Nocchi FCD20/VLR16 Series User manual

GRUPPI DI PRESSIONE A VELOCITA’ VARIABILE

FREQUENCY - CHANGER

IManuale di uso e manutenzione

GB Use and maintenance manual

FManuel d’utilisation et d’entretien

DBedienungs - und Wartungsanleitung

EManual de uso y manutenciòn

NL Handleiding voor gebruik en onderhound

PL Recyzny uzywaine i obslugi

RUS Bycnherwbb gj ecnfyjdrt bBycnherwbb gj ecnfyjdrt b

Bycnherwbb gj ecnfyjdrt bBycnherwbb gj ecnfyjdrt b

Bycnherwbb gj ecnfyjdrt b

aeyrwbjybhjdfyb/aeyrwbjybhjdfyb/

aeyrwbjybhjdfyb/aeyrwbjybhjdfyb/

aeyrwbjybhjdfyb/

pag. 1

,, 12

,, 23

,, 34

,, 56

,, 67

,, 78

pag. 45

Chap.1 – General information

Chap.2 – Limits of use

Chap.3 – Hydraulic Installation

Chap.4 – Priming of the group

Chap.5 – Electric connection

CONTENTS

Chap.6 – Starting up

Chap.7 – Modification in configuration and working

parameters

Chap.8 – Failure messages

Chap.9 – Operation without inverter

12

GENERALSAFETYWARNINGS

Warningsforthesafetyofusersandobjects.

Payparticular attentiontothesignsand theirsymbols

DANGER

Risk of electrical

discharge.

DANGER

WARNING

The nonobservance of instructions may lead to risk of electrical

discharge.

Thenonobservanceofinstructionsmaycausedamagetopeopleand/

orthings.

Thenonobservanceoftheinstructionsmayleadtodamageofthemotor

pump.

CAUTION:beforeassembling,carefullyreadthecontentsofthismanual.Thenonobservanceoftheinstructions

will result in the annulment of the warranty.

Chap.1 – General Information

Our pressurization groups must be installed in premises protected against bad weather and frost, well ventilated and

in a non dangerous atmosphere. Each of our groups is entirely tested in our establishments.

Upondelivery, check thatthe group hasnot suffered anydamageduring transportation; inthis case, contactimmediately

the retailer. In case of claims, contact immediately the retailer within eight days of purchase.

Chap.2 – Limits of use

Our pressurization groups are constructed for the raising clean water without solid suspended particles or abrasive

materials.

WARNING The group is not suitable for pumping chemically aggressive or

inflammable liquids.

WARNING Avoidanydry-operatingofthemotorpump.

MAXIMUMTEMPERATUREOF THELIQUIDPUMPED 40°C

MAXIMUM/MINIMUM AMBIENT TEMPERATURE 40°C

Chap.3 – Hydraulic installation

DANGER

Risk of electrical

discharge.

All the assembly operations must be carried out with group

disconnectedfrom the power grid.

In the case where the pressurization group is fed by a tank, avoid any unpriming phenomena; we recommend to

control the following characteristic data:

- static level (initial level of the well)

- dynamic level (level reached during the group operation)

- flow rate

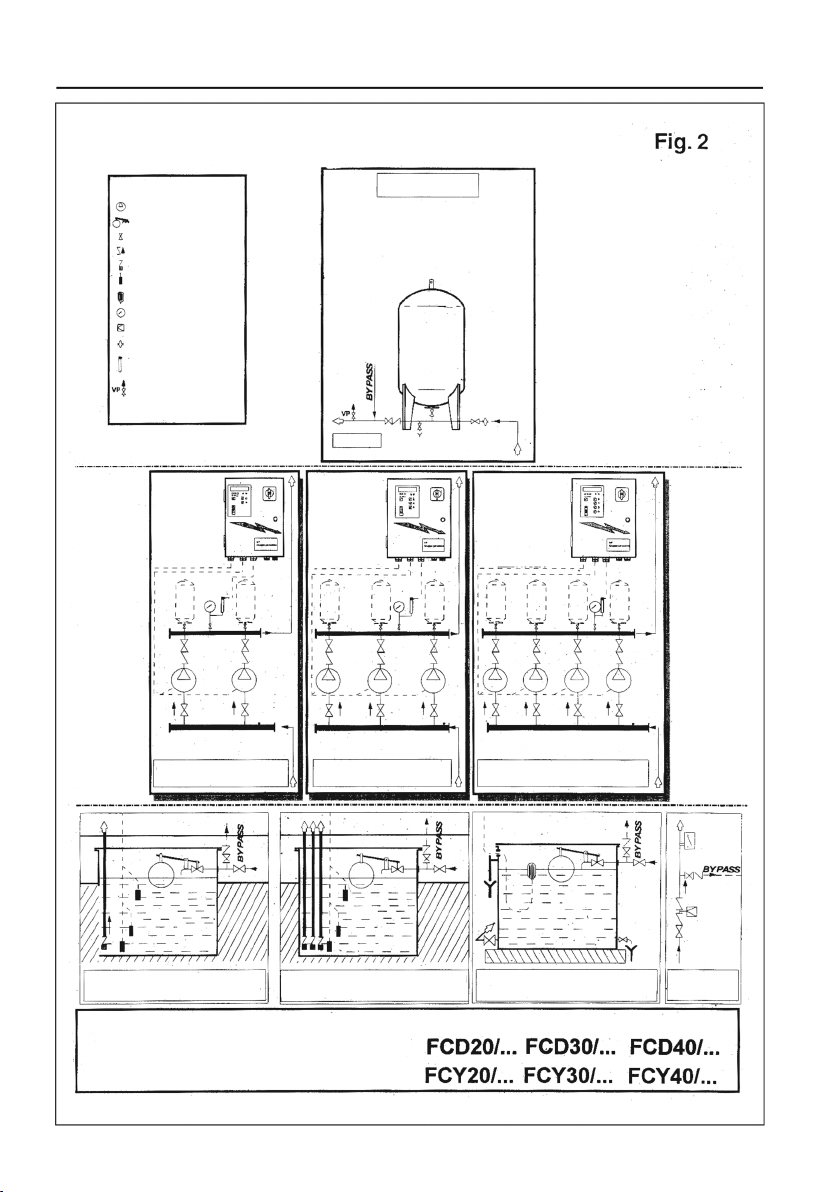

Fig.2 shows the assembly diagrams normally used.

GB

DANGER

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

13

To reduce losses during replenishment it is necessary to install the group as close as possible to the pumping point

and to install a suction pipe with a minor number of curvatures that should have a sufficiently wide radius.

Even the diameter of the pipe should be calculated so as to reduce load losses, what requires dimensions greater

than or equal to those of the motor pump aspiration inlet.

In order to avoid the formation of air locks into the suction pipes, these ones must have a positive gradient, from

bottom to top, avoiding countergradients or “goosenecks”, and there must not any infiltration in the connections.

Connect the delivery collector to the distribution collector by interposing vibration-damping joint.

This connection can be done either on the right side or on the left side of the collector by displacing the blind flange

or the threaded cover.

WARNING It is a good rule to foresee the evacuation of water losses in case of

bad seal of joints, mechanical seal, tanks overflowing.

In the case where there would not be any pumping in close proximity from the group, on the discharge line, the

installation of a test faucet is recommended.

It is necessary to control from time to time the pre - replenishment pressure of membrane vessel that must be 0.2

bar lower than the minimum closing pressure of the pressure switch calibrated lower.

This control must be done without pressure in the installation or with the tanks disassembled.

Chap.4 – Priming of the group

DANGER

Risk of electrical

discharge

Alwaysshut off the voltage beforeproceeding to any operation.

WARNING Thegroup needs to be filledupbefore putting it in operation.Thedry-

operationof the motor pump damagesthe hydraulic parts.

In case of aspiration with upper suction head, open storage, aqueduct or water pipe under pressure, prime the group

as follows:

- open all valves and remove the priming plugs on the aspiration collector and on the motor pumps

- open the water supply on-off valve until the evacuation of the liquid

- close again the feed faucet and the pumping plugs

In the case where the group supply is with lower suction head, underground well or tank, prime the group as follows:

- open all valves and to and remove the priming plugs on the aspiration collector and on the pumps

- fill with water through the suction pipe

- make the necessary topping-up through the priming plugs on the pump casing until complete filling-up

- re assemble the plugs

See fig.2

DANGER

Risk of electrical

discharge

WARNING

Check that the power supply is provided with an efficient ground

installation which conforms with the regulations in force.

Check that the voltage and frequency indicated on the data plate

correspondtothoseoftheavailablepowergrid.

WARNING the power supplyis equipped with differential circuit breakerwiththe

sensitivity required by the regulations in force for this type of

equipment.

Chap.5 – Electric connection

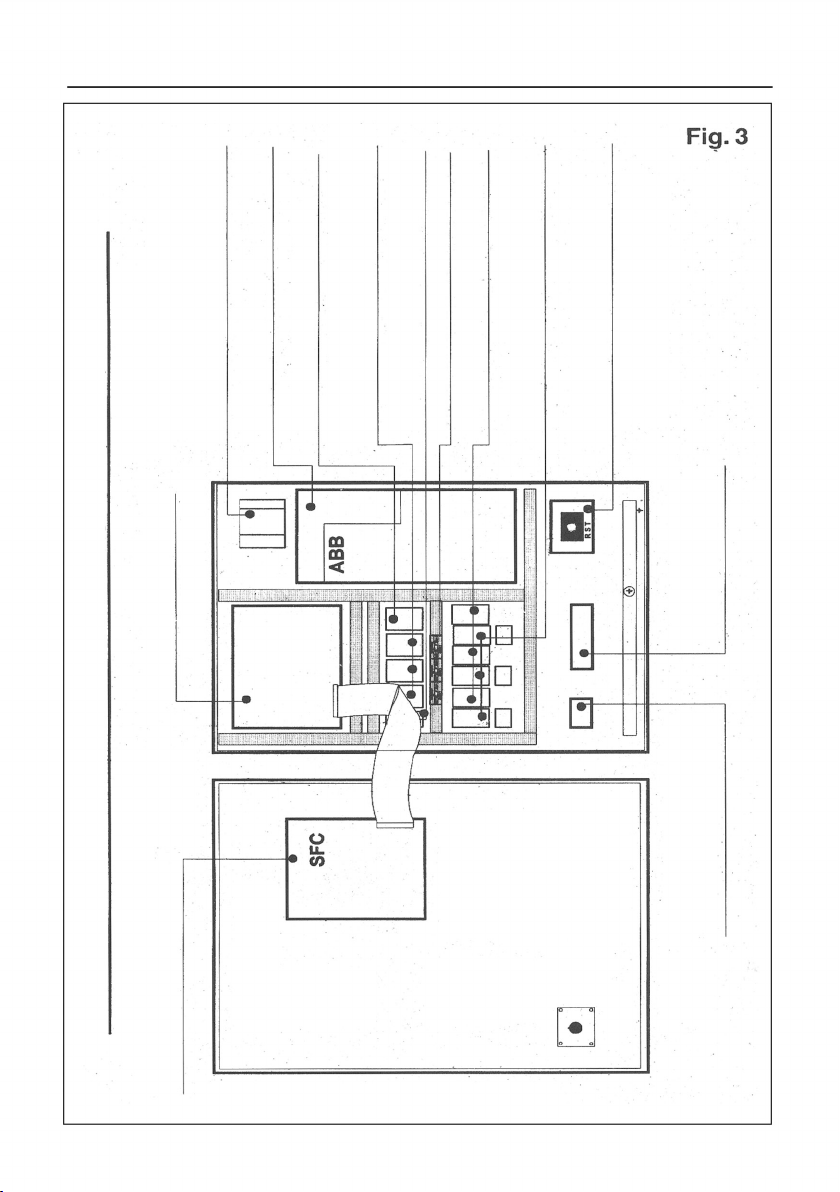

See fig.3-4-5 and other schemes reported on the switchboard

GB

14

WARNING Before connecting the powersupplycableto the control board, check

that it has sufficient dimensions to support the maximum voltage

requiredbygrouppumps.

WARNING The connection of the distribution boards to the power grid must be

doneaccordingtoindicationsreported ontheelectricconnectionscheme

situated in the control board.

DANGER

Risk of electrical

discharge

Thesubstitutionofelectricandelectroniccomponentsmusttobedone

by a skilled staff.

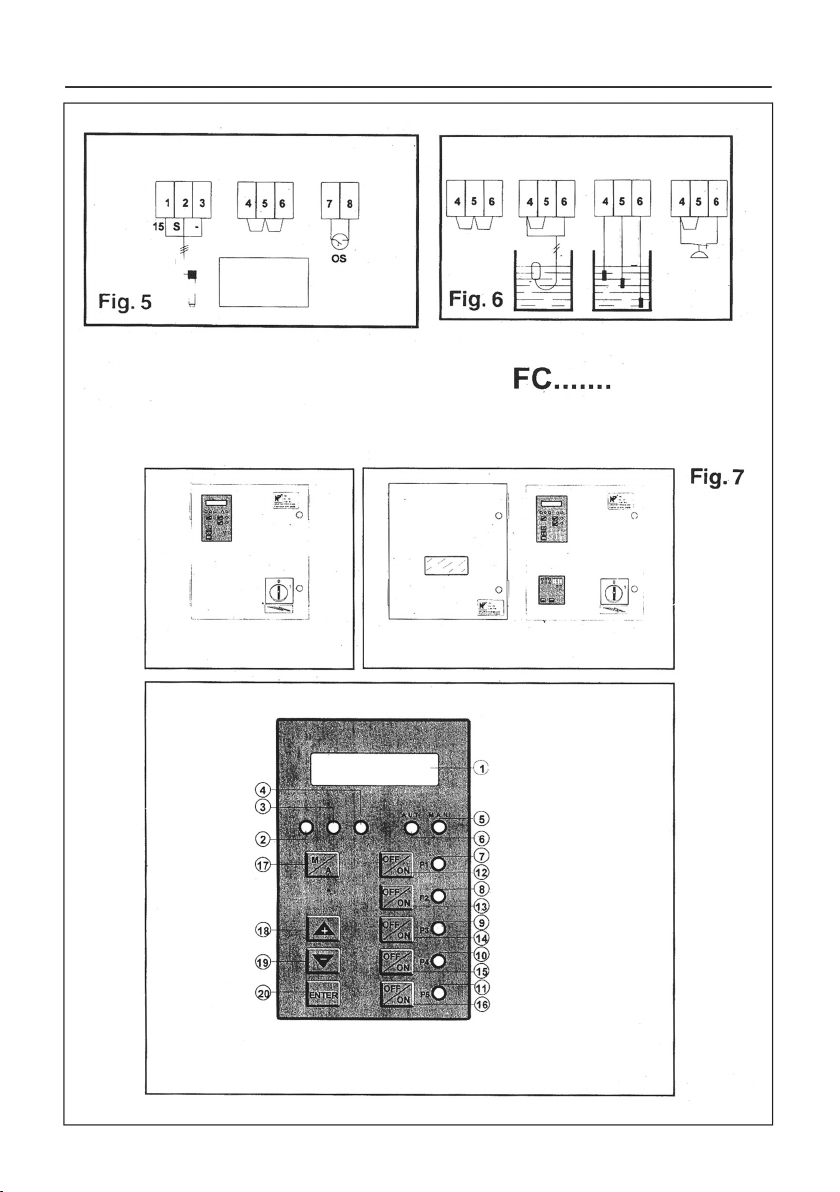

Protection against the dry-operation of the motor pumps (See fig.6)

On the switchboard it is possible to connect a device for control of the level into the tank. (Our groups are delivered

with jumped terminals 4-5-6)

WARNING In this case the group is not protected against dry-operation. It is

therefore necessary to remove the electric jumpers and to connect

them to the control device chosen as follows:

1) float switch

The float must be installed in the tank and connected thanks to two wires to the special terminals on the control board.

2) electronic control with probes

The three probes should be specially placed in the first collection deposit and should be then connected to terminals

inside the board. The COMMON probe must be installed at the lowest level in the tank and anyway always at a level

lower than the minimum level probe (LOW) that prevents from the working of the pilot pump when water descends

below this level. The maximum level probe (HIGH) allows again the working of the pilot pump when the water reaches

this level.

3) Inverted minimal pressure sensor

In the case where the group is fed by a water duct under pressure (for example municipal water system), it is

necessary to install a minimal pressure sensor which prevents from the working of the group if the pressure in the

duct descends below the preset value.

Chap.6 – Starting up

See fig.3-4-5-6-7-8 and diagrams in the distribution board.

Control of the direction of rotation of the pump with inverter drive.

Once all the hydraulic and electric connections have been done for the hydraulic priming of the pumps and collectors,

proceed as follows:

- close all the valves of the distribution system

- open all the valves of the group, included those of the membrane ways

- control the closing of the distribution board hatch

- place the power supply disconnector on I (ON)

DANGER

Risk of electrical

discharge

Warning: from this moment any operations on pump ducts, pressure

transducer, pressure sensor, etc. must be done after having cut the

voltage off from the distribution board.

The following message (1) will be displayed

- a small bell will give out a set of beeps

- the green LED (2) will lit

Push the key until the following message is displayed

NOCCHI PUMPS

Bar 05.0

LINEA

M

A

GB

15

Control of pump priming (see Fig. 9).

The installation is prepared for MANUAL working

Push key (2) : n.1 pump will enter in function; push again the same key to stop the pump and to control

the sense of rotation of pump n.2 pump therefore the one of all other.

In the case where pumps would not turn all in the same sense, before proceeding to the correction check sense

of rotation of pumps directly fed (and no from an inverter).

Check the sense of rotation of pumps directly started

With the installation and the switchboard set for manual working, press key (12)

Pump n.1 will enter in function controlled by the inverter and, while maintaining it in operation, start pump 2 by pressing

the key (13). Premere nuovamente lo stesso e controllare il senso di rotazione della pompa n. 2.

Do the same operation on all other pumps, always with pump n.1 in operation. Stop pump n.1; enable pump n.2 as

first pump and check the sense of rotation of pump n.1.

- if pumps, either fed by an inverter or fed directly, have an inverted sense of rotation, proceed as follows:

DANGER

Risk of electrical

discharge.

Cutoffthegeneralvoltageandreversetwophasesofthepowersupply

cable of the switchboard.

- If on the contrary the sense of rotation of the pumps is inverted only when fed by inverter, proceed as follows:

DANGER

Risk of electrical

discharge.

Cutthe general voltage and reverse two phasesofpower supply cable

on the inverter (outlet terminal of the inverter)

WARNING The inversion of power phases of the inverter does not produce any

effect on the sense of rotation of the pumps.

- if one or several pumps supplied by the inverter do not have the same sense of rotation, proceed as follows:

DANGER

Risk of electrical

discharge.

Cut the general voltage off and reverse two drivers on power supply

leads on the inverter contactor of the pump in question.

- if one or some of the pumps directly fed have a reversed sense of rotation, proceed as follows:

DANGER

Risk of electrical

discharge.

Cut the general voltage off and reverse two leads on power supply

terminals of the contactor (or of direct contactor) of the pump in

question.

WARNING WARNING: before proceeding to control the priming of the pump,

checkthattheirmaximumpressure,reportedonthesamepumpplate,

is compatible with the pressure supported by the installation and by

facilities and that the possible safety valves have an intervention

value higher than the one of the maximum pump pressure.

By keeping closed all collecting valves

DANGER

Risk of electrical

discharge.

Acting on the main switch, cut voltage off on switchboard, open the

shutterandpositionn.1switchon TEST and all others on EXCLUSION.

MANUAL FUNCTION

Bar 05.0

OFF

ON P1

OFF

ON P1

OFF

ON P2

GB

16

Close the board and give voltage; pump n.1 pump will enter in function, control that network pressure reaches the

maximum value. In the contrary case perform again the operations of replenishment of the aspiration collector until

the body of the pump. Repeat the operation on all pumps of the group.

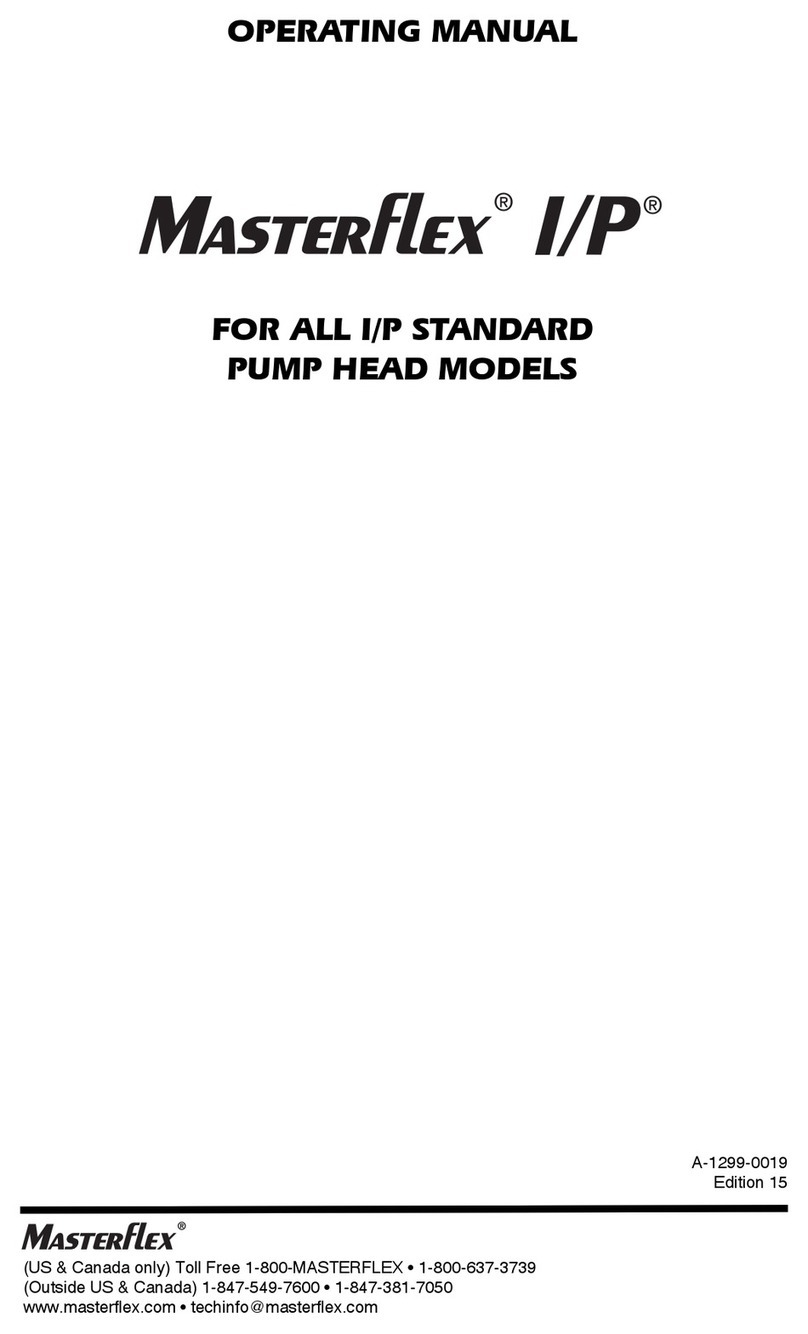

Automatic starting up of the group (see fig.7-8).

After having put under pressure groups while manipulating the pump by hand, cut voltage off switchboard by

positioning the main switch on 0 (OFF).

Wait some seconds and send current to the switchboard: the green LED will lit and the small bell will give out

some beeps. The following message will be displayed:

The green LED will lit.

From this moment the groups will function automatically according to water flow withdrawn by the user.

Modification of the working pressure (see fig.7-8)

To change the value of the working pressure, maintain closed all drawings, rotate the main switch of the switchboard

on I (ON), press key (17) until the red LED will lit (manual working).

M

A

AUT

NOCCHI PUMPS

Bar 05.0

LINEA

WARNING WARNING: in all examples that follow (pressure, time, YES/NO etc…)

XXletterscanbeascribed or to indicative values (eg: 0.5 bar).Actually,

the parameters wished by the user shall be entered.

The following message will be displayed:

MANUAL FUNCTION

Bar 05.0

PROGR MENU.

INVERTER

THRESHOLD

Push the key (20) until the following message will be displayed:

SET POINT

Bar 05.0

Corresponding to the pressure value that the group will maintain in the delivery collector.

By using the combination of keys set the pressure parameter at the value desired.

At the end of the operation the following message will be displayed:

ENTER

STOP THRESHOLD

Bar 05.0

Corresponding to the pressure value of the last pump. Normally is set to a value of 0.5 bar at the SET POINT

pressure.

By using the combination of keys set the pressure parameter at the value desired.

At the end of the operation the following message will be displayed:

PROGR. MENU

TEMP. KICK STOP

ENTER

+-

ENTER

+-

MAN

GB

17

To exit from the programming mode press several times key (19)

PROGR. MENU

TEMP. KICK STOP

PROGR. MENU

INVERSION

PROGR. MENU

EXIT

MANUAL FUNCTION

Bar 10.0

NOCCHI PUMPS

Bar 05.0

-

--

- -

M

A

By pressing key (17) the unit will begin to function in AUTOMATIC

Chap.7–Change configuration and operational parameters

See fig.7-8

The program includes two menus:

1) Configuration menu of the machine and authorization to access calibration menu

2) Menu for the regulating of the working and calibration parameters

1) Configuration and access parameters of the machine and calibration menu

To access the menu, the board must be fed and set for the MANUAL working of the pump.

Check that all drawings are tightly closed and that the water distribution network is cut. Bring the general switch of

the switchboard to position I (ON). While the small bell gives out some beeps, press the key until the following

message will be displayed:

M

A

MANUAL FUNCTION

Bar 05.0

Press key (20) for about 10” up to when the following message will be displayed:

ENTER

- Line n. 1 - NUMBER OF PUMPS

By acting on keys it is possible to change the number of pumps controlled by the program.

Minimum 2 pumps

Maximum 5 pumps

- Line N.2 - SYSTEM STABILITY

This parameter determines a start-up delay time of pumps 3–4–5 which is added to the one set as start in menus 8

Minimum value 0

Maximum value 4

SYSTEM STABILITY – Time schedule in tenth of seconds (1/10”)

Set value

Pump 3

Pump 4

Pump 5

0

7

6

5

1

8

7

6

2

9

8

7

3

10

9

8

4

11

10

9

ENTER

+-

NUMBER OF PUMPS 5

STAB. SYSTEM 4

3

GB

18

- Line n.1 TRANSLATOR

Non modifiable description

- Line n.2 VALUE MAXIMUM BAR XX

The maximum value of the pressure transducer must be entered. Normally in our standard groups a transducer 0-5V

0-10 bar is used, therefore value 10 must be entered for this transducer.

TRANSDUCER

VALUE MAX Bar 10

4

MENU ACCESS

TOTALYES/NO

5

- N.1 line ACCESS MENU

Description non modifiable

- N.2 line TOTAL XX

YES permits to access menus 8–9–10

NO disable access to menus 8–9–10

Menu 6 regulating of operational parameters is accessed to by pressing key (20).

2) Menu for regulating operational and calibration parameters

The access to this menu is direct from configuration menu 1, otherwise proceed as follows:

check that all drawings are closed or that the water distribution network is cut. Bring the main switch to position I (ON).

While the small bell gives out some beeps, press the key, until the following message will be displayed:

M

A

MANUAL FUNCTION

Bar 05.0

ENTER

Press key (20) for about 2” until the following message will be displayed: appears the menu

ENTER

PROG MENU.

THRESHOLD

INVERTERS

6

Press key (20) ENTER

SET POINT

Bar 05.0 6a

- Line n.1 SET POINT

Indicates pressure value of the group

Following option

STOP THRESHOLD

Bar 05.0 6b

Line n.1 STOP THRESHOLD

- Indicates pressure stop value of the pump controlled by the inverter.

This function makes it possible to load membrane vessel to value superior than the one of the regulation pressure,

so as to allow a higher reserve of pressurized water and therefore a longer detention time.

GB

19

MENU PROGR.

TEMP. KICK STOP

7

Press key (20) ENTER

K.S DELAY.

10

05 7a

KS identifies the function inserted for stopping the pump controlled by the inverter. At time intervals corresponding

to the KS value established, the inverter feeds the pump at the maximum frequency (50 Hz) during the time set in

menu 7b - length KS.

Line n.1 DELAY KICK STOP

minimum interval 0 seconds (disabled)

maximum interval 99 minutes and 99 seconds.

KS LENGTH

05 /10 7b

- Line n.1 LENGTH KICK STOP

Minimum 0/10 seconds

Maximum 99/10 seconds

If during this period the pressure of installation reaches the value set in point 6b STOP THRESHOLD, the pump stops,

otherwise the modulation starts again.

If at option 5, NO has been inserted, the menu next is:

PROGR. MENU

EXIT

Which makes it possible to exit the programming.

Vice versa, if YES is entered, the following option is displayed

PROGR. MENU

DIRECT THRESHOLDS

Press key (20) ENTER

Bar PO: 2

Max04.2 Min03.7

For every pump successive to the first, it is possible to establish the pressure value appropriate for startup (Min.)

and for stop (Max.). The minimum pressure must be lower than the value ascribed to the SET POINT. The maximum

pressure must be higher than SET POINT value and lower or equal to the STOP THRESHOLD VALUE. The minimum

pressure ascribed to a pumps must be lower than the maximum one. The values ascribed to each pump are

interdependent and, except in particular needs of the plant, they can be the same for all pumps directly operated.

Example

STOP THRESHOLD

MAX PRESSURE

SET POINT

MIN PRESSURE

5.5

5,0

5,3

4,7

5,3

4,7

5,3

4,7

5,3

4,7

BAR PUMP 2 PUMP 3 PUMP 4 PUMP 5

GB

20

Note

The number of pumps that do not compose the group has no connection with the numbering used by the

microprocessorprogram.Infacttheprogramlogicconsiders as pump 1 the one that leaves first; pump 2 the one

that leaves for second and so on. The choice of the pump that leaves first (that can be n.3 or n.4 or n.5 or n.2 or

n.1) is carried out by the section of the program that manages the logic of inversions and commands.

PROG MENU.

DIRECT TEMP.

9

By press key (20) the following option is displayed:

ENTER

P.2 TEMPORIZATION

START 8 STOP 0 9a

- Line n.1 TEMPORIZATION P.2

Description non modifiable

- Line n.2 START XX

Indicates delay time, in seconds, for starting the second pumps in the presence of suitable pressostatic conditions

for startup.

Minimum 0 tenth of seconds.

Maximum 99 tenth of seconds.

- Line n.2 STOP XX

Indicates delay time, in seconds, for stopping the second pumps in the presence of suitable pressostatic conditions

for stoppage.

Minimum 0 tenth of seconds.

Maximum 99 tenth of seconds.

Follows the insertion of START and STOP parameters of the other pumps.

PROGR. MENU

INVERSION

10

By pressing key (20) the following option will be displayed:

ENTER

- Line n.1 CYCLIC BLOCKAGE XX

YES The inverter is associated to the pumps indicated in the second line.

CYCLIC BLOCK = YES

BLOCK OF PUMP 3 10a1

BL. CICLICO NO

CONTR.ESTERNO NO 10a2

- Line n.1 CYCLIC BLOCKAGE XX

NO

- Line n.2 EXTERNAL CONTR. (external control)

NO

The inverter is moved on the different pumps according to the logic of the cyclic inversion of the program at the end

of each working cycle.

If

- Line n. 2 EXTERNAL CONTROL

YES

The inverter is moved on the various pumps according to the cyclic inversion logics of the program at the successive

starting up after the closing of an external contact (for example: timer) or after the closure of an external contact

(example: daily timer). In this case the change of pump under inverter occurs after the first pause (the external

contact must be of short length and in any cases opened before the operational pause of the group).

GB

21

Cyclic inversion logics: at every beginning of the working cycle, the pump which has been last started is enabled

first. During the working of the group the pumps controlled directly are stopped in reverse order respect to the

one start up order.

Example: GROUP WITH 4 PUMPS

First pump started up controlled by the inverter of pumps 2

Second pump started up direct control of pump 3

Third pump started updirect control of pump 4

If the drawing is reduced, pump 3 is the first to stop, then pump 4

After the stop of all the pumps:

First pump started up controlled by the inverter of pumps 3

Second pump started up direct control of pump 1

Third pump started up direct control of pump 2

PROGR. MENU

EXIT

11

By pressing key (20) the system returns to MANUAL WORKING - red LED lit.

By pressing key (17) he green LED (6) s lit and the system begins to function automatically.

ENTER

MAN

M

A

AUT

Chap.8 – Failures

In case of system failure , the following messages can be displayed on the control board:

STOP FOR

LOW WATER LEVEL

A1

SYSTEM INVERTER

BLOCKED - RESET

A2

TEMP. P 3 4

Bar 04.6

A3

Explanation of messages (see fig.6)

1) Lack of water in withdrawal tank

The level control signals the lack of water in the withdrawal tank, or low pressure in the feed duct(aqueduct). At the

same time the red LED - BLOCKAGE LEVEL shall be lit. The same thing occurs in case of false contacts or absence

of level control if the relative terminal have not been short-circuited.

2) Blockage inverter

The inverter is blocked. The reason of the blockage is indicated on inverter display whose manual gives detail of the

position intervened. If the reason is accidental: momentary overcharge of the motor pump (example excessive

request of water), or electric too high or too low voltage, by pushing the RESET key situated on the inverter keyboard,

the system be reset. Otherwise cut the voltage off the switchboard for a few seconds and connect it again. In case

of failure, repeat the operation a second time.

If the blockage persists, it is possible to disable the inverter following the instructions reported in the following

chapter.

3) Thermal blockage

In case one the thermal relays protecting against overcharge or lack of power supply of the motor operating directly

(not controlled by the inverter) is tripped, in addition of the message on the display, the red LED (4) ANOMALY is lit

(the same of INVERTER BLOCKAGE). In this case the programs automatically excludes the pump or pumps that

generated the event and the group operates regularly, even if with a reduced rating. In order to reset, after having

verified the accidental origin of the overcharge, press the resetting lever situated on the thermal relays concerned.

GB

22

Chap.9–Exclusion of the inverter

In case of breakdown of the inverter, while waiting for the appropriated repair intervention, the group can operates

automatically or manually:

1) Automatic operation

The motor pumps are operated by an SFC card on pressure levels.

In this case it is necessary to cut the voltage off the switchboard and open the protective fuse-holder of the inverter

(see fig.3). It is therefore necessary to increase the value of STOP THRESHOLD following the indications reported

in chap.6 – starting up in point Modification of the working pressure established. The value of SET POINT

represents the startup pressure of the first pump. The one of STOP THRESHOLD indicates the value of stop pressure

of the last pump. The difference between these values must be of at least 1 bar.

Example

SET POINT 5.0 bar

STOP THRESHOLD 6,. bar

If tanks under pressure connected to the delivery collector of the group have a sufficient volume, the installation will

get back in function in the pressure range established (one of pumps, the one that should have been started up

controlled by the inverter will remain in stop). If one observes an abnormal operation (frequent starts up and stops

of pumps) it will be necessary to modify the pressure values established for every pump as described in point 2) of

Chap.7.

2) Manual working (see fig.9)

Theselectorssituated insidethe switchboardmakesit possibletooperate allpumps withexclusionof theinverter,

theSFC keyboard and thecard YES. If the selectoris in vertical position(EXCLUSION: the related pumpcannot

operates).

WARNING WARNING:inthiscasethe pumps can operate only if thewaterispumped

bythe user.Theworking of pumpswithoutpumpingmay cause damageto

pumpsandthegroup.

GB

Electropump

Float valve

On-off valve

Check valve

Standing valve with

filter

Level control

electrode

Level switch

Gauge - Vacuum

gauge

Hydraulic circuit

breaker

Flexible coupling

SYMBOLS USED AUTOCLAVE WITH

MEMBRANE DIAGRAM

USER

ELECTRIC

POWER SUPPLY

ELECTRIC

POWER SUPPLY

ELECTRIC

POWER SUPPLY

FC 20/ GROUP...

2 PUMPS MODULATED IN SPEED

FC 30/ GROUP...

3 PUMPS MODULATED IN SPEED

PRESSURE GROUP FC.40/..

4 PUMPS MODULATED IN SPEED

UNDERGROUND TANK WITH

ONE ONLY SUCTION

UNDERGROUND TANK WITH

INDEPENDENT SUCTION EXTERNAL TANK PRESSURE

DUCT

TYPICAL DIAGRAMS OF INSTALLATION

SERIES GROUPS

89

INTERNAL ARRANGMENT OF THE ELECTRIC BOARD COMPONENTS

FREQUENCY – CHANGER

CARD INTERFACE CARD

AUXILIARY DEVICE TRANSFORMER

INVERTER

FUSE CARRIER INVERTER

FUSE CARRIER DIRECT PUMPS

FUSE CARRIER AUXILIARY DEVICE

AUT – 0 – TEST SELECTOR

INVERTER PUMPS CONTACTOR

DIRECT PUMPS CONTACTOR

MAIN SWITCH

(ELECTRIC POWER SUPPLY)

ELECTROPUMPS

TERMINAL BOARD

EXTERNAL DEVICES

TERMINAL BOARD

SI

90

FREQUENCY CARD - CHANGER

WITH KEYBOARD

INVERTER INTERFACE CARD

PRESSURE

SENSOR

INVERTER

REMOVE THE

JUMPERS AND

CONNECT THE

CONTROL OF

SELECTED LEVEL

LEVEL CONTROL

TIMER FOR

TIMED

EXCHANGE

(OPTIONAL)

TERMINAL

BOARD FOR

POSSIBLE

PRESSURE

SWITCHS

(CHECK

AUTOCLAVE

VOLUME)

TERMINAL BOARD DEVICES OUTSIDE ELECTRIC BOARD

ELECTRIC

POWER SUPPLY

380 V 50 Hz

ENGINE VARIABLE

SPEED POWER

SUPPLY LINE

ELECTRONIC CARDS - INVERTER - EXTERNAL DEVICES TERMINAL

BOARD INTERCONNECTION DIAGRAM

Free

Free

High

Low

91

TERMINAL BOARD DEVICES OUTSIDE ELECTRIC BOARD LEVEL CONTROL CONNECTION

PRESSURE

SENSOR

REMOVE THE

JUMPERS AND

CONNECT THE

CONTROL OF

SELECTED LEVEL

LEVEL CONTROL

TIMER FOR

TIMED

EXCHANGE

(OPTIONAL)

NO CONTROL FLOAT ELECTROPROBE

MINIMUM

PRESSURE

SWITCH

HIGH

LOW

COMMON

PRESSURE GROUPS

FREQUENCY CHANGER MODEL

ELECTRIC BOARDS AND ELECTRONIC CARD KEYBOARD

CONTROL BOARD WITH

INVERTER INVERTER BOARD CONTROL BOARD

ELECTRONIC CARD KEYBOARD

Red indicator light anomaly

Red indicator light

thermal trip

Green indicator light line

present

Selection push button

Man / Aut

Menu increment push

button

Menu decrement push

button

Menu access and

confermation push button

2 lines 16 characters display

Red indicator light manual operation

Green indicator light automatic operation

Green indicator light no. 1 pump operation

Manual operation push button pump no. 1

Green indicator light no. 2 pump operation

Manual operation push button pump no. 2

Green indicator light no. 3 pump operation

Manual operation push button pump no. 3

Green indicator light no. 4 pump operation

Manual operation push button pump no. 5

Green indicator light no. 5 pump operation

Manual operation push button pump no. 5

LINEA

BLOCCO

LIVELLO ANOMALIA

92

NOCCHI PUMPS

Bar 05.0

MANUAL FUNCTION

Bar 05.0

NUMBER OF PUMPS 5

STAB. SYSTEM 4

TRANSDUCER

VALUE MAX Bar 10

MENU ACCESS

TOTAL YES/NO

PROG. MENU

THRESHOLD INVERTERS

MENU PROGR.

TEMP. KICK STOP

PROGR. MENU

DIRECT THRESHOLDS

SET POINT

Bar 05.0

STOP THRESHOLD

BAR 05.0

K.S DALAY.

10 05

KS LENGTH

05/10

Bar PO:2

Max 04.2 Min 03.7

Bar PO:3

Max 04.2 Min 03.7

Bar PO:4

Max 04.2 Min 03.7

Bar PO:5

Max 04.2 Min 03.7

P.2 TEMPORIZATION

START 8 STOP 0

P.3 TEMPORIZATION

START 3 STOP 0

P.4 TEMPORIZATION

START 3 STOP 0

P.5 TEMPORIZATION

START 1 STOP 0

PROGR. MENU

DIRECT TEMP.

PROGR. MENU

INVERSION

CYCLIC BLOCK = YES

BLOCK OF PUMP 3

CYCLIC BLOCK = NO

EXTERN.CONTR. YES

PROGR. MENU

EXIT

MANUAL FUNCTION

Bar 10.0

NOCCHI PUMPS

Bar 05.0

STOP FOR LOW

WATER LEVEL

SYSTEM INVERTER

BLOCKED - RESET

TEMP. P 3 4

Bar 04.6

FREQUENCY CHANGER DIAGRAM

FLOW DIAGRAM OF THE MENUS AND FAULT MESSAGES

FAULT MESSAGES

BY KEEPING PRESSED FOR 10” BY KEEPING PRESSED FOR 2”

93

PUMP No. 1 PUMP No. 2

PUMP No. 1 PUMP No. 2 PUMP No. 3

CUT-OUT

DIRECT

START

TEST

AUTOMATIC

CARD

CUT-OUT

DIRECT

START

TEST

AUTOMATIC

CARD

CUT-OUT

DIRECT

START

TEST

AUTOMATIC

CARD

CUT-OUT

DIRECT

START

TEST

AUTOMATIC

CARD

CUT-OUT

DIRECT

START

TEST

AUTOMATIC

CARD

94

95

I

This manual suits for next models

1

Table of contents

Other Nocchi Water Pump manuals

Popular Water Pump manuals by other brands

North Ridge Pumps

North Ridge Pumps NOVA ROTORS DIAMOND DX Series OPERATING, USE AND MAINTENANCE INSTRUCTIONS

Masterflex

Masterflex I/P 73 operating manual

GORMAN-RUPP

GORMAN-RUPP SM SERIES manual

Milton Roy

Milton Roy MAXROY Series Actuator Capacity Control Manual

CLAS

CLAS OH 0014 manual

Teral

Teral NSVM Series Installation & operating manual