6

Structural Leading Edge (SLE) - provides more rigidity and stability along

the span of leading edge but also allows full exibility along the both

the vertical and horizontal axis. A reduction in the amount of Mylar, in

comparison to previous proles, has resulted in less weight which makes

it easier to inate the wing.

3D Pattern Cut Optimization (3DP) - an optimised process to cut the

fabric panels to ensure the perfect form of the leading edge. Creating

separate panels for each of the sections at the front of the wing means

the sail fabric is tauter and crease-free. During the cutting, the optimal

orientation of the fabric section is selected, depending on its nal location.

If the fabric pattern is properly aligned with the axes of load, it suffers less

deformation after repeated use, to the long-term benet of the leading

edge.

3D Leading Edge (3DL) - adding an extra reinforced seam to the leading

edge helps to ensure more consistency and volume in the prole. This

provides a more efcient 3D contour.

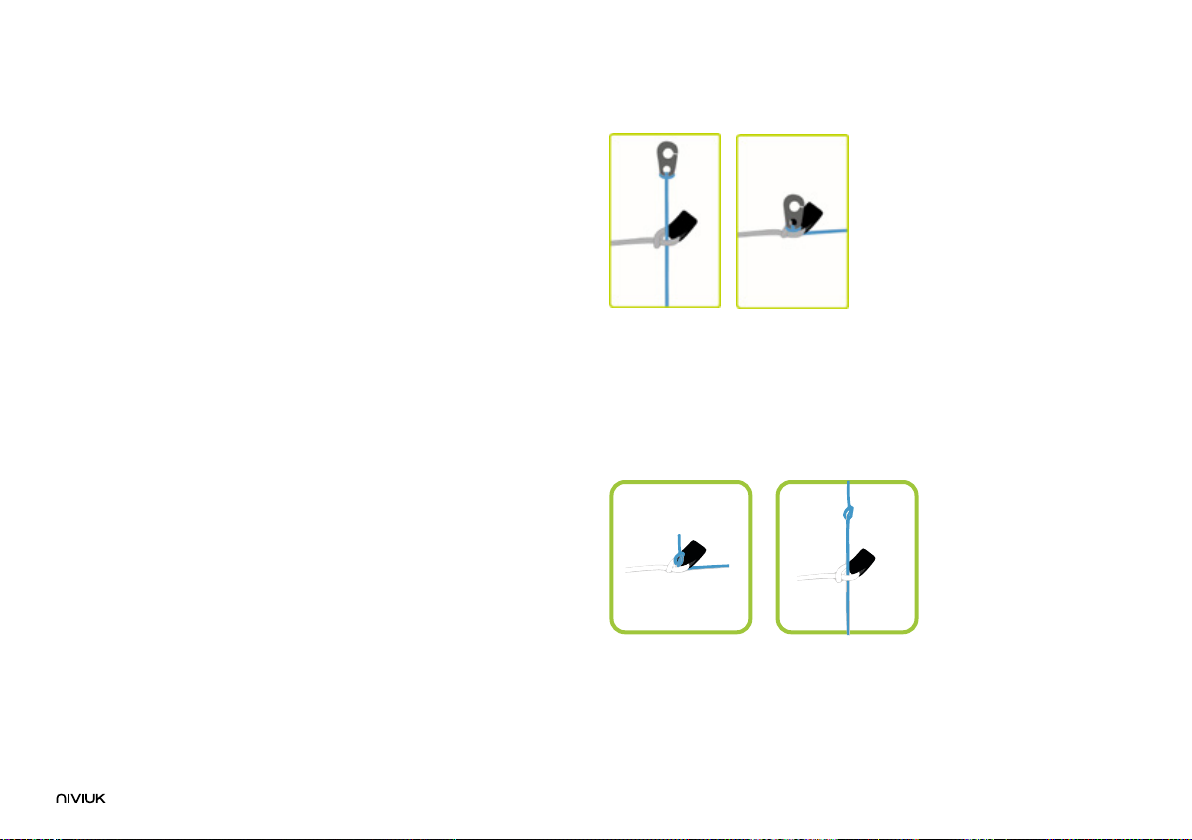

Interlock System (IKS) - is an ultralight connection system specially

designed for mountain and lightweight equipment. With less weight than

the traditional delta maillon it is nevertheless much stronger.

The use of these technologies is a big technological leap forward in

building wings and a big improvement in ight comfort.

For the construction process of the KODE P we use the same criteria,

quality controls and manufacturing processes as in the rest of our range.

From Olivier’s computer to the nished cut piece of fabric, not even

the minutest of error is permitted; the cutting of each of the assembly

elements that make up the paraglider is carried out one by one, through

rigorous and extremely meticulous work. The same meticulous system

is used for the subsequent marking and numbering of each piece, thus

avoiding possible errors in this very delicate process.

The jigsaw puzzle assembly method makes it easier to organise, saves

resources and provides excellent quality control. All Niviuk gliders go

through an extremely rigorous and detailed nal inspection. For example,

the canopy is cut and assembled through an automated process that

follows a very strict order where there is no margin for error.

Finally each wing is individually inspected.

The same fabric has been used as in the rest of the range, ensuring its

guaranteed lightness, strength and durability without fading.

The main lines are made from and the mid and gallery lines are made from

unsheathed Aramid.

The line diameter has been calculated depending on the workload and

aims to achieve the required best performance with the least drag.

The lines are semi-automatically cut to length and all the sewing is

completed under the supervision of our specialists.

Once the nal assembly of the canopy is concluded, every line is checked

and measured.

Each glider is packed according to the most advanced material

maintenance and conservation guidelines..

Niviuk gliders are made of premium materials that meet the requirements

of performance, durability and certication that the current market

demands.

Information about the various materials used can be viewed in the nal

pages of this manual.

1.5 ELEMENTS/COMPONENTS

The KODE P is delivered with a series of accessories that will greatly

assist in the maintenance of the paraglider:

- A Kargo bag. This bag is large enough to hold all equipment comfortably

and with plenty of space.

- An inner bag to protect the wing during storage and transport.

- An adjustable compression strap to compress the inner bag and reduce

its volume.

- A riser protector, which will prevent metal parts from coming into contact