Page 2

Wiring Apply power only after all

connectionshavebeenmadeand

inspected. Do not coil excess

wiringinsidethe detector.

•Terminals 1 (-) & 2 (+): Voltagelimitsare9

to15VDC. Use nosmallerthan#22 AWGwire

pair (500 feet/150m max) between the detector

andthe power source.

• Terminals 3 & 4: Alarm relay (reed) contacts rated at 3 watts, 0.125 amps,

28VDCmaximumfor DC resistive loads and protected by a4.7ohm,1/2watt

resistor.

NOTE: Do not use with capacitive or inductive loads.

•Terminals 5 & 8: Spare.

•Terminals 6 & 7: Tampercontacts rated at 28VDC, 0.125A.

•

Plug the wire entrance hole with the foam plug that has been provided.

LED Operation

The detector uses a tri-color LED to indicate the various alarm and supervision

troubles that may exist. See chart below:

If the detector experiences a Microwave or PIR self-test failure, it is in need of

replacement.

During walk testing, the LED will light for the first technology (microwave or

PIR) and then light red to indicate a detector alarm. The LED will not indicate

activationof the second technology by lightingits color.

Feature Selection

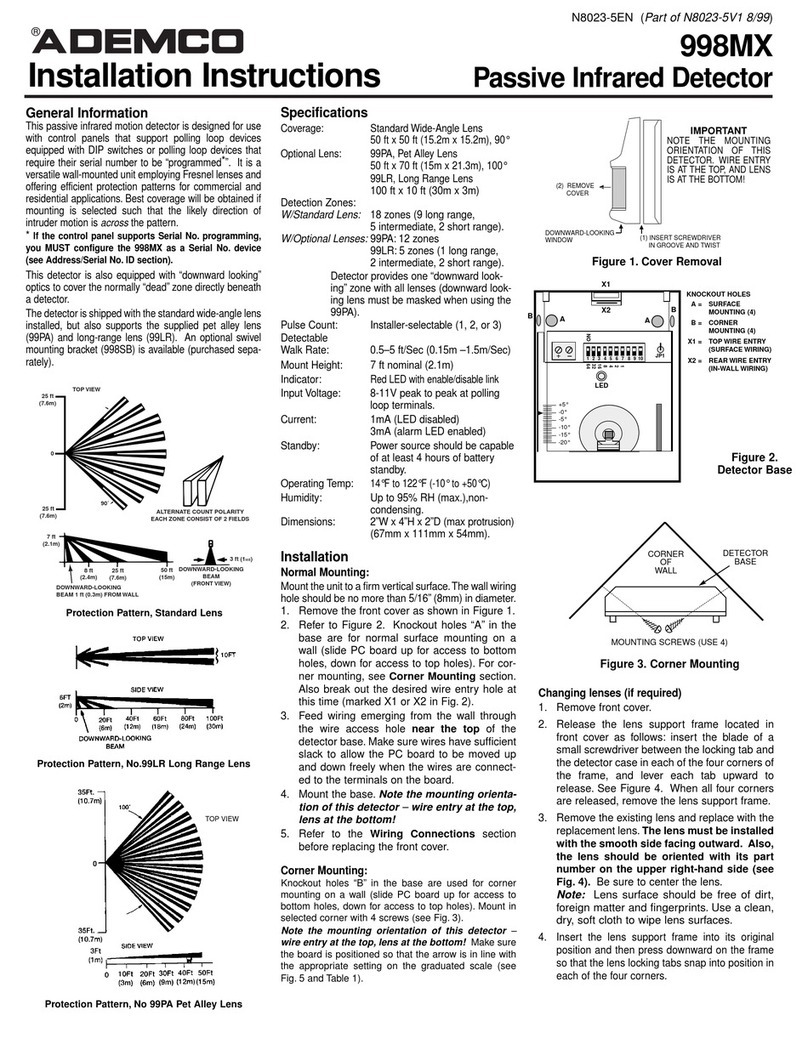

LED On/Off pins: The ON position allows

operation of the tri-color LED. If the tri-color

LEDindication is not desiredafter the setup

andwalk tests have been completed, place

theplug in the OFF position.

NOTE: TheOFF position does not prevent

thetri-color LED from indicating a

supervisiontroublecondition.

PIR Sensitivity Selection Pins: Selection of the PIR response sensitivity

may be selected by placing the plug across the pins marked STD for standard

orINTforintermediatemode.

Standard Sensitivity:

Thisis the recommended setting for maximumfalse

alarmimmunity. It toleratesenvironmentextremes on this setting.

Intermediate Sensitivity:

Therecommendedsetting for any location where

an intruder is expected to cover only a small portion of the protected area. It

toleratesnormal environments on this setting. This settingwill improve your

intrudercatchperformance.

Set-up and Walk Tests

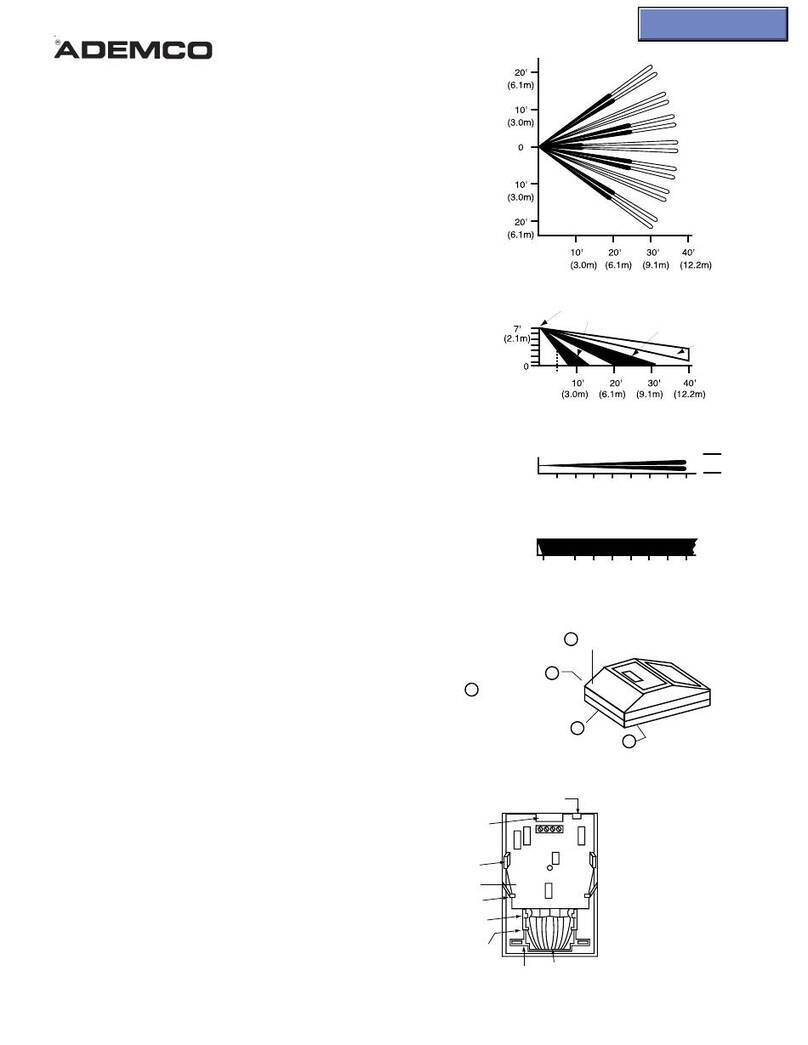

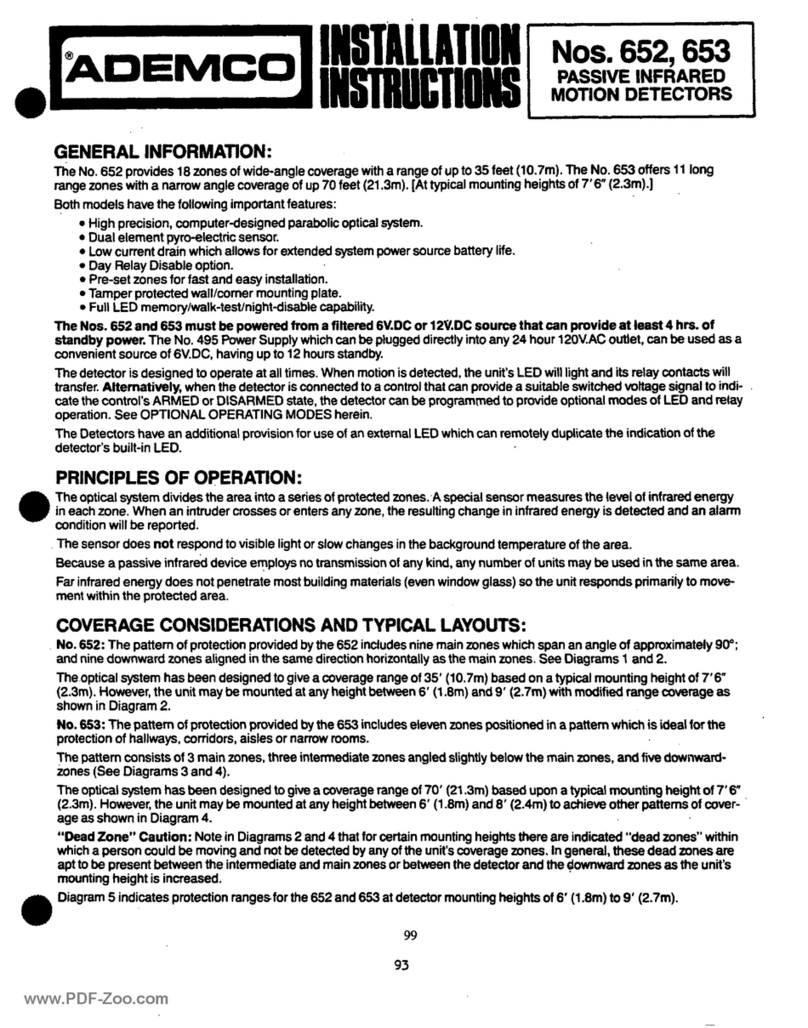

Selectthe vertical starting anglefrom the chart

tothe right.

Adjustthe vertical starting angle for thedesired

mountingheightandrange.

• Place the LED plug in the ON position and

replacethecover.

•Wait at least two minutes, after applying power, before starting walk tests.

NOTE: During the warm-up period, the tri-color LED will flash red until the unit

has stabilized and has seen no movement for two seconds (approxi-

mately one to two minutes). When the LED stops flashing, the

detector is ready to be tested. With no motion in the protection area,

the LED should be OFF. If the LED is on, re-check the protection

area for disturbances affecting the microwave (yellow) or PIR (green)

technologies.

Establishing PIR pattern coverage

• TurntheMicrowave range adjust to minimum.

• Walktest across thepatternatitsfarthestedge,thenseveraltimescloserto

thedetector. Start walkingfrom outside of the intendedprotection area, and

observe the tri-color LED. The edge of the pattern is determined by the first

green,PIRactivationoftheLED (or the first red activation if the yellow micro-

wave LED activates first).

• Walktestfrom the opposite direction to determine both boundaries. The cen-

terofthepatternshouldbepointedtowardthe center of the intended protec-

tionarea.

• Slowlybringyour arm up and into the patterntomarkthe lower boundary on

PIRalarm.Perform this task at 10 to 20 ft.(3.1to6.1m)from the unit. Repeat

from above for the upper boundary. The center of the pattern should not

be tilted upward.

Ifdesiredcoveragecannotbeachieved,tryangling the coverage pattern up

ordownto assure the pattern is not aimedtoohighor low. The angle of the

PIR pattern may be vertically positioned between -10° and +2° by loos-

eningthe VerticalAdjust screw and slidingthe circuit board upor down.

Moving the board up will angle the pattern downward.Tightenthe screw

snugwhenpositioningiscompleted.

NOTE: The pattern may be moved ±10° horizontally by moving the lens

windowleft/right.

Establishing Microwave Coverage

NOTE: Itis important to wait one minute afterremoving/replacing the cover

so the microwave portion of the detector can settle, and to wait at

least10 seconds between the following walk testingprocedures.

• The tri-color LED should be OFF before walk testing.

• Walk test across the pattern at the intended coverage’s farthest end. Start

walking from outside the intended protection area and observe the tri-color

LED. The edge of the microwave pattern is determined by the first yellow,

microwave activation of the LED (or the first red activation if the green PIR

LED activates first).

• Ifadequaterangecannotbereached,increasethe Micro-

wave Range Adjust slightly.Continue walk testing (wait-

ing one minute after removing/replacing the cover) and

adjusting the range until the farthest edge of desired cov-

eragehasbeen accurately placed.

Donotadjust the microwave range higherthanrequired.Doingsowill enable

thedetectorto catch movement outside of the intendedcoveragepattern.

• Walk test the unit from all directions to determine all the detection pattern

boundaries.

Establishing Detector Coverage

• Withnomotionintheprotectedarea,thetri-colorLEDshouldbeOFFbefore

walktesting.

• Walktesttheunit from all directions to determine the detection boundaries. A

detector alarm is signaled by the first red activation of the tri-color LED after

aninitial green or yellow activation.

Supervision Features

Thesupervision features function as follows:

•PIR/Microwave: If the PIR or microwave subsystem fails, the tri-color LED

will flash red four times per cycle. The complete circuit operation of these

subsystems is checked approximately every 12 hours.

•Default: Thedetector will default toPIR technology protection if the micro-

wavesubsystemfails.Whendefaultingto PIR, the PIR signal processing will

change from INT to STD.

Other Information

Maintenance: Atleast once a year, the range and coverage should be

verified. To ensurecontinual daily operation, the end user shouldbe instructed

to walk through the far end of the coverage pattern. This ensures an alarm

outputprior to arming the system.

Pattern Masking: The PIR coverage pattern may be masked using masking

tape or electrical tape on the inside of the lens.

NOTE: Masking only eliminates the PIR portion of the coverage and has no

effecton the microwave pattern.

www.PDF-Zoo.com