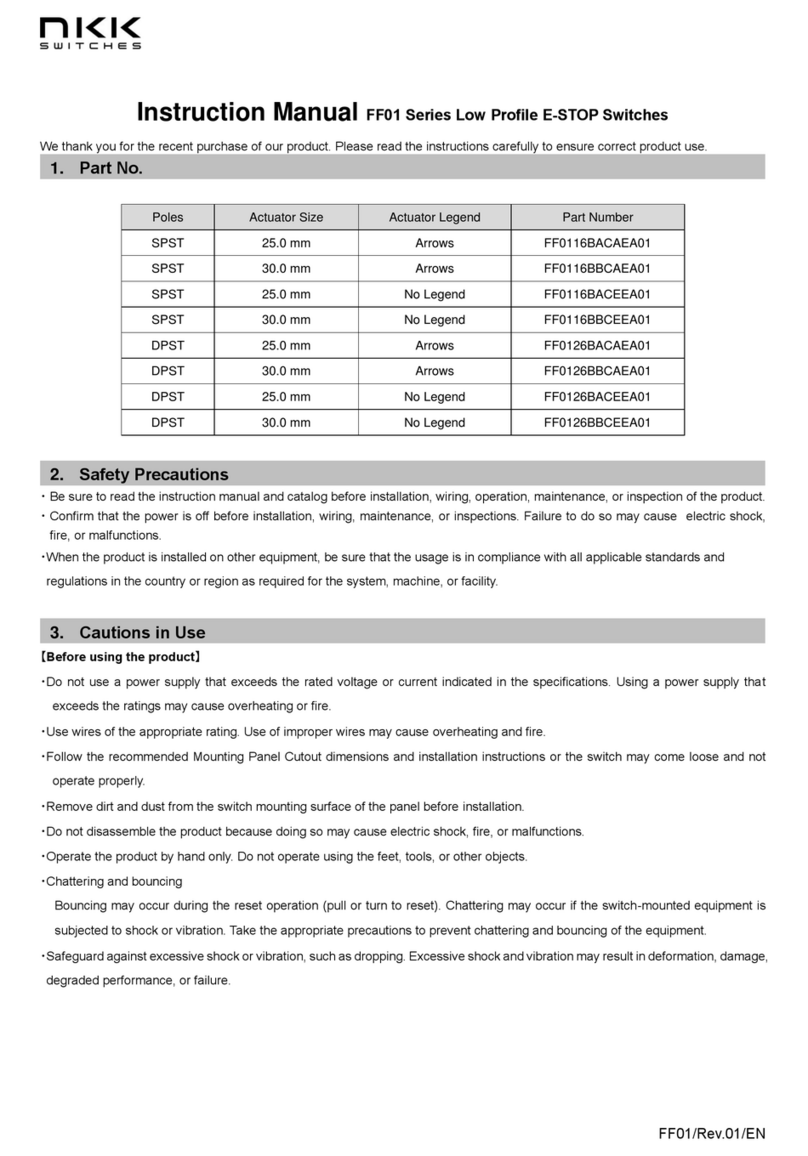

NKK SWITCHES FF01 Series User manual

Other NKK SWITCHES Switch manuals

NKK SWITCHES

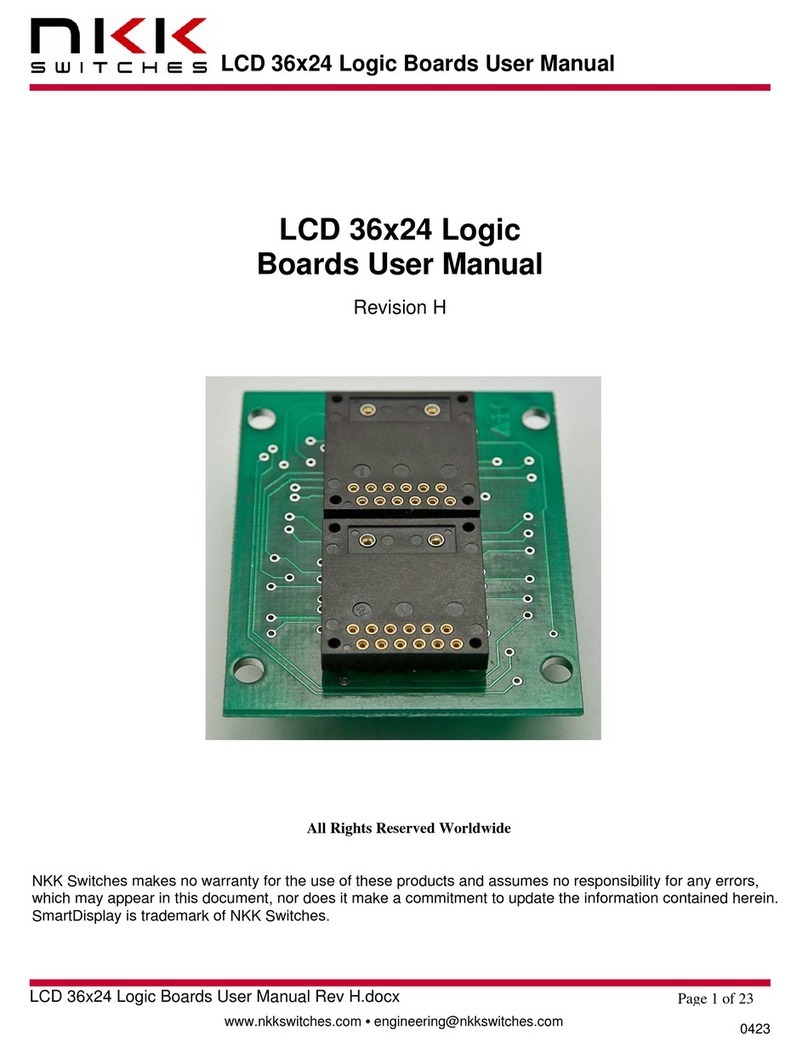

NKK SWITCHES LCD 36x24 Logic User manual

NKK SWITCHES

NKK SWITCHES FF01 Series User manual

NKK SWITCHES

NKK SWITCHES IS-S04G1LC-S User manual

NKK SWITCHES

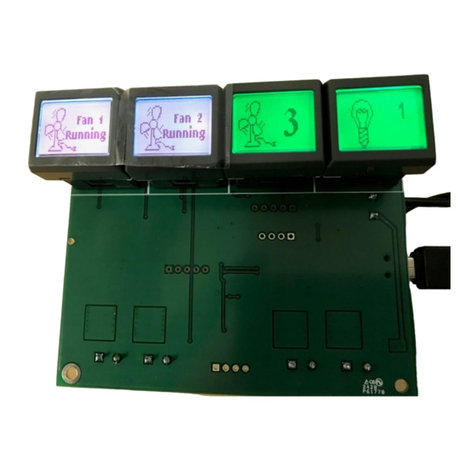

NKK SWITCHES SmartDisplay Keypad User manual

NKK SWITCHES

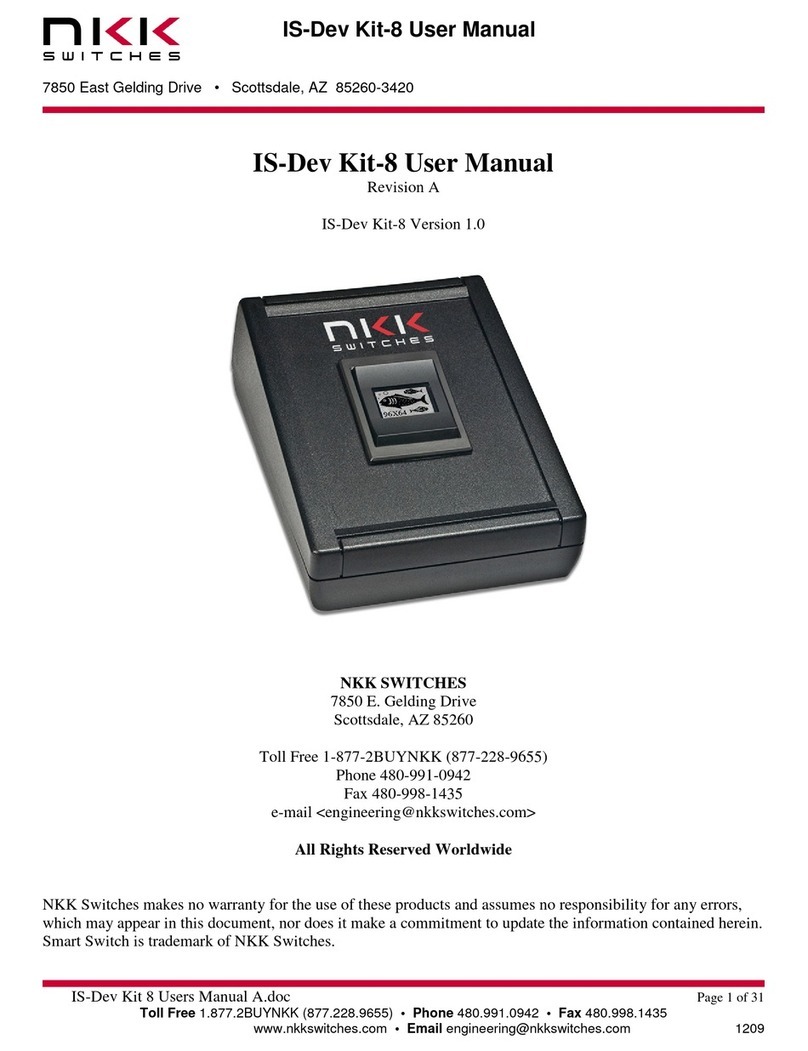

NKK SWITCHES IS-Dev Kit-8 User manual

NKK SWITCHES

NKK SWITCHES FF01 Series User manual

Popular Switch manuals by other brands

Digisol

Digisol DG-GS1528HP user manual

FIBARO

FIBARO FGS-2 3 Series operating manual

ADTRAN

ADTRAN 600 Series Interface guide

Avocent

Avocent DSR Series DSR2035 release note

Cooper

Cooper Crouse-Hinds CEAG KO operating instructions

Brooks Instrument

Brooks Instrument IPS122 Series Installation and operation manual