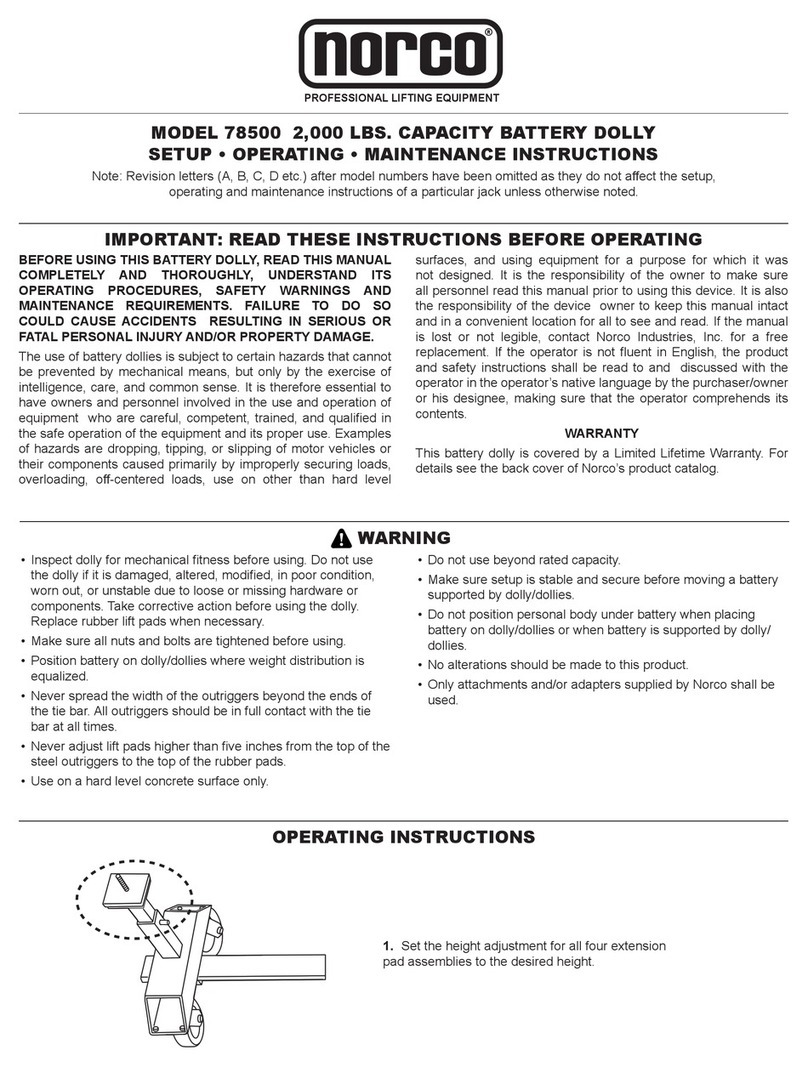

OPERATING INSTRUCTIONS

1. Lift the vehicle to the desired work height and support the

vehicle in accordance with the manufacturer’s recommended

support procedure and the warnings given in this manual.

2. Follow the manufacturer’s recommended service procedure for

removing and installing the component.

3. When removing a transmission, use an under hoist stand rated

greater than the weight of the engine to support the engine before

unbolting the transmission from the engine.

4. Position the lift table directly under the component to be lifted.

Connect shop air supply to the air/hydraulic foot pump (use

minimum 90 P.S.I. air pressure, do not exceed 120 P.S.I.).

5. IMPORTANT: Become familiar with the operation of the air/

hydraulic pump before using the table under load. To raise: turn

ngertip control lever closest to the air inlet clockwise. A gentle

turn will result in a slower lift; a rm turn will result in a faster lift.

To lower: turn ngertip control lever farthest from the air inlet

clockwise. A gentle turn will result in a slow, gradual descent; a

rm turn will result in a quick descent.

6. If using the universal table, adjust the blocks to t the

component conguration. Secure the blocks to the universal

table by tightening the bolts provided. If using the transmission

adapters, adjust the support arms or position the risers to t the

oil pan ange conguration. Tighten the hardware that secures the

support arms to the adapter.

7. Turn the universal saddle adjusting screws to align the saddles

or adapters with the component lift surface.

8. Use the included tie downs to secure the components to the

saddle or adapter. Make sure the setup is stable before lowering

the load.

9. Follow the vehicle manufacturer’s recommended service

procedure and this manual’s operating instructions when

reinstalling the component.

REPAIR SERVICE

If your Norco product requires service or repair, contact the Norco

Customer Service Department for the location of the nearest Norco

Authorized Service Center.

Norco Industries, Inc.

365 West Victoria St.

Compton, CA 90220

(310) 639-4000 • Fax: (310) 639-7411

www.norcoindustries.com

It will be necessary to provide the Norco Authorized Service Center

with a copy of the bill of sale if requesting warranty repair. If the

authorized service center determines your product is eligible for

warranty repair, the repair will be made at no charge and returned

freight prepaid. The cost of non-warrantable service, repair, and

return freight is the customer’s responsibility.

1. Always store the lift table in a well protected area where it will

not be exposed to inclement weather, corrosive vapors, abrasive

dust, or any other harmful elements. The lift table must be cleaned

of water, snow, sand, or grit before using.

2. Lubricate moving parts once a month with a general purpose

grease. Inspect all lift arms, saddle base and cylinder assemblies

to make sure all related bolts and nyloc nuts are tight but do not

restrict the movement of assembly components that rotate on the

bolts.

3. It should not be necessary to rell or top o the reservoir with

hydraulic uid unless there is an external leak. An external leak requires

immediate repair which must be performed in a dirt-free environment

by qualied hydraulic repair personnel who are familiar with this

equipment. Norco Authorized Service Centers are recommended.

IMPORTANT: In order to prevent seal damage and lift table

failure, never use alcohol, hydraulic brake uid, or transmission

oil in the lift table’s hydraulic ram or air/ hydraulic foot pump.

Only use hydraulic oil with the specication AW ISO 32

4. Every lift table owner is responsible for keeping the lift table

label clean and readable. Use a mild soap solution to wash external

surfaces of the lift table but not any moving hydraulic components.

Contact Norco Industries for a replacement label if your jack’s label

is unreadable.

5. Inspect the lift table before each use. Do not use the lift table if

any component is cracked, broken, bent, shows sign of damage,

or leaks hydraulic uid. Do not use the lift table if it has loose or

missing hardware or components, or is modied in any way. Take

corrective action before using the lift table again.

6. Do not attempt to make any hydraulic repairs unless you

are a qualied hydraulic repair person that is familiar with this

equipment.

PREVENTATIVE MAINTENANCE

72674