Troubleshooting

Troubleshooting

Thissectionwilldiscussvariousissuesthatmayoccur,

whatcausesthem,andwhatpossiblesolutionsare.

1) No status LEDs turned on in Diagnostic Cockpits.

Checkinputmains ACpowersupply andinternal

wiring.

- ConrmthattheACpowerissecurelyconnected

toterminalsL1&N.

- Withamultimeter,measurethephase-to-phase

ACvoltage(L1-N).Voltagereadingsshouldbe

between200and240VAC.

oIfthevoltagesarenotmeasuredasindicated,

inputpowermustbe adjustedtoreectthe

abovespecications.

2) Drive Status LED1 flashing red, green off.

SK200Eisfaultedandtripneedstobecleared.

- Thenumber oftimes theLED ashes beforea

pauseindicatestheerrorcode.Example:LED1

ashes red 3 times before a pause. This indi-

cateserrorcode3whichmeansanovercurrent

faulthasoccurred.Theerrorcode,description,

andremediescanbefoundinsection7.2ofthe

SK200EoperationmanualBU0200.

- UsingeithertheNORDCONsoftwareortheSK

PAR-3Hparameterbox,theerrorcodecanalso

be determined by observing parameter P700

[-01] – Current Fault. Parameter P700[-01] is

locatedintheInformationparametergroup.

- TheconditionsthatcausedtheSK200Etofault

mustbeclearedbeforethedrivemaybestarted

again.

3) Drive Status LED1 flashing green slowly (standby

mode) but will not run when given enable

command.

Digital inputs 1 & 2 may not be wired and/or

conguredproperly.

- Check wiring of M12 receptacle. Conrm the

yellowwireisproperlyconnectedtoterminal21

and the grey wire is properly connected to

terminal 22.

- Conrm digital input parameters (Control

ClampsGroup)areconguredproperly.

oParameterP420[-01]:1-Enableright

oParameterP420[-02]:3-Phaseseq.reversal

- CheckparameterP708(Informationgroup)for

statusofdigitalinputswhilethecontrolpanelis

sendingenablecommands.

oIf using NORDCON, the status window does

not automatically update when the digital

input state changes. Press “Read” button

toupdatestatuswindow.Activeinputswill

haveacheckmarkdisplayed.

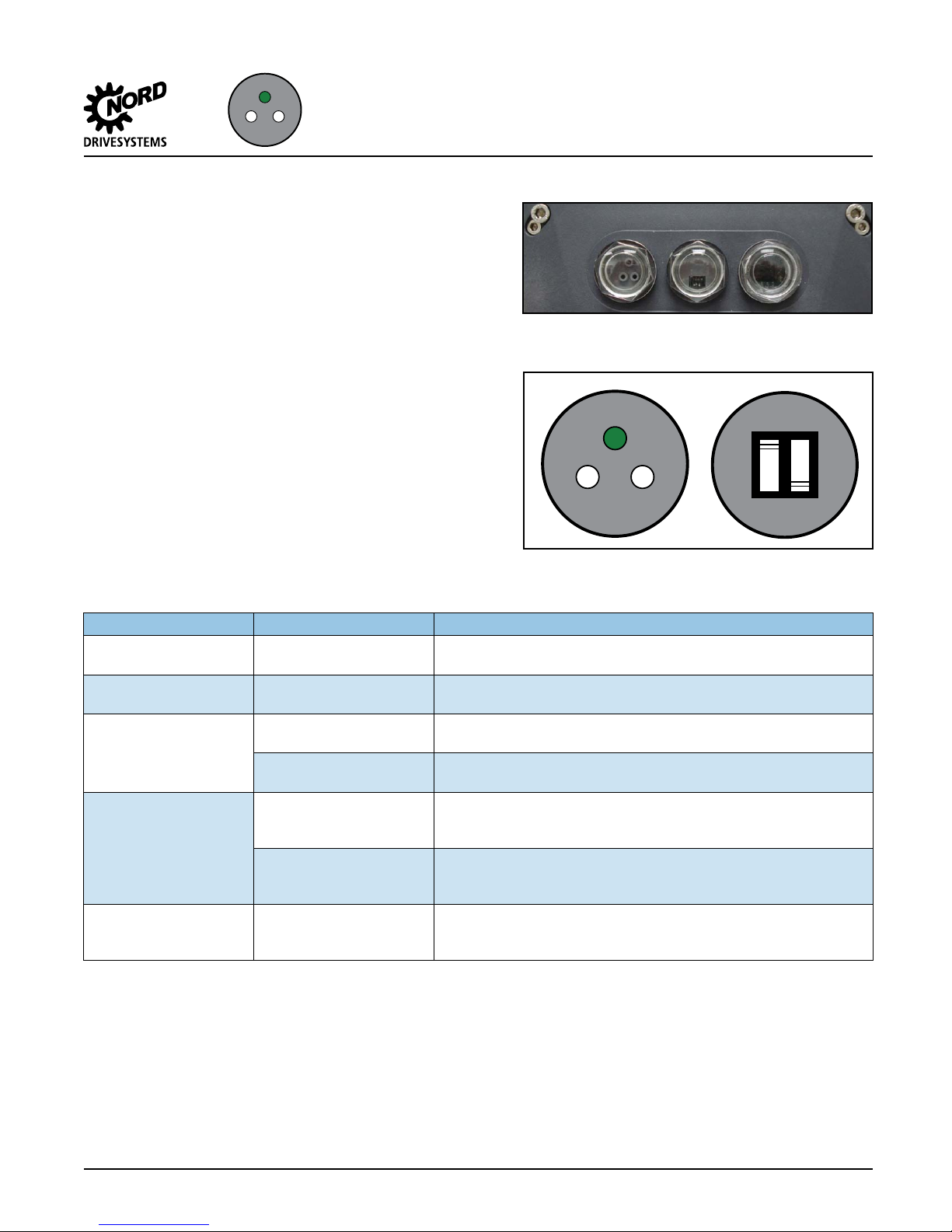

oIfusingtheSKPAR-3Hhandheldprogramming

tool,thedigitalinputstatewillautomatically

be displayed when changed. Active inputs

willbedisplayedasa“1”andinactiveinputs

willbedisplayedas“0”.Digitalinput1&2

willbeshownasthe1stand2nddigitsfrom

therightsideofthedisplayrespectively.The

5thdigitshouldalwaysshow“1”.Figure13

showsthisstate.

Figure 13 - State of Digital Inputs, P708

- Iftheinternalwiringiscorrectandifthestatus

ofparameterP708doesnotshowtheseinputs

as active, check external control wiring and

control.