5

Inner width of sash - 150

●Cut the rail to the inner width of the sash less

150mm.

●Cut off the correct end according to the

instructions given on the sticker as follows:

• For the right-handed opening type, cut off

the right end as viewed from the front.

• For the left-handed opening type, cut of the

left end as viewed from the front.

● If the distance between the cutting face of the

rail and the reference mounting hole is no

less than 80mm, make a new hole φ5.5mm

for installing the rail at the position 50mm

from the end.

50

If no less than 80mm, make a new hole.

32.5

●Insert 2 plate nuts in the T groove in the rail.

●Match the plate nuts to the mounting holes in

the control rack set, then install the control

rack set with screws (M4 ×8 truss screws)

furnished with the product.

90-100mm

A+120 120 120 120

2

1

32

22

3 4 5

矢印方向を扉の

中心に向けて

取

り付けて下さい

ハンガーA

中

心

125

Pitch of 300 A

10

125

ハンガーB

心

中中心に向

けて

取

矢印方向を

扉の

り付

けて

下

さい

6

6

り付けて

下

さい

中心

に

向

け

て

取

矢印方向を扉の

ハンガーA

SC−C03

心

中

L/

NXX

XXX

●In assembling and reengaging the clutch gears, follow the

"Procedure for assembling and reengaging clutch gears."

●Install the control device on the hanger on the door front end with

screws (M5 ×12 pan head screws) furnished with the product.

Install it with the door open by at least 60cm (where it does not

engage with the control rack set).

7

8

注意

故障の原因と

なりますの

で調整は下記の範囲内で

行

って下さい

。

強方向:

5

回転以下

弱方向:

2

回転以下

弱

PS−03R

LOTNO.

04223

強

行って下

さい。

故障の原因となりま

す

の

で調整は下記の範囲内

で

強方向

:5回転以下

弱方向

:2回転以下

注意

PS−03R

強

LOTNO.

04308

弱

矢印方向を扉の

中心に向けて取

り付けて下さい

ハンガーA

中

心

SC−C03

L/NXXXXX

●Temporarily tighten the screws

(M4 ×5 pan head screws) fur-

nished with the product, on the

fittings for installing the pull

spring. Then insert them into the

T groove in the bottom of the rail.

●Tighten the screws to fix the

fittings. Install the pull spring on

the fittings for installing the pull

spring, with screws (M3 ×8 pan

head screws) furnished with the

product.

●Install the stop roller on the hanger on the door

front end with screws (M5 ×8 pan head screws)

furnished with the product.

●Insert the plate nuts in the T groove in the rail,

then install the plate spring with screws (M4 ×8

truss screws) furnished with the product.

9

り付けて下さい

ハンガーA

矢印方向を扉の

中心に向け

て取 中

心

SC−C03

L/NXX

XXX

L/N 04126

中心に向けて取

り付けて下さい 心

矢印方向を扉の

ハンガーA

中

SC−C08

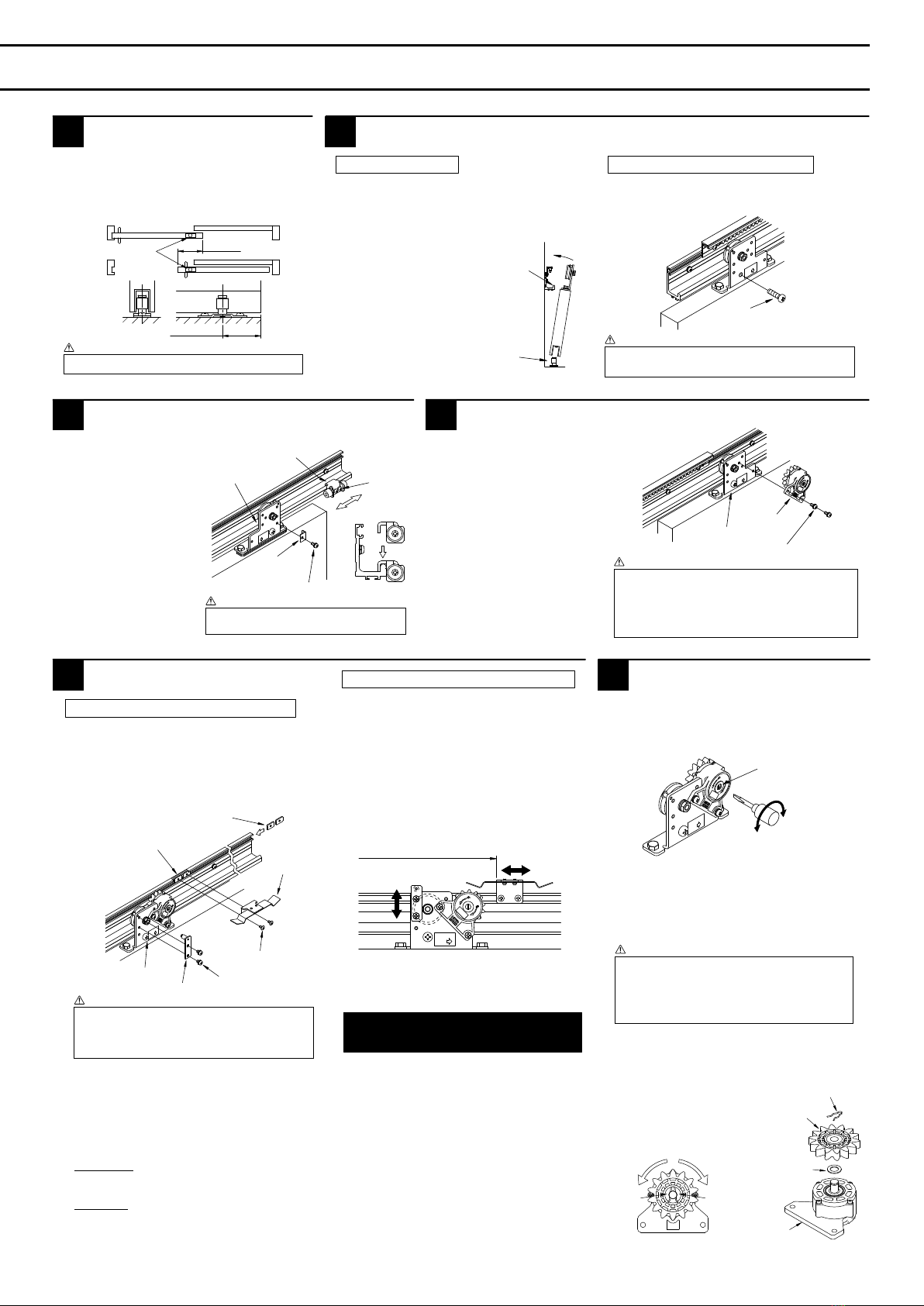

●If the closing force needs

adjustment, turn the gear shaft

with a screwdriver for

adjustment.

Label on the component

Turn it in the direction of

"Strong" →to increase the

closing force.

Turn it in the direction of "Weak"

→to decrease the closing force.

●Turn the speed

adjusting screw of

the control device

with a screwdriver

to adjust the

closing speed. (It is

factory-configured

to the highest

speed.)

●Slide the control rack set to adjust the controlling

interval, thus adjusting the closing speed.

• Shorten the controlling interval →to increase

the closing speed.

• Elongate the controlling interval →to decrease

the closing speed.

10

04223

弱方向:2

回転以下

強方向:5

回転以下

行って下さい。

故障の原因と

なり

ま

す

の

で調整は下記の範囲内

で

注意

強

弱

PS−03R

LOTNO.

ハンガーA

り付け

て下さい

中心に向けて取

矢印方向を扉の 中

心

SC−C03

L/NXX

XXX

Installation Procedure for

NSC-CW

For wooden fittings, horizontal

Installation Procedure for

NSC-CW

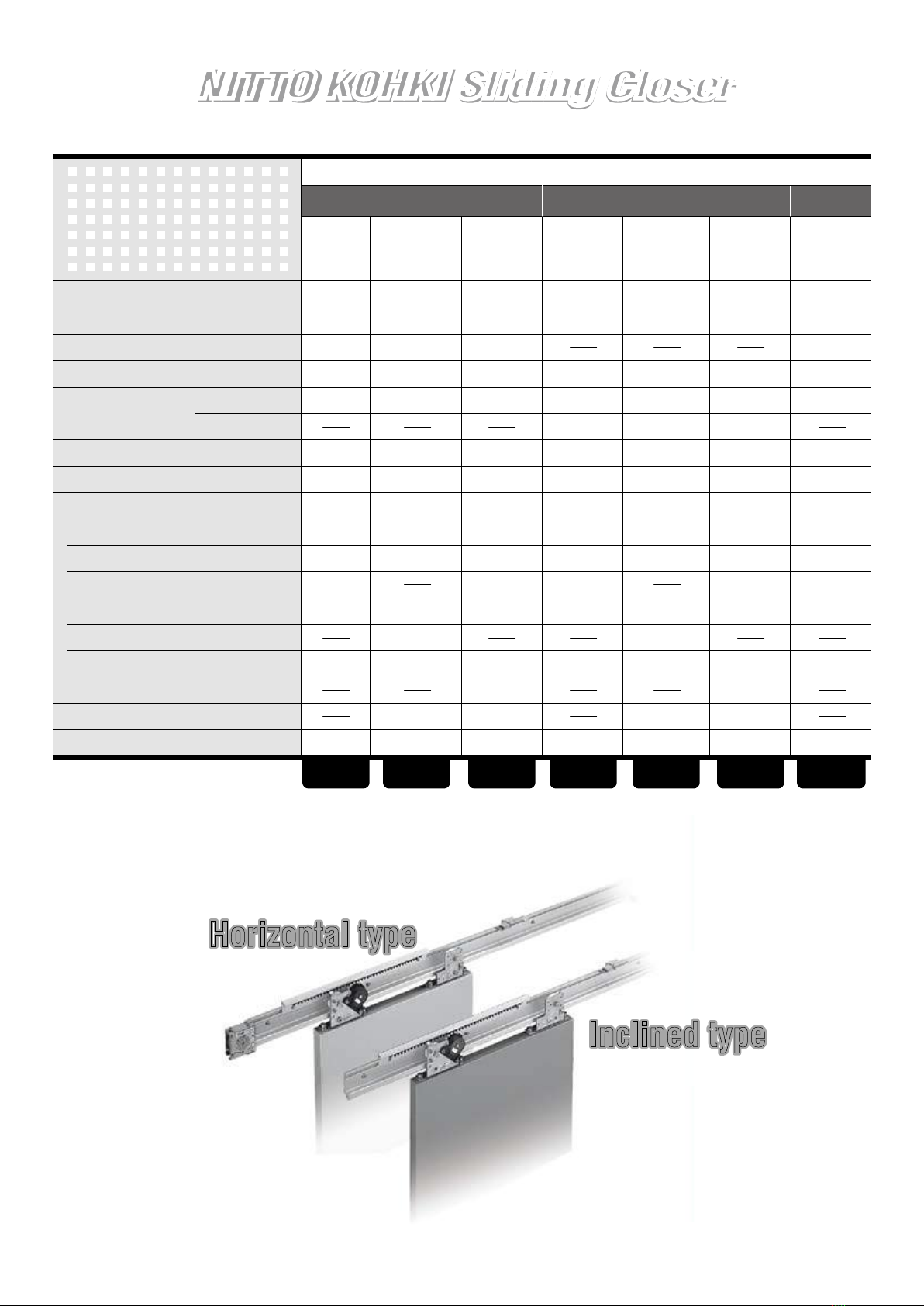

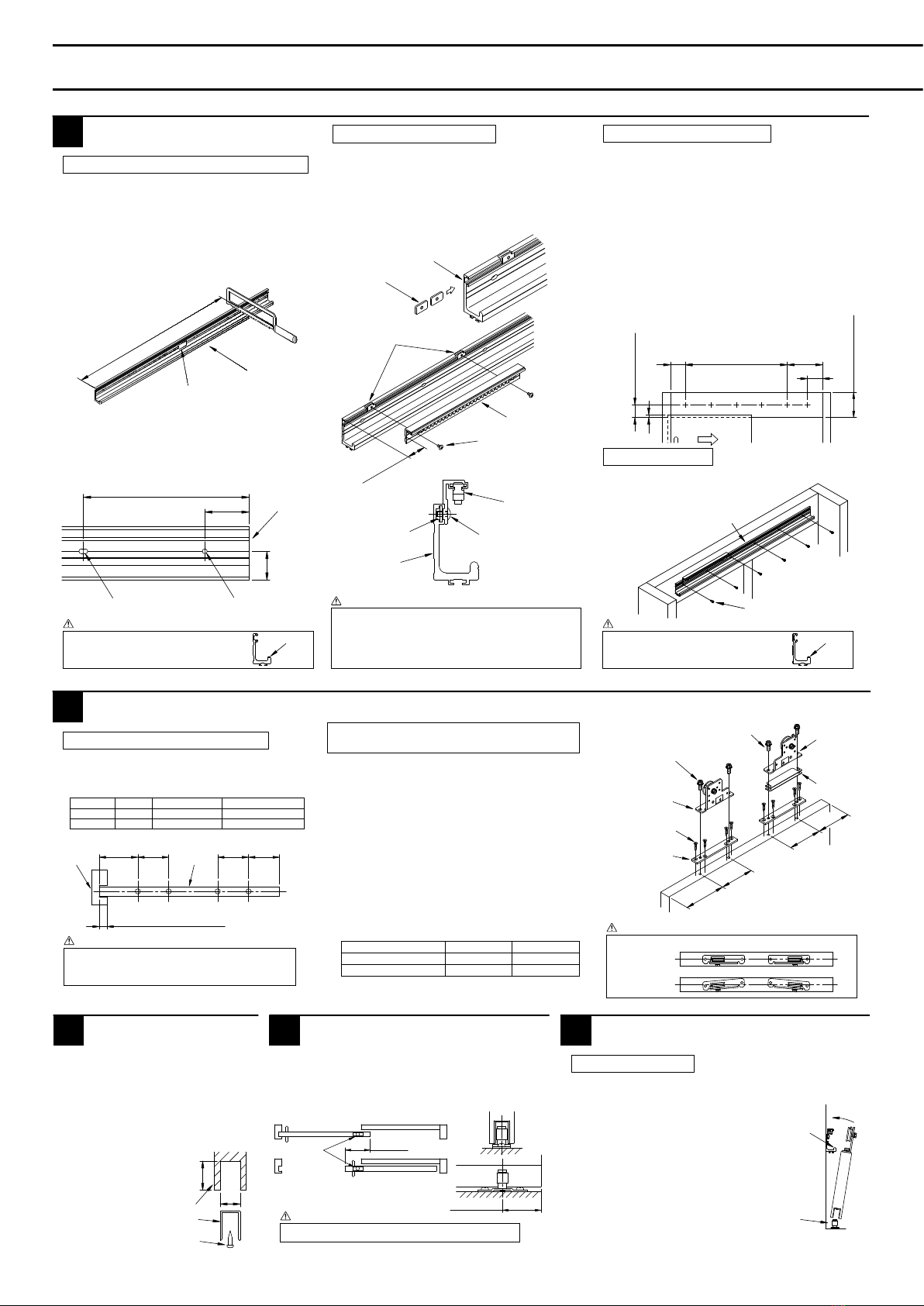

1) Cutting the rail, making a new mounting hole

2) Installing a control rack set

Installing a rail

Sticker

Front

Cutting face of rail

R groove

Reference mounting hole Make a new hole φ5.5mm

T groove of rail

Plate nut

Plate nut

Plate nut

Control rack set

Control rack set

M4 ×8 truss screw

M4 ×8 truss screw

Rail

●When making any change in the rail,

take care not to scratch the runway.

Caution

Cautions

Runway ●Install the rail horizontally.

●When installing the rail, take care not

to scratch the runway.

Caution Runway

●Be sure to use specified screws furnished with the

product. Using any unspecified screw may cause it to

interfere with the clutch gear of the control device

●Tighten the screws securely. Otherwise an abnormal

noise or imperfect control may result.

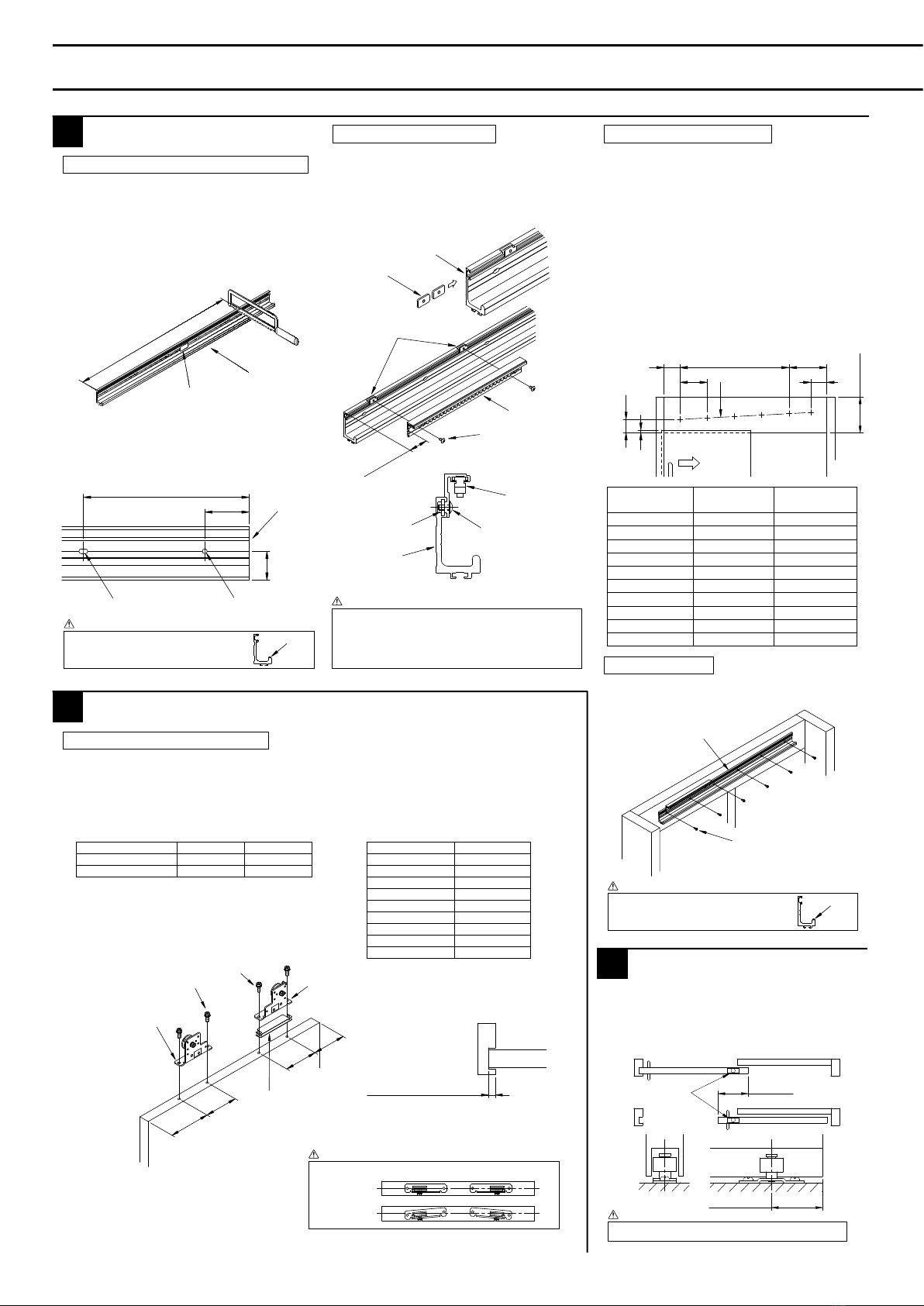

●Tap holes (M5, pitch 0.8) horizontally at

intervals of 300 with the hole specified below

as the reference point.

• Dimension from the inside of the sash on

the door front end = 125mm

• Dimension from the bottom of the top frame

of the sash = 65mm (CW23)

= 70mm (CW36/CW48)

(When the cover between the top frame and

door is 10mm)

●If the dimension A in the diagram below (the

dimension from the final hole at a pitch of 300

to the inside of the sash on the door back

end) is no less than 155mm, tap a hole at

125mm from the inside of the sash.

3) Setting rail mounting holes

●Install the rail with screws (φ5mm ×30 truss

tapping screws or M5 ×16 pan

head screws) furnished

with the product.

4) Installing the rail

65 (CW23)

70 (CW36/CW48)

No less than 125 (CW23)

No less than 130 (CW36/CW48)

Door front end

Right-handed

opening

Door back end

Rail

φ5mm ×30 truss tapping

screws or M5 ×16 pan

head screws

●For the bottom diameter of the coach screws, be

sure to follow the specified dimension. If the bottom

hole diameter is too large, the door may come off.

Caution

●Make holes in the top of the door at the

positions shown in the diagram below, as

specified below.

1) Making holes in the top of the door

Installing the hanger

Model

CW23

CW36/48 φ5.5-6

φ9Coach screw

Wooden door plate

Hole Remark

●As shown in the diagram, install the wooden

door plate with screws (φ5mm ×30 pan head

tapping screws) furnished with the product,

with the M8 screw as the reference point.

(The wooden door plate is installed on the

CW36/48 only.)

●As shown in the diagram, install the hanger A,

hanger B, and height adjusting plate.

●Install the hanger while orienting it as shown

in the table below, according to the

instructions given on the sticker attached to

the hanger.

2) Installing the wooden door plate, and the

hanger

Right-handed opening type

Left-handed opening type

Hanger A side

Door front end Door back end

Hanger B side Hanger B side

Hanger A side

A

+120 120 120 120

φ8×50 Coach screw (CW03)

M8 ×30 Hexagon head bolt (CW08)

φ8×50 Coach screw (CW03)

M8 ×25 Hexagon head bolt (CW08)

Hanger A

for right-handed door

front end

for left-handed door back

end

φ5×30

Countersunk head tapping

screw

(CW36/48 only)

Wooden door plate

(CW36/48 only)

Door front end

Door

back end

Hanger B

for right-handed

door front end

for left-handed

door back end

Height

adjusting plate

●Install the hanger on the centerline of the door.

Caution

Good

No good

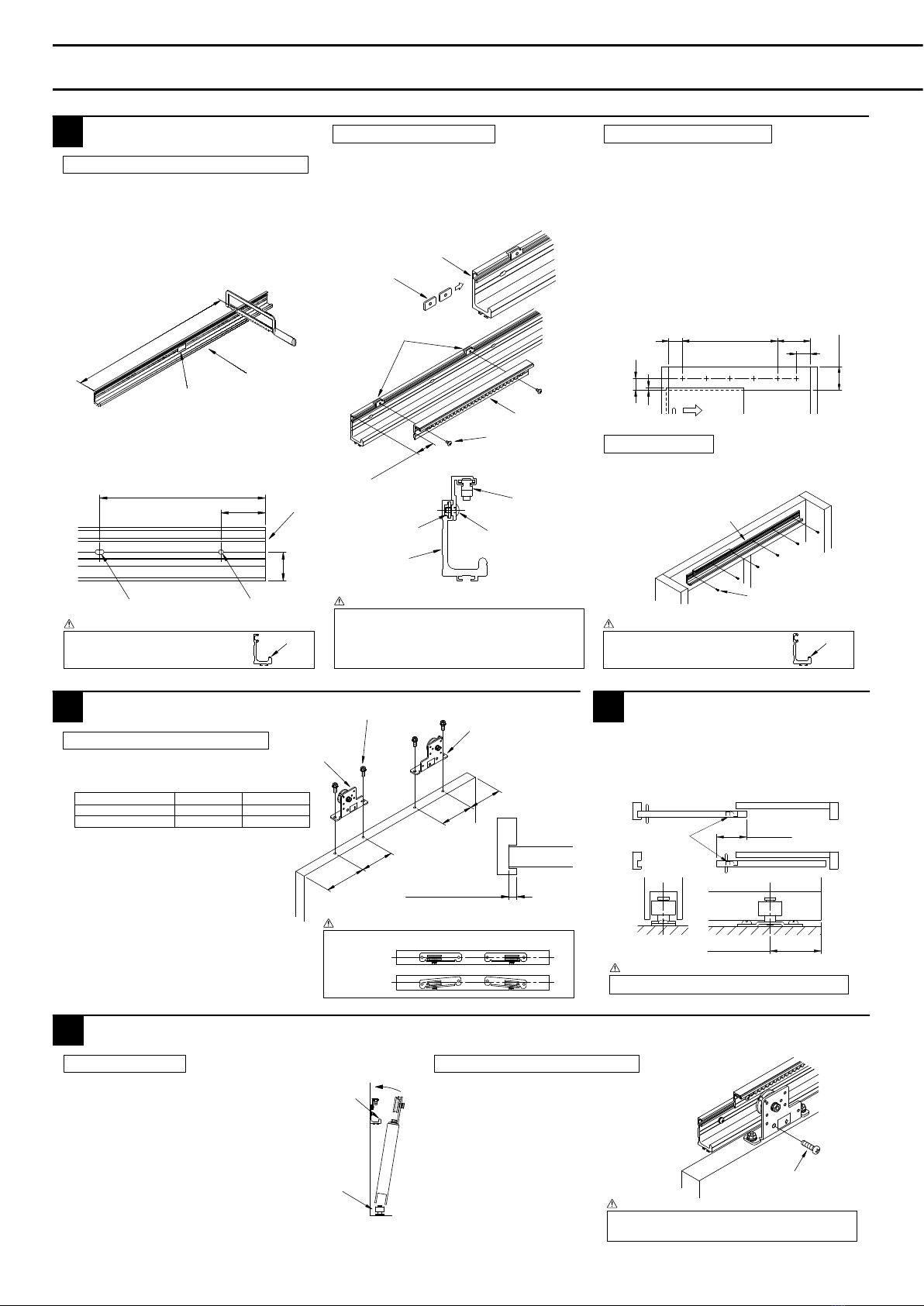

●Cut off the guide rail according to

the door width.

●Carve the door bottom to the

dimension shown in the

dimension specified below, then

install the guide rail with screws

(φ4mm ×16 pan head tapping

screws) furnished with the

product.

Installing the guide rail

Door bottom

Guide rail

φ4mm ×16 pan head

tapping screws

●Install them in the middle of the door lap.

(The product does not come with such

mounting screws.)

●Install them so that the door become vertical

with the floor area.)

Installing the guide rollers

●Be sure to use the guide rollers.

Caution

Guide rollers

Lap

Lap/2

5

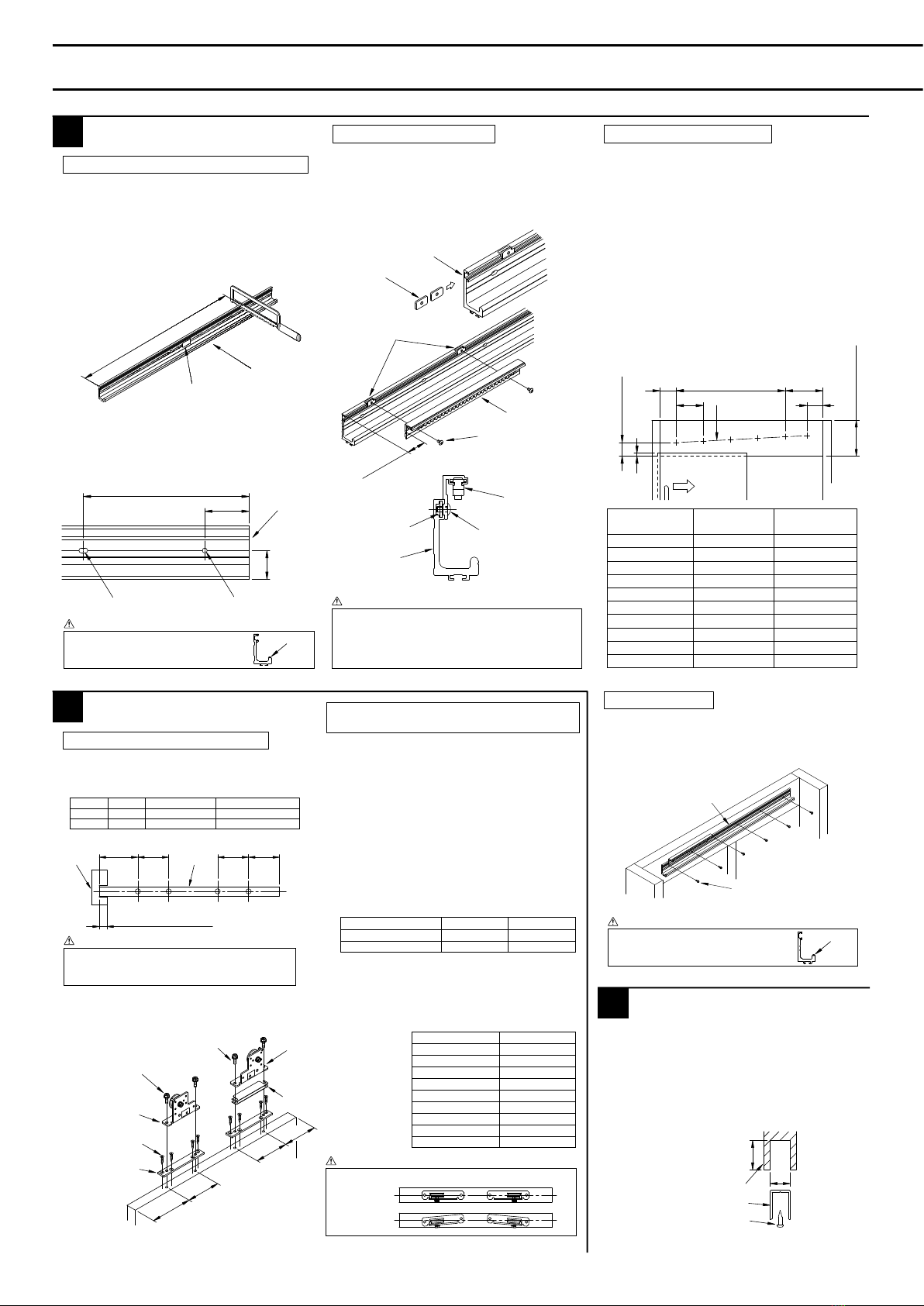

●Before mounting the door, wipe off the dirt

from the rail runway.

●Match the door bottom to the

guide rollers, then suspend the

door rollers and mount them

onto the rail runway.

●Check that the door operates smoothly.

●Adjust the clearance between the door

and jamb by changing the number of

height adjusting plates (optional).

1) Mounting the door

Mounting the door

Guide rollers

Runway

●Tighten the

door-retaining

screws (M8 ×30 pan

head screws) in the

hangers A and B.

2) Installing the door-retaining screws

●Tighten the screws securely to prevent the door from

coming off.

Caution Door-retaining screw

(M8 ×30 pan head screw)

●Install the door stopper bearing plate on the

hanger on the door back end with screws

(M5 ×8 pan head screws) furnished with the

product.

●Insert the door stopper fittings in the rail

runway. Slide the door stopper fittings, adjust

the door-opening position, then tighten the 2

fixing screws and fix the fittings.

Installing the door stopper

Hanger at door

back end

Door stopper fitting

Fixing screw

Door stopper

bearing plate

M5 ×8 pan head screw

●Tighten the fixing screws securely, or the door

stopper fittings may become out of place.

Caution

Installing the control device

Hanger on

door front end

Control device

M5 ×12 pan head screw

●Check the orientation of the control device

(right- or left-handed). Be sure to orient it

correctly, or the control will not work.

●Be sure to install the control device after

mounting the door. When suspending and

mounting it, the door may strike and

damage the rail or other component.

Caution

1) Installing the stop roller and plate spring

●Adjust the position of the plate spring to stop it at

the position where the door is fully open.

●Move the stop roller up and down to adjust the

stopping force.

•

Increase the stopping force. Raise the stop roller.

•

Reduce the stopping force. Lower the stop roller.

2) Adjusting the stopping position and force

Installing the stop device

Adjusting the closing force and closing speed

Installing a pull spring

1) Installing a pull spring 1) Adjusting the closing force

●Draw the wire of the pull spring,

then hook it on the hanger on

the door

front end.

2) Setting the wire

M4 ×5 pan

head screw M3 ×8 pan

head screw

Pull spring

Fitting for installing

the pull spring

T groove in the rail

●Do not draw the wire with the pull spring

alone (before the installation).

Any such practice might scratch the wire.

Caution

●Be sure to use the specified screws furnished with the product.

Using any unspecified screw may cause it to interfere with

another component.

●Securely tighten the screws furnished with the product, to keep

the stop roller and plate spring in place at all times.

Caution

Effective opening + 160 - cut-in

at door front end

(distance from rail tip at door front end)

Plate nut

Plate nut

Plate spring

Hanger on door front end M4 ×8 truss screw

M5 ×8 pan head screw

Stop roller

2) Adjusting the closing speed

●Turn the speed adjusting screw lightly. Otherwise an

imperfect control may result. After turning it all the way home,

do not turn it with overstrain.

●A change in the ambient temperature varies the closing speed

somewhat. As the temperature rises, the speed increases. As

the temperature declines, the speed decreases.

Caution

●Overwinding it in the direction of "Strong" will cause a

breakdown. Be sure to set it to a value not exceeding the

number of windings indicated on the label on the component.

Caution

Speed adjusting screw

Becomes slower

(direction S)

Becomes faster

(direction F)

R

The control device used for this product is for both orientations (right- and left-handed). The orientation of the clutch gear determines whether it is right- or left-handed.

When assembling and reengaging the clutch gear, follow the procedure described below.

1. Procedure for assembling the clutch gear

• Insert the washer into the shaft of the control device.

• Insert the clutch gear into the shaft.

If right-handed

Make the white surface (the R-stamped surface) at the center of the clutch

gear face upwards, then insert it while turning it in the direction of the arrow

for the right-handed opening type illustrated in the right-hand diagram.

If left-handed

Make the blue surface (the L-stamped surface) at the center of the clutch

gear face upwards, then insert it while turning it in the direction of the arrow

for the left-handed opening type illustrated in the right-hand diagram.

• Install the snap retainer in the groove at the tip of the shaft.

2. Procedure for reengaging the

clutch gear

• Remove the clutch gear in reverse order

of assembly. (Remove the clutch gear

while turning it in the same direction as

in assembly.)

• Assemble the clutch gear according to

the assembly procedure.

• The product comes with one spare snap

retainer.

Procedure for assembling and reengaging the clutch gear

Direction of rotation

for assembly

for left-handed (for L)

Direction of rotation

for assembly

for right-handed (for R)

Blue surface

at the center

for left-handed

(for L)

White surface

at the center

for right-handed

(for R)

Snap retainer

Clutch gear

Washer

Control device

Jamb Door top

Door front end Door back end

A (cut-in at door front end)

(The diagrams shown represent a right-handed opening type. The left-handed

opening type is symmetrical with the type represented in these diagrams.)

35mm and over

20mm and over

Depth

When the clutch gear is inserted or removed,

be sure to turn it as following instruction.