BEAMEX PGC User manual

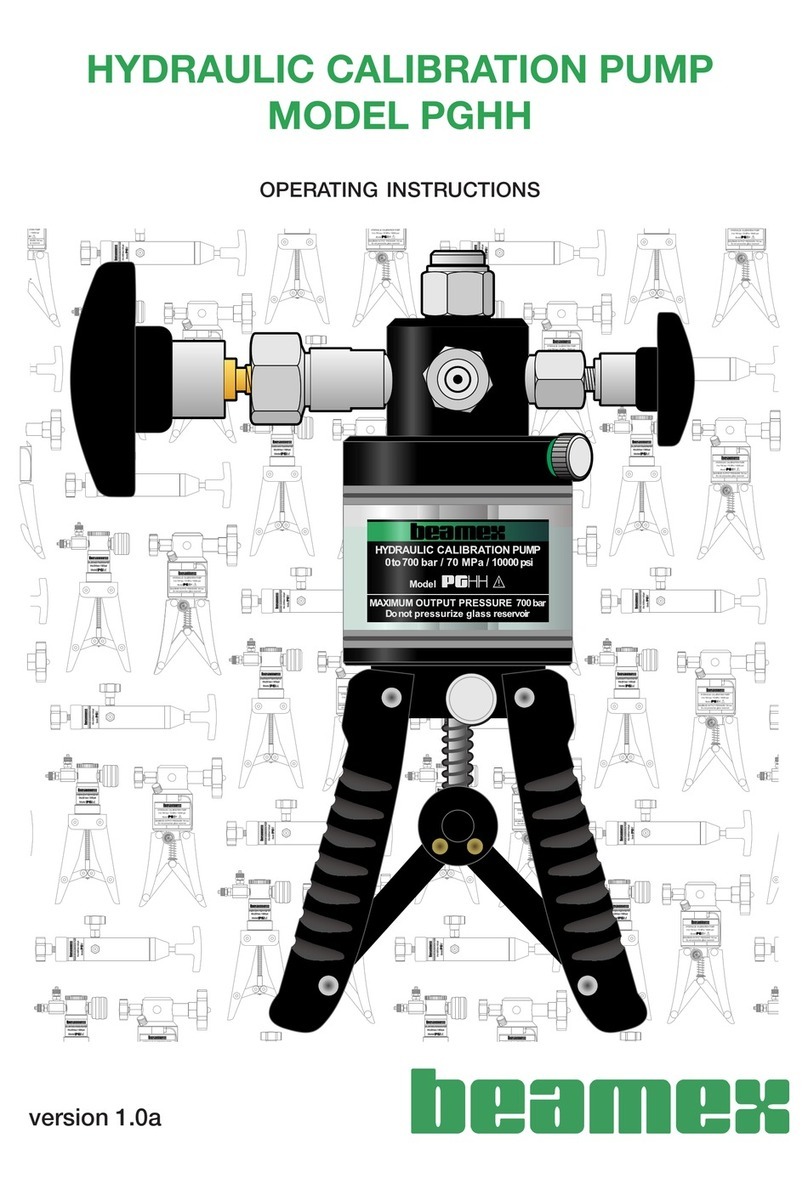

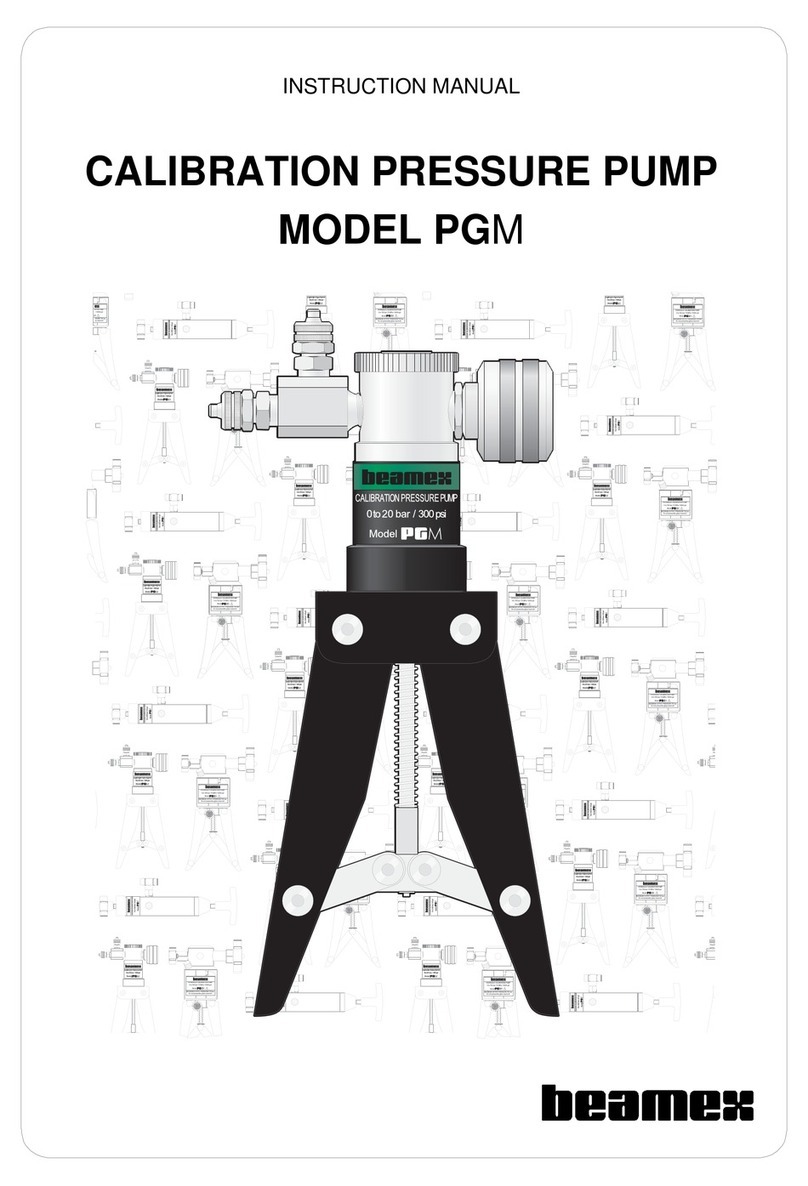

INSTRUCTION MANUAL

BEAMEX®PRESSURE/VACUUM

PUMP MODEL PGC

Dear user,

We have made every effort to ensure the accuracy of the contents

of this manual. Should any errors be detected, we would greatly ap-

preciate to receive suggestions to improve the quality of the contents

of this manual.

The above notwithstanding, we can assume no responsibility for any

errors in this manual or their eventual consequences.

We reserve rights to make modifications to this manual without any

further notice.

For more detailed technical data about the Instruction manual for

PGC Calibration Pressure Pump, please contact the manufacturer.

© 2016

BEAMEX OY AB

Ristisuonraitti 10

FIN-68600 Pietarsaari

FINLAND

Tel +358 - 10 - 5505000

Fax +358 - 10 - 5505404

Internet: http://www.beamex.com

8804900 / PGCuEng / Version 1

CONTENTS

DESCRIPTION ............................................................................................. 1

Standard Accessories.........................................................................................1

Optional Accessories ..........................................................................................1

USING THE PUMP.......................................................................................3

Preparation..........................................................................................................3

Operation (Pressure)...........................................................................................4

Operation (Vacuum)............................................................................................5

When Calibration is Done....................................................................................5

TROUBLESHOOTING/MAINTENANCE .....................................................6

Seal Replacement...............................................................................................6

SPECIFICATIONS........................................................................................ 8

The Pump Unit....................................................................................................8

The Pressure Measurement T-hose (Part of Pump Kit)......................................8

WARNINGS..................................................................................................9

1

DESCRIPTION

Beamex®PGC calibration pressure pump is designed to manually generate be-

tween -0.95 to 35 bar (approx. -13.7 to 510 psi) of vacuum and pressure for quick

and accurate calibration of pressure gauges, transducers and other pressure meas-

urement instruments.

Standard Accessories

The standard accessory for a stand-alone pump is:

This manual

Additionally, for a pump kit:

Connector kit:

●G 1/8’’ male, 60° internal cone / G 1/8’’ male + o-ring

to replace a Hydrotechnics®connector in Beamex®MC6 Calibrator's

internal high pressure modules.

●G 1/8’’ male, 60° internal cone / G 1/4’’ B female + 2 seals.

An adapter for connecting the pressure measurement T-hose to

Beamex' high pressure EXT modules.

●G 1/8’’ male, 60° internal cone / G 1/4’’ NPT male.

An adapter for connecting the pressure measurement T-hose to

the instrument to be calibrated (DUT).

40 bar measurement T-hose.

Carrying case.

Optional Accessories

The optional accessories are as follows:

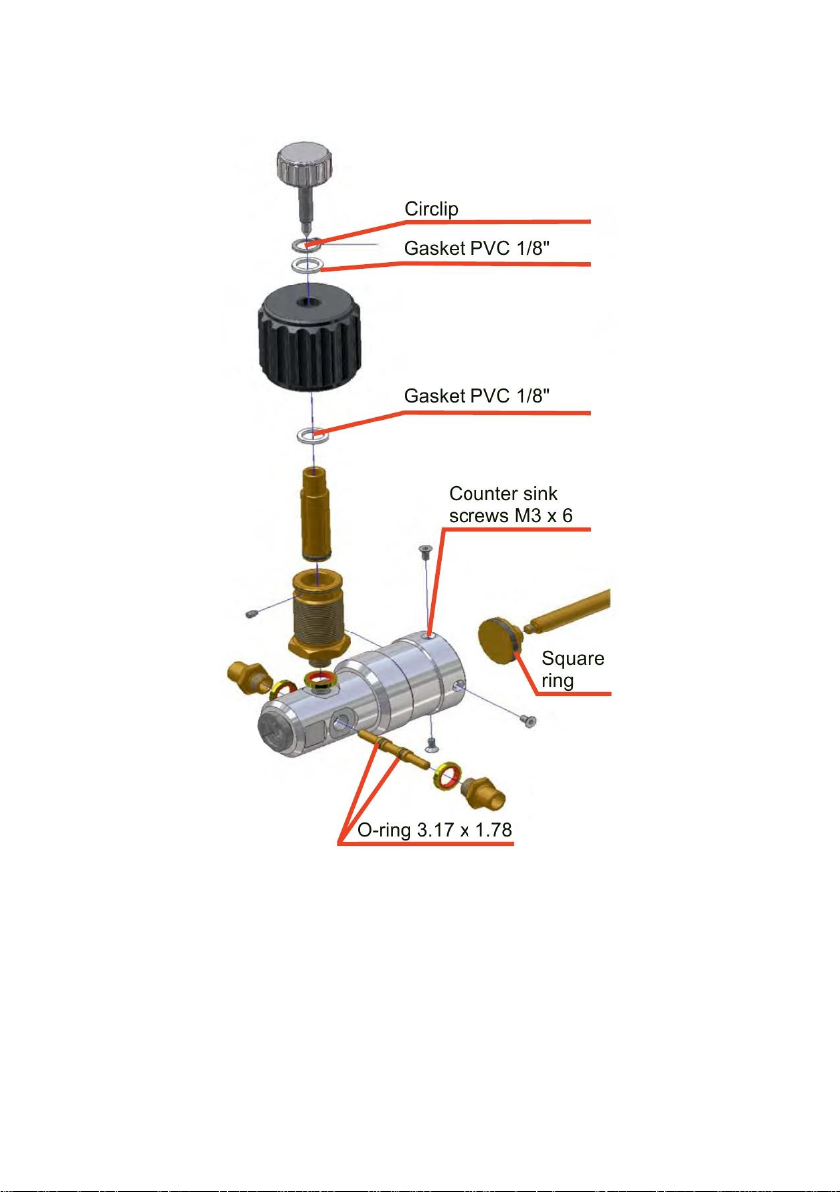

Service seal kit containing a set of seals and gaskets.

For details, see picture on page 7.

Fine adjustment valve including relief valve and gaskets.

Upper part of pump (cylinder) including pressure/vacuum selector.

Bottom part including handles and piston.

2

Presenting PGC.

Device Under Test

(DUT)

Reference meas-

urement

Connection diagram when calibrating

3

USING THE PUMP

Preparation

Before applying pressure/vacuum, ensure that the pressure/vacuum selector is ac-

cording to your calibration needs. If not, check that the release valve is open, and

then use a small screw driver to change the setting of the pressure/vacuum selector.

IMPORTANT

Never change the pressure/vacuum selector's setting when there is

pressure or vacuum in the pump/system.

Please read all the warnings found on page 9.

Before doing the connections, check that the pressure hose is intact and the o-rings

in it are in place. Use only the pressure measurement T-hose delivered with the

pump. Also check that the pump is in working condition.

Use the pressure measurement T-hose to connect the Device Under Test (DUT) and

the reference (a calibrator with internal pressure modules or an external pressure

module communicating with a calibrator) to the pump. For help on connections, refer

to the adjacent connection diagram. Use hand tightening for the connections. Ensure

that the measurement range of the connected reference is appropriate.

Note.

It is not recommended to use the plugged connection on top of PGC. Further

information in warnings, presented on page 9.

Normally: Check that the thumb nut of the stroke length setting is approx. 1 centime-

ters from the lowermost position. If you for some reason need to reduce the volume

per stroke, raise the thumb nut to squeeze the spring. This can also be done during

the calibration run.

Turn the release valve clockwise to close it.

Continue either from chapter Operation (Pressure) on page 4 or Operation (Vac-

uum) on page 5.

4

Operation (Pressure)

Turn the fine adjustment valve counterclockwise until it is fully open. Approximately

halfway, if you do not need to use the full pressure range of the pump.

Pump to raise the pressureclose to the next calibration point. Use the fine adjustment

to raise the pressure to the calibration point.

Notes.

The maximum pumping pressure is approximately 25-30 bar. The rest of the

pressure is done using the fineadjustment valve. The total maximum pressure

value depends on the volume of the calibration circuit.

After increasing the pressure, the reading may slightly drop again for about 30

seconds. This is caused by thermodynamic effects, the tube connection and

the sealing gaskets. If the pressure does not come to a standstill, check the

measuring circuit for tightness.

When the calibration point with the highest pressure value is reached and there is no

need for calibration points with decreasing pressure, either

Open the release valve, close it and start a new calibration repeat, or

continue to chapter When Calibration is Done on page 5.

If there is need for calibration points with decreasing pressure, carefully open the

release valve to decrease the pressure. When getting close to the required pressure,

close the release valve and use the fine adjustment valve to lower the pressure to the

calibration point. Again, wait for approximately 30 seconds for the pressure to stabi-

lize.

When the last calibration point is done, either do another calibration run or continue

to chapter When Calibration is Done on page 5.

WARNINGS!

Do not exceed the max. operating pressure of the pump and the hose.

If there is a strong counterforce while operating the handles, but no pressure

increase is indicated, stop pumping and locate the fault. Always keep a reliable

indicator connected to the measurement system.

A full list of warnings is on page 9.

5

Operation (Vacuum)

Turn the fine adjustment valve clockwise until it is fully closed.

Pump to lower the pressure close to the next calibration point. Use the fine adjust-

ment to lower the pressure to the calibration point.

Notes.

After decreasing the pressure, the reading may slightly change for about 30

seconds. This is caused by thermodynamic effects, the tube connection and

the sealing gaskets. If the pressure does not come to a standstill, check the

measuring circuit for tightness.

When the calibration point with the lowest pressure value is reached and there is no

need for calibration points with increasing pressure, either

Open the release valve, close it and start a new calibration repeat, or

continue to chapter When Calibration is Done on page 5.

If there is need for calibration points with increasing pressure, carefully open the re-

lease valve to increase the pressure. When getting close to the required pressure,

close the release valve and use the fine adjustment valve to increase the pressure to

the calibration point. Again, wait for approximately 30 seconds for the pressure to

stabilize.

When the last calibration point is done, either do another calibration run or continue

to chapter When Calibration is Done on page 5.

When Calibration is Done

IMPORTANT!

Open the release valve to remove pressure/vacuum before disassem-

bling the measurement system.

Disassemble the measurement system and make sure the pump is left in a state that

allows easy start the next time the pump is used. (Release valve open, stroke length

set to maximum etc.)

6

TROUBLESHOOTING/MAINTENANCE

If the pump assembly fails to indicate a pressure increase/decrease after considera-

ble pumping action of the handle, check the following things:

Assure that the connections between the pump, the hose end and the at-

tached instrument(s) are tight and retry pumping.

Check that all the unused output connectors are properly plugged. Also

check that the release valve is closed.

Check that the pressure/vacuum selector is not left somewhere in between

pressure side and vacuum side. If so, push it in place as needed.

If a pressure increase/decrease still cannot be obtained, it’s possible that one or more

of the seals in the Pressure Pump is leaking and needs to be replaced.

If the test pump has not been used for a longer period of time, the first lift may be

somewhat sluggish. This effect will disappear again during further operation.

Do not continue pumping if the functionality of the pump is not normal. Lo-

cate the fault before you continue using the pump.

Seal Replacement

Depending on the frequency of use, the seals will eventually need replacing. The

replacement seals are an optional accessory, but the picture on next page presents

where the seals go.

7

8

SPECIFICATIONS

The Pump Unit

Weight 820 g 1.81 lb

Dimensions Height 220 mm approx. 8.7"

Width 120 mm approx. 4.7"

Depth 65 mm approx. 2.6"

Pressure range*-0.95 to 35 bar -13.7 to 510 psi

Pressure media Air

Output connector

G 1/8’’ male, 60° internal cone.

Material Aluminium, brass, ABS, NBR

The Pressure Measurement T-hose (Part of Pump Kit)

Max. length 1.5 m 4.9 ft

Connectors (all ends) G 1/8’’ female, 60° internal cone.

External diameter 5 mm 0.2"

Operating pressure max. 40 bar 4 MPa 580 psi

9

WARNINGS

Read the instruction manual carefully prior to setting up and using the pres-

sure pump. The pressure built up internally during use can be extremely high.

Only personnel with good experience and knowledge of high pressure media,

high pressure instruments and connections are allowed to work with the

pressure pump. Incorrect use may result in damage to the pump, the instru-

ment connected to the pump and/or personal injury.

Use only the pressure measurement T-hose delivered with the pump, marked

with "Max. 40 bar". Other hoses may not withstand the pressure generated

with PGC.

Use eye shields.

Do not connect the pump to an external pressure source.

Never change the pressure/vacuum selector's setting when there is pressure

or vacuum in the pump/system.

Vent external systems before connecting to the pump.

Ensure that all connections are made correctly and that the hose and the con-

nectors are undamaged. Do not use faulty hoses or connectors.

The environmental conditions may restrict the allowable maximum pres-

sure/vacuum to a lower level than the pump and the hose enable.

Always depressurize PGC when it is left on its own.

Use only the connector provided with the pump. Impurities from wrong mate-

rials may plug the pump.

It is not recommended to use the plugged connection on top of PGC. PGC's

body is made of Aluminium and the thread may be damaged when using too

much force to open/close the connection.

No Teflon (PTFE) tape may be used to seal anything in the pump.

Do not use PGC in any other way than as described in this manual.

10

BEAMEX OY AB Phone +358 - 10 5505000

Ristisuonraitti 10 Fax +358 - 10 5505404

Internet http://www.beamex.com

Beamex Inc

2152 NW Parkway

Suite A

Marietta, GA 30067

U.S.A.

Phone 800 888-9892,

+1-770-951-1927

Fax +1-770-951-1928

E-mail beamex.inc@beamex.com

Beamex Limited

Newtown Grange Farm Business Park

Desford Road

NEWTOWN UNTHANK

Leicestershire LE9 9FL

United Kingdom

Phone 01455 821 920

Fax 01455 821 923

E-mail beamex.ltd@beamex.com

Beamex S.A.S.

253 Boulevard de Leeds

59777 Lille

FRANCE

Phone +33 (0)3 28 53 58 27

Fax +33 (0)3 28 53 57 50

E-mail beamex.fr@beamex.com

Representative:

Table of contents

Other BEAMEX Water Pump manuals

Popular Water Pump manuals by other brands

Reverso

Reverso DTP-50 instructions

Crane

Crane Barnes SE Series Installation and operation manual

Davey

Davey PowerMaster Eco-Series Installation and operating instructions

Wilo

Wilo DrainLift SANI-L Series Installation and operating instructions

Pentair

Pentair STA-RITE DURA-JET 5DJ Series owner's manual

Larzep

Larzep W07807 INSTRUCTIONS AND MANUAL