Description

Operation

Principal of Operation

Under normal conditions, the current in one wire of a two

wire load is equal in strength but opposite in sign to the cur-

rent in the other wire. The two wires create magnetic fi elds

that cancel, a condition known as “Zero Sum Current”. If

any current leaks to ground (Ground Fault), the two currents

become unbalanced and there is a net resulting magnetic

fi eld. The AG detector detects this minute fi eld and changes

the output state. This concept extends to three phase systems

such as 3 wire Delta and to 4 wire Wye.

AG Series detectors work in the same environment as mo-

tors, contactors, heaters, pull-boxes, and other electrical

enclosures. They can be mounted in any position or hung

directly on wires with a wire tie. Just leave at least one

inch distance between detector and other magnetic devices.

Run all current carrying conductors through the opening in

the detector. (See “Principal of Operation”) Be Sure all

wires are oriented so current fl ows in the same direction.

Installation & Wiring

AG Series detectors monitor all current carrying wires in

single or three phase systems to detect ground faults. They

provide a contact output that can operate relays, contactors

or signal automation systems.

Wiring

Use 22-14 AWG copper conductors and tighten terminals

to 5-7 inch-pounds torque.

Power

Connect power wiring to Terminals 1 & 2. Be sure that

the power supply matches the power rating on the detec-

tor label.

Output

Connect output wiring to Terminals 3 & 4.

Reset Switch

Connect a momentary dry contact to the reset terminals

5 & 6. Limit wire run to 200’ of 18 AWG or larger wire.

Momentary Reset

The detector will not work properly if the reset terminals

are closed (shorted) continuously. Only close the reset

terminals momentarily.

Parallel Reset Connection

Multiple detectors may be connected to the same reset switch

in parallel. Only the detectors that have detected a fault and

have latched will be reset. A detector will not reset unless

the fault has dropped below setpoint.

AG Series Latching Ground fault detectors operate in one of

two states: Reset or Latched. If control power is removed,

the detector remains in it’s last state (latched or reset).

Reset

The detector has not detected a fault and the output is in

the “normal” position.

For -NOR1 suffi x, the contact is normally open in the reset

condition.

For -NCR1 suffi x, the contact is normally closed in the

reset condition.

Latched

Upon detecting a fault or when the TEST switch is pressed,

the output will switch and “latch”. The output will remain

latched until the ground fault is removed and the output is

reset by a momentary dry contact on Terminals 5 & 6. Also,

cycling power to the sensor will reset the output.

Testing

To test operation, gently press the TEST button. This simu-

lates a fault and tests the internal switching circuits. After

the test is complete, reset the detector with a momentary

dry contact on Terminals 5 & 6. CAUTION: Any circuit

connected to the detector will be operated.

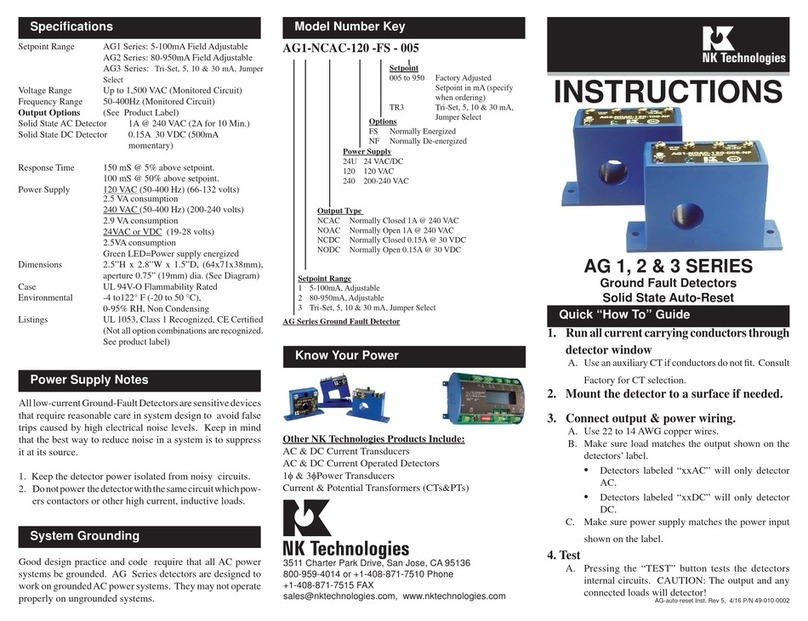

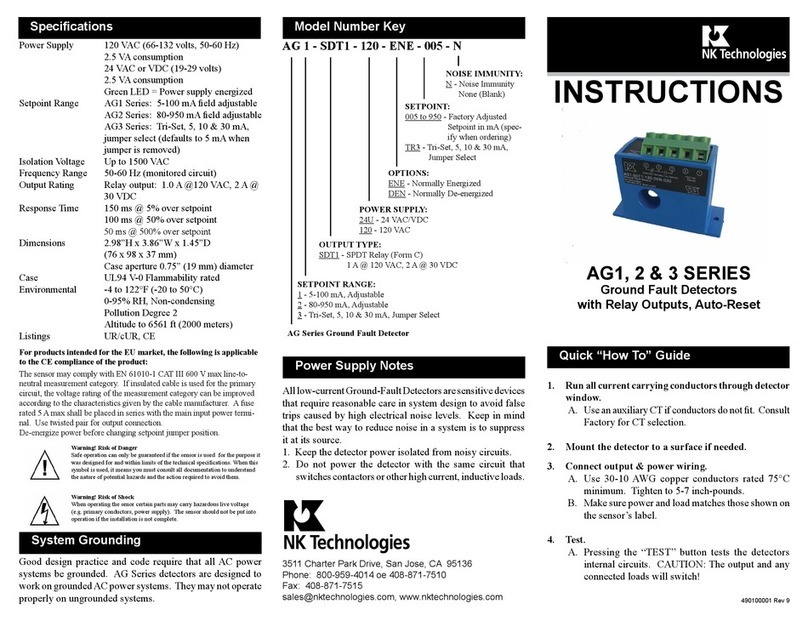

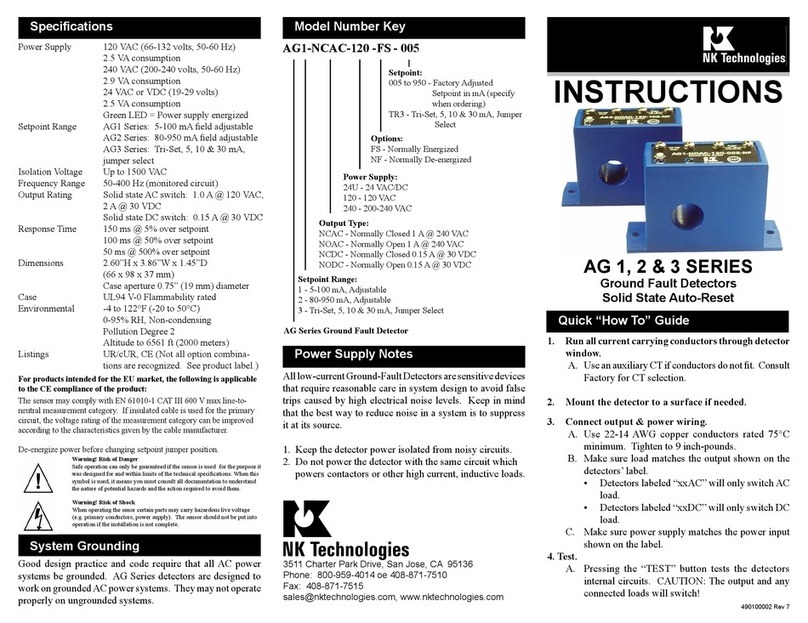

Setpoint adjustment, CW to adjust higher located

under label (AG1 & 2 only)

Test Button (Activates

output relay)

Red Status LED (On when

tripped)

Green Power

LED (On when

powered) G R

Power Supply

Input (1&2)

Output External Reset

Button (5&6)

When used with an external CT, the detector will be set

to trip at a point much lower than without the CT. This

setpoint adjustment should be done with the load passing

through the CT in that application.

Single Phase (Phase

& Neutral or Phase to

Phase)

3 Phase Delta (Include

neutral if the load uses

neutral)

3 Phase Wye (Include

neutral if load uses

neutral)

3 Phase Load, using an auxiliary Current Transformer.

Contact factory for details.

Field Setpoint Adjustment

While not as precise as having it set at the factory, the set

point can be adjusted in the fi eld through use of the small

potentiometer located beneath the label to the right of the

red LED (status). Though not recommended, if a fi eld

adjustment of setpoint is desired, the recommended steps

are as follows:

1. Develop a load of the magnitude at which you want

the detector to trip; e.g., a 4000 ohm resistor at 120 VAC

should provide a load of 30 mA while 4 watt “night light”

bulb would create a load of approximately 33.33 mA.

2. With the load energized and passing through the sens-

ing aperture, turn the potentiometer counterclockwise

(CCW) until the detector trips. Then turn the pot back

(CW) one eighth of a turn.

490050006 Rev 6