce a naked flame into the range of the sensor by using a

lit match or cigarette lighter held 1-10m in front of the

detector. Check that the detector gives an alarm condition

within 15 seconds. Check the LED indicator on the EV-UV

sensor illuminates and any remote indicator LED fitted

also illuminates.

iii)After the sensor has given the alarm condition, reset the sensor

from the control panel. It may be necessary to allow a short

time to elapse before resetting the detector.

Functional Tests:

The functional test checks the detector's operation. These detectors

may be returned to our factory for Functional Testing.

Cleaning:

Note: The sensor head should NOT be disassembled.

i) Carefully remove the sensor head from its base.

ii) Use a soft, lint-free cloth, moistened with alcohol for sticky

deposits, to clean the plastic casing. Be careful not to wipe

abrasive particles, e.g. dust and grit, across the quartz glass

window of the detector when cleaning.

iii)If the unit needs further cleaning, or is damaged or corroded,

please return the complete sensor to Nittan (UK) Ltd. for service.

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

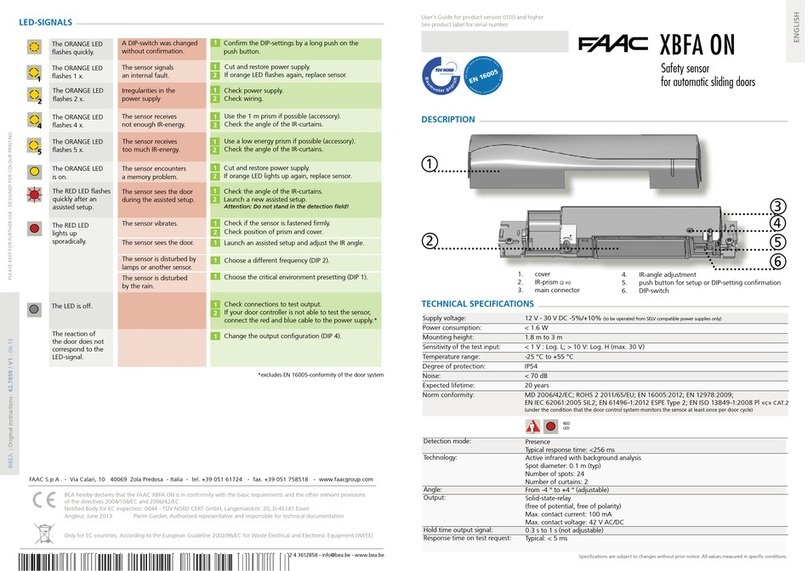

Section 7 - SPECIFICATIONS

Model Reference: - EV-UV

Computer Reference: - F16J71005

Sensing Wavelength: - 185 - 260nm

Detection Angle: - 100 degrees

Sensor Type: UV Tron (Part #: R2868)

Operating Current: - 1mA

fire alarm (LED on)

5.2mA

Standard: - EN54 Part 10:2001

Mass: - 102g (excluding base)

Charging Time: - 20 seconds

Ambient Temperature

Range: - -10 ºC to +55 ºC

IP Rating: - 51

Section 8 - ENVIRONMENTAL

PARAMETERS

Temperature Considerations:

Over the range from -10 ºC to +55 ºC

Humidity:

Relative Humidity of up to 95%, measured at 50 ºC,

non condensing.

Section 9 - EMC

Installation

The installation shall be in accordance with the regulations either

of the approval body for an approved system, or otherwise, to

the national code of practice/ regulations for the installation of

the fire alarm system, e.g. BS 5839 part 1.

Electromagnetic Compatibility (EMC)

On a site where there is an unusually high level of potential

electrical interference, e.g. where heavy currents are being

switched or where high levels of R.F. are prevalent, care then

must be taken in the type and routing of cables. Particular care

should be given to the separation of zone wiring from the cable

carrying the interference.

7

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

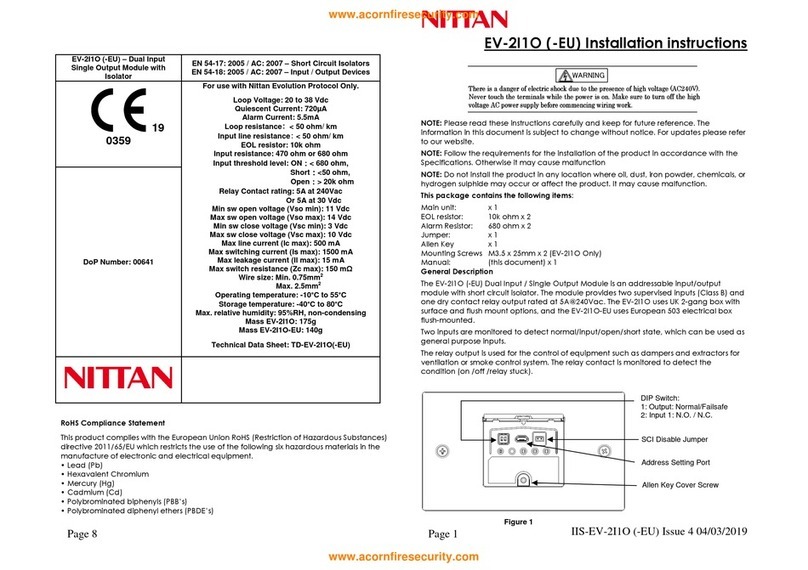

Section 10 - CONNECTIONS

8

CIE

Section 11 - DIMENSIONS

Auxiliary terminal RIL current limited to 2mA.

27 mm

43 mm

20 mm

41 mm

4.5 mm

9 mm

2.8 x 6mm

GRUB SCREW

15 mm

104.5 mm

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

Section 12 - AREA COVERAGE

9

Fig. 1. shows the area coverage of an EV-UV detector when

mounted at a height of 10 metres on a ceiling. The

approximate area coverage is 340 square metres.

Fig. 2. shows the area coverage of an EV-UV detector when wall

mounted at a height of 10 metres on a ceiling. The

approximate area coverage is 570 square metres.

FIG. 1.

FIG. 2.

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

10

Sensitivity results have all been obtained

by testing theEV-UV with the following

flame size as below:-

The EV-UV sensor may be positioned in two ways. Each way determines the distance and area coverage

of a single detector.

Fig. 3. shows the EV-UV in the B-D position, and Fig. 4. shows the EV-UV in the C-A position. In both

examples, the shaded area indicates the actual detection area achieved for each positioning of

the sensor. The examples are based on tests carried out using a fuel fire covering an area of

approximately 33 square centimetres. (See Fig. 5.)

Fig. 6. demonstrates how the area of coverage of

the EV-UV sensor increases the further away

from the sensor head you go. The sensor

has a maximum detection angle of 100 degrees.

FIG. 3. FIG. 4.

FIG. 5.

FIG. 6.

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

11

Section 13 - DISPOSAL

This symbol on the EV-UV indicates that this product must not be

disposed of with household waste. Instead, it is your responsibility to

dispose of your waste equipment by handing it over to a designated

collection point for the recycling of waste electrical and electronic

equipment. The separate collection and recycling of your waste

equipment at the time of disposal will help to conserve natural

resources and ensure that it is recycled in a manner that protects

human health and the environment. For more information about

where you can drop off your waste equipment for recycling, please

contact your local city office or your household waste disposal service.

Section 14 - ROHS COMPLIANCE

STATEMENT

(RoHS compliant and lead-free)

This product complies with the RoHS (Restriction of Hazardous

Substances) directive.

This product complies with the RoHS (Restriction of Hazardous

Substances) directive which restricts the use of six hazardous

materials in the manufacture of electronic and electrical equipment.

This product complies with the European Union RoHS (Restriction of

Hazardous Substances) directive 2002/95/EC which restricts the use

of the following six hazardous materials in the manufacture of

electronic and electrical equipment.

• Lead (Pb)

• Hexavalant Chromium

• Mercury (Hg)

• Cadmium (Cd)

• Polybrominated biphenyls (PBB’s)

• Polybrominated diphenyl ethers (PBDE’s)

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Technical Manual:

EV-UV

- 000023 (Changes are subject to DCRN)

12

FIG. 7.

Section 15 - FLAMEPROOF

HOUSING

The EV-UV detector may also be used with the NITTAN NFD-FPH

Flameproof housing. The NFD-FPH is for use in areas made

potentially hazardous by the presence of flammable liquids or

vapours (zone 1 or zone 2).

The housing has a threaded cover to enable ease of access for

installation and includes internal and external earth terminals

suitable for up to 4mm sq. cable. The EV-UV, when installed in the

NFD-FPH, requires a special bracket and base inside the housing to

enable correct mounting of the flame detector - this is included in

the housing.

Fig. 7. (below) is a diagram of the housing.

Flameproof Housing Specifications:

Model Reference: - NFD-FPH

Computer Reference: - F07N*63542

Body & Cover - Copper free aluminium (Chromate primed

polyester powder coated)

Locking Screw - Steel zinc plated

Window - Heat resistant quartz glass

IP Rating - I.P.66

Cable Entries - 2 x M20 (1.5mm pitch)

Weight - 2.3 Kgs

Standards:

CENELEC

EN 50014/50018 & NBM C23.001/103

INIEX

ATEX Approved to II 2 G D, EExd IIC T6 (85 ºC)

• Ref No: NISM/EV-UV/01 • Date: 16.04.09 • Issue: 1

• evolution advanced • EV-UV • analogue addressable ultraviolet flame sensor

instruction manual

Table of contents

Other Nittan Security Sensor manuals

Popular Security Sensor manuals by other brands

Visonic

Visonic K-980D installation instructions

F&F

F&F DR-03 quick start guide

Honeywell

Honeywell Notifier FST-951 Installation and maintenance instructions

Optex

Optex sensor manual

Agilent Technologies

Agilent Technologies 1100 Series Reference manual

project mc2

project mc2 Lie Detector quick start guide