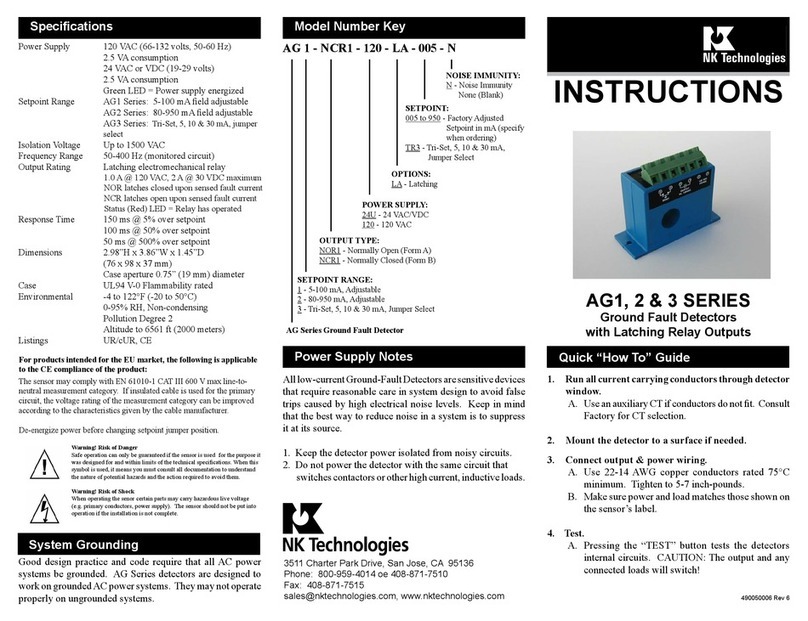

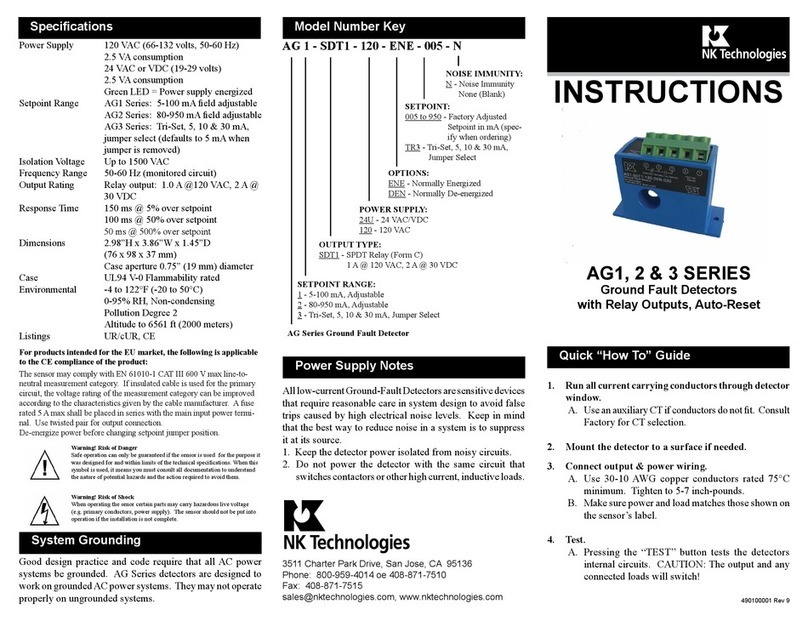

NK TECHNOLOGIES AG 1 Series User manual

INSTRUCTIONS

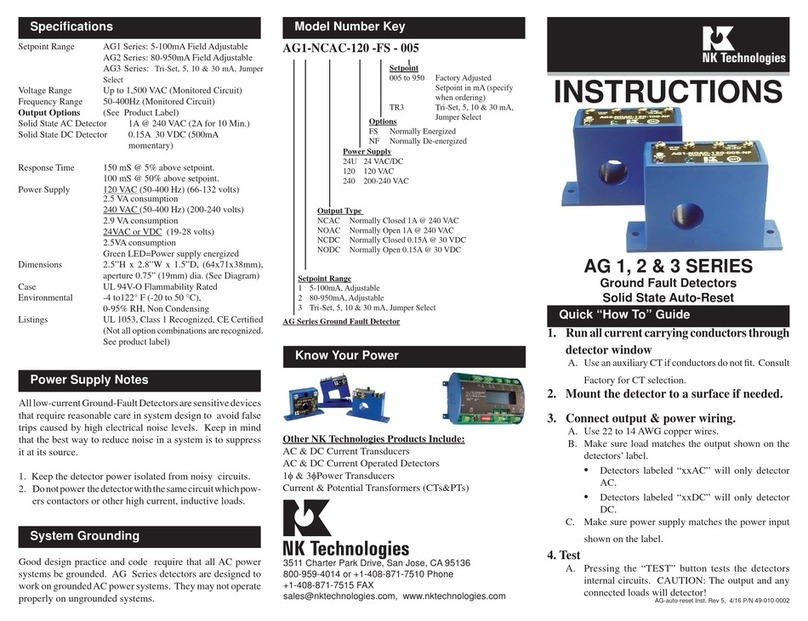

1. Run all current carrying conductors through detector

window.

A. Use an auxiliary CT if conductors do not fi t. Consult

Factory for CT selection.

2. Mount the detector to a surface if needed.

3. Connect output & power wiring.

A. Use 22-14 AWG copper conductors rated 75°C

minimum. Tighten to 9 inch-pounds.

B. Make sure load matches the output shown on the

detectors’ label.

• Detectors labeled “xxAC” will only switch AC

load.

• Detectors labeled “xxDC” will only switch DC

load.

C. Make sure power supply matches the power input

shown on the label.

4. Test.

A. Pressing the “TEST” button tests the detectors

internal circuits. CAUTION: The output and any

connected loads will switch!

AG1-NCAC-120 -FS - 005

Model Number KeySpecifi cations

Quick “How To” Guide

Power Supply Notes

AG 1, 2 & 3 SERIES

Ground Fault Detectors

Solid State Auto-Reset

490100002 Rev 7

Output Type:

NCAC - Normally Closed 1 A @ 240 VAC

NOAC - Normally Open 1 A @ 240 VAC

NCDC - Normally Closed 0.15 A @ 30 VDC

NODC - Normally Open 0.15 A @ 30 VDC

Power Supply:

24U - 24 VAC/DC

120 - 120 VAC

240 - 200-240 VAC

Setpoint Range:

1 - 5-100 mA, Adjustable

2 - 80-950 mA, Adjustable

3 - Tri-Set, 5, 10 & 30 mA, Jumper Select

AG Series Ground Fault Detector

Power Supply 120 VAC (66-132 volts, 50-60 Hz)

2.5 VA consumption

240 VAC (200-240 volts, 50-60 Hz)

2.9 VA consumption

24 VAC or VDC (19-29 volts)

2.5 VA consumption

Green LED = Power supply energized

Setpoint Range AG1 Series: 5-100 mA fi eld adjustable

AG2 Series: 80-950 mA fi eld adjustable

AG3 Series: Tri-Set, 5, 10 & 30 mA,

jumper select

Isolation Voltage Up to 1500 VAC

Frequency Range 50-400 Hz (monitored circuit)

Output Rating Solid state AC switch: 1.0 A @ 120 VAC,

2 A @ 30 VDC

Solid state DC switch: 0.15 A @ 30 VDC

Response Time 150 ms @ 5% over setpoint

100 ms @ 50% over setpoint

50 ms @ 500% over setpoint

Dimensions 2.60”H x 3.86”W x 1.45”D

(66 x 98 x 37 mm)

Case aperture 0.75” (19 mm) diameter

Case UL94 V-0 Flammability rated

Environmental -4 to 122°F (-20 to 50°C)

0-95% RH, Non-condensing

Pollution Degree 2

Altitude to 6561 ft (2000 meters)

Listings UR/cUR, CE (Not all option combina-

tions are recognized. See product label.)

System Grounding

3511 Charter Park Drive, San Jose, CA 95136

Phone: 800-959-4014 oe 408-871-7510

Fax: 408-871-7515

[email protected], www.nktechnologies.com

All low-current Ground-Fault Detectors are sensitive devices

that require reasonable care in system design to avoid false

trips caused by high electrical noise levels. Keep in mind

that the best way to reduce noise in a system is to suppress

it at its source.

1. Keep the detector power isolated from noisy circuits.

2. Do not power the detector with the same circuit which

powers contactors or other high current, inductive loads.

Good design practice and code require that all AC power

systems be grounded. AG Series detectors are designed to

work on grounded AC power systems. They may not operate

properly on ungrounded systems.

Setpoint:

005 to 950 - Factory Adjusted

Setpoint in mA (specify

when ordering)

TR3 - Tri-Set, 5, 10 & 30 mA, Jumper

Select

Options:

FS - Normally Energized

NF - Normally De-energized

For products intended for the EU market, the following is applicable

to the CE compliance of the product:

The sensor may comply with EN 61010-1 CAT III 600 V max line-to-

neutral measurement category. If insulated cable is used for the primary

circuit, the voltage rating of the measurement category can be improved

according to the characteristics given by the cable manufacturer.

De-energize power before changing setpoint jumper position.

Warning! Risk of Danger

Safe operation can only be guaranteed if the sensor is used for the purpose it

was designed for and within limits of the technical specifi cations. When this

symbol is used, it means you must consult all documentation to understand

the nature of potential hazards and the action required to avoid them.

Warning! Risk of Shock

When operating the senor certain parts may carry hazardous live voltage

(e.g. primary conductors, power supply). The sensor should not be put into

operation if the installation is not complete.

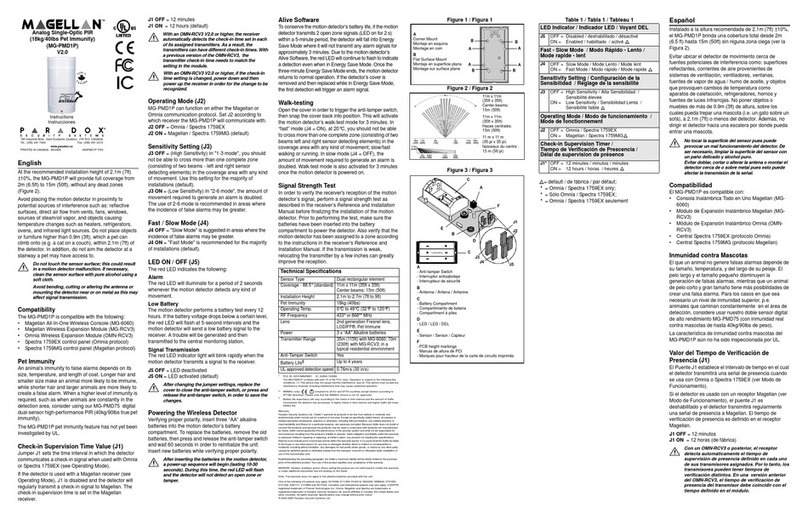

Normally Energized Models (-FS) Detects Ground Faults and loss of control power

CONTROL POWER APPLIED

NO POWER No Fault Fault Detected

Output Style Output LED Output LED Output LED

N.C. Normally Closed CLOSED Off OPEN ON CLOSED OFF

N.O. Normally Open OPEN Off CLOSED ON OPEN OFF

Normally De-Energized Models (-NF) Detects Ground Faults only.

CONTROL POWER APPLIED

NO POWER No Fault Fault Detected

Output Style Output LED Output LED Output LED

N.C. Normally Closed CLOSED Off CLOSED OFF OPEN ON

N.O. Normally Open OPEN Off OPEN OFF CLOSED ON

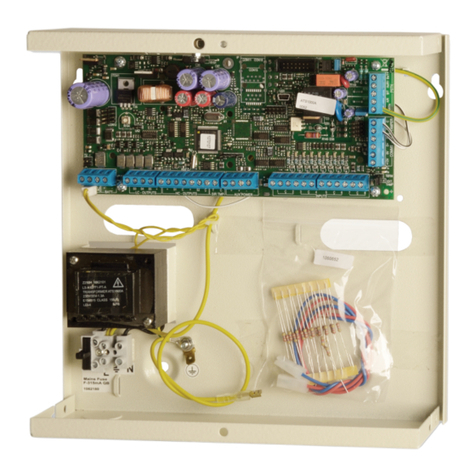

Description

Operation

Principal of Operation

AG Series ground fault detectors work in the same environ-

ment as motors, contactors, heaters, pull-boxes, and other

electrical enclosures. They can be mounted in any position

or hung directly on wires with a wire tie. Just leave at least

one inch distance between detector and other magnetic

devices.

Run all current carrying conductors through the detector

aperture in the same direction. (See “Principal of Operation)

Connect power wiring to the detector. Be sure that the power

supply matches the power rating on the detector label. Use

22-14 AWG copper conductors and tighten terminals to 9

inch-pounds torque.

Connect controlled load to terminals. Be certain the output

current draw is lower or equal to the output rating on the

detector label.

Installation & Wiring

To test operation, gently press the

TEST button. This simulates a

fault and tests the internal sensing

circuits. You should observe the

following operation.

CAUTION: Any circuit con-

nected to the detector will be

operated.

Power Output

Control Power

Match Detector Rating

(See Label)

Setpoint Adjust

Factory calibrated &

covered. Remove cover,

adjust & relabel if required

(AG1 & 2 only).

Load

Contactor, Relay, Shunt Trip Breaker, etc.

Do not exceed Rating (See Label)

Output Power

Match Detector Rating

(See Label)

TEST

For DC Output Version

Observe Polarity

Setpoint Adjustment

AG1 & AG2 Series detectors are factory calibrated to trip

at the setpoint specifi ed at the time order. We highly recom-

mend leaving this factory calibrated setpoint alone. If you

must change the factory setpoint, follow these steps:

A. Setup

Connect control power and output circuits. Run a conduc-

tor through the aperture with current equal to your desired

set point.

B. Adjust Setpoint to Maximum

Remove the Setpoint Cover. Turn the adjustment pot 4

revolutions CCW (Counter Clockwise) to the maximum

(least sensitive) setpoint. The Status LED should be OFF.

The adjustment pot has a slip clutch so you cannot feel or

damage the end point.

C. Dial in new Setpoint

Turn the pot slowly CW (Clockwise) until the LED turns

ON. The detector is now adjusted to trip at the current that

is passing through the aperture. Reset the detector.

D. Relabel Detector

Relabel the detector with the new setpoint. Use a label maker

or tape with a permanent marker.

AG3 Move the jumper to the desired setpoint as shown on

the label. No other adjustment can be made.

Under normal conditions, the current in one wire of a two

wire load is equal in strength but opposite in sign to the cur-

rent in the other wire. The two wires create magnetic fi elds

that cancel, a condition known as “Zero Sum Current”. If

any current leaks to ground (Ground Fault), the two currents

become unbalanced and there is a net resulting magnetic

fi eld. The AG detector detects this minute fi eld and changes

the output state. This concept extends to three phase systems

such as 3 wire Delta and to 4 wire Wye.

AG Series ground fault detectors monitor all current carry-

ing wires in single or three phase systems to detect ground

faults. They provide a contact output that can operate relays,

contactors or signal automation systems.

Power Supply LED

Contact Status LED

490100002 Rev 7

This manual suits for next models

7

Other NK TECHNOLOGIES Security Sensor manuals

Popular Security Sensor manuals by other brands

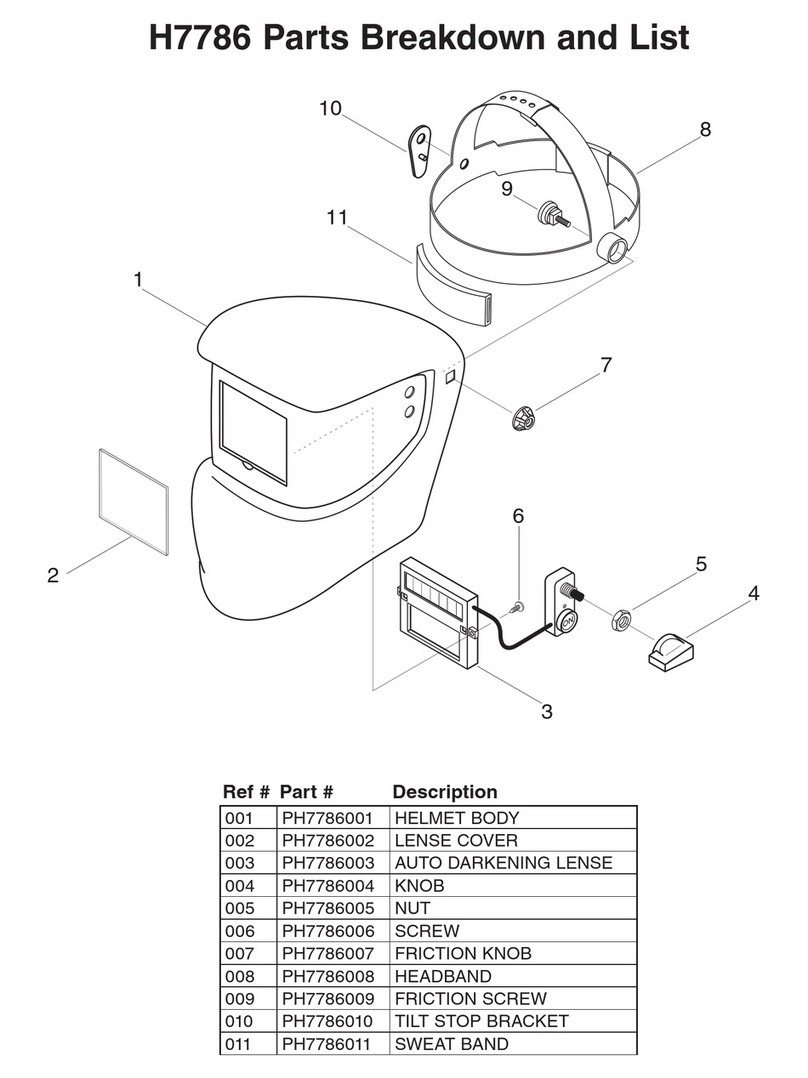

Grizzly

Grizzly H7786 Parts Breakdown

Crewsaver

Crewsaver CREWFIT 165 SPORT owner's manual

Vanderbilt

Vanderbilt GM710 installation manual

Cooper safety

Cooper safety CEAG Brillant 1883 LED GGLine Mounting and operating instructions

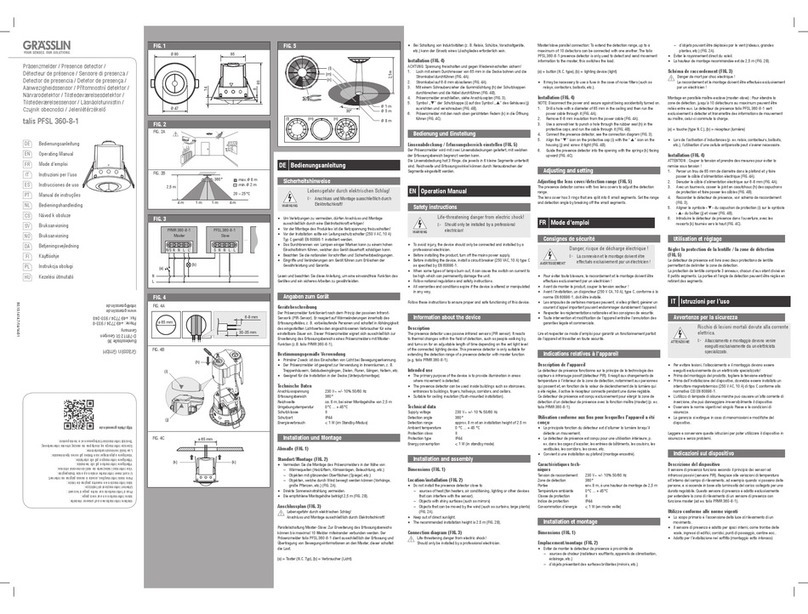

Grasslin

Grasslin talis PFSL 360-8-1 operating manual

ST

ST STEVAL-IFS014V1 user manual