6

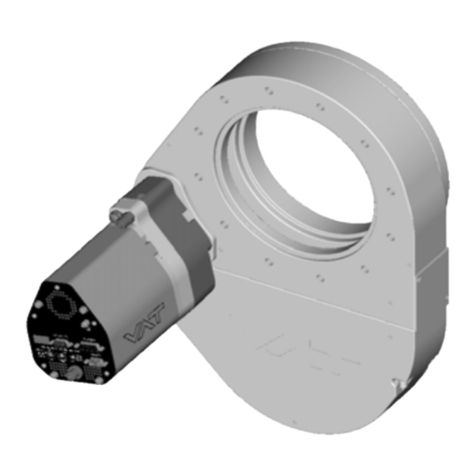

Electrical Interfaces .................................................................................................. 23

Main electrical interface .................................................................................... 24

Fast wavelength modulation input ................................................................. 24

Laser Control ............................................................................................................. 24

User interface ...................................................................................................... 24

Status LEDs ................................................................................................................26

Module labels ............................................................................................................ 27

Section 2 OPERATING THE LASER 29

2 Communicating with the Laser ...................................................................................... 31

CONTROL software .................................................................................................. 31

Installing the software ........................................................................................ 31

Software Development Kit ...................................................................................... 31

Generic User Interface ....................................................................................... 31

Connecting the laser to a PC with CONTROL .................................................. 32

Connecting the laser to a PC using the Generic User Interface .................. 34

3 Turning On the Laser ...................................................................................................... 35

Safety ........................................................................................................................... 35

Preparation ................................................................................................................. 35

Controlling the laser emissions ............................................................................ 36

Turning On the laser .......................................................................................... 36

4 Using CONTROL ............................................................................................................... 39

CONTROL overview ................................................................................................ 39

Relocating panels ............................................................................................... 40

Toggling panels .................................................................................................... 41

Connecting to the laser ...................................................................................... 41

Status panel ................................................................................................................ 41

Status indicators .................................................................................................. 42

System info ........................................................................................................... 42

Emission button ................................................................................................... 43

CONTROL settings ............................................................................................. 43