FEATURES AND FUNCTIONS

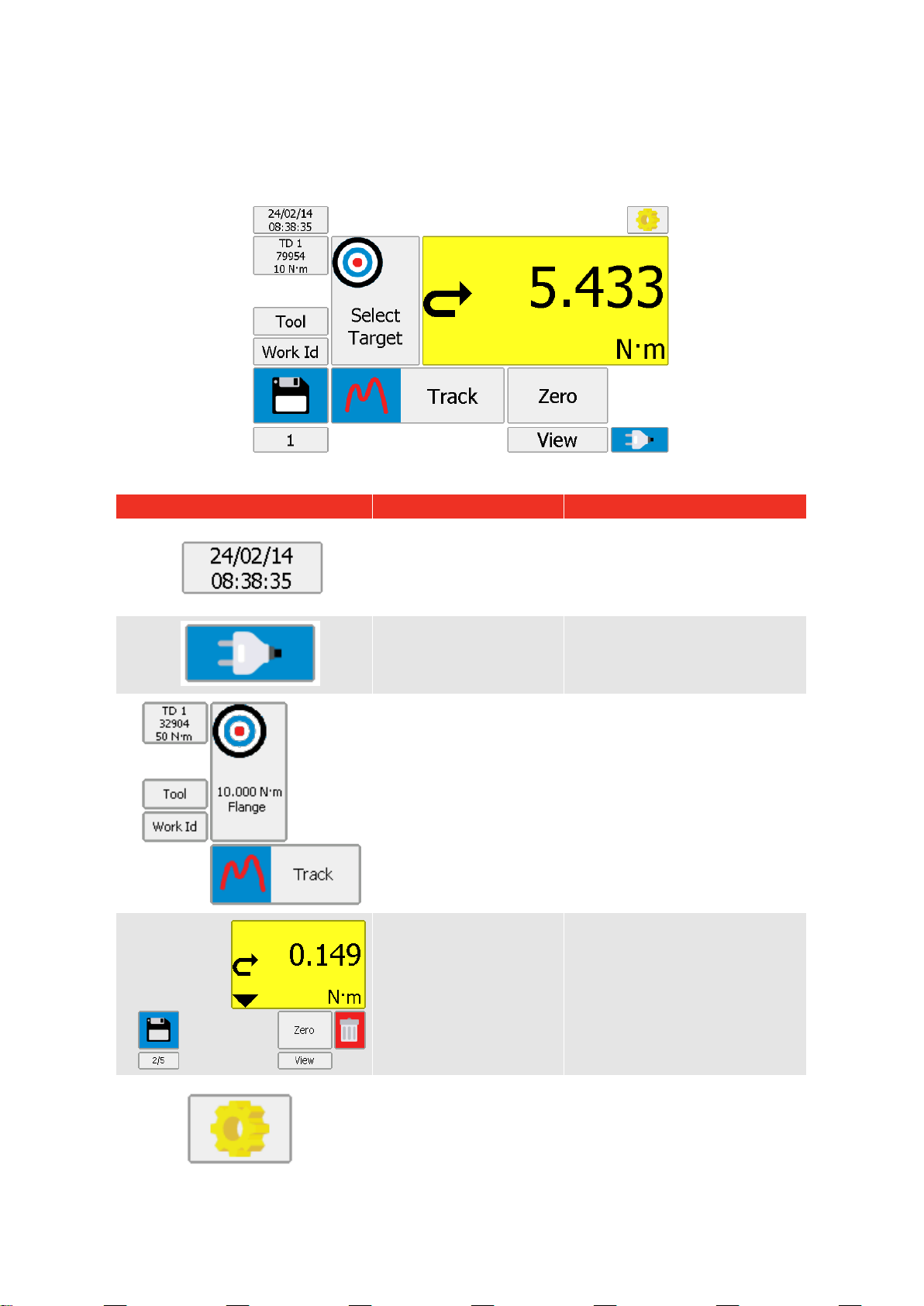

7” WVGA Colour touch screen with clear icons for ease of use.

Hand held with neck strap or bench mounted.

4 transducer inputs with ergonomic front panel selection switch.

Automatically recognises any ‘SMART’ Norbar transducer.

Can also work with most mV/V transducers from Norbar or other manufacturers.

5 digit resolution for all Norbar transducers.

Operational from internal rechargeable battery or power supply adaptor.

Multiple Targets to indicate status of Torque & Angle results. The Targets status is shown as symbols and

background colours on the display, as well as outputs on the ancillaries connector and serial port.

Continuous Data logging of Torque or Torque & Angle results for transfer to TDMS.

Ability to link targets for applications that require tightening in a sequence.

Selectable frequency response for each mode of operation.

Password protection of all selectable features to virtually eliminate operator induced errors.

Ancillaries connector with analogue output & GO/NO GO control for external equipment.

Serial Port for data output to a PC or printer.

93MB results memory. An example of memory storage.

1000 sets of 20 results 6,000KB

Templates for all Norbar tools (Torque Wrenches, PneuTorques & EvoTorques) to enable the operator to

easily perform calibrations on their tools to the relevant ISO standard using the in-built calibration

program.

In addition templates exist for all torque tools covered in ISO 6789:2003 with other tools easily added.

Pre-programmed calibration routines to ISO6789:2003.

Automatically guides the user through the calibration routine required for the Tool.

2 USB ports for data transfer. Can be used with Bar code scanner, Mouse, Keyboard, Printer, Hub, etc.

12 languages.

8 modes for torque tool measurement: ‘Track’, ‘Click’, ‘Dial & Electronic’, ‘Stall’, ‘Screwdriver’,

‘Hydraulic’, ‘Graph’ (for visual analysis of torque profiles) and ‘Pulse’ (with a unique pulse tool algorithm

to accurately determine pulse tool torque output).

All Peak and 1st Peak modes can be configured for either Manual or Auto Reset.

13 Torque units. Plus custom units for measurement of load, pressure, etc.

Time & date stamp with results.

Displays torque only, torque & angle, torque & speed, torque & power, torque & turns and torque & rate.

TDMS (Torque Data Management System) software included for complete data management and

archiving to a PC. Includes seamless data synchronisation. See TDMS Operator’s Manual part number

34342 for more information.