Version Screen

Set Up Menu

Setting Options

Language: en / fr / de / it / da / es / fi /

sv / no / pt

LCD Contrast: 1 – 255 (Default 160)

LCD Invert: Invert (✓) or non-invert ()

Zero: Reset the stored Zero value

Beep: Enable (✓) or disable ()

Active From: 2.0 to 40.0 % (default 2.0%)

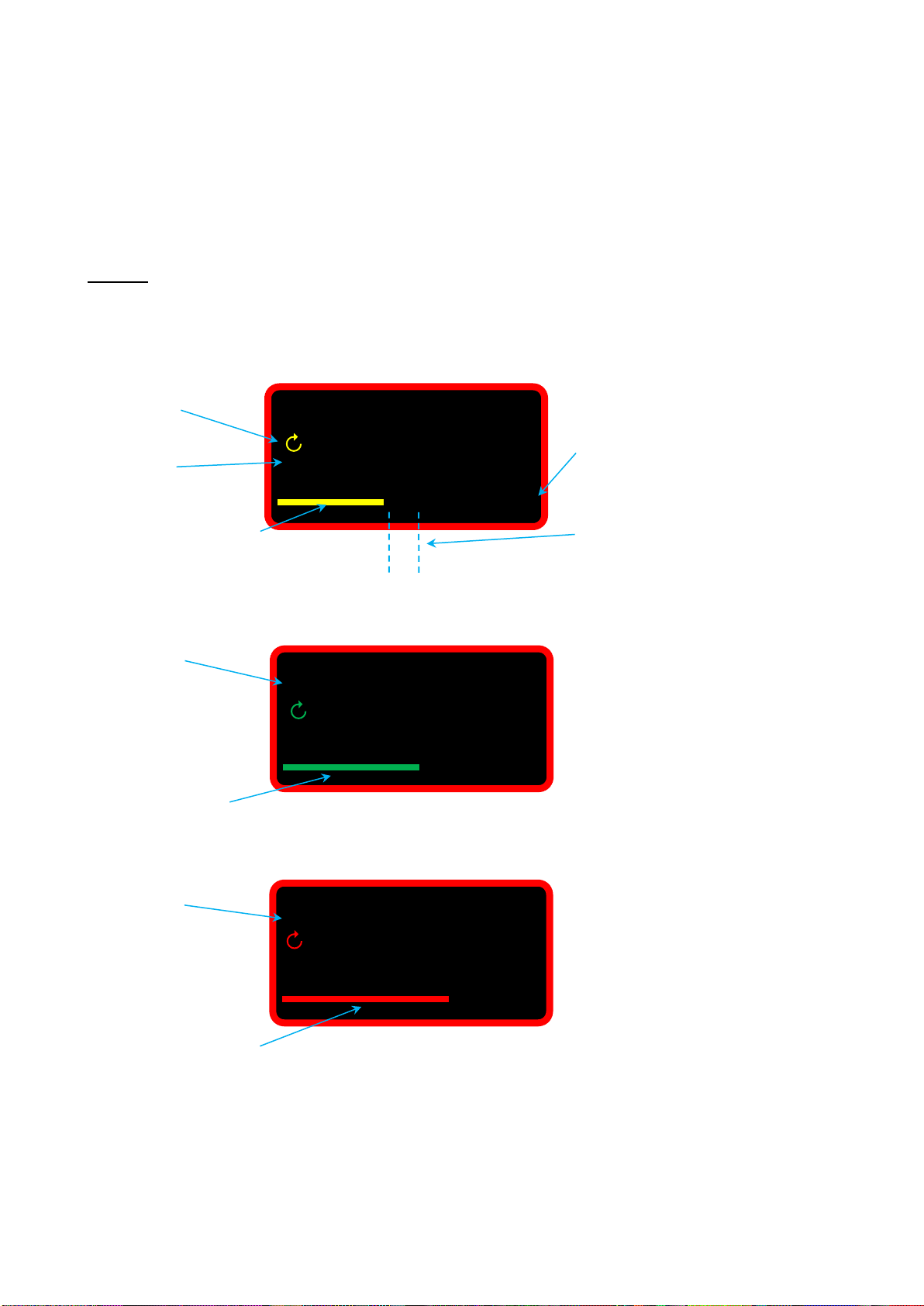

Zero Resetting

Zero resetting should only be performed if the TruCheck™ 2 Plus won’t zero in Track mode. If this is the

case the transducer may have been overstrained.

If the reading is unstable the TruCheck™ 2 Plus should be returned to a supplier approved agent for repair. It

is recommended to get the TruCheck™ 2 Plus recalibrated as soon as possible after resetting the zero.

Make sure no torque is being applied to the TruCheck™ 2 Plus and remove any tools from the input drive

when resetting the zero.

Active From Setting

This is the percentage of capacity at which Click mode and Dial mode will start to capture peak values.

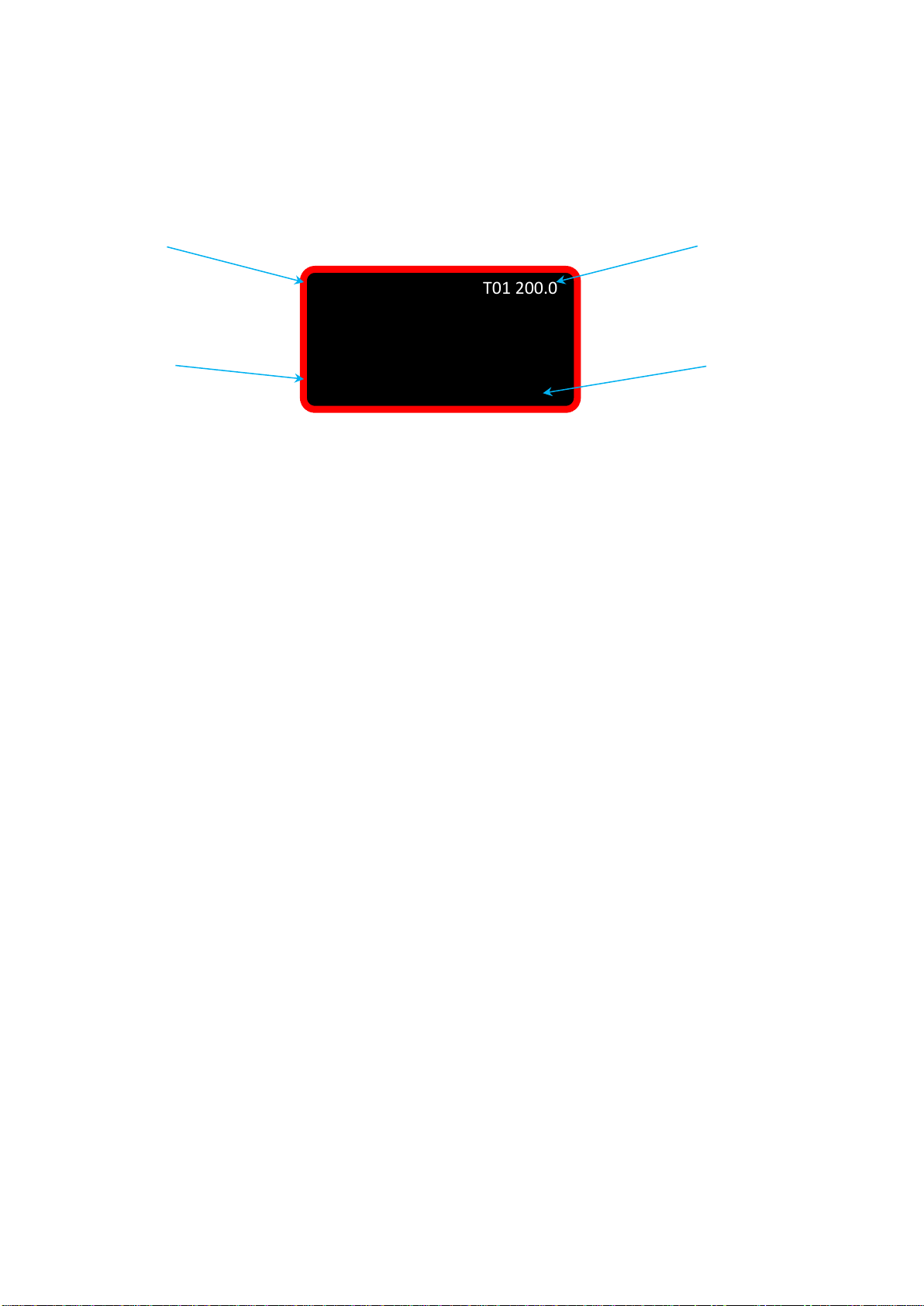

P/N 43525

S/N 124356

S/W 1.0.1

Press and hold from the measurement screen

to view the version screen

The version screen contains:

P/N (Part Number of the TruCheck™2 Plus)

S/N (Serial Number)

S/W (Software Version Number)

Press to return to the measurement screen

or

Press to enter the set up menu

Language en

LCD Contrast 160

LCD Invert ✓

Zero

Beep ✓

Active From 2.0%

Select menu item (e.g. Language)

Confirm item

Change setting (e.g. en to fr)

Confirm setting

Select and press to save and exit

Cancel (exit without saving changes)