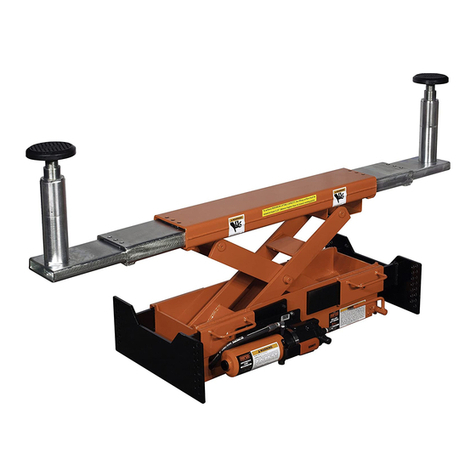

OPERATING INSTRUCTIONS

Hydraulic bottle jacks are used on every model wheel dolly.1.

Become familiar with the operation of the bottle jack. The jack’s

release valve knob must be turned in a clockwise direction until

tight before the jack can be pumped. Turning the release valve

knob very slowly in a counterclockwise direction lowers the load in

a safe controlled manner. There should never be a reason to turn

the release valve knob in a counterclockwise direction more than

two full turns.

Bottle jacks are used to lift tire and wheel combinations that2.

are supported by the lift arms on the models 82300, 82301, 82303

and 82315. A winch is used to lift the tire and wheel combinations

on the model 82302. Read the winch operations manual that

accompanied this wheel dolly for instructions on the proper use

and care of the winch.

Models 82300, 82301, 82303 and 82315 are equipped with3.

screw adjustable rear caster/s that are manually raised or lowered

to match the spindle angle. The bottle jack on the model 82302

serves the same purpose.

After the vehicle is raised and correctly blocked, push the4.

wheel dolly in towards the tire/wheel combination to be lifted. The

wheel dolly lift arms should straddle the tire and the sidewall of the

tire should be as close as possible to the vertical portion of the lift

member. Raise the lift arms to meet the tire/s and adjust the lift

arm angles so the arms are in full contact with the tire/s.

Secure the tire/wheel combination to the dolly with the safety5.

restraint chain provided. Wrap the chain around the tire and secure

the chain hook or chain loop to the dolly.

Continue to lift the tire/wheel combination until the entire weight6.

is supported by the dolly lift arms. Back the dolly away to remove

the tire/wheel combination.

If the wheel bearings need packing, lower the tire/wheel7.

combination to the oor, remove the safety chain and then remove

the dolly. The model 82303 lift/tilt wheel dolly has a tilt feature

which permits packing of wheel bearings while the tire/ wheel

combination remains on the dolly.

After packing the wheel bearings, install the wheel dolly and8.

safety restraint chain around the tire and raise the tire/wheel

combination to the required height. Adjust the lift arm tilt to match

the spindle angle and install the assembly. Make sure the tire/

wheel combination is securely positioned on the wheel spindle and

then back the dolly away.

REPAIR SERVICE

If your Norco product requires service or repair, contact the Norco

Customer Service Department for the location of the nearest Norco

Authorized Service Center.

Norco Industries, Inc.

365 West Victoria St.

Compton, CA 90220

(310) 639-4000 • Fax: (310) 639-7411

www.norcoindustries.com

It will be necessary to provide the NorcoAuthorized Service Center

with a copy of the bill of sale if requesting warranty repair. If the

authorized service center determines your product is eligible for

warranty repair, the repair will be made at no charge and returned

freight prepaid. The cost of non-warrantable service, repair, and

return freight is the customer’s responsibility.

Always store the wheel dolly in a well protected area where1.

it will not be exposed to inclement weather, corrosive vapors,

abrasive dust, or any other harmful elements. The wheel dolly

must be cleaned of water, snow, sand, or grit before using.

Lubricate moving parts once a month with a general purpose2.

grease, particularly the rear caster/s adjustment thread.

It should not be necessary to rell or top off the reservoir with 3.

hydraulic uid unless there is an external leak. An external leak

requires immediate repair which must be performed in a dirt-

free environment by qualied hydraulic repair personnel who are

familiar with this equipment. NorcoAuthorized Service Centers are

recommended. IMPORTANT: In order to prevent seal damage

and hydraulic failure, never use alcohol, hydraulic brake uid,

or transmission oil in the hydraulic system.

Every wheel dolly owner is responsible for keeping the dolly4.

labelcleanandreadable.Use amild soapsolutiontowashexternal

surfaces of the dolly but not any moving hydraulic components.

Contact Norco Industries for a replacement label if your dolly label

is unreadable.

Inspect the wheel dolly before each use. Do not use the dolly if5.

any component is cracked, broken, bent, shows sign of damage,

or leaks hydraulic uid. Do not use the dolly if it has loose or

missing hardware or components, or is modied in any way. Take

corrective action before using the dolly again.

Do not attempt to make any hydraulic repairs unless you6.

are a qualied hydraulic repair person that is familiar with this

equipment.

PREVENTATIVE MAINTENANCE

82300 / 82301 / 82303 / 82315 / 82303