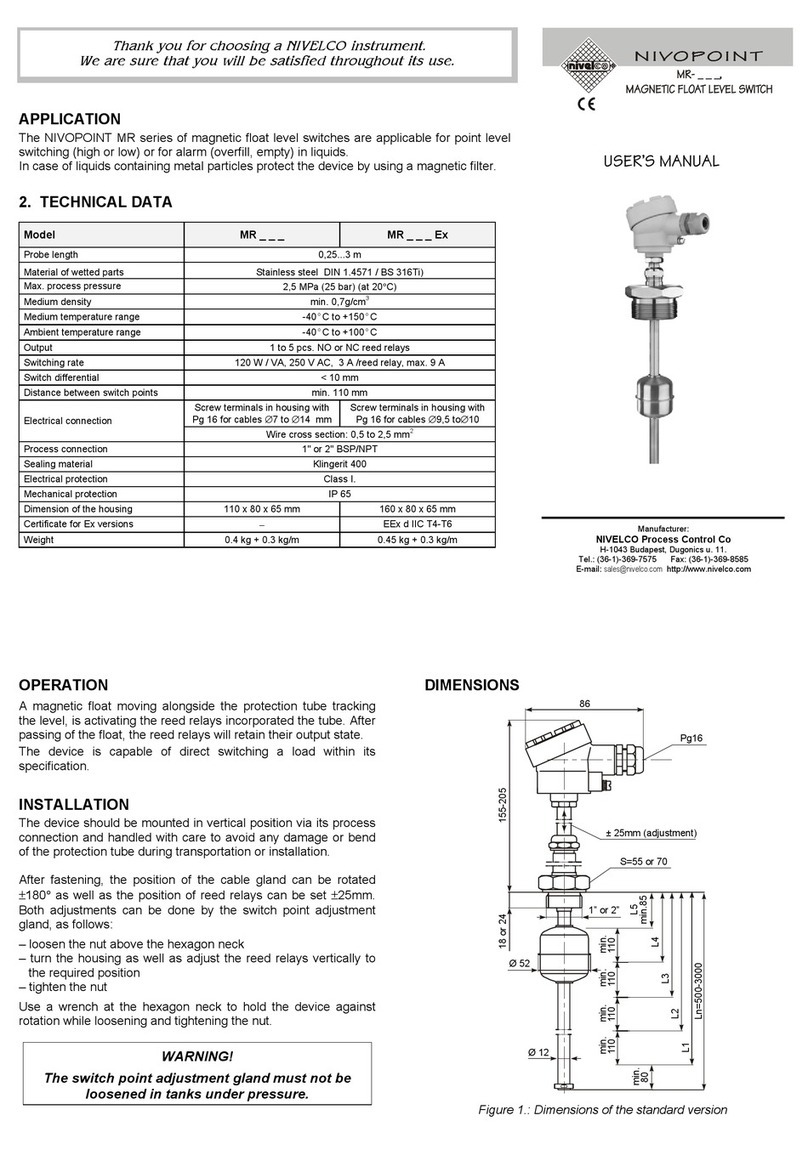

NIVOPOINT MR Series User manual

EXNB17ATEX0003X ♦mra1053a0600h_09 ♦1/2

NIVOPOINT

Manufacturer

H-1043 Budapest, Dugonics u. 11.

Phone: (36-1) 889-0100 Fax: (36-1) 889-0200

NIVELCO Process Control Co.

E-mail: sales@nivelco.com www.nivelco.com

Thank you for choosing a NIVELCO instrument.

We are sure that you will be satisfied throughout its use.

1. APPLICATION

The interaction of the magnetic float and the reed relays (incorporated in the protection tube) is the basis of

the NIVOPOINT magnetic float level switch series operation. They are suitable for level indication of normal

and explosive liquids, and can be used for level control tasks. The protecting tube contains a max. of 5

relays. Parts of the instrument are: probe tube with magnetic float and housing containing the connection

terminal.

The magnetic float moves alongside the protection tube tracking the level of the liquid and activating the reed

relays. As the float passes a relay it changes the output state of the relay which retains this state latching

until the level decreases and the float moves again along the respective relay to switch its state back.

2. TECHNICAL DATA

2.1. GENERAL DATA

TYPE MR – MP–

MR

–

-7

Ex

MR

–

-8

Ex

Insertion length 0.25 m ... 3 m

Material of wetted parts Stainless steel

(1.4571 / BS 316Ti)

PVDF float / PFA coated

probe

Stainless steel

(DIN 1.4571 / BS 316Ti)

Max. process pressure 2.5 MPa (25 bar) at +20 °C 0.3 MPa (3 bar) at +20 °C 2.5 MPa (25 bar) at +20 °C

Medium density min. 0.8

kg/dm3

min. 0.5

kg/dm3

min. 0.7

kg/dm3

min. 0.8

kg/dm3

Nominal float

dimensions / shape

∅52x59mm*

cylinder

∅96 mm*

ball

∅76x87 mm

cylinder

∅52x59 mm

cylinder

Medium temp. range -40 °C ... +150 °C -40 °C ... +80 °C See temperature classes table

Ambient temp. range -40 °C ... +95 °C -40 °C ... +95 °C

Output 1 ... 5 pcs reed-switches, connecting one side of each, NO/NC

Switching rate 120 W / VA, 250 V AC/DC, 3 A /reed relay, max. 9 A

Switch differential < 10 mm

Distance of switches min. 110 mm

Electrical connection M20 x 1.5 for cables ∅6 … ∅12

M20 x 1.5

for cables

∅9.5 … ∅10

without cable

gland

terminal, wire cross section: 0.5 … 2.5 mm2

Process connection 1", 1½", 2" BSP

1", 1½", 2" NPT

PP flange

DN 80, DN 100

1", 1½", 2" BSP

1", 1½", 2" NPT

Sealing material Klingerit 400 — Klingerit 400

Electrical protection Class I, Protecting cable 4 mm2

Ingress protection IP67 (as per EN 60529:2015)

Ex marking

—

II 2 G Ex d IIC T6 … T3 Gb

Dimension of the hous. 116 x 80 x 65 mm 124 x 80 x 65 mm

Mass 0.4 kg + 0.3 kg/fm 0.45 kg + 0.3 kg/fm

* dimensions of the float depend on the order

Note: the device must be installed with Ex d IIC certified explosion-proof cable gland.

2.2. ADDITIONAL DATA FOR EX APPROVED MODELS

CLASS T6 T5 T4 T3

Max. ambient temperature from –40 °C +65 °C +80°C +95 °C +95 °C

Max. medium temperature from –40 °C +80°C +95 °C +130 °C +150 °C

2.3. ACCESSORIES

−User’s Manual

−Certificate of Warranty

−Declaration of Conformity

−1 pc Gasket (for threaded versions)

2.4. ORDER CODE

NIVOPOINT M

–

–

***

TYPE CODE PROCESS CONNECTION CODE SWITCH POINT CODE LENGTH CODE LENGTH CODE FLOAT

/

EXCODE

Standard R 1” BSP

A

1 pc. NO/NC 10 m 00 m 0 *** / normal 3

Standard / plastic

coating and float P 2” BSP C2 pcs. NO/NC 21 m 10.1 m 1 ∅52

1.4571 / Ex 7

1” NPT D3 pcs. NO/NC 32 m 2::

2” NPT G 4 pcs. NO/NC 4 3 m 3 0.8 m 8 ∅52

8

1½" BSP B5 pcs. NO/NC 50.9 m 9 1.4571 / Ex

Notes: 1½" NPT E without

cable gland

** The order code of an Ex version should end in ’Ex’ *** Depends on the order: ∅52 / 1.4571, ∅96 /1.4571 MP version: ∅76 / PVDF

2/2 ♦EXNB17ATEX0003X ♦mra1053a0600h_09

2.5. DIMENSIONS

STANDARD VERSION MR- EX VERSION M

R

- STANDARD VERSION MP- TERMINAL BOX

~75

~175-230

min. 100

min. 118

L4

L3

L2

L1

Lnévl.

min.

110

min.

95

min.

11 3

"2 BSP/NPT

96

127

Ø96

±25 mm

"1 BSP/NPT

Ø124

~78

±25 mm

L5

min. 85

L4

L3

L2

L1

Lnévl.

min.

110

min.

80

~195,9 max. (-50 mm)

"2 BSP/NPT

"1 BSP/NPT

60

Ø53,5

~75

min. 130 mm

±25 mm

min. 95

L5

L4

L3

L2

L1

Lnévl.

min.

11 0

min.

90

Ø76

87

DN80

DN100

12345C

LEVEL

NO

NC

3. INSTALLATION

For mounting the unit 1", 1½", 2" BSP or NPT threads can be used. Minimal gap

diameter for the float is ∅55 mm. Use the M20x1.5 cable gland for electrical

connection.

The only version that can be installed without removing the float from the shaft

and reassembling it from the inside of the tank is the version with 2” (BSP or

NPT) process connection. If protection tube is used the minimum tube diameter

should be ∅75 mm (for insertion lenght < 1.5m and ∅95 mm for insertion

length > 1.5m). When using a ∅90 mm float the tube diameter should be min.

∅130 mm.

WARNING!

The sliding sleeve must not be loosened in tanks under pressure.

The unit should be mounted in vertical position via its process connection and

handled with care to avoid any damage or bend of the protection tube during

transportation or installation.

4. WIRING

Depending on the grounding system either the inner or the outer grounding

terminal should be connected to the EP network.

Standard version

Remove the cover. Feed the electrical cables through the cable gland and

connect them in accordance with the sketch on the cover where the (NO/NC)

states of the relays are marked. The terminal of the lowest switch point has to

be number 1.

„C” is common terminal.

The cross section of the connecting cable has to be between 0.5 and 2.5 mm2.

Ex version

Remove the safety clamp and screw the cover off. Feed the electrical cables

through the cable gland and connect them in accordance with the sketch on the

cover where the (NO/NC) states of the relays are marked.

Connect the grounding screw to the grounding system. Place the cover back

and fasten the safety clamp by setting it into one of the notches of the cover.

5. SET UP, ADJUSTMENT

After screwing in and before tightening the sliding sleeve the direction of the

cable gland and the position of the reed-relay set can be adjusted.

An open-end wrench should be used when loosening or screwing tight the

sliding sleeve. The position of the reed-relay set can be vertically adjusted by a

max. of ±25 mm.

5.1. SPECIAL CONDITIONS OF THE EX APPLICATION

The apparatus met the requirements specified for mechanical strength with

reduced impact energy (4 J = 1 kg; 0.4 m). On the basis of the above the place

and way of installation should guarantee the protection of the unit against

external mechanical impacts during service.

Before the installation of the device it must be equipped with a certified cable

gland with II 2 G Ex d IIC protection type. Prior to installing the Ex d certified

cable gland the red protection cap should be removed.

6. MAINTENANCE, REPAIR

The unit does not require regular maintenance. In some instances, however, the

probe may need occasional cleaning to remove surface deposits. This must be

carried out gently, without harming the probe.

All repairs will be carried out at the manufacturer’s premises.

7. STORAGE CONDITIONS

Ambient temperature: -20 °C ... +60 °C

mra1053a0600h_10

January, 2018

Nivelco reserves the right to change technical specifications without notice.

This manual suits for next models

3

Other NIVOPOINT Switch manuals

Popular Switch manuals by other brands

SMC Networks

SMC Networks EZ Switch SMC105DT Specifications

NETGEAR

NETGEAR JFS516 Brochure & specs

CYP

CYP EL-8100V Operation manual

NTI

NTI UNIMUX-USBV-xHD Installation and operation manual

K-TEK

K-TEK KP Installation & operation manual

Comtech EF Data

Comtech EF Data SMS-758 Installation and operation manual

Cisco

Cisco 2970 - Catalyst Switch Hardware installation guide

Rose electronics

Rose electronics ServeView 2X Installation and operation manual

e+p

e+p HDMS 121 instruction manual

DANLERS

DANLERS CEFL PIR LR Installation notes

Pilz

Pilz PSEN ma1.4n-50 operating instructions

Vigitron

Vigitron MaxiiNet Vi3003W user manual