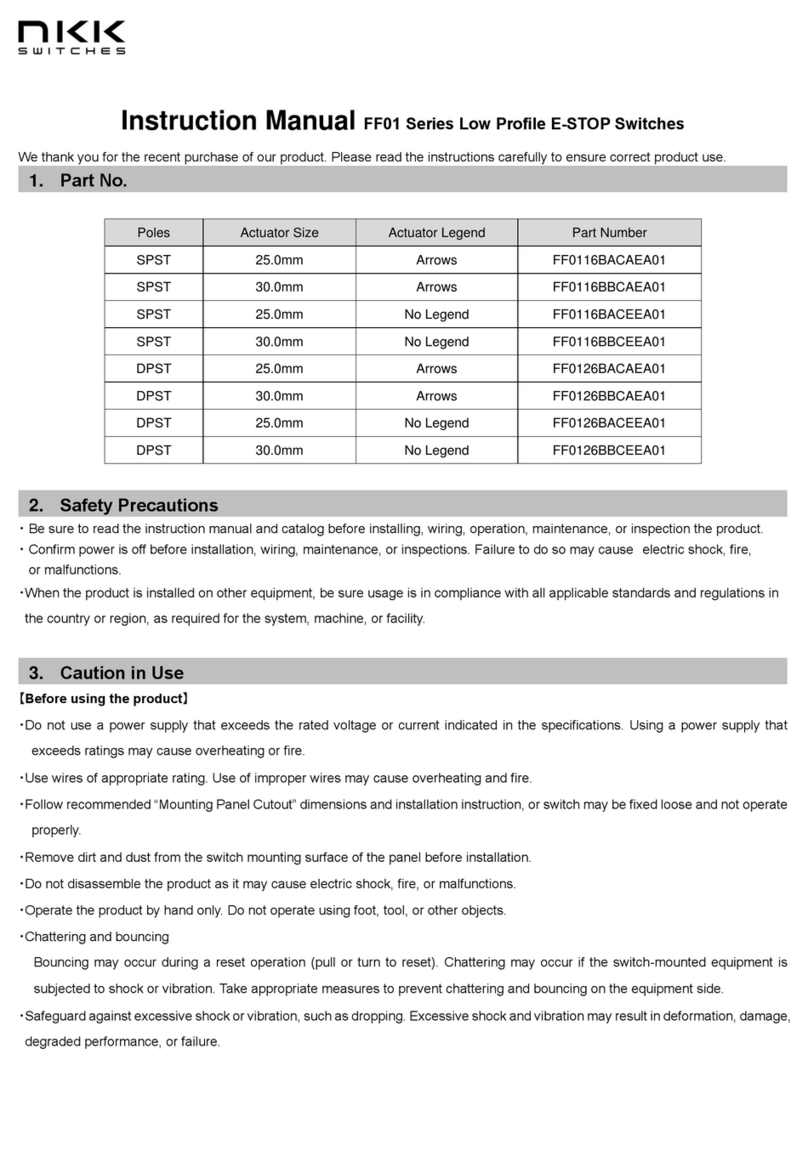

5. General Specifications

UL508/EN60947-5-1/EN60947-5-5

Rated Operating Voltage (Ue)

Rated Operating Current

Resistive Load (DC-12) 24 V DC 0.5 A

※UL, TUV certified rating

Rated Insulation Voltage (Ui)

Rated Impulse Withstand Voltage

Front panel: IP65 (IEC 60529)

Short-Circuit Protection Device

Conditional Short-Circuit Current

Ambient Operating Temperature

-25°C to +60°C (no freezing)

Ambient Storage Temperature

-45°C to +80°C (no freezing)

Push to lock: 10.8 N Pull to reset: 8.5 N Turn to reset: 0.13 N・m

Minimum force to achieve direct opening

action of all break contacts

Minimum travel including travel beyond

the minimum travel position

Maximum travel of actuator

50 mΩ maximum (initial value)

100 MΩ minimum (500 V DC megger)

Durability: 1,000 m/s2

Malfunction: 150 m/s2

Durability: 10 to 500 Hz half amplitude: 0.35 mm, acceleration: 50 m/s2

Malfunction: 10 to 500 Hz half amplitude: 0.35 mm, acceleration: 50 m/s2

Electrical Life/ Mechanical Life

Electrical Life/ Mechanical Life:100,000 operations

Minimum (resistive load), 6050 times

Minimum (inductive load (DC-13))

Recommended Fixing Nut Mounting

Torque

Effective Panel Thickness

Effective panel thickness of 0.8 to 4.5 mm

(Effective panel thickness range with a nameplate or switch guard of 0.5 to 3.0 mm)

* UL, TÜV certified rating

・UL/ TÜV certified rating: 24 V DC, 0.5 A (DC-13)

Minimum applicable load (reference value): 5V DC 1 mA

(Usage conditions and load types may affect the allowable operating range.)