67

ES

4.4 LIFE SPAN

The operational life span of the OCTAGON reserve parachute should

not exceed 10 years. If past that period, the product is deemed to be

B.E.R (beyond economical repair) and should be removed from service,

not to be used again (contact your local dealer or school on the correct

way to dispose of the reserve parachute).

4.5 REPAIRS

Repairs of the reserve parachute should be made by a professional

certied outt using genuine parts, materials, fabric and threads

matching the original strength and colours.

All threads stitching should have 6.5-11 stitches per inch, overlapping

stitch row at least 2-inches.

Zigzag stitching should extend at least 1/2-inch into the undamaged

stitching at each end. Re-stitching should be made directly over the ori-

ginal stitching, following the original stitch pattern as closely as possible.

All thread on the canopy should be V-T-295e, Type 2, Class A, Size E

and applied with a light or medium duty machine.

CAUTION!

Any repairs should only be carried out by the manufacturer or by an

approved agent. This will ensure that the correct materials and repair

techniques are used.

5. SAFETY AND RESPONSIBILITY

It is well known that paragliding is considered a high-risk sport, where

safety depends on the person who is practicing it.

Wrong use of this equipment may cause severe injuries to the pilot,

The materials used in the OCTAGON rescue have been carefully

selected for maximum durability. Nevertheless, maintaining your

rescue following the guidelines below will extend its lifetime.

4.2 STORAGE

Unnecessary exposure to UV rays, heat and humidity should always

be avoided. Keep your harness and reserve parachute in your rucksack

when not in use. Store all your paragliding equipment in a cool, dry

place, and away from solvents such as grease, acid, oil, paint and

abrasive materials.

Never stow your reserve parachute when damp or wet. If your reserve

parachute does ever get wet (i.e. water landings or snow), it must be

taken out of the harness, allowed to dry in a shaded area and properly

repacked before inserting it back into the reserve parachute container.

A dirty reserve parachute canopy or container can be cleaned with

lukewarm water. Mild soap may be used if necessary without rubbing

the fabric. Do not use caustic chemicals.

Rinse the canopy thoroughly and allow it to dry naturally. If the

canopy shows signs of mildew, it must be sent to the distributor or

manufacturer for repair, as its integrity could be compromised.

If the rescue parachute is to be stored for an extended period, the

canopy should be opened and loosely rolled.

Observe the following precautions: use care in handling packed

parachutes in case you cause any damage. Damage to the canopy

materials could result from watches, rings, bracelets, etc. Protect the

parachute from damaging elements, dust, oil, grease and caustic pro-

ducts. Place the unpacked reserve parachute in aviator kit bag/duffel

bag. When not in use, cover the canopy. Avoid prolonged exposure to

sunlight, inspection lights or orescent lights. Nylon material is sub-

ject to deterioration under ultraviolet light. If available, use a climate

controlled building to store parachutes. Store the parachute in a dry,

well-ventilated location, away from dampness, re, dirt, insects and

direct sunlight.

Use a climate controlled building to store parachutes when available.

Store parachute in a dry, well-ventilated location, dampness,re, dirt,

insects, and direct sunlight.

CAUTION!

Leaving the packed parachute system exposed to the sun will greatly

decrease its service life.

4.3 CHECKS AND CONTROLS

CANOPY

Canopy Assembly Fabric

Inspect for rips, tears, dampness, debris, broken or loose

stitching, marks and seams which are damaged or loose.

APEX

LINES

Inspect for holes, cuts, frays, tears, burns, loose or

broken bres.

APEX

WEBBING

LOOPS

Inspect for rips, tears, dampness, debris, broken or

loose stitching, marks and seams which are damaged

or loose.

GORES

SECTIONS

Inspect for loose or broken stitching, frays, tears, burns,

and cuts.

BRIDLE Inspect for damaged or loose seams, burns, stains, torn

fabric.

SUSPENSION

LINES

Inspect the symmetry of the length of the lines. Inspect

the zigzag stitching on the lines.

ENG

even death. Manufacturers and dealers are not responsible for any act

or accident that may be the result of practicing this sport.

You must not use this equipment if you have not been properly trained

to use it. Do not take advice or accept any informal training from

anyone who is not properly qualied as a ight instructor.

6. WARRANTY

The entire equipment and components are covered by a 2-year

warranty against manufacturing defects.

The warranty does not cover misuse or inappropriate use of the

product.

7. PACKING

The OCTAGON rescue parachute is initially inspected and packed

at the factory and it is recommend to have it serviced by a qualied

professional outt or parachute rigger prior to its installation inside the

harness. The reserve parachute’s efciency, and your life will depend

on it.

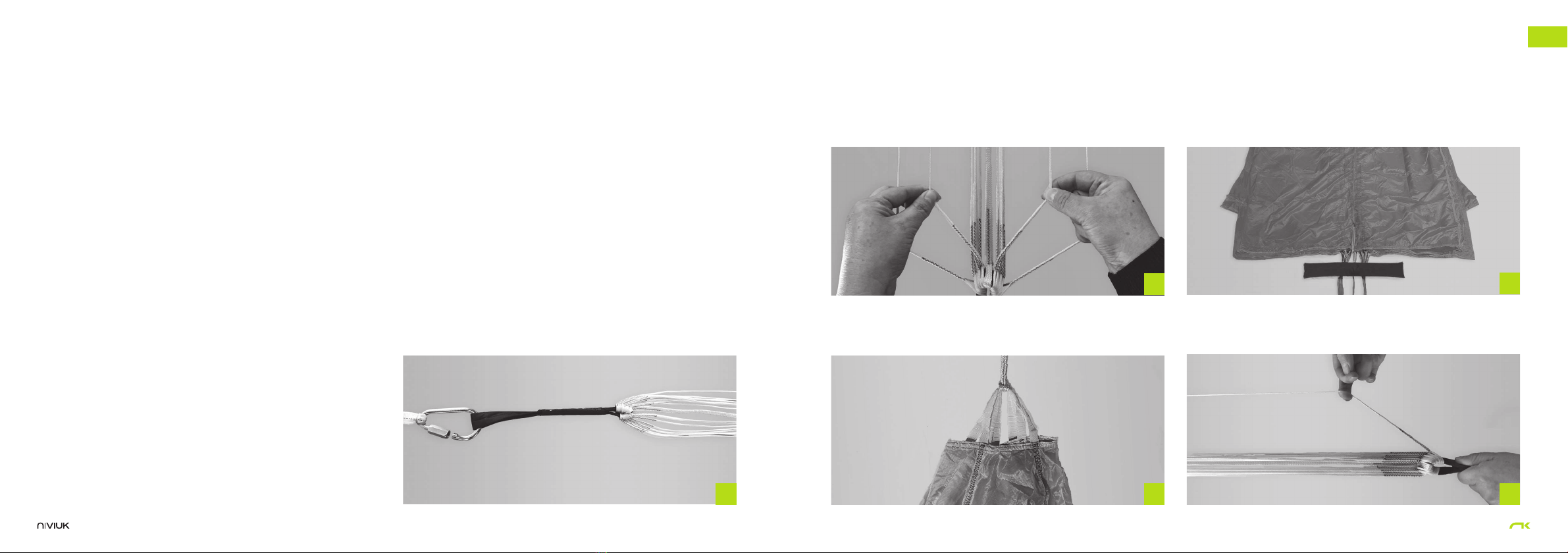

7.1 INSTALL THE RESERVE PARACHUTE AS FOLLOWS

• Check the reserve parachute and components have been assembled correctly.

• Place the packing tools in a convenient location on the packing table.• Lay out the canopy lengthwise on the packing table and attach the canopy’s packing loop to one end of the table.

• Fix the lines at the other end of the table and apply tension to extend the parachute fully.

• Check the apex line to determine if the canopy is inverted or