Nomadio Sensor User manual

USERS GUIDE

Version 1.0.2

Published July 2005

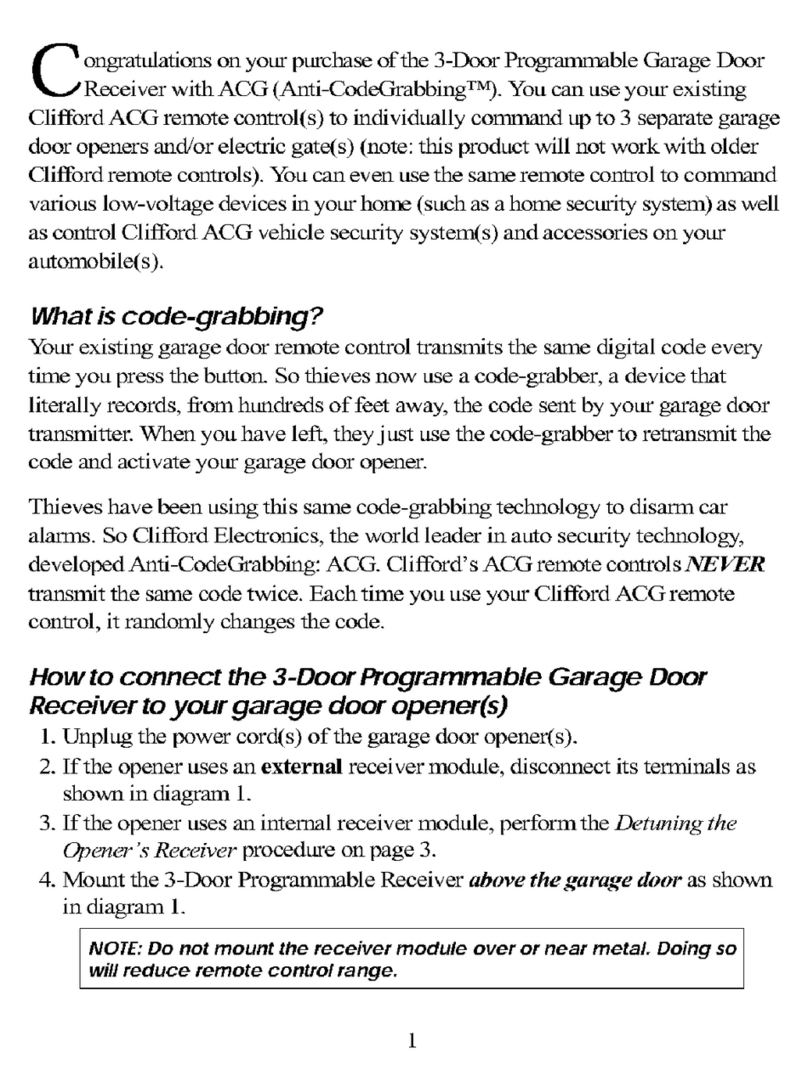

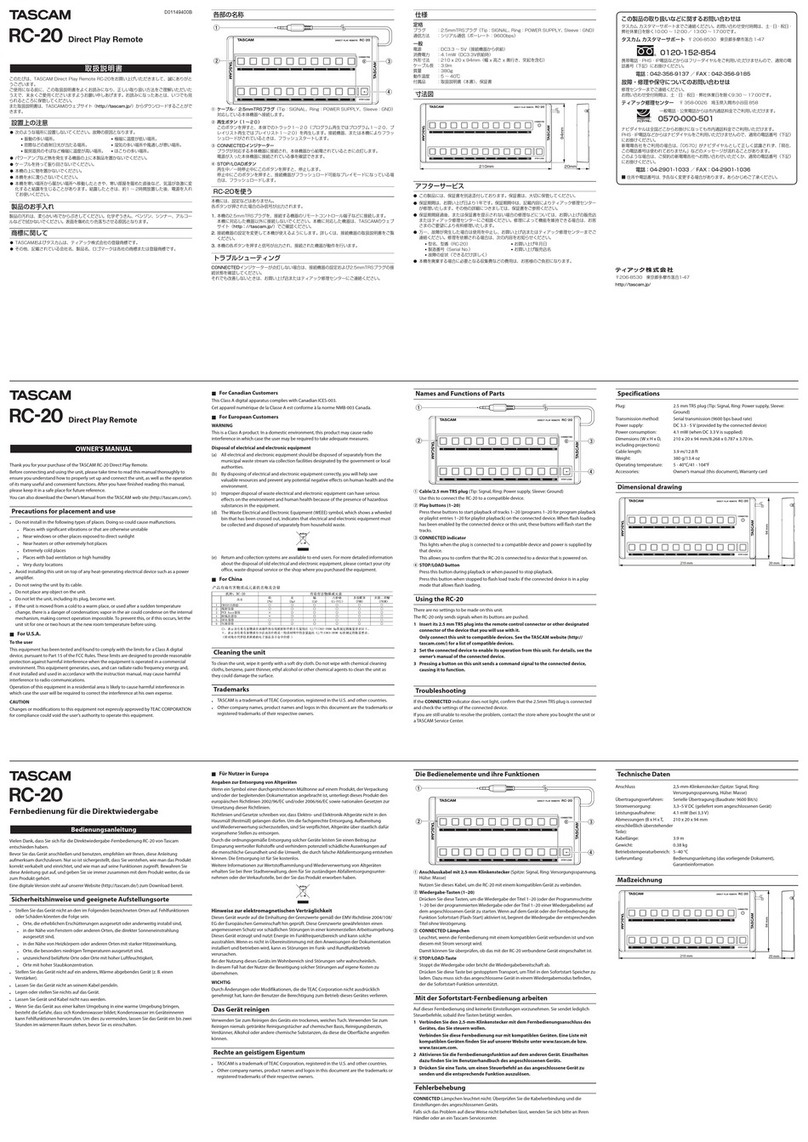

Sensor Quick Reference

Display Screen

Antenna

Speaker

Throttl

e

Trigger

Headphone &

PC Connections

Steering Trim

Shift Buttons

Batter

y

Compartment /

Receiver Programming

Cable

Steering W heel

Display Screen

Navigation

Controls

(T1) Throttle Dual

Rate Trim (T2) Steering Dual

Rate Trim (T3) ThrottleTrim

(TR) Steering Trim

(TL) Steering Trim

Menu Button

On/Off Switch

Selection Buttons

Transceiver Quick Reference

Receptacle for:

Car Battery Sensor

Receptacles for:

RXBattery(power)

Steering (Ch1)

Throttle(Ch2)

Shift Servo (Ch3)

Receptacle for:

Digital Sensor (e.g.,

RPM/Speed ) /Receiver

Programming Cable

BIND button

(recessed)

Indicator LED

Receptacle for:

Analog Sensors

(e.g., Temp)

Sensor Quick Reference.................................. II

Transceiver Quick Reference.........................III

Statement of Compliance ................................ 2

Getting to know your Sensor........................... 3

PowerSwitch......................................................3

Display Screen....................................................3

MenuButton.......................................................3

NavigationButtons...............................................3

SelectionButtons.................................................4

Trim Buttons.......................................................4

GripButtons.......................................................4

ConnectionPorts.................................................4

Charging and Installing Batteries ...................5

Charging the SuppliedNiMH Batteries......................5

Installing the Batteries..........................................5

Adjusting the Screen........................................ 6

Converting for Left Handed Use...................... 7

Installing the Transceiver................................ 9

Mounting the Transceiver......................................9

Connecting the Transceiver....................................9

Installing the Sensors....................................10

Receiver Battery Sensor...................................... 10

Voltage Sensor.................................................. 10

Temperature Sensor........................................... 10

Connecting the Temperature Sensor...................... 11

Binding the Transceiver.................................12

How the BindingProcess Works............................ 12

Bindingyour transceiver the first time.................... 14

Sensor Controls ..............................................15

Top Menu Level................................................. 16

SteeringFunctions............................................. 16

Throttle Functions.............................................. 30

ShiftServo Functions.......................................... 46

ModelManagement............................................ 56

ControllerSetup................................................ 60

Failsafes.......................................................... 64

Sensor Digital RC Desktop.............................66

Minimum System Requirements............................ 66

Installing the RC Desktop.................................... 66

Connecting the Sensor to yourComputer................ 73

Using theSensorDigitalRC Desktop...................... 73

Registration...................................................... 74

Receiving SettingsFrom the Sensor....................... 76

EditingSettings................................................. 77

Saving Settings................................................. 77

SendingSettings to the Sensor............................. 78

Installing Sensor Firmware.................................. 78

Specifications .................................................79

SensorController............................................... 79

Transceiver...................................................... 79

Support ...........................................................80

Nomadio 3 Year Limited Warranty................81

Warranty Coverage............................................ 81

Exclusions and Limitations................................... 81

Statement of Compliance

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced technician for help.

• This device complies with Part 15 of the FCC Rules and with RSS-210 of Industry Canada.

Operation is subject to the following two conditions:

1) this device my not cause harmful interference, and

2) this device must accept any interference received, including interference that may cause undesired operation.

• The users manual or instruction manual for an intentional or unintentional radiator shall caution the user that

changes or modifications not expressly approved by the party responsible for compliance could void the user's

authority to operate the equipment.

Warning: Changes or modifications made to this equipment not expressly approved by Nomadio may void the

FCC authorization to operate this equipment.

RF Exposure Statement

This transmitter has been tested and meets the FCC RF exposure guidelines when used with the Nomadio

accessories supplied or designated for this product, and provided at least 20 cm separation between the antenna

and the user's body is maintained. Use of other accessories may not ensure compliance with FCC RF exposure

guidelines.

Sensor and its software are designed and manufactured in the United States of America.

3

Getting to know your Sensor

Power Switch

This switch turns the Sensor on and off.

Display Screen

Driving screen

This is the screen you’ll be seeing 95% of the time

while using the Sensor. It displays radio andbattery

status, telemetry data that you select, and your

servo information.

Menu screen

This screen is the gateway to the Sensor’s menu

system, which is described in detail later. You can

alwaysgo back to the driving screen by just

pressing the menu key.

Menu Button

men

u

Pressing this button toggles Sensor between the driving screen

and the top level function menu, or returns to the previous

level from a sub-menu.

Navigation Buttons

Button In the driving screen In the function menu

Moves to next higher menu item.

Moves to next lower menu item.

OK

Displays previous reading. Decreases selected value.

4

Displays next reading. •Increases selected value.

•Goes to next sub-menu.

OK

•Goes to selected sub-menu

•Saves the change to the

selected setting.

Selection Buttons

In the function menu

Sets the currently edited value to its maximum

value.

Sets the currently edited value to its minimum

value.

Cancels any changes made and resets value to

where it was before you started editing.

Resets the value to the factory default

Trim Buttons

T1 Adjusts the throttle dual rate setting.

T2 Adjusts the steering dual rate setting.

T3 Adjusts the throttle trim setting.

Left steering trim

button Adjusts the steering trim to the left or

right

Right steering trim

button Adjusts the steering trim to the left or

right.

Grip Buttons

Performsshifting action on channel 3.

Connection Ports

Headphone

port Accepts a 1/8” stereo headphone jack. The

output is the same in each ear (mono).

Computer port This connects to the USB port ofyour

computer using the supplied cable.

5

Charging and Installing Batteries

The Sensor is powered by fourAA-size batteries (1.2~1.5V). You may use the fourAA-size

1.2V NiMH batteries provided with the Sensor, or you may use AA-size alkaline batteries

(1.5V). Before using your Sensor, make sure the batteries are fully charged.

The Sensor is reverse voltage protected: installing batteries backwards cannot damage it. If

the batteries are backwards, simply reverse the batteryconnector.

Also inside the batterycompartment is the 4 wire ReceiverProgramming Cable. This cable

can be plugged into the receiver’sTACH pins in orderto upgrade the software on the receiver.

The RC Desktop will instruct you when a software upgrade is available.

Charging the Supplied NiMH Batteries

When using the supplied NiMH batteries, charge the batteries for 12-14 hours (using the

supplied charger) before using the Sensor. Be sure to get the polarity correct when installing

the batteries into the charger.

Installing the Batteries

1. Slide and remove the battery compartment cover at the bottom of the

Sensor.

2. Remove the battery holder.

NOTE:

The battery holderwires connect toa receptaclein the battery compartment.

It is not necessary to unplug the connectorwhen you remove the battery holder.

However, if you do unplug the connector, note its orientation first. Ifyou plug it

in wrong,your Sensor will not turn on - no damage will be done to your

Sensor, just remove and reverse it.

3. Install the batteries in the battery holder. Observe proper polarity.

4. Plug the battery holder connector into the receptacle in the battery

compartment.

5. Place the battery holder in the battery compartment. Make sure the

wires do not pinch.

6. Slide the battery compartment cover into place.

6

Adjusting the Screen

The display screen atthe top ofthe Sensor canbe repositioned for easier viewing.

Tools needed:

7/64” hexwrench

1. Make sure Sensor is turned off before

moving the screen.

2. Using the hex wrench, loosen the two

screws holding the display screen.

3. Reposition the display screen.

4. Retighten the screws

7

Converting for Left Handed Use

You can easily convert the Sensorto left-handed use.

Tools needed:

#2 Phillips screwdriver,

7/64” hex wrench

A: Removethe Steering Wheel Assembly

A1: Make sure the Sensor is turned off

A2. Carefully removethe Nomadio emblem in the

center of the steering wheel. It is held in place by

friction and pulls toward you, it does not twist.

A3. Use the Phillips screwdriver to loosen and remove

the screw holding the steeringwheel. Remove the

steering wheel.

A4. Usethe hexwrenchtoremove thethree screws

holding the steering wheel assembly.

A5. Carefully pull the steering wheel assembly away

from the Sensor body.

A6. Carefully unplug the connector fromthe steering

wheel assembly.

B: Remove the Speaker Assembly B1. Usethe hex wrench to remove the four screws

holding the speaker assembly.

B2. Pull the speaker assembly away from the Sensor

body.

B3. Use the Phillips screwdriver to remove the two

speaker clamp screwsholding the speakerto the plastic

cover.

C: Swap the Assemblies C1. Pass the steering wheel connector wire through the

Sensor body so it comes out the LEFT side hole (where

the speakerused to be).

C2. Pass the speaker through the Sensor body so it

comes out the RIGHT side hole (where the steering

wheelusedtobe).

8

D: Re-assemble D1. Reattachthe speakertothe plastic coverusing the

two screws. Becarefulnot to overtighten andbreak

the speakerclamp.

D2. Reconnect the steeringwheelwire connectorto the

steering wheel.

D3. Reattach the speaker assembly to the RIGHT side

of the Sensor body.

D4. Reattachthe steering wheel assembly to the LEFT

side of the Sensor body.

D5. Reattachthe steeringwheel.

Make sure the steering wheel has full left-and-right

movement.

D6. Reinsert the Nomadio emblem in the center ofthe

steering wheel.

9

Installing the Transceiver

Mounting the Transceiver

•Install the transceiver so it is protected from vibration or shock.

•Use double-sided tape or Velcro® to mount the transceiver.

•Position the transceiver where it will not contact other solid components.

•Mount the transceiver away from moving parts, sharp corners, and possible contaminants (fuel, dirt,

etc.).

•When possible, waterproof and protect the transceiver by wrapping it in foam rubber and placing it in a

rubber balloon or plastic bag. If you accidentally get moisture or fuel inside the transceiver, intermittent

or erratic operation may result.

•Position the transceiver so the sensors can be easily connected to it.

Antenna

•The thinner portion at the end of the antenna wire must be outside the vehicle body

•DO NOTCUT the antenna wire

Connecting the Transceiver

Servo Input Plugs

The transceiver is designed to use Futaba J-style input plugs

with wiring order asshown in the diagram.

Servo lead wires MUST be in this order.If the servo wires are

in a different order,you must re-order the wires in the input

plug. Check with your servo manufacturer about the color and

order of the servo lead wiring.

When you insert the servo input plug into the transceiver, note

that the input plug may have an alignment tab. Orient the

alignment tab properly before inserting the input plug.

To remove in input plug from the transceiver, pull the input

plug rather than the servo wires.

Servo Connection

Connect the servostothe appropriate positions inthe transceiver:

Connect… …into transceiver receptacle

Receiver battery “Power”

Steering servo “Steering”

Throttle servo or ESC “Throttle”

Shifting servo “Shft/CH3”

10

Installing the Sensors

Your Sensor radio system comes with several sensors that you can install in your vehicle and

connect tothe transceiver. Whenproperly installed and connected, these sensorswill send

information backto the Sensor so that you can monitorthe readingswhile you drive.

Receiver Battery Sensor

The transceiver monitorsthe receiverbattery voltage fromthe POWER receptacle. There is no

installation necessary for this sensor.

Voltage Sensor

The voltage sensor is used to monitorthe voltage of a separate batterypack(forexample, an

electric car’s main battery pack). In a Nitro car, this sensor is not needed.

1. Connect the REDwire of voltage sense to the positive

terminal of your battery pack and the BLACK wire ofthe

voltage sense tothe negative terminalof the battery pack

you want to monitor.

2. Carefully route, protect, and secure the sensor wires.

3. Plugthe voltage sensor intothe BATT receptacle.

Temperature Sensor

The temperature sensor is used to monitorthetemperature

of a vehicle component such as a main battery pack, electric

motor, or nitro engine.

Installation

The tip ofthe triangular temperature sensor is the active

measuring element. Installthe sensor sothat this tip is

pressed againstthe item whose temperature you wish to

measure.

The sensor has been designed to be thin enough to fit between the fins on aheat sink. Two

sets of holes are provided to wire-tie the sensor in place if desired. Alternately, a high-

temperature epoxy may be used to securethe sensor.

When installing on a nitro motor, place the sensor as low as possible on the head, opposite

the exhaust port. The sensor may also be installed on an electric motor, battery pack, or ESC

heat sink.

11

Connection

Connecting the Temperature Sensor

After you install the temperature sensor in

the vehicle, plug it into the “Sensor 1” or

“Sensor 2” receptacle.

The four-pin connector onthe sensor cable

has only three wires populated. The

unpopulated pin should be the one furthest

from the connector key in the receiver

plastic.

The Sensortransceiverwill automatically

detect which sensors are installed.

Unused Pin

Connected Pins

12

Binding the Transceiver

The binding process “locks” the Sensor and atransceivertogether sothat they listen onlyto

each other.

Since the Sensor has eight model memories, it is possible that your Sensorwill be used to

communicatewitheight transceivers.You must therefore performthe binding process once for

each transceiver that will communicate with your Sensor.

Note thatthe Sensorcannot communicate with allofthe transceivers at the same time, but

rather the Sensor will communicate only with the transceiver associated with the Sensor’s

currently active model. For more information, see “Managing Models” later in this instruction

manual.

How the Binding Process Works

The binding process is set in motion by depressing the “bind” button on the transceiverwhen

the Sensor is in “bind mode.”The transceiverbroadcasts an inquiry message, indicating that it

is looking for a Sensor to bind to.

The Sensor responds backtothe transceiver, indicating its ID number(forexample,the

Sensor ID may be 123456789). Thetransceiver responds back to the Sensor, indicating its

own VIN number(forexample,the VIN may be 987654321). After that, the binding process is

complete.

13

Now, everytime youturn on the Sensor and set it to the appropriate modelID (see “Managing

Models” later in this manual), the Sensor goes to a special “lookup channel” and searches for

messages from the appropriate VIN.

When you turn on the vehicle’stransceiver, thetransceiver goesto the lookup channel and

broadcasts its VIN so it can be found by the appropriate Sensor.

Whenthe Sensor findsthe appropriate VIN, the connection is made.The Sensorthen searches

for a clear frequency channel;when one is found,the Sensor “tells” thetransceiverto jump to

that clear frequency channel.

14

Binding your transceiver the first time

1. Install a transceiver into your vehicle.

(For this example, install a transceiver into your electric touring car, which will be known to

the Sensor as “Model 1.”)

2. Inthe Sensor’s “Manage Models” function menu, go to“Active Model” and select the

appropriate model ID forthe vehicle you are going to bindto. (Forthis example, select “Model

1.”)

3. After putting your model on a stand to prevent runaways, power upthe vehicle and

transceiver.

4. Bring the Sensor close to the model. This will help the transceiver and Sensor to “find”

each other more easily.

5. In the Sensor’s “Manage Models” function menu, select “Rebind.”

6. Using an extended paperclip, depress and hold the transceiver’s “bind” button until the

onboard LED illuminates.

7: Confirm binding on your Sensor by pressing the “OK”asthe transceiverVIN number is

displayed.

The binding process is now complete!

15

Sensor Controls

The functions of the Sensor are controlled through the function menu and/ortrim controls.

To performthis action… Press…

Toggles between the driving screen and the function

menu or returns to the previous level from a sub-

menu

menu

Menu: Go to the selected sub-menu

OK

Menu: Move to the nexthigher menu item.

Menu: Move to the next lower menu item.

Menu: Go to the selected sub-menu.

Drive: Display next statistic.

Menu: Decrease the selected value setting.

Drive: Display previous statistic.

Menu: Set currently edited value to maximum.

Menu: Set currently edited value to minimum.

Menu: Cancel changes made to the current

parameter.

Menu: Reset currently edited value to factory default.

16

Top Menu Level

The following illustration shows the function menu structure for the top level menu. All main

sub-menus may be accessed from the top menu level.

Top Level Menu

Stee rin g (Ch1)

Throttle (Ch2)

Shift (Ch3)

Advanced

ManageModels

ControllerSetup

Statistics

Steering Functions

The following illustration shows the function menu structure for the steering functions:

Steering

(

Ch

1

)

Trim

Dual Rate

Expo

Left End Point

ServoReverse

Servo Type

Right End Point

-

100

to

100

0

-

100

0

to

100

Off

,

On

A

nalog

,

Digital

-

100

to

100

0

to

100

Trim Increment

1

-

20

1

-

20

DRIncrement

Sub Trim

-

100

to

100

Servo Speed

Input,Return,Trigger

,

17

Steering Trim

Steering trim adjusts the

center point ofthe steering

servo by adjusting the

center point within the

steering servo’s total travel

range. Unlike steering sub-

trim, the steering left and

right end points are

unaffected by steering trim;

by moving the center point

of the steering servo using

trim, the center position

moves closer to one end

point orthe other.

Steering trim should be

used only after you have

initially adjusted steering

sub-trim.

Steering (Ch1)

Throttle (Ch2)

Shift (Ch3)

Steering Trim

On the driving screen,

steering trim is represented

by the position of the

pointer on the upper bar.

As you change the steering trim, it is shown graphically on the driving screen trim indicator

bars:

Steering trim is centered in range (value = 0)

Steering trim is offset to the RIGHT (+ve value)

Steering trim is offset to the LEFT (-ve value)

If you find that you haveto use a large amount of steering trim to get the vehicle to

drive straight, you should consider resetting the steering trim to 0 and re-adjusting the

servo horn on the servo output shaft.

Other manuals for Sensor

1

Table of contents

Other Nomadio Remote Control manuals

Popular Remote Control manuals by other brands

Philips

Philips SBC RU 220/00 Instructions for use

Porter

Porter 12002 Sportsonic II Installation & operation manual

Nautamatic

Nautamatic TR-1 Gold owner's manual

StarLogixs

StarLogixs GateKeeper RR-07 operating instructions

RadioLink

RadioLink RC8X quick start guide

HomeMatic

HomeMatic HM-RC-12-B operating manual