SK 54xE – Users Manual for Frequency Inverters

6 BU 0505 EN-3021

Pos: 11 /Allgemein/St euermodule/Inhal tsverzeichnis @ 0\mod_1317 978518480_388.doc x @ 4078@ @ 1

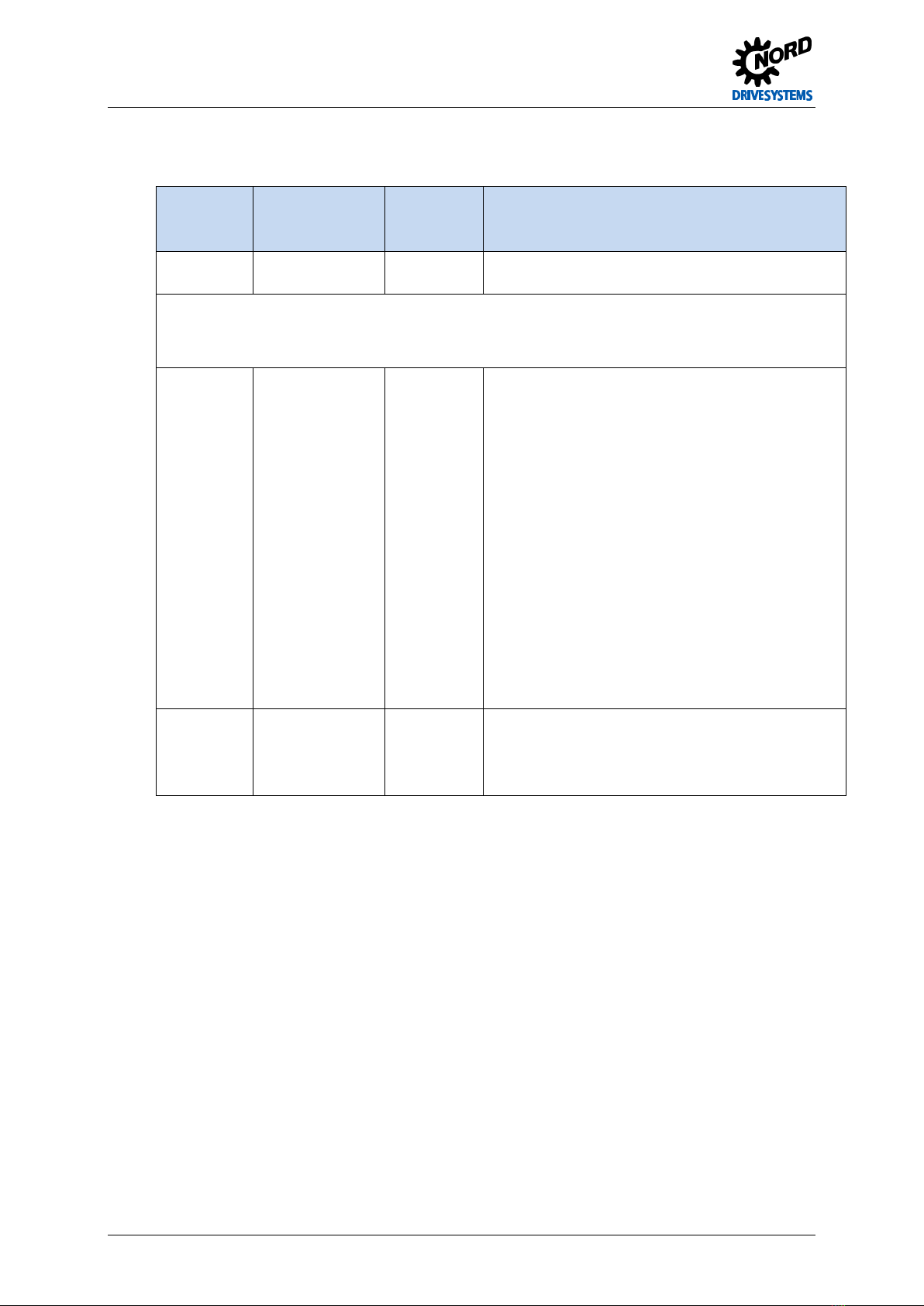

Table of Contents

=== Ende der Liste für Textmarke Inhal tsverzeichnis ===

1General................................................................................................................................................................ 10

1.1 Overview ..........................................................................................................................................................10

1.2 SK 5xxE with or without integrated mains filter...............................................................................................12

1.2.1 Operation of an SK 5xxE-…-A frequency inverter ..............................................................................12

1.2.2 Operation of an SK 5xxE-…-O frequency inverter..............................................................................12

1.2.3 Which type of inverter should be used?............................................................................................13

1.3 Delivery ............................................................................................................................................................13

1.4 Scope of supply ................................................................................................................................................13

1.5 Safety and installation notes ............................................................................................................................18

1.5.1 Explanation of labels used.................................................................................................................19

1.5.2 List of safety and installation notes...................................................................................................19

1.6 Standards and approvals ..................................................................................................................................21

1.7 UL and cUL (CSA) approval ...............................................................................................................................21

1.8 Type code / nomenclature ...............................................................................................................................27

1.8.1 Type plate..........................................................................................................................................28

1.8.2 Frequency inverter type code ...........................................................................................................28

1.8.3 Optional technology units (module type codes) ...............................................................................28

2Assembly and installation .................................................................................................................................... 29

2.1 SK 5xxE, standard version.................................................................................................................................30

2.2 SK 5xxE…-CP in ColdPlate version.....................................................................................................................31

2.3 External heat sink kit ........................................................................................................................................32

2.4 Snap-on mounting rail kit SK DRK1-…...............................................................................................................34

2.5 EMC Kit .............................................................................................................................................................35

2.6 Brake resistor (BR)............................................................................................................................................36

2.6.1 Electrical data for brake resistors......................................................................................................37

2.6.2 Dimensions of bottom-mounted BR SK BR4......................................................................................38

2.6.3 Dimensions of chassis BR SK BR2.......................................................................................................40

2.6.4 Brake resistor assignments................................................................................................................40

2.6.5 Combination of brake resistors .........................................................................................................41

2.6.6 Monitoring of the brake resistor .......................................................................................................44

2.6.6.1 Monitoring with a temperature switch 44

2.6.6.2 Monitoring with current measurement and calculation 44

2.7 Chokes ..............................................................................................................................................................45

2.7.1 Mains chokes.....................................................................................................................................45

2.7.1.1 Link circuit choke SK DCL- 45

2.7.1.2 Input choke SK CI1-… 46

2.7.2 Output choke SK CO1 ........................................................................................................................47

2.8 Line filter ..........................................................................................................................................................49

2.8.1 Mains filter SK NHD (up to size 4)......................................................................................................49

2.8.2 Mains filter SK LF2 (size 5 - 7) ............................................................................................................49

2.8.3 Line filter SK HLD ...............................................................................................................................50

2.9 Electrical connection ........................................................................................................................................51

2.9.1 Wiring guidelines...............................................................................................................................52

2.9.2 Adaptation to IT networks.................................................................................................................53

2.9.3 DC-coupling .......................................................................................................................................55

2.9.4 Electrical connection of power unit...................................................................................................58

2.9.5 Electrical connection of the control unit ...........................................................................................60

2.10 Colour and contact assignments for encoders .................................................................................................73

2.11 RJ45 WAGO- Connection module.....................................................................................................................76

3Displays and control............................................................................................................................................. 77

3.1 Modular assemblies SK 5xxE ............................................................................................................................77

3.2 Overview of technology units...........................................................................................................................78

3.3 SimpleBox, SK CSX-0.........................................................................................................................................80

3.3.1 PotentiometerBox, SK TU3-POT ........................................................................................................83

3.4 Connection of multiple device to a parameterisation tool...............................................................................84

4Commissioning .................................................................................................................................................... 85

4.1 Factory settings ................................................................................................................................................85