Component

Parts

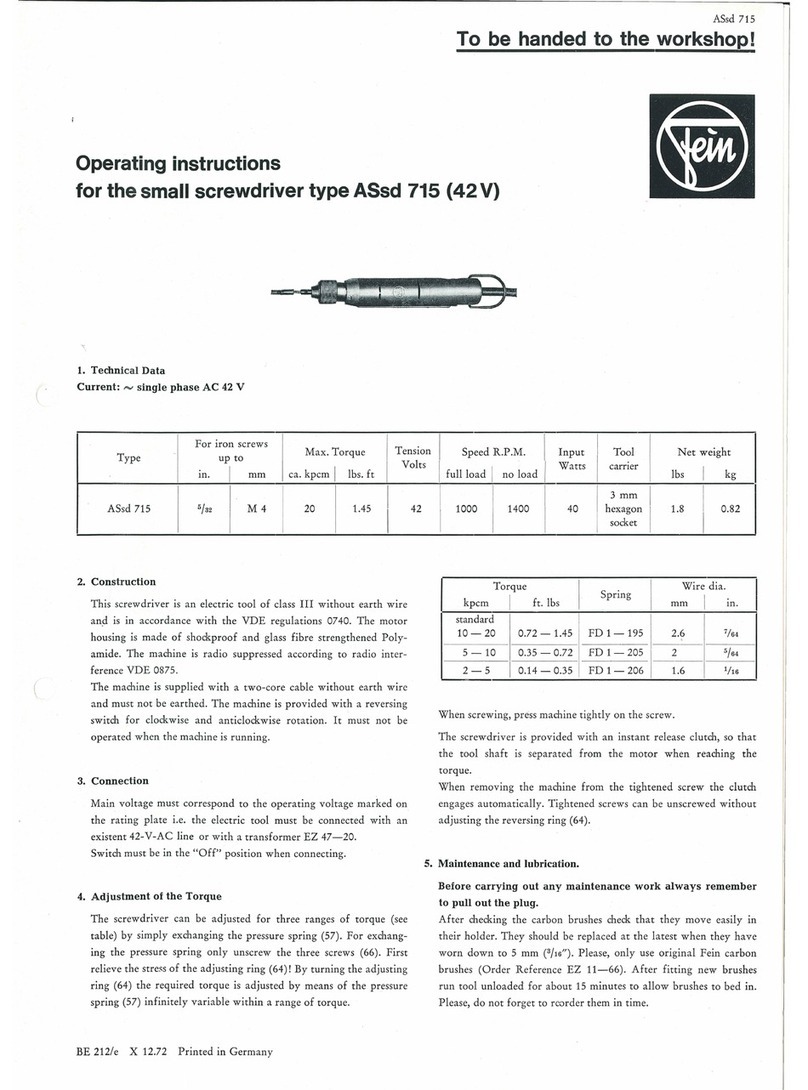

0

z

Ord

er

>..

D

es

cription

....

ry

....

Reference

"'

p..

0

z Order

>..

....

ry

Descri

ption

....

Reference

"'

p..

1-25

MK

1-18-2 1

motor

housing,

assembled

40

LK

1-32 1 ball bearing

with

cable

41

ZR15-16x0,75 1 gear

wh

eel for ASs 636, 46 tee

th

1-15

MK

1-18-1 1 motor housing, assembled

41

ZR15-35x0,75 1 gear

whe

el

for

ASs 636 b, 34 teeth

1

MK

1-18 1 motor housing 42

LK

15-4 1 bearing

2

EZ

1-58 1 switch 43 BF 19-40 1 pressure

pin

FD

1-196 1 spring 43a

FD

1-152 1 compression spring

3

EZ

22-35 1

int

e

rfer

ence capacitor 44

LK

1-1 2 ball bearing

4 EZ 1-59 1 reversing switch 45

LK

6a-11 1 needle cage

5-7

EZ

12-43-1 2 carbon holder, assembled 46

PT

8-153 1

dr

iv

ing

plate

8 EZ 11-59 2 carbon brush 47 ZR16-16x0,75 1 countershaftpinion

for

ASs 636, 9teeth

9

EZ

13-8 2 sliding cover 47 ZR16-19x0,75 1 countershaftpinion

for

ASs 636 b,

10 SR 2-M3,5x12 4 cylindrical screw

21

teeth

11

BF 19-42-1 1 locking pin, assembled

48

ZR

15-13x0,75 1 countershaft gear

whe

el, 30 tee

th

12

state

type

1 pole housing

wi

th

winding

and

volt

age

13 SR 2-M3,5x50 2 cylindrical

sc

re

w

13a

PT

6-M 3,5 2 securing

plate

I14 JS 28-4 1 insulating

ring

15 JS 15-11 1 bolster

16

EZ

7-101 1 cable

I 17 JS 13-7 1 cable protecting sl

ee

ve

18

PT

31

-21 1 cable clamping

br

id

ge

19 SR3-M3,5x10 2 fillister he

ad

screw

20-23

GH

1-

18

-1 1 cover

20-23

GH

1-20-1 1 cover wi

th

bow

24 SR2-M3,5x15 2 cylindrical screw

25

SR6-M3,5x8 1 fillister screw

26

state

tyfce 1

armature

with

wi

nding

and

vo

cage collector

and

fan

49-51

WB

16-4-1 1 countershaft, assembled

49

WB

16-4 1 countershaft

50 ZR15-15x0,75 1 countersh

af

t gear wheel,

31

tee

th

51

ZR15-14x0,75 1 counters

haft

gear wheel,

41

teeth

52 A 4-37 1

tool

holder

53

FD

6-14 1 ball retaining ring

I 54

LK

8-2,5 3 ball

55

SR

18-9 1 setting screw

56 SR 9-M4x8 1 grubscrew I

57

LG

3-14 1 bearing bushing

58

JS 15-9 1 securing

plu

g I

59-63

BU

4-24-1 1 guide bush, assembled

59

BU

4-24 1 guide bush

60

FD

1-90 1 compression spring

61

RJ

2-17 1 lock ring

30

ZR

4-42 1

armature

dri

ve, 6 teeth

31

SR2-M3,5x6 3 cylindrical screw

32

PT

5d

-M3,5 3 securing

plate

33

LK

16-

35

2 ba

ll

bearing

63

FD

6-13-1 1 spring

ri

ng

64

RJ

12-47 1 sealing

rin

g

65 SR2-M3,5x60 2 cylindrical screw

66 SR2-M3,5x

45

2 cylindrical screw

34-63 LA 8-102-2 1

gear

head,

assembled

34-37 LA 6-142-1 1 intermediate bearing, assembled

35

LG

1-94 1 bearing bushing

36

LG

4-3 1 coun

ter

sha

ft

bea

rin

g

37 SR2-M3,5x10 2 cy

lind

rical screw I

38--63 LA 8-102-1 1

outer

bearing, assembled

38 LA 8-102 1 outer bearing

39

WB

8-17 1 cl

aw

sha

ft

I

Parts

for

low

voltage

42

Volts

1-15

MK

1-18-3 1

motor

housing, assembled

16

EZ

6-126 1 c

ab

le

Accessories

BU

81-9,5x

11

1 centering

bu

sh }

further

sizes

Z 81-8x1,2 1 screw

driver

bit

see leaflet Zs 1

Z

81k-2H

1 screw

driver

bit

(ASs 636 b)

21

EZ

11-59 2 c

ar

bon

brush