NorAM 65E Turbo User manual

NORAM 65ET GRADER

01

<SectTitle- 0

65E

TURBO

|

Motor Grader

Operator’s Manual

June, 2009

EFF. S/N 9500

Catalog #13961

This page intentionally left blank.

NORAM 65ET GRADER

0-1

SAFETY ............................................................................... 0-1

GENERAL INFORMATION.................................................. 1-1

OPERATION ........................................................................ 2-1

LUBRICATION AND MAINTENANCE ................................ 3-1

SPECIFICATIONS ............................................................... 4-1

TROUBLESHOOTING......................................................... 5-1

CONTENTS

NORAM 65ET GRADER

0-2

NORAM 65ET GRADER

0-1

Safety 0

Throughout this manual and on machine decals, you will find precautionary statements ("CAUTION", "WARNING",

and "DANGER") followed by specific instructions. These precautions are intended for the personal safety of you and

those working with you. Please take the time to read them.

CAUTION: THE WORD "CAUTION" IS USED WHERE A SAFE BEHAVIORAL PRACTICE

ACCORDING TO OPERATING AND MAINTENANCE INSTRUCTIONS AND COMMON SAFETY

PRACTICES WILL PROTECT THE OPERATOR AND OTHERS FROM ACCIDENT INVOLVEMENT.

WARNING: THE WORD WARNING DENOTES A POTENTIAL OR HIDDEN HAZARD WHICH HAS A

POTENTIAL FOR SERIOUS INJURY. IT IS USED TO WARN OPERATORS AND OTHERS TO

EXERCISE EVERY APPROPRIATE MEANS TO AVOID A SURPRISE INVOLVEMENT WITH

MACHINERY.

DANGER: THE WORD "DANGER" DENOTES A FORBIDDEN PRACTICE IN CONNECTION WITH A

SERIOUS HAZARD. FAILURE TO FOLLOW THE "CAUTION", "WARNING", "DANGER", AND

"STOP" INSTRUCTIONS MAY RESULT IN SERIOUS BODILY INJURY OR DEATH.

MACHINE SAFETY

Additional precautionary statements ("ATTENTION" and "IMPORTANT") are followed by specific instructions.

These statements are intended for machine safety.

ATTENTION:The word "ATTENTION" is used to warn the operator of potential machine damage if a certain

procedure is not followed.

IMPORTANT: The word "IMPORTANT" is used to inform the reader of something he or she needs to know to

prevent minor machine damage if a certain procedure is not followed.

PRECAUTIONARY STATEMENTS

PERSONAL SAFETY

1

NORAM 65ET GRADER

0-2

Safety

0

A careful operator is the best operator. Most

accidents can be avoided by observing certain

precautions. To help prevent accidents, read and take

the following precautions before operating machine.

Equipment should be operated only by those who are

responsible and instructed to do so.

GENERAL

1. Read the Operator's Manual carefully before using

the machine. Lack of operating knowledge can lead

to accidents.

2. Only allow properly trained and qualified persons

to operate the motor grader.

3. Wear proper safety equipment as required by the

job, such as hard hats, safety glasses, ear protection,

heavy gloves, reflective vests, etc. Consult your

employer, site supervisor or OSHA for specific

requirements.

4. To prevent falls, use assist rails and steps when

getting on and off the machine. Keep steps and

platform clear of mud, oil, grease, snow, tools, and

debris.

5. Do not use controls or hoses as handholds when

climbing on or off machine. Controls may move and

inadvertently cause machine travel or implement

movement.

6. Do not permit anyone but the operator to ride on

the motor grader. There is no safe place for extra

riders.

7. Never use moldboard or implements as a

personnel lift.

8. Do not use the machine as scaffolding or a work

platform.

9. Replace all missing, illegible or damaged safety

decals.

10. Keep safety decals free of dirt and grime.

11. Do not modify or alter or permit anyone to

modify or alter machine or any of its components or

machine functions without first consulting an

authorized dealer.

12. Do not operate machine without ROPS or FOPS

in place and in good condition.

13. Install all shields before starting or operating

machine.

14. Do not operate an unsafe machine. If items are

found during inspection that render a machine

unsafe, be sure any malfunctions are remedied before

accepting responsibility for operation.

OPERATING

1. Do not start engine or operate controls while

standing beside the vehicle. Always sit in the seat

when starting engine or operating controls.

2. Do not operate an unsafe machine. Be sure that

any reported problems have been repaired and all

shielding is in place before accepting responsibility

for machine operation.

3. Do not bypass transmission neutral start switch.

Consult an authorized dealer if the neutral start

controls malfunction. Use jumper cables only in the

recommended manner. Improper use can result in a

runaway vehicle.

4. Check brakes, steering and implement controls

before moving. Advise maintenance personnel of

malfunctions before operating. Be sure malfunctions

are remedied before accepting responsibility for

operation.

5. Avoid accidental contact with the transmission

control lever while the engine is running. Unexpected

movement may result from such contact.

6. Do not get off or on the vehicle while it is moving.

7. Lower unlocked implements to the ground, apply

parking brake and shut off the engine before getting

off the machine.

8. Do not use machine to carry loose objects or attach

implements in ways other than intended.

SAFETY PRECAUTIONS

NORAM 65ET GRADER

0-3

Safety 0

9. Install lock pins in front and rear mounted

implements before transporting machine between

job sites.

10. Do not park on a steep incline.

11. Do not operate the vehicle in an enclosed building

without adequate ventilation. Exhaust fumes can

cause death.

12. If the power steering or engine ceases to operate,

stop the vehicle immediately.

13. Stop the engine and relieve pressure before

connecting or disconnecting hydraulic, steering or

fuel lines.

14. Tighten all connections before starting engine or

pressurizing lines.

15. Remember that the vehicle, if abused or

incorrectly used, can be dangerous and become a

hazard to the operator and bystanders.

16. Noise levels can exceed recommended levels when

working between buildings or in confined areas on

canopy equipped machines or cab equipped

machines with doors and windows open. Use ear

protection when warranted.

17. Always look in the direction of travel when

moving the machine. Be sure personnel in the area

are clear before moving the machine or implements.

If someone arrives in the operating area, stop the

machine immediately.

18. When transporting or travelling on roads,

position moldboard within width of machine.

19. When driving on roads have consideration for

other road users. Pull to the side of the road so

following traffic may pass. Maintain a safe distance

from other vehicles. Yield right of way to loaded

machines.

20. Obey federal, state and local laws concerning

slow-moving emblems, flashers, rotating beacons

and licensing requirements.

21. Obey flagmen, safety signals and signs.

22. Dim vehicle lights when meeting a vehicle at

night. Make sure lights are adjusted to prevent

blinding oncoming drivers.

23. Reduce speed before turning or applying brakes.

24. Use extreme caution and avoid hard application

of brakes when towing.

25. Always check overhead clearance, especially

when transporting. Be aware of low, overhanging

obstacles, such as trees and bridges.

26. Know the exact location of gas lines, utility lines,

sewers, overhead and buried power lines and other

obstructions before operating in an area.

27. Use a signal person in congested areas or when

people are around.

28. Use extreme caution when operating on slopes.

Avoid traveling across slopes. Drive up and down

slopes whenever possible.

29. If slopes cannot be avoided, keep moldboard low

and close to the machine. If machine starts to slip,

lower moldboard to the ground.

30. To avoid overturns, drive the vehicle with care

and at speeds compatible with safety, especially when

operating over rough ground, when crossing ditches

or slopes and when turning.

31. Select the same gear when going downhill as you

would going uphill. Select the gear before starting

down the slope.

32. Do not coast or freewheel machine down hills or

slopes.

SERVICING

1. Do not allow unauthorized personnel to service or

maintain this machine. Do not perform any work

that is not authorized.

2. Machine should not be serviced with anyone in the

operator's seat unless that person is qualified and is

assisting in the service procedure. Be sure operator

can see mechanic.

1

NORAM 65ET GRADER

0-4

Safety

0

3. Always use external supports when working under

any linkage or raised part of the machine. Lower

implements to the ground whenever possible.

4. The cooling system operates under pressure that is

controlled by the radiator cap. It is dangerous to

remove the cap while the system is hot. Always turn

cap slowly to the first stop and allow pressure to

escape before removing the cap entirely.

5. The hydraulic system operates under pressure that

is controlled by the reservoir cap. Always turn cap

slowly to relieve pressure before removing cap

entirely or disconnecting any hydraulic lines.

6. Do not smoke while refueling the vehicle. Keep any

type of open flame away. Wait for the engine to cool

before refueling.

7. Keep vehicle, particularly brakes and steering,

maintained in a reliable and satisfactory condition to

ensure your safety and comply with legal

requirements.

8. To prevent fire or explosion, keep open flames

away from battery or cold weather starting aids. To

prevent sparks which could cause explosion, use

jumper cables according to instructions.

9. Do not attempt to service air conditioning system,

if equipped. It is possible to be severely frostbitten or

injured by escaping refrigerant. Special equipment

and instruments are required to service air

conditioning system. See an authorized dealer for

service.

10. Stop the engine before performing any service on

the vehicle.

11. Always turn master switch to the "off" position

when maintaining or servicing machine.

12. When using compressed air for cleaning parts,

use safety glasses with side shields or goggles. Limit

pressure to 30 psi.

13. Escaping diesel/hydraulic fluid under pressure

can penetrate skin causing serious injury.

14. DO NOT use your hand to check for leaks. Use a

piece of cardboard to search for leaks.

· Stop engine and relieve pressure before connecting

or disconnecting lines.

· Tighten all connections before starting engine or

pressurizing lines.

· If fluid is injected into skin, obtain medical

attention immediately or gangrene may result.

15. Do not modify or alter or permit anyone else to

modify or alter the vehicle or any of its components

or any functions without first consulting an

authorized dealer.

16. Fuel oil in the injection system is under high

pressure and can penetrate the skin. Unqualified

persons should not remove or attempt to adjust a

pump, injector nozzle or any other part of the fuel

injector system. Failure to follow these instructions

can result in serious injury.

17. Continuous long-term contact with used engine

oil may cause skin cancer. Avoid prolonged contact

with used engine oil. Wash skin promptly with soap

and water.

18. Wheels can be very heavy. Handle with care and

ensure, when stored, that they cannot fall and cause

injury.

19. When checking tire inflation pressure, stand to

the side in case of explosion.

20. Never use reconditioned tire rims.

21. If brakes are to be serviced, the machine must be

secured to prevent movement.

22. Dispose of all drained fluids and removed filters

properly.

NORAM 65ET GRADER

0-5

Safety 0

DIESEL FUEL

1. Under no circumstances should gasoline, alcohol

or blended fuels be added to diesel fuel. These

combinations can create an increased fire or

explosive hazard. In a closed container, such as a fuel

tank, these blends are more explosive than pure

gasoline.

2. Never remove the fuel cap or refuel with the

engine running.

3. Do not smoke while refueling the machine or when

standing near fuel. Keep any type of open flame

away.

4. Maintain control of the fuel filler nozzle when

filling the tank.

5. Do not fill the fuel tank to capacity. Allow room for

expansion.

6. Wipe up spilled fuel immediately.

7. Always tighten the fuel tank cap securely.

8. If the original fuel tank cap is lost, replace it with a

genuine replacement cap. A non approved cap may

not be safe.

9. Keep equipment clean and properly maintained.

10. Do not drive equipment near open fires.

11. Never use fuel for cleaning purposes.

12. Arrange fuel purchases so that summer grade

fuels are not held over and used in winter.

OPERATOR AREA

1. The motor grader is equipped with Roll Over

Protection System (ROPS) and a Falling Object

Protection System (FOPS) which must be

maintained in a serviceable condition.

2. Do not modify, drill, weld or alter the ROPS or

FOPS in anyway. Doing so could render you liable to

legal prosecution in some countries.

3. Never attempt to straighten or weld any part of

the main frame or retaining brackets that have

suffered damage. By doing so the structure may be

weakened and safety compromised. Replace all

damaged parts.

4. Be careful when driving under bridges or working

in confined spaces with low headroom.

5. Never attach chains or ropes to the ROPS or

FOPS for pulling purposes.

6. Never take unnecessary risks even though the

ROPS and FOPS provide protection.

1

NORAM 65ET GRADER

0-6

Safety

0

Safety Decals

The following safety decals have been placed on your machine. They are intended for your personal safety and for

those working with you. Please take this manual and walk around your machine to note the content and location of

these warning signs. Review these warning signs and the operating instructions detailed in this manual with the

operators of this machine.

NORAM 65ET GRADER

0-7

Safety 0

The motor grader is equipped with a Roll Over

Protection System (ROPS) and Falling Object

Protection System (FOPS) and a seat belt. An optional

enclosed cab is available which is also ROPS and FOPS

certified. The seat belt must be used for the ROPS and

FOPS to function and keep the operator in the

prescribed area.

WARNING: ALWAYS USE THE SEAT BELT.

If the motor grader has rolled over or the ROPS or FOPS

has been damaged, it must be replaced to provide the

original amount of protection. Damage may be caused

by rollover, striking an object while being hauled on a

trailer, rocks falling on the top canopy, etc.

IMPORTANT: Do not attempt to weld or straighten

ROPS or FOPS components.

ROPS/FOPS MAINTENANCE AND INSPECTION

To continue to provide the maximum protection

available, the ROPS and FOPS must be maintained for

the life of the machine. Every 500 hours or three

months:

1. Check torque of cab and ROPS mounting bolts.

Torque cab mounting bolts, 1, to 745-814 N×m (550-

600 ft-lbs.). Torque ROPS mounting bolts, 2, to 311-447

N×m (230-330 ft-lbs.).

2. Check the operator's seat and seat belt mounting

bolts, 1. Torque seat belt and eyelet anchor bolts to 54-

61 N×m (40-45 ft-lbs.). Inspect the seat belt for tears,

rips, worn or stretched areas. Replace any worn or

damaged parts.

WARNING: IF ROPS/FOPS IS REPLACED, MAKE CERTAIN PROPER HARDWARE IS USED AND

CORRECT TORQUE VALUES ARE APPLIED TO MOUNTING BOLTS.

ROPS AND FOPS USAGE

1

NORAM 65ET GRADER

0-8

Safety

0

NORAM 65ET GRADER

1-1

General Information 1

SECTION 1 - GENERAL INFORMATION

INTRODUCTION TO THIS MANUAL

This manual provides correct procedures for break-in,

driving, operating and maintaining the motor grader.

The manual is divided into five sections as detailed in

the “Table of Contents” page.

Read this manual carefully and keep it in the manual

holder inside the storage compartment for future

reference. If at any time a question arises concerning the

equipment, contact an authorized NORAM Dealer.

Factory-trained personnel, genuine replacement parts

and the necessary equipment are available for all service

requirements.

This machine has been designed and built to give

maximum performance, economy and ease of operation

under a variety of operating conditions. Prior to

delivery, the unit was carefully inspected, at the factory

and by the dealer, to ensure that it is delivered in

optimum condition. To maintain this condition and

ensure trouble-free operation, it is important that the

routine services, as specified in this manual, are carried

out at the recommended intervals.

All data given in this book is subject to production

variations. Dimensions and weights are approximate

only and the illustrations do not necessarily show

equipment in standard condition.

To provide a better view, certain illustrations in this

manual show safety shields removed. It is important that

the machine never be operated this way. Keep all shields

in place.

The information contained in this manual is intended to

be of general nature only. The manufacturer may at any

time, for technical or other necessary reasons, modify

any of the details or specifications of the product

described in this manual. The dimensions, weights and

capacities shown within normal manufacturing

techniques. Please read the safety precautions carefully

and follow the advise offered BEFORE operating the

machine.

1

NORAM 65ET GRADER

1-2

General Information

1

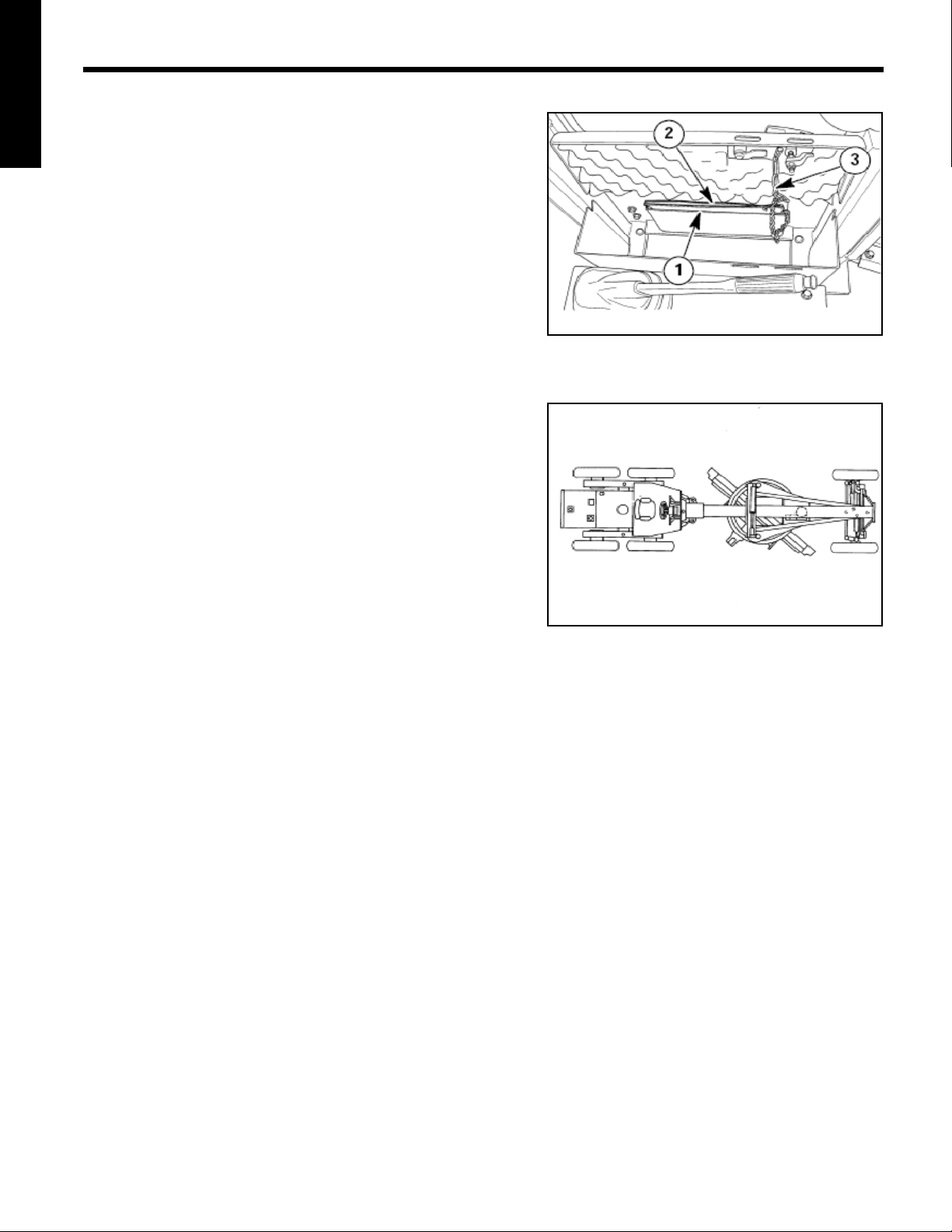

OPERATOR’S MANUAL HOLDER

Inside the storage compartment on the left side of the floor is a

slot, 1, for storing the Operator's Manual, 2. A chain lanyard, 3,

inside the storage compartment secures the manual to the machine.

IMPORTANT: According to OSHA regulations, this manual

must be available to the operator of this machine at all times. If the

manual becomes illegible or is lost, contact an authorized dealer

for instructions on how to order a replacement manual.

ORIENTATION

The NORAM 65ET motor grader is an articulated grader designed

for moving material using a moldboard mounted underneath

between the front and rear wheels. Options are available for front

and rear mounted attachments to compliment the use of the mid-

mounted moldboard.

References will be made throughout this manual to describe

location and direction. Unless otherwise specified, reference to

direction is from the operator's seat.

TERMINOLOGY

Front and rear modules are separated at the articulation pins in front of the cab. The moldboard is suspended from the

front frame through a series of hydraulic cylinders and a circle. The circle is rotated by a gearbox. Load is transferred

through a draw bar attached to the front frame.

Articulation allows the motor grader to bend at a pivot point between the front and rear modules. Steering is also

available through the front tires. Additional control is provided by front tire lean.

The engine power is delivered through the transmission, rear axle and tandem cases to the rear wheels. A torque

converter controls power delivery into the transmission.

NORAM 65ET GRADER

1-3

General Information 1

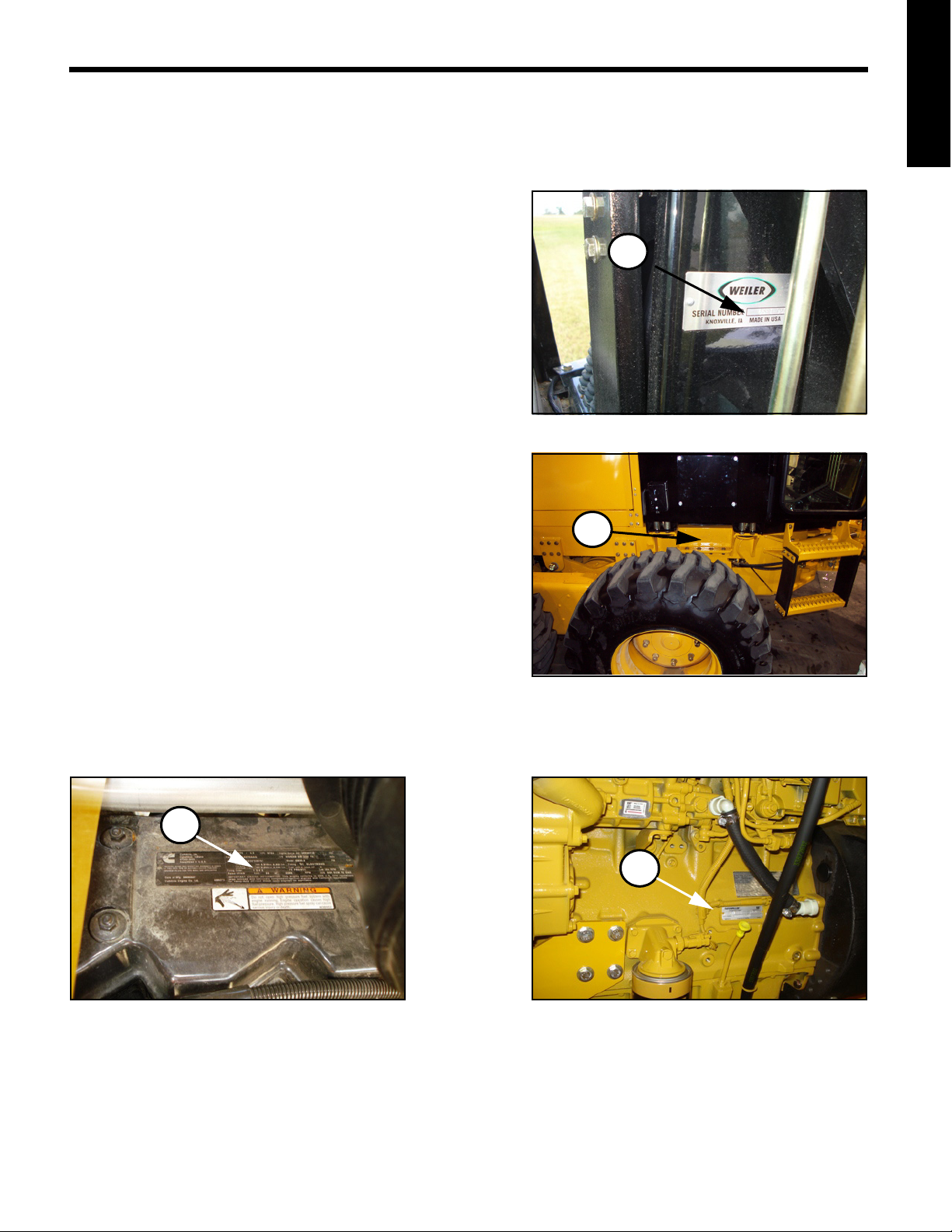

IDENTIFICATION NUMBERS

The motor grader and major components are identified by serial numbers. The serial numbers are required when

ordering parts. For easy reference the identification data should be recorded and kept in a safe place away from the

machine.

The vehicle serial number and point of manufacture is stamped

into the serial tag, 1, placed on the left side of the steering column.

The vehicle serial number,1, is also stamped into to right side of

the frame below the operators platform.

An engine identification plate, 1, is located on the top of the Cummins engine (left picture). The identification plate is

located on the left side of the Cat engine (right picture).

CUMMINS ENGINE CAT ENGINE

1

1

1

1

1

NORAM 65ET GRADER

1-4

General Information

1

The differential identification plate, 1, is located on the right

tandem support.

The transmission identification plate, 1, is located on the front side

of the transmission below the drive shaft.

1

1

NORAM 65ET GRADER

1-5

General Information 1

PROTECTIVE SHIELD

The engine and transmission compartments are covered to protect personnel from hot and moving parts. Inside the

rear shell shields surround the fan and belts at the rear of the machine.

WARNING: DO NOT OPERATE MOTOR GRADER WITHOUT ENGINE COVER AND ACCESS

DOORS IN PLACE AND LATCHED. DO NOT OPERATE WITH FAN AND BELT GUARDS REMOVED

OR BROKEN.

Engine access doors are located on each side of the engine cover.

A lock is in the handle (1). Turn the handle 180° to unlatch.

The left side door provides access to the following:

CUMMINS ENGINE CAT ENGINE

1. Engine air filter 1. Engine air filter

2. Primary fuel filter 2. Primary fuel filter

3. Secondary fuel filter 3. Secondary fuel filter

4. Engine oil dipstick 4. Engine oil dipstick

5. Fuel fill neck 5. Fuel fill neck

6. Washer fluid tank 6. Engine oil filter

7. Muffler 7. Muffler

1

1

3

4

6

5

2

7

1

5

2

4

6

3

7

1

NORAM 65ET GRADER

1-6

General Information

1

The right side door provides access to the following:

CUMMINS ENGINE CAT ENGINE

1. Electric master switch 1. Electric master switch

2. Brake reservoirs 2. Brake reservoirs

3. Engine oil filter 3. Washer fluid tank

On top of the engine cover is the radiator access door, 1. The hydraulic reservoir fill cap, 2, is inside the right side

door panel.

The transmission oil fill neck and dipstick, 1, is located behind the

right side access door.

1

2

3

1

2

3

1

2

1

NORAM 65ET GRADER

1-7

General Information 1

FOPS AND ROPS

All motor graders are equipped with a seat belt. A Roll Over Protection System (ROPS) and Falling Object

Protection System (FOPS) are standard. If the unit were to rollover, keep hands and feet within the area of the ROPS.

The seat belt must be used to keep the operator in the seat.

Optional on the 65ET is an enclosed cab with heater and optional air conditioning for additional protection against

weather and operation in cold and hot climates. The cab is also FOPS and ROPS certified.

LOCK PINS

Lock pins are provided to prevent accidental movement of

hydraulic cylinders during maintenance or transport. The

articulation lock pin, 1, prevents articulation and should be stored

in the storage bracket, 2, during operation except when loading

machine on a trailer.

The wheel lean lock pin, 1, prevents side-to-side movement of the

front steering wheels but does not prevent steering. Remove the

wheel lock pin when operating the machine.

Front and rear-mounted implements have a lock pin, 1, to prevent

lowering of the implement. Implements should be locked when

ever travelling between job sites or transporting the motor grader

on a trailer.

1

NORAM 65ET GRADER

1-8

General Information

1

LIGHTING

Two work lights, 1, are mounted on the front frame facing the

moldboard. Two headlights and turn signals, 2, are mounted at the

front of the machine. Two optional work lights, 3, may be

mounted on the top of the cab facing forward.

Two optional work lights, 1, are mounted on top of the cab facing

rearward. Turn signals/taillight/brake lights, 2, are mounted at the

rear.

IMPORTANT: Do not use work lights for highway travel.

1

2

3

1

2

Other manuals for 65E Turbo

1

Table of contents

Other NorAM Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Landoll

Landoll 600C Series Operator's manual

Toro

Toro TransPro 80 installation instructions

Ifor Williams Trailers

Ifor Williams Trailers HBX User handbook

Hisun Motors

Hisun Motors SECTOR 450 Maintenance handbook

Ventrac

Ventrac KW452 Operator's manual & parts drawings

J&J Amusements

J&J Amusements Falcon Go-kart 2018 Service manual