NOCRY NCS-10NM User manual

Cordless Screwdriver

Instruction Manual

We've tried to make this manual useful, simple, and understandable.

Please read it carefully, and keep it safe for future reference.

WHAT'S INSIDE THIS MANUAL

GENERAL POWER TOOL SAFETY WARNINGS 2

W ork area safety 2

E lectrical safety 2

P ersonal safety 3

P ower tool use and care 4

S ervice 5

SAFETY WARNINGS FOR ELECTRIC SCREWDRIVER 6

D escription of symbols 6

P roper use 7

TECHNICAL DATA 7

B efore starting the equipment 8

SCREWDRIVER IMAGES 9

P art list 9

OPERATION 10

Charging the battery 10

Change of direction switch 11

ON/OFF switch 11

LED lamp 12

Torque setting 12

Changing the tool 12

Screwdriving 12

CLEANING AND MAINTENANCE 13

Cleaning 13

Maintenance 13

Disposal and recycling 13

WARRANTY 14

HOW TO CONTACT NOCRY 1 5

1

GENERAL POWER TOOL SAFETY WARNINGS

READ ALL SAFETY WARNINGS AND ALL INSTRUCTIONS

Failure to follow the warnings and instructions may result in electric shock, fire

and/or serious injury. Before use, be sure everyone operating this tool reads and

understands all safety instructions and other information in this manual.

Review frequently prior to use and when instructing others.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (with a

power cable) power tool, and to battery operated tools (without a power cable).

WORK AREA SAFETY

- KEEP WORK AREA CLEAN AND WELL ILLUMINATED. Untidy or unlit work areas

can result in accidents.

- CONSIDER WORKING ENVIRONMENT. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

- KEEP CHILDREN AND BYSTANDERS AWAY while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

- GUARD AGAINST ELECTRIC SHOCK. Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching outlets will reduce risk of

electric shock.

2

- AVOID BODY CONTACT with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

- DO NOT EXPOSE TO RAIN AND WET CONDITIONS. Water entering a power tool

will increase the risk of electric shock.

- DON’T ABUSE CORD. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges, and moving parts.

Damaged or entangled cords increase the risk of electric shock.

- USE EXTENSION CORD WHEN OUTSIDE. When operating a power tool outdoors,

use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor

use reduces the risk of electric shock.

- USE RESIDUAL CURRENT DEVICE IF DAMP CONDITIONS ARE UNAVOIDABLE. If

operating a power tool in a damp location is unavoidable, use a residual current

device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

PERSONAL SAFETY

- STAY ALERT. Watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol, or medication. A moment of inattention while operating power tools

may result in serious personal injury.

- USE SAFETY GLASSES AND OTHER SAFETY EQUIPMENT. Protective equipment

such as safety glasses, gloves, dust-masks, non-skid safety shoes, hard hats,

and/or hearing protection used for appropriate conditions will reduce personal

injuries.

- PREVENT UNINTENTIONAL STARTING. Ensure the switch is in the off-position

before connecting to the power source and/or battery pack, picking up, or carrying

the tool. Carrying power tools with your finger on the switch or connecting the

appliance to the mains when it is switched on, can lead to accidents.

- REMOVE ANY ADJUSTING KEY OR WRENCH before turning the power tool on. A

wrench or a key left attached to a rotating part of a power tool may result in

personal injury.

3

- DO NOT OVERREACH. Keep proper footing and balance at all times to keep

control in unexpected circumstances. Taking unnecessary risks may cause injury or

harm.

- DRESS PROPERLY. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from hot and moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

- DUST SAFETY. If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used. Use of dust

collection systems can reduce dust-related hazards.

POWER TOOL USE AND CARE

- DON’T FORCE THE TOOL. Do not overload the power tool. Use the correct power

tool for your application in the manner it was designed. The correct power tool will

do a better and safer job for which it was designed than for those which it wasn’t.

- DO NOT USE A MALFUNCTIONING TOOL. Do not use the power tool if the switch

does not turn it on and/or off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

- DISCONNECT TOOLS. Disconnect the plug from the power source and/or the

battery pack from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the

risk of starting the power tool accidentally.

- STORE IDLE POWER TOOLS out of the reach of children and do not allow persons

unfamiliar with the power tool, or these instructions, to operate the power tool.

Power tools are dangerous in the hands of untrained users.

- MAINTAIN POWER TOOLS. Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

- KEEP YOUR CUTTING TOOLS SHARP AND CLEAN. Carefully maintained cutting

tools with sharp cutting edges will jam less and are easier to control.

- CORRECT USE OF ACCESSORIES AND ATTACHMENTS. Use the power tool,

accessories, and attachments in accordance with these instructions, taking into

4

account the working conditions, and the work to be performed. Use of the power

tool for operations different from those intended could result in a hazardous

situation. Note: Refer to WORK EXAMPLES section of this manual for further

details.

- ONLY CHARGE THE BATTERIES WITH CHARGERS THAT ARE RECOMMENDED BY

THE MANUFACTURER. A charger that is designed for a certain type of battery may

pose a fire risk if it is used with other types of battery.

- USE THE CORRECT BATTERIES IN THE ELECTRIC TOOL. The use of other

batteries may result in injuries and a risk of fire.

- KEEP UNUSED BATTERIES AWAY from paper clips, coins, keys, nails, screws, and

any other metallic objects that could cause a short circuit between the contacts. A

short circuit between the battery contacts may cause burns or a fire.

- IN CASE OF INCORRECT USE, FLUID MAY ESCAPE FROM THE BATTERY. Avoid

contact with it. If you touch it by accident, rinse the affected area with water. If you

get the fluid in your eyes, also seek medical attention. Leaking battery fluid can

cause skin irritation or burns.

SERVICE

- Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

- Hold the equipment by the insulated handles when carrying out work during

which the screw or the plug-in tool could strike concealed power cables. Contact

with a live cable may also make the metal parts of the equipment live and cause an

electric shock.

5

SAFETY WARNINGS FOR ELECTRIC

SCREWDRIVER

DESCRIPTION OF SYMBOLS

Pay attention to all the signs and symbols shown in these instructions and on your

tool. Make a note of these signs and symbols. If you interpret the signs and

symbols correctly, your work with the machine will be safer and better.

6

PROPER USE

The cordless screwdriver is designed for tightening and undoing screws.

The machine is to be used only for its prescribed purpose. Any other use is deemed

to be a case of misuse. The user/ operator and not the manufacturer will be liable

for any damage or injuries caused as a result of this.

Please note that our equipment has not been designed for use in commercial,

trade or industrial applications. Our warranty will be voided if the machine is used

in commercial, trade or industrial businesses or for equivalent purposes.

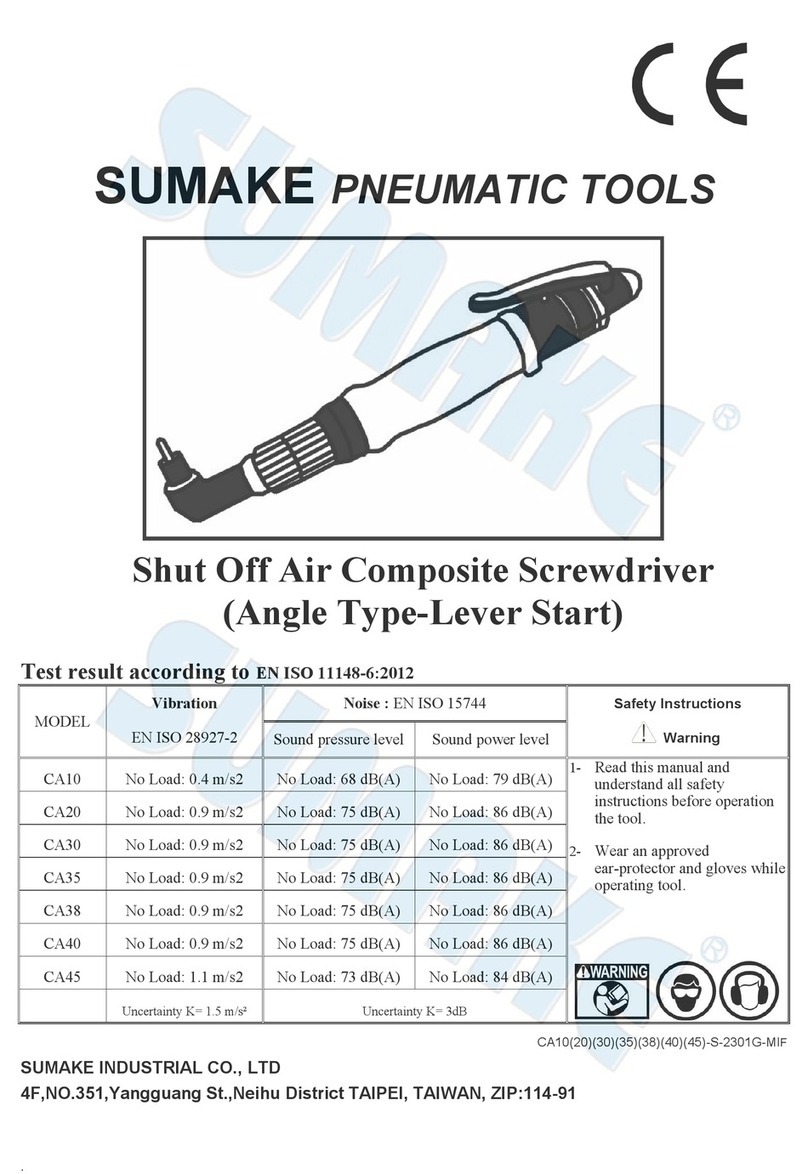

TECHNICAL DATA

Model

NoCry NCS-10NM Cordless Screwdriver

Idling speed

0-230rpm

Bit chuck diameter

1/4in

Torque settings

5+1

Maximum torque

6N.m (soft)

10N.m (hard)

Rotation direction

clockwise & counter-clockwise

Motor power supply

rechargeable 7.2V D.C./1.3Ah Lithium Ion battery

Battery charge voltage

9.5V D.C.

Battery charge current

500Ma

Battery charger supply

100-240V / 50-60Hz

Charging time

3 hours

7

Weight

1.27lb

Protection class

回/II

L

PA

sound pressure

level*

67 dB (A)

K

PA

uncertainty*

3 dB

L

WA

sound power level*

78 dB (A)

K

WA

uncertainty*

3 dB

a

h

vibration emission

value**

2.39ft/s

2

K uncertainty**

4.92ft/s

2

* The sound and vibration values have been determined in accordance with

EN60745. The vibration value changes according to the area of application of the

screwdriver, and may exceed the specified value in exceptional circumstances.

** These values describe screwing without hamme actions, and sound and have

been determined in accordance with EN60745. The vibration value changes

according to the area of application of the screwdriver, and may exceed the

specified value in exceptional circumstances.

BEFORE STARTING THE EQUIPMENT

Be sure to read the following information before you use your cordless screwdriver

for the first time:

1. Charge the battery pack with the charger supplied.

2. Only ever use screwdriver bits which are suitable for the purpose and in

faultless condition.

3. Always check for concealed electric cables, and gas and water pipes when

drilling and screwing in walls.

8

SCREWDRIVER IMAGES

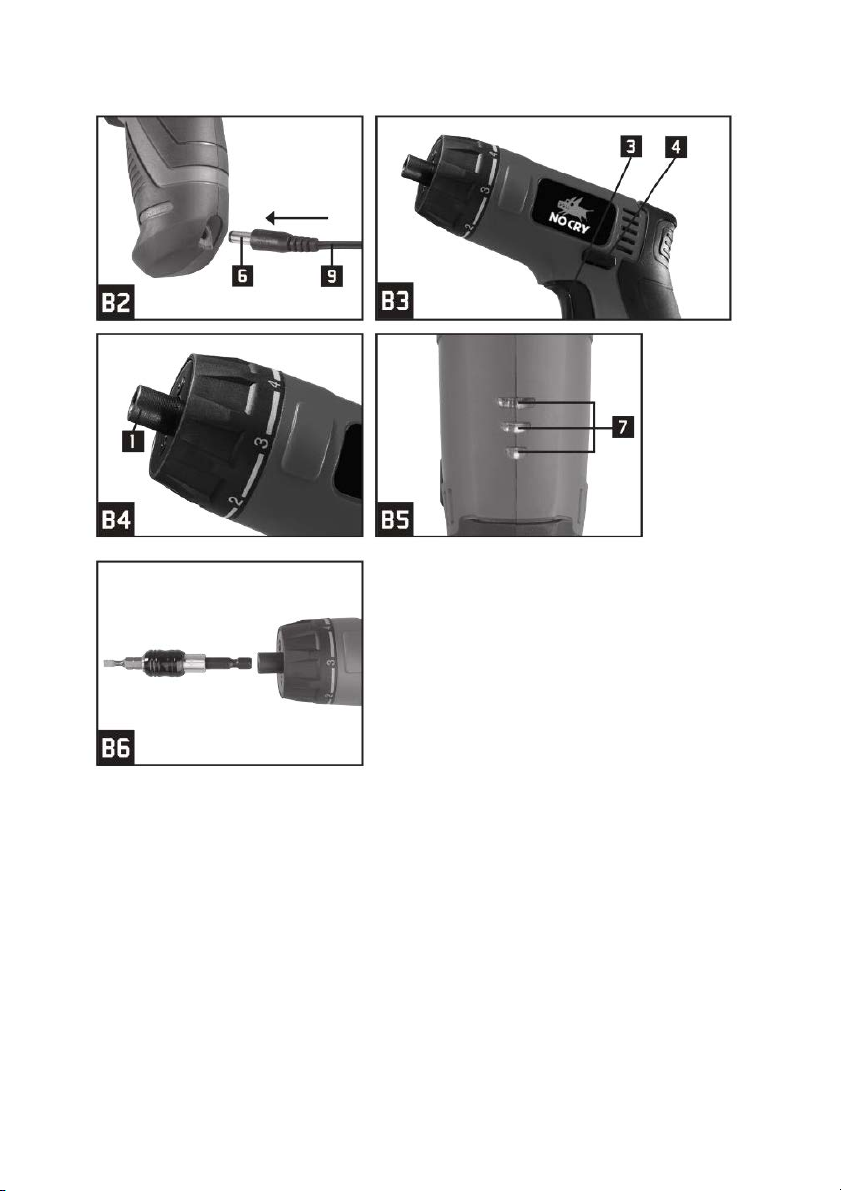

PART LIST

1. Bit Chuck 2. Torque selector 3. ON/OFF switch 4. Clockwise/Counter-clockwise

selector switch 5. Lamp 6. Charging socket 7. Battery capacity indicator 8. Battery

charger 9. Charging cable

9

OPERATION

Charging the battery (Fig.1)

The battery is protected from exhaustive discharge. An integrated protective circuit

automatically switches off the equipment when the battery Is flat. In case the bit

chuck will cease to turn.

Warning! Do not press the ON/OFF switch any more if the protective circuit has

actuated. This may damage the battery.

10

1. Check your mains voltage is the same as that marked on the rating plate

of the battery charger. Plug the battery charger in the plug socket and

connect the charging cable to the socket. (6)

LED indications:

1. Red LED illumination: Charge the electric screwdriver.

2. Yellow and red LED illuminated: Battery has sufficient charge.

3. All LED illuminated: Battery is fully charged.

If the battery pack fails to charge, please check whether there is voltage at the

socket/ outlet, and that there is proper contact between the tool and the battery

charger points.

If the battery still fails to charge, contact with us at wecare@nocry.com

Timely recharging of the battery pack will increase the battery life of the product.

Never allow the battery pack to become fully discharged, as it might cause defects

in the operation.

Change of direction switch (Fig 2. / Item 4)

The sliding toggle above the ON/OFF switch is for setting the direction of rotation

of the cordless screwdriver, and for preventing the cordless screwdriver from being

switched on inadvertently. You can select between clockwise and counter-

clockwise rotation. Change the direction of rotation only when the equipment is at

a standstill. Failure to do so may damage the gearing. When the toggle is in the

middle position, the ON/OFF switch is blocked.

ON/OFF switch (Fig. 2 / Item 3)

Press the ON/OFF switch to switch the cordless screwdriver on. Release the

ON/OFF switch to switch the tool off.

11

LED lamp

The LED lamp (5) can be used in poor lighting conditions to illuminate the area

where you want to screw.

Torque setting (Fig. 3)

The cordless screwdriver is fitted with a mechanical torque selector. The torque for

a specific size of screw is selected by rotating the front of the screwdriver (2). The

correct torque depends on several factors:

- The type and hardness of the material in question

- The type and length of the crews being used

- the requirements needing to be met by the screwed joints.

The clutch will disengage with a grating sound to indicate when the set torque is

reached.

Changing the tool (Fig. 5)

Important! Set the sliding toggle to the center position whenever you carry out

work (for example changing the inserts, maintenance work, etc.) on the cordless

screwdriver.

Screwdriving

We recommend using self-centering screws (e.g. Torx screws, recessed head

screws) designed for reliable working. Be sure to use a bit that matches the screw

in shape and size. Set the torque, as described elsewhere in these operating

instructions, to suit the size of the screw.

12

CLEANING AND MAINTENANCE

Before any work on the machine itself, pull the mains plug. For safe and proper

working, always keep the machine and ventilation slots clean.

Cleaning

Keep all safety devices, air vents, and motor housing free of dirt and dust as much

as possible. Wipe the equipment with a clean cloth or blow it with compressed air

at low pressure.

We recommend that you clean the device immediately each time you have finished

using it.

Clean the equipment regularly with a moist cloth and some soft soap. Do not use

cleaning agents or solvent; these could damage the plastic housing of the tool.

Ensure that no water can seep into the device.

Maintenance

There are no parts inside the tool which require additional maintenance. If the

replacement of the supply cord is necessary, this must be done by an authorized

service agent in order to avoid a safety hazard.

Disposal and recycling

The unit is supplied in packaging to prevent it being damaged in transit. This

packaging is raw material and can therefore be reused or can be returned to the

raw material system. Electrical products should not be discarded with household

products. Electrical products used must be collected separately and disposed of at

collection points provided for this purpose. Talk with your local authorities or dealer

for advice on recycling.

13

WARRANTY

All NoCry products are inspected and tested to ensure their quality before leaving

the factory. If you’re not happy with your NoCry product, please contact us within

30 days of receiving it at wecare@nocry.com to return it for free for a replacement

product or to receive a full refund. The choice is yours.

Each NoCry electric product is warranted to be free of defects in material and

workmanship for the period of FOUR years from the date of original purchase.

Warranty does not cover normal wear and tear, abuse, altered products,

modifications, and products that have been repaired or attempted to be repaired

by others than NoCry. At NoCry’s discretion, a defective product will be repaired or

replaced.

This warranty gives you specific legal rights, but may be superseded by any other

rights or warranties in effect, which may vary from state to state (or based on your

local jurisdiction). If you think you might have a defective product, please contact

us at wecare@nocry.com. Our customer care team will be happy to help and start

the (free) procedure to determine whether your product is defective.

NoCry’s warranty applies to ONLY products being sold by Authorized Resellers. We

regretfully will not provide any warranty for products sold by any other sources.

Proof of purchase will be required to obtain warranty. Please review the warranty

carefully, and contact us if you have any questions.

14

HOW TO CONTACT NOCRY

We're glad to have you join the NoCry community, and we hope you are happy with

your new NoCry cordless screwdriver. If you have any questions or concerns, let us

know by emailing wecare@nocry.com

We'd also love to connect with you via social media. You can find us on Instagram,

Facebook and Pinterest by searching “NoCry Work & Safety Gear”.

www.nocry.com

wecare@nocry.com

15

Table of contents

Popular Power Screwdriver manuals by other brands

Senco

Senco DS212-18V operating instructions

Bosch

Bosch GSR 6-25 TE PROFESSIONAL Original instructions

Black & Decker

Black & Decker CS3651LC Original instructions

Ingersoll-Rand

Ingersoll-Rand QiS Series Product information

Parkside

Parkside PSSA 3.6 C3 Translation of the original instructions

Makita

Makita BFL122F instruction manual