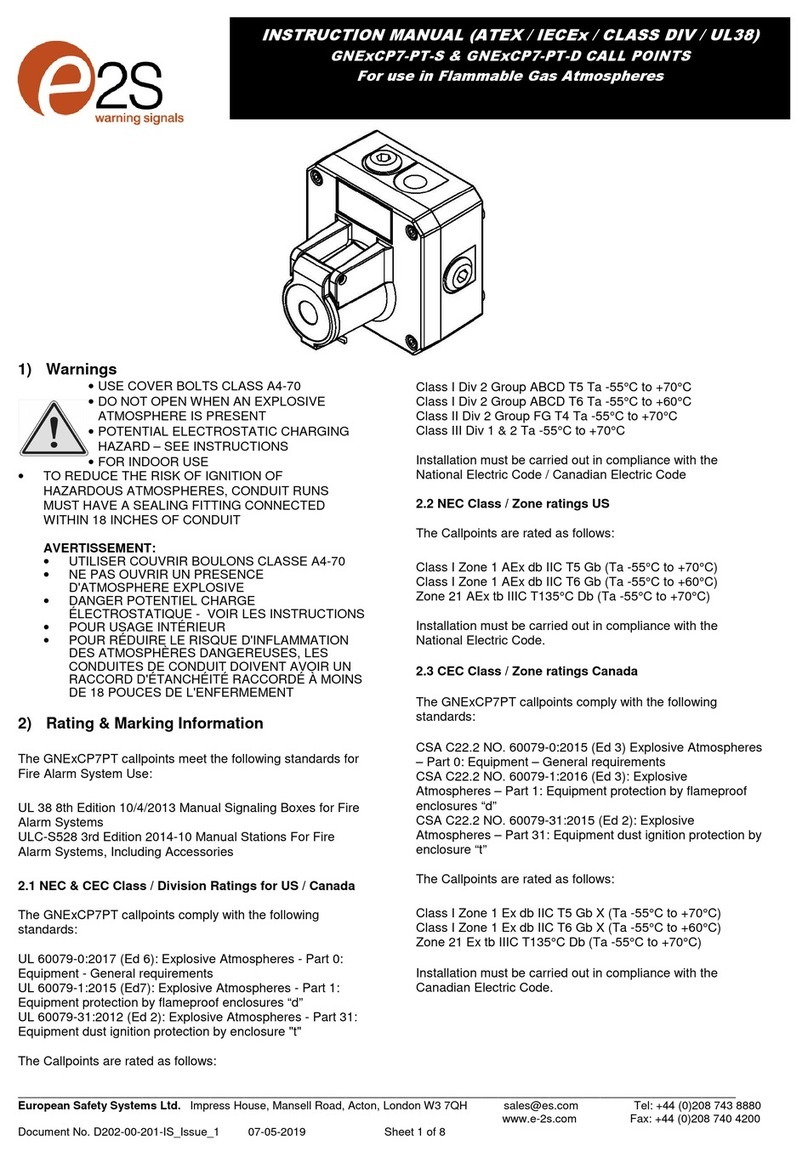

Normally Energized Models (-ENE) Detects Ground Faults and loss of control power

CONTROL POWER APPLIED

NO POWER No Fault Fault Detected

Output Output LED Output LED Output LED

N.C. Normally Closed CLOSED Off OPEN OFF CLOSED ON

N.O. Normally Open OPEN Off CLOSED OFF OPEN ON

Normally De-Energized Models (-DEN) Detects Ground Faults only.

CONTROL POWER APPLIED

NO POWER No Fault Fault Detected

Output Output LED Output LED Output LED

N.C. Normally Closed CLOSED Off CLOSED OFF OPEN ON

N.O. Normally Open OPEN Off OPEN OFF CLOSED ON

Description

Operation

Principal of Operation

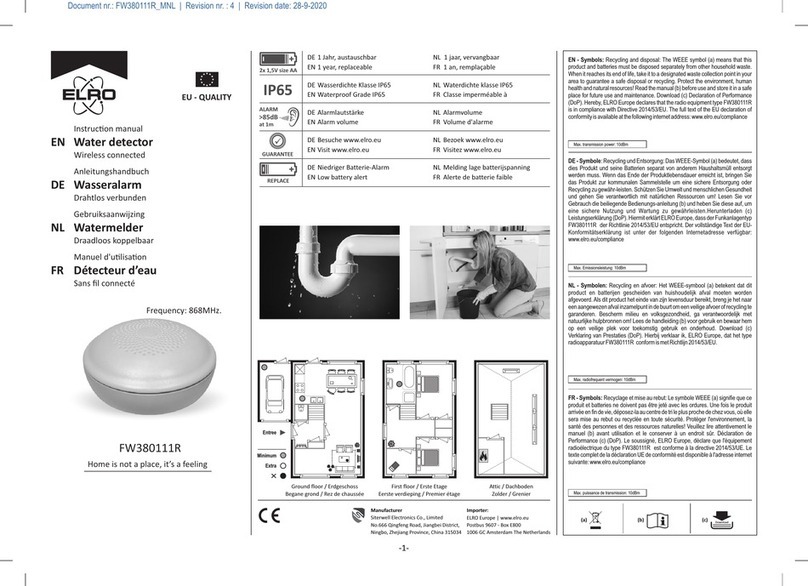

Under normal conditions, the current in one wire of a two

wire load is equal in strength but opposite in sign to the cur-

rent in the other wire. The two wires create magnetic fields

that cancel, acondition known as“Zero Sum Current”.If any

current leaks to ground (Ground Fault), the two currents be-

come unbalanced and there is a net resulting magnetic field.

The AG detector detects this minute field and changes the

output state. This concept extends to three phase systems

such as 3 wire Delta and to 4 wire Wye.

AG Series detectors work in the same environment as mo-

tors, contactors, heaters, pull-boxes, and other electrical

enclosures. They can be mounted in any position or hung

directly on wires with a wire tie. Just leave at least one inch

distance between detector and other magnetic devices.

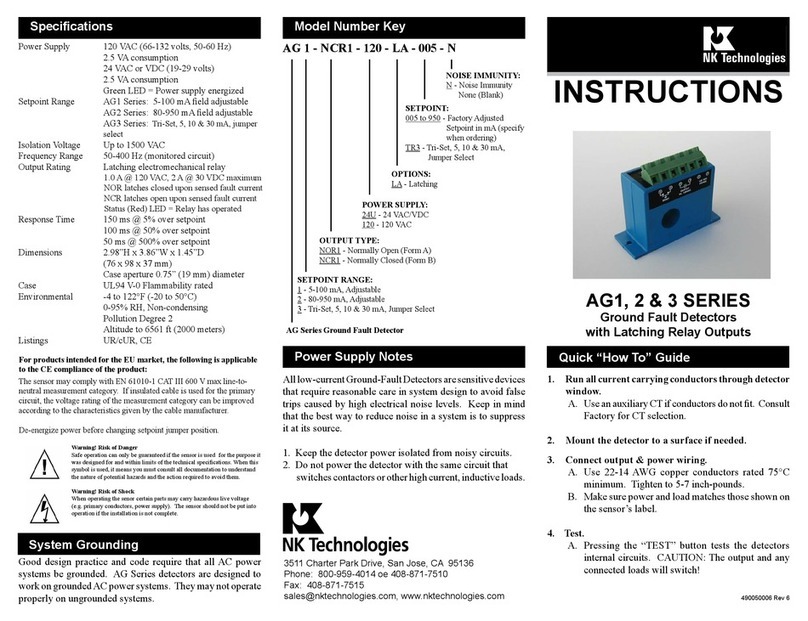

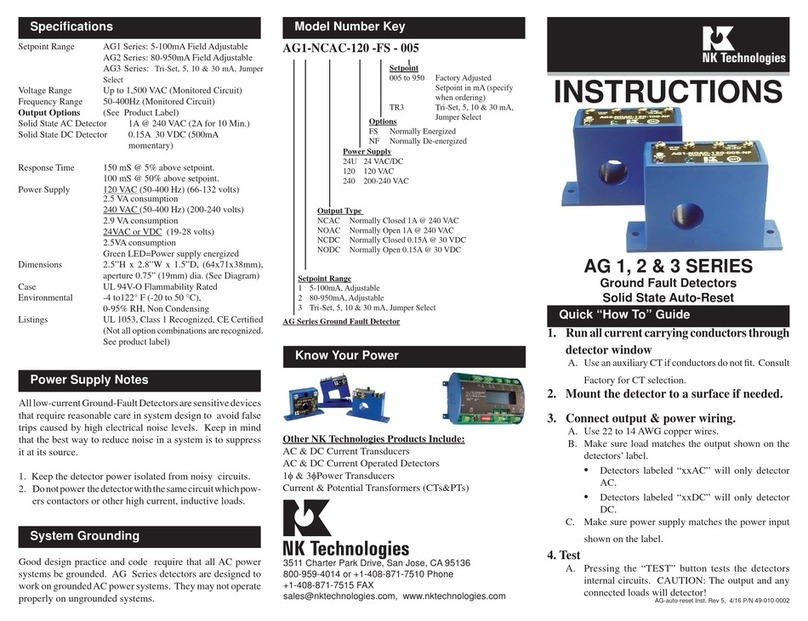

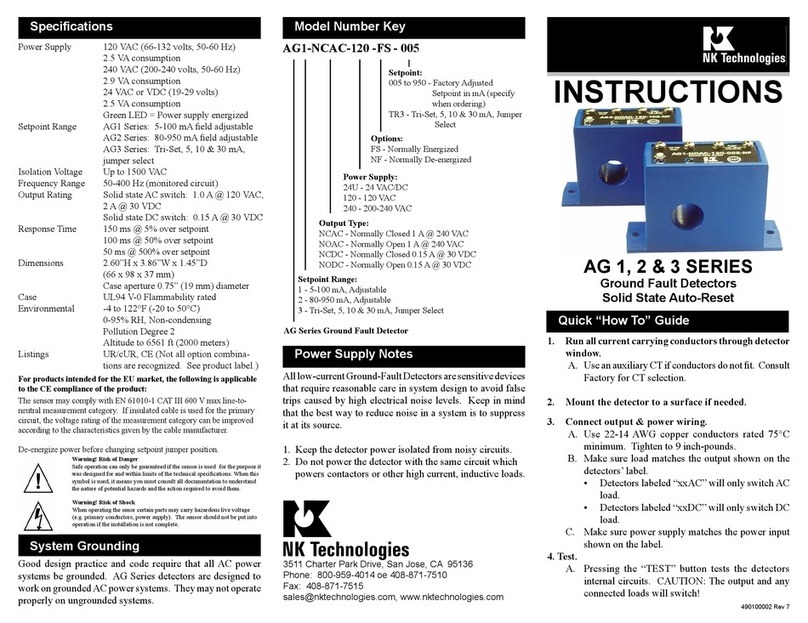

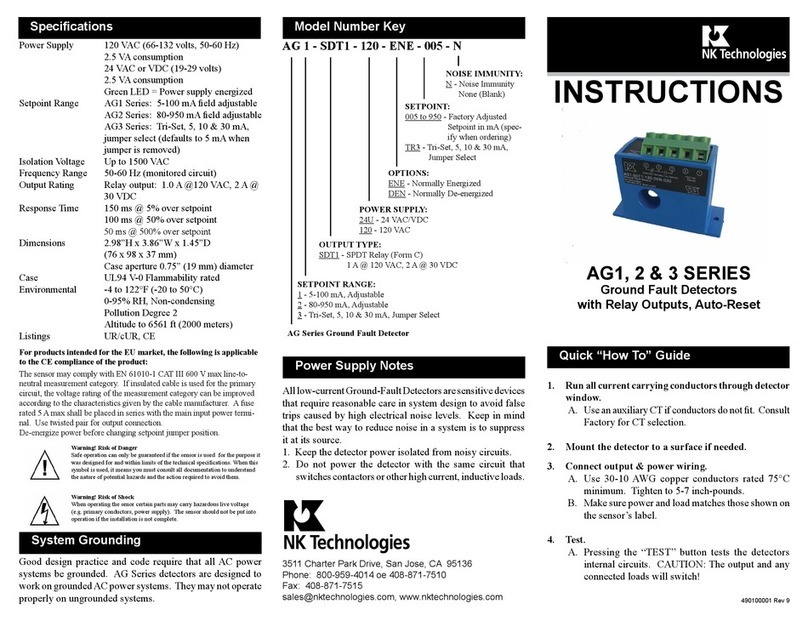

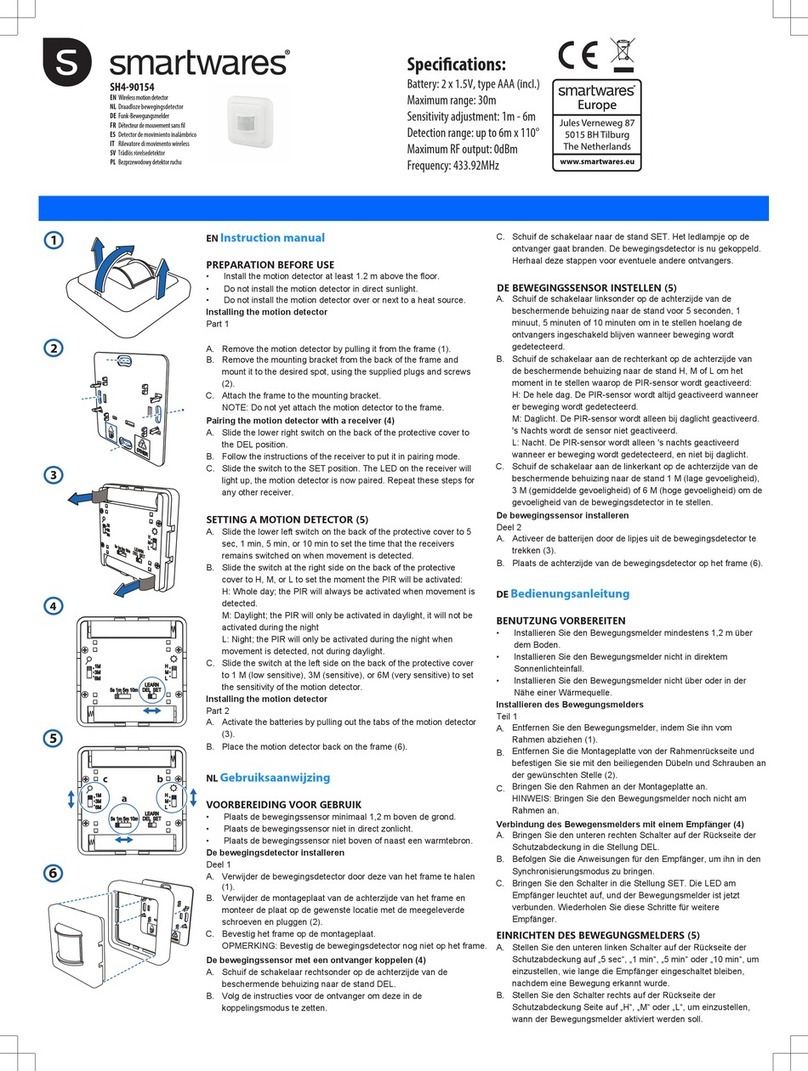

Runall current carrying conductors throughthe detectorape-

ture in the same direction. (See “Principal of Operation”)

Connect power wiringto the detector. Be sure that the power

supply matches the power rating on the detector label. Use

up to 14 AWG copper wire and tighten terminals to 4.5

inch-pounds torque.

Connect output wiring to the detector. Be sure that the

Installation & Wiring

output load is less than or equal to the output rating on the

detector label. Use up to 14 AWG copper wire and tighten

terminals to 4.5 inch-pounds torque.

To test operation,gently pressthe

TEST button. This simulates a

faultandteststhe internalswitch-

ing circuits. You should observe

the following operation.

CAUTION: Any circuit con-

nected to the detector will be

operated.

Power Output

GX

Control Power

Match Detector

Rating

(See Label)

Setpoint Adjust

(AG1&2) Factory calibrat-

ed & covered. Remove

cover, adjust & relabel if

required.

AG3 Move jumper to select

setpoint.

Load

Contactor, Relay, Shunt Trip

Breaker, etc.

Do not exceed Rating (See

Label) Output Power

Match Detector

Rating

(3-4 Normally Open,

4-5 Normally Closed)

1A@125VAC or 2A

TEST

Setpoint Adjustment

AG Series detectors monitor all current carrying wires in

single or three phase systems to detect ground faults. They

provide a contact output that can operate relays, contactors

or signal automation systems.

AG1 &AG2 Series detectors are factory calibrated to trip

atthesetpointspecifiedat thetimeorder. We highly recom-

mend leaving this factory calibrated setpoint alone. If you

must change the factory setpoint, follow these steps:

A. Setup

Connect control power and output circuits. Run a conduc-

tor through the aperture with current equal to your desired

set point .

B. Adjust Setpoint to Maximum

Remove the Setpoint Cover. Turn the adjustment pot 5

revolutions CCW (Counter Clockwise) to the maximum

(least sensitive) setpoint. The Status LED should be OFF.

The adjustment pot has a slip clutch so you cannot feel or

damage the end point.

C. Dial in new Setpoint

Turn the pot slowly CW (Clockwise) until the LED turns

ON. The detector is now adjusted to trip at the current that

is passing through the aperture. Reset the detector.

D. Relabel Detector

Relabelthedetectorwiththenewsetpoint. Usealabelmaker

or tape with a permanent marker.

AG3 Move the jumper to the desired setpoint as shown

on the label.

12345

R

Power Status