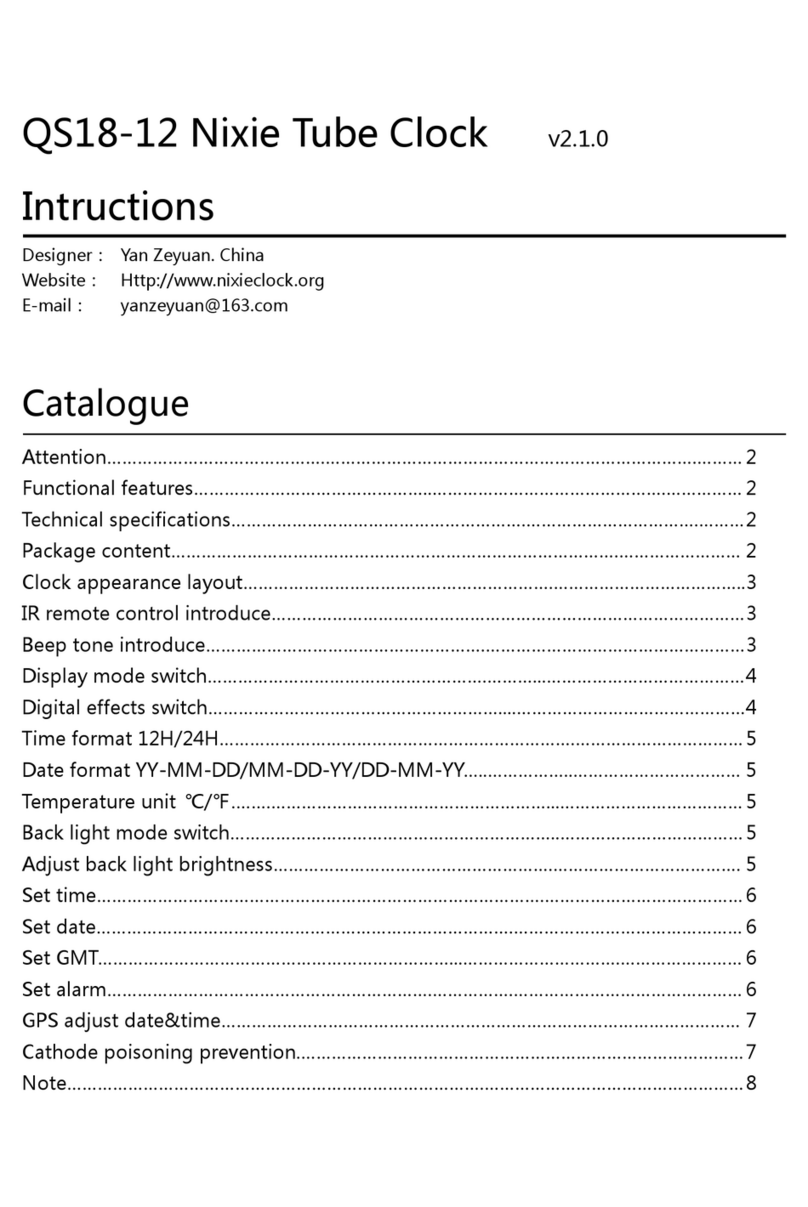

Nixie Clock IN-16 User manual

Other Nixie Clock Clock manuals

Nixie Clock

Nixie Clock IN-18 Blue Dream User manual

Nixie Clock

Nixie Clock MOD-SIX Use and care manual

Nixie Clock

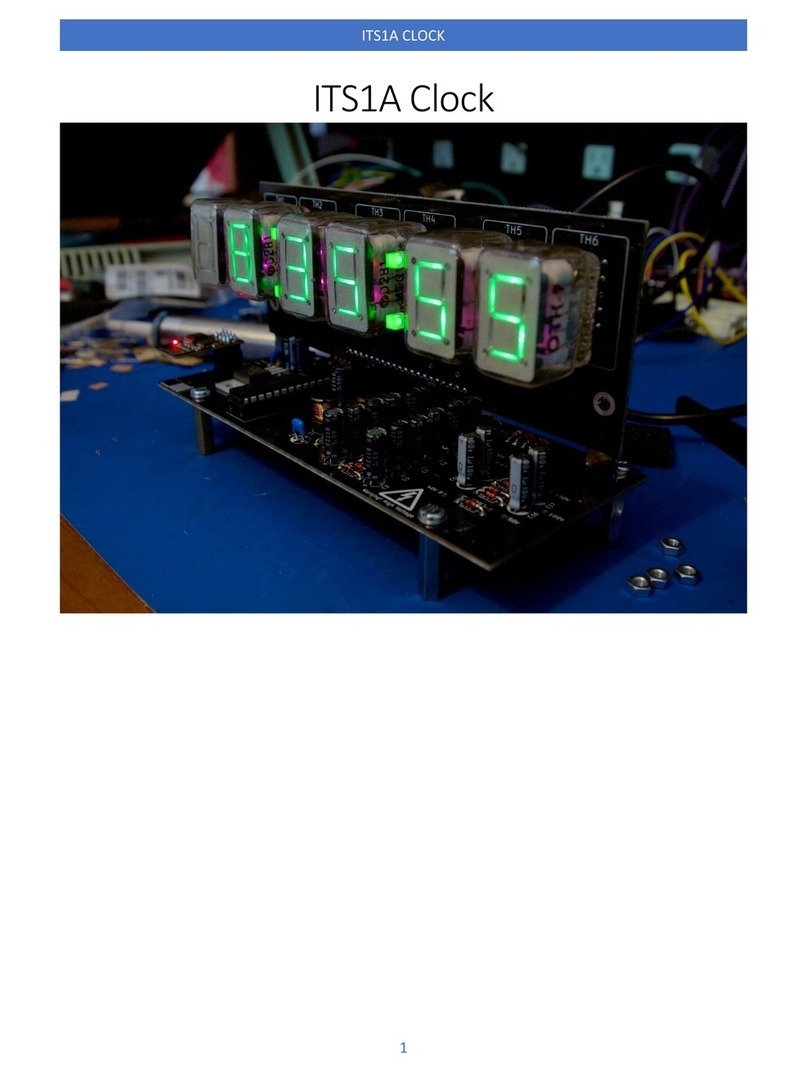

Nixie Clock ITS1A User manual

Nixie Clock

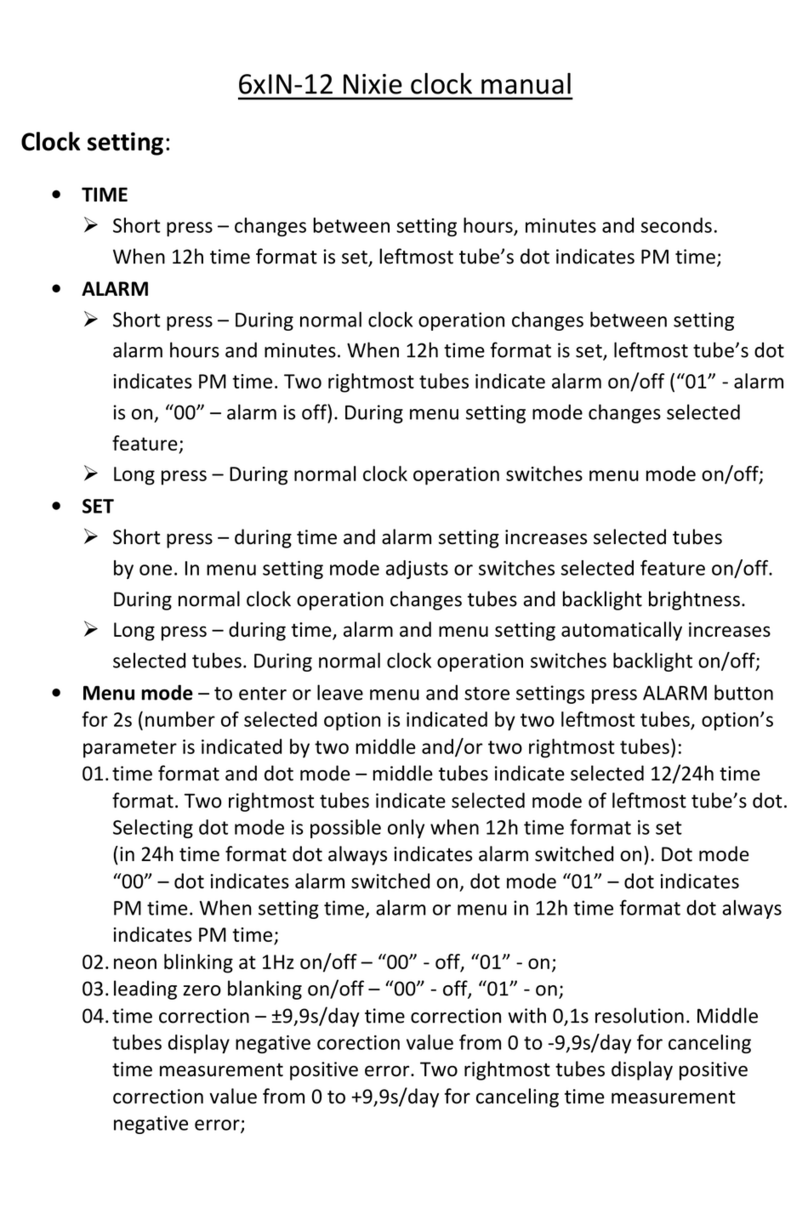

Nixie Clock 6xIN-12 User manual

Nixie Clock

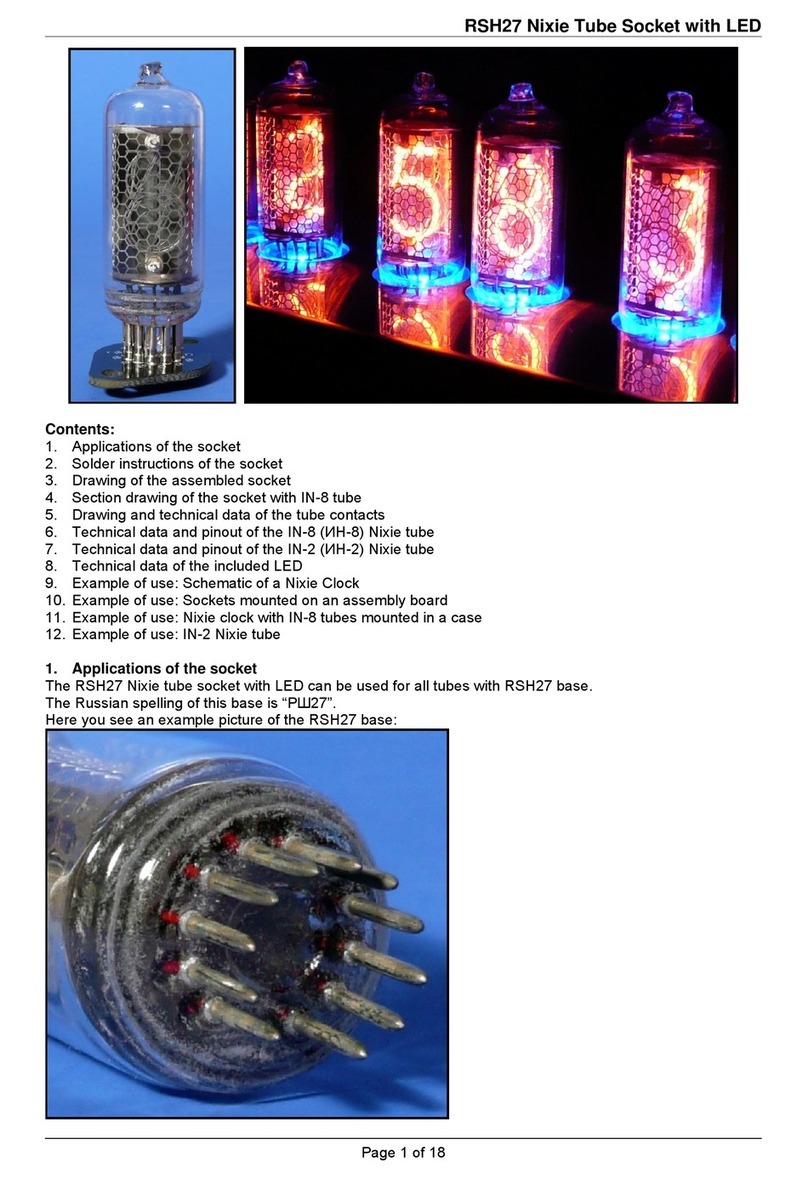

Nixie Clock RSH27 User manual

Nixie Clock

Nixie Clock Gemini Two User manual

Nixie Clock

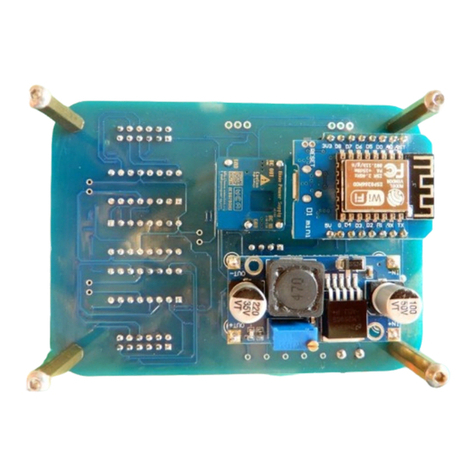

Nixie Clock Wemos Series User manual

Nixie Clock

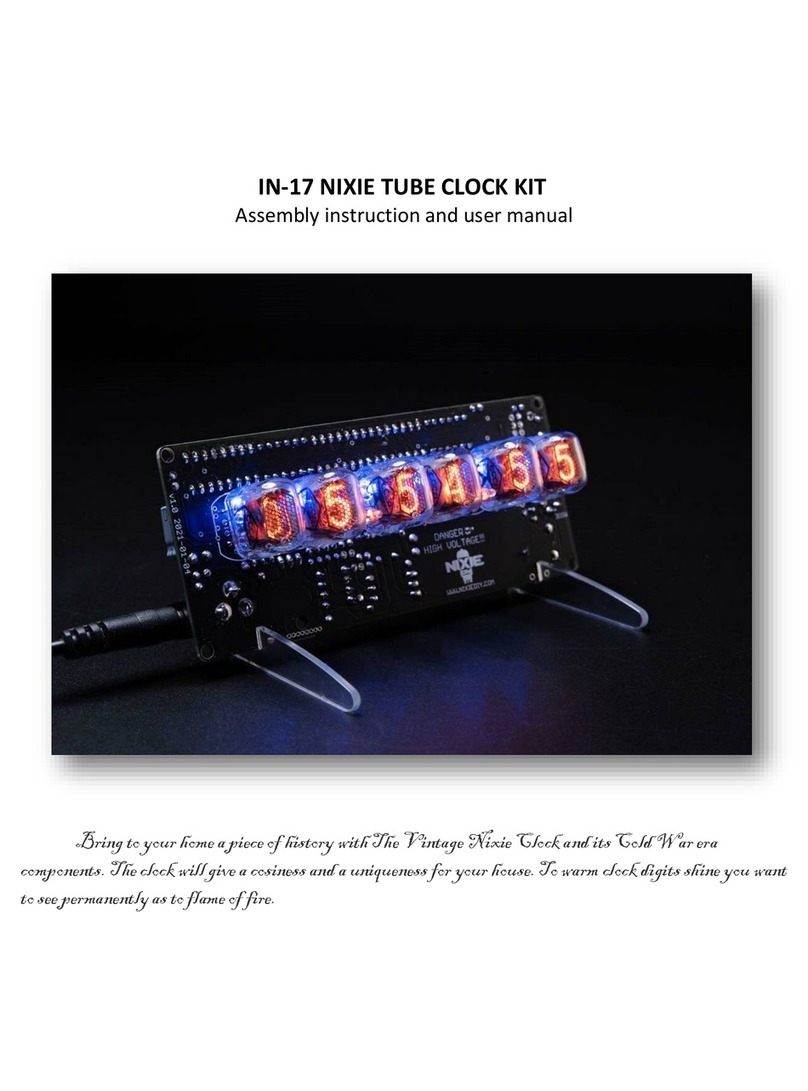

Nixie Clock IN-17 Installation instructions

Nixie Clock

Nixie Clock CHRONOTRONIX V400 User manual

Nixie Clock

Nixie Clock DA-2000 User manual

Nixie Clock

Nixie Clock IV-11 User manual

Nixie Clock

Nixie Clock IN-14 All-In-One Instructions for use

Nixie Clock

Nixie Clock IN-14 All-In-One User manual

Nixie Clock

Nixie Clock IN-14 All-In-One User manual

Nixie Clock

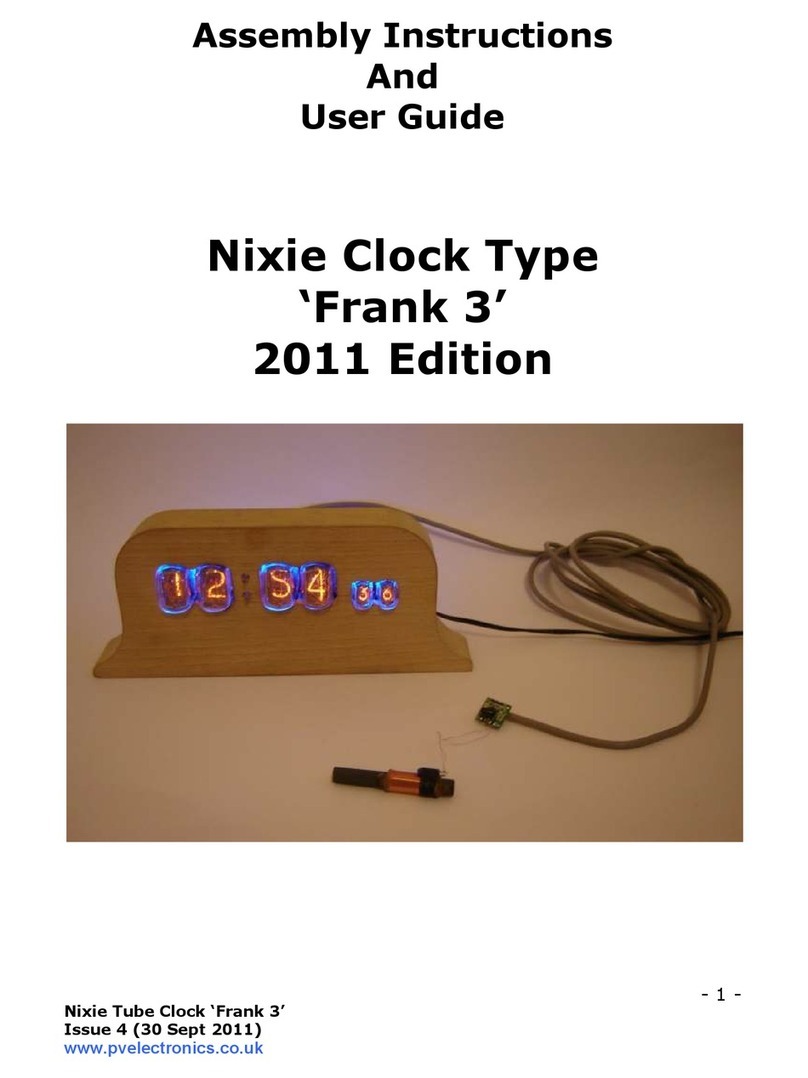

Nixie Clock Frank 3 Configuration guide

Nixie Clock

Nixie Clock IN-14 All-In-One Specification sheet

Nixie Clock

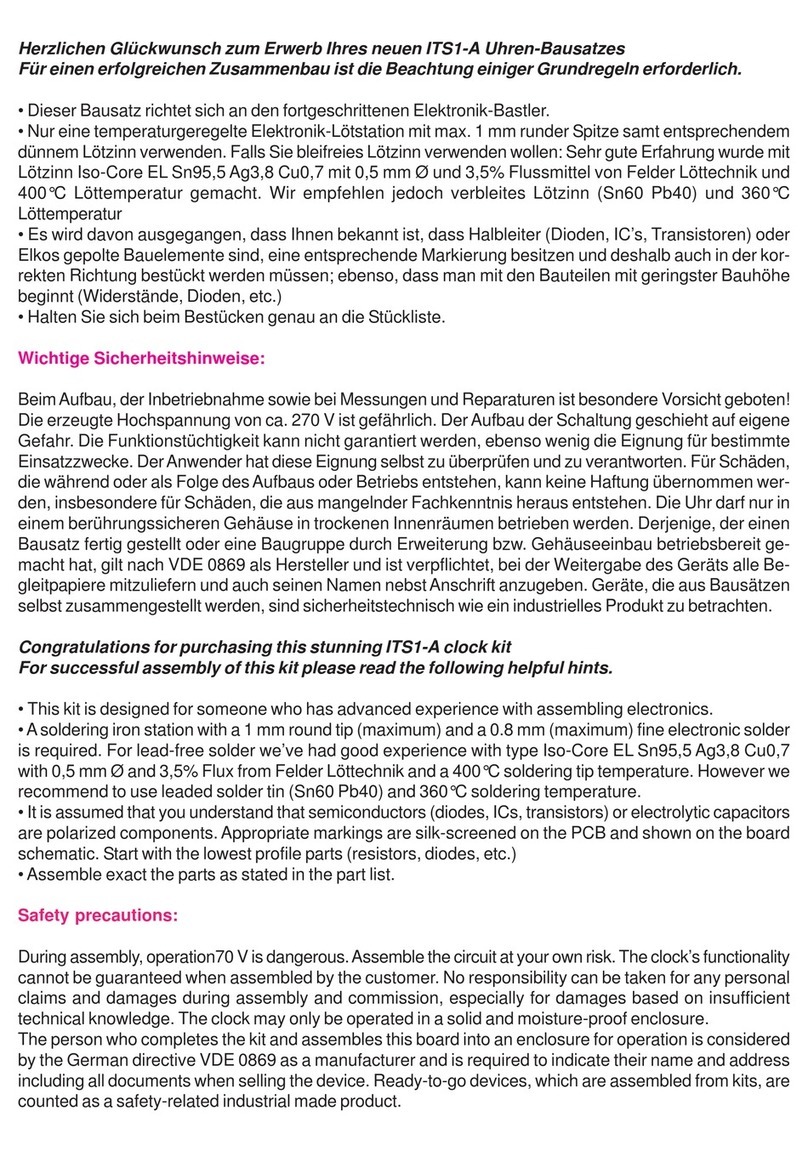

Nixie Clock Thyratron ITS1-A/B User manual

Nixie Clock

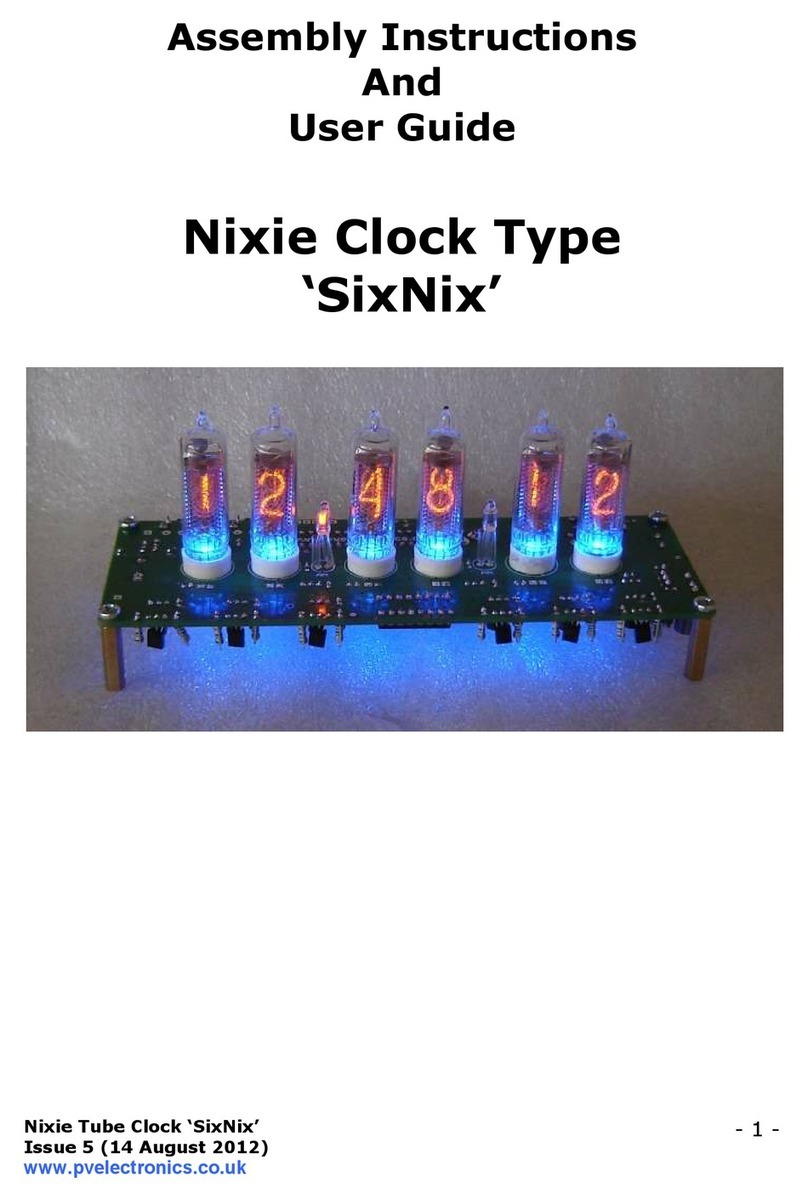

Nixie Clock SixNix Configuration guide

Nixie Clock

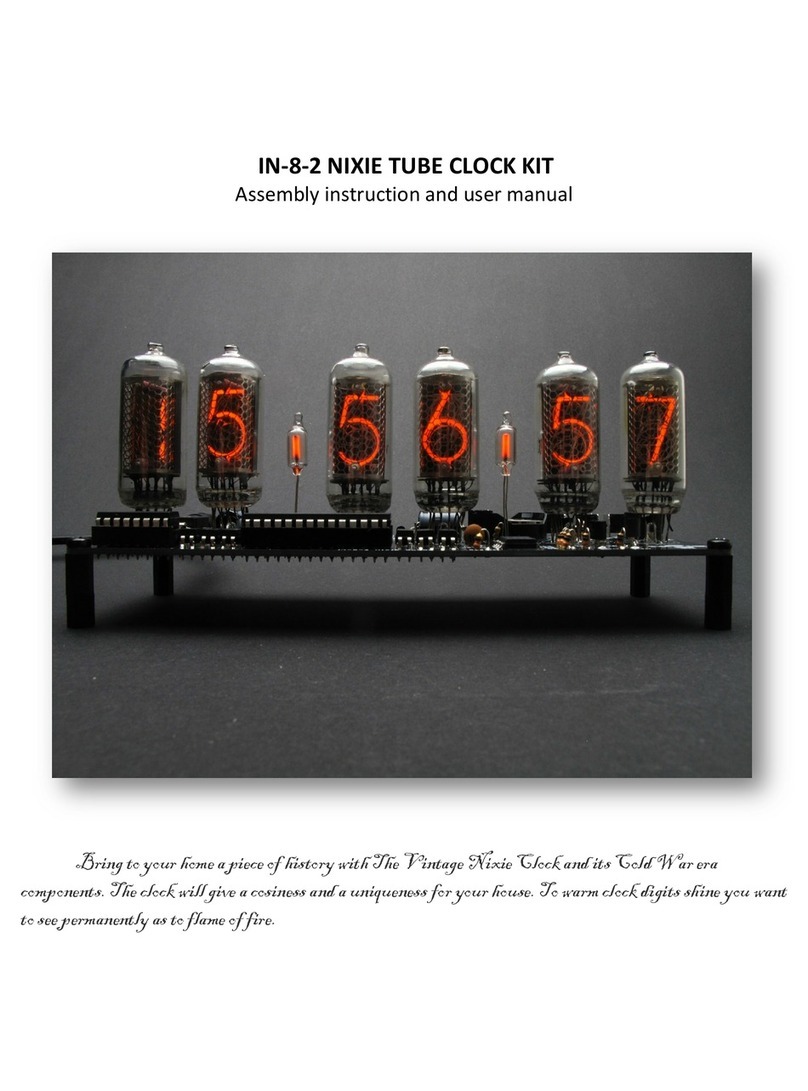

Nixie Clock IN-8-2 Installation instructions

Nixie Clock

Nixie Clock Divergence Meter User manual

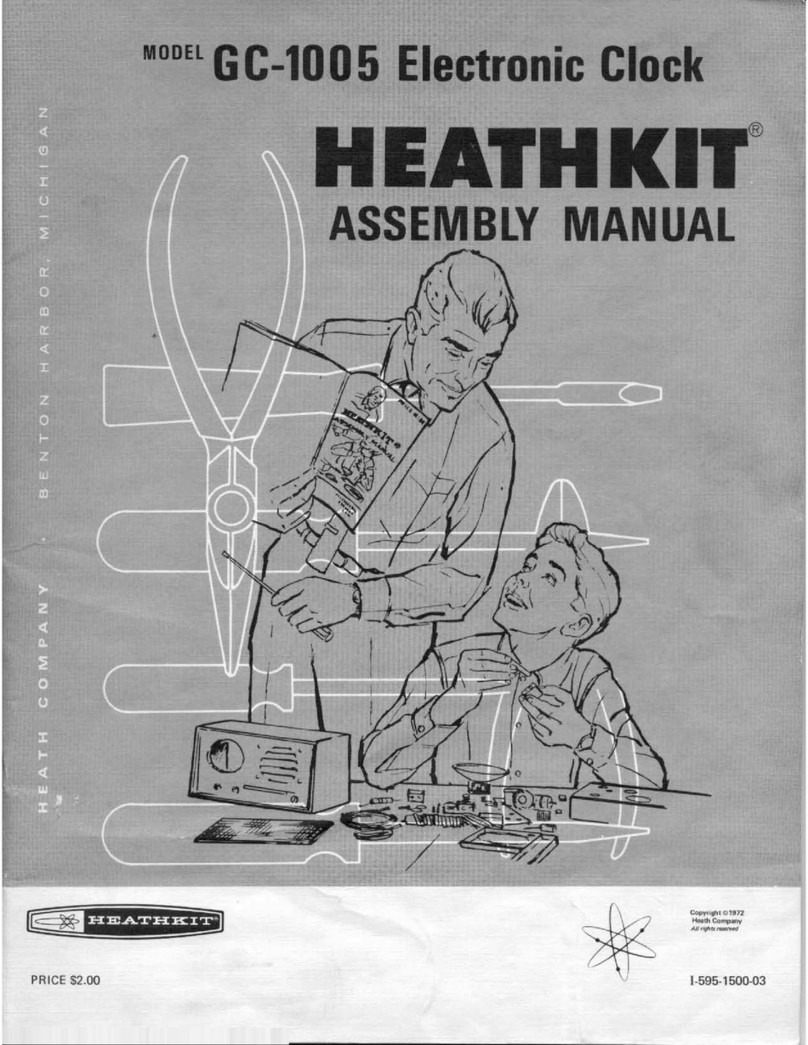

Popular Clock manuals by other brands

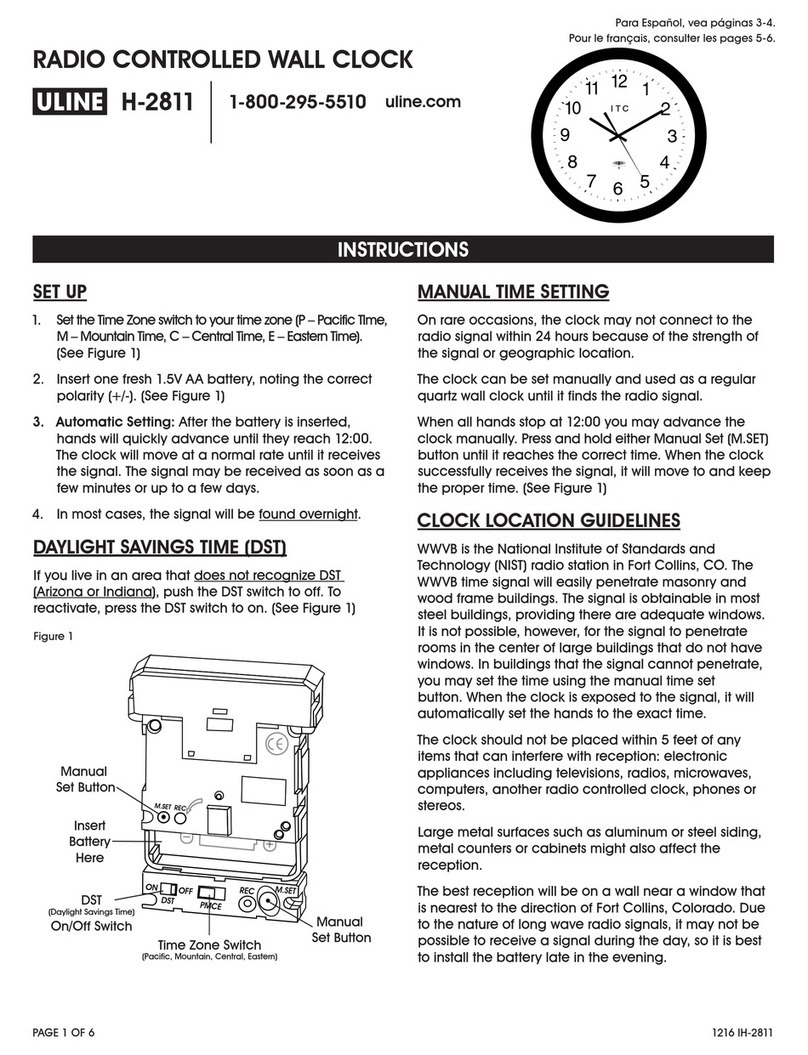

Sapling

Sapling NTP 7000 Series installation manual

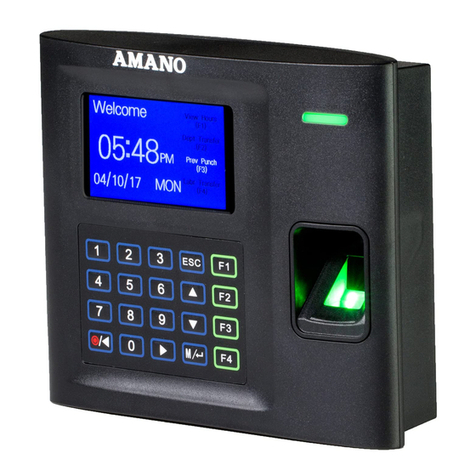

Amano

Amano MTX-30F Installation & operation guide

La Crosse Technology

La Crosse Technology BBB86118v3 Setup guide

BEARWARE

BEARWARE 304474 manual

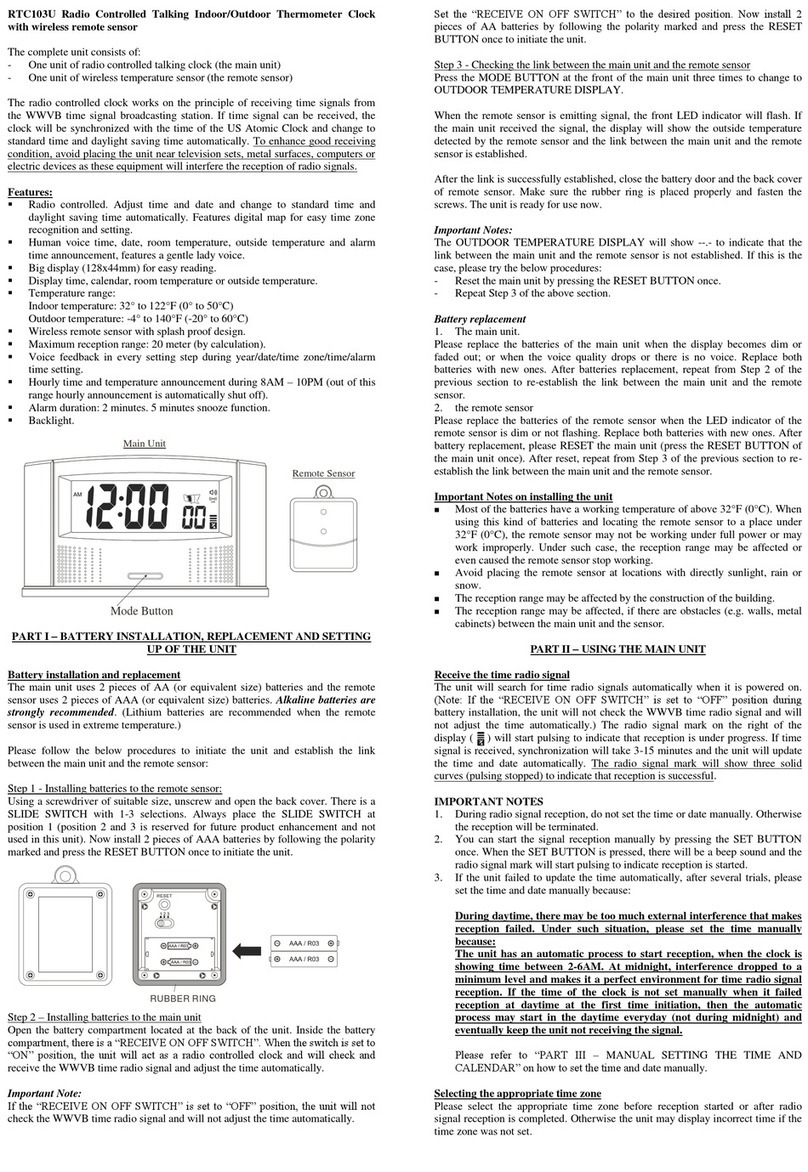

LS & S

LS & S RTC103U instruction manual

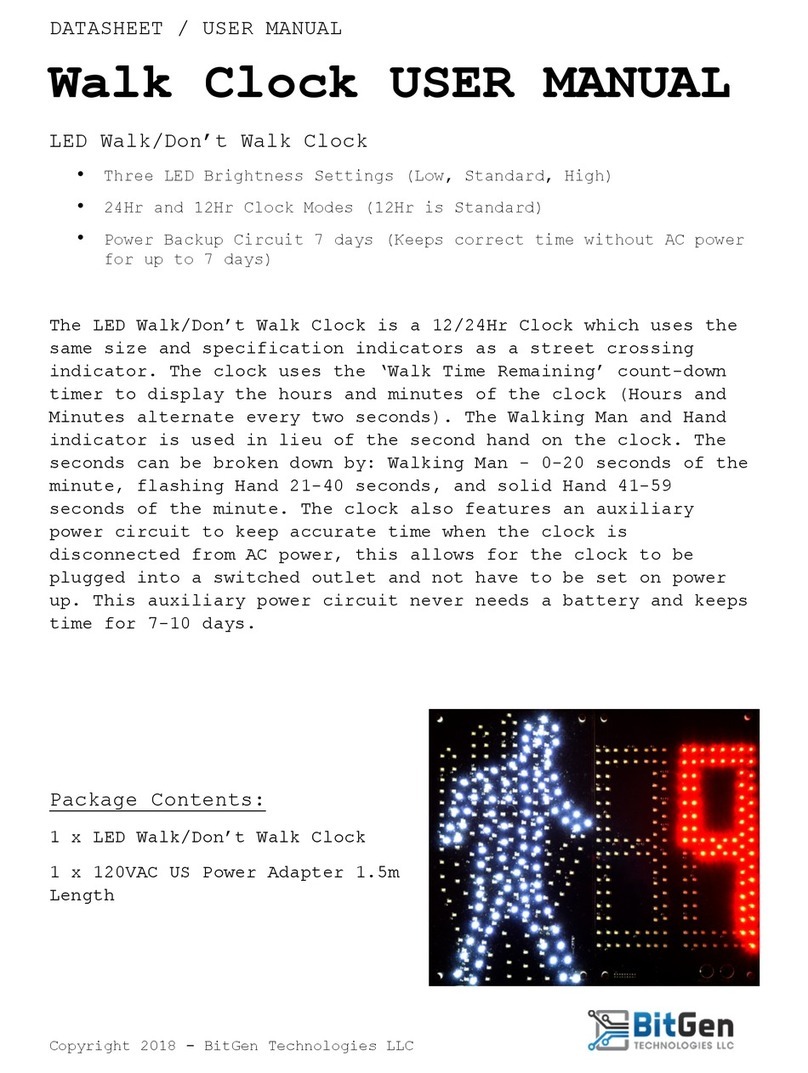

BitGen Technologies

BitGen Technologies LED Walk/Don't Walk Clock user manual