TABLE OF

CONTENTS

1

2

4

6

8

10

41

41

41

Table of contents page

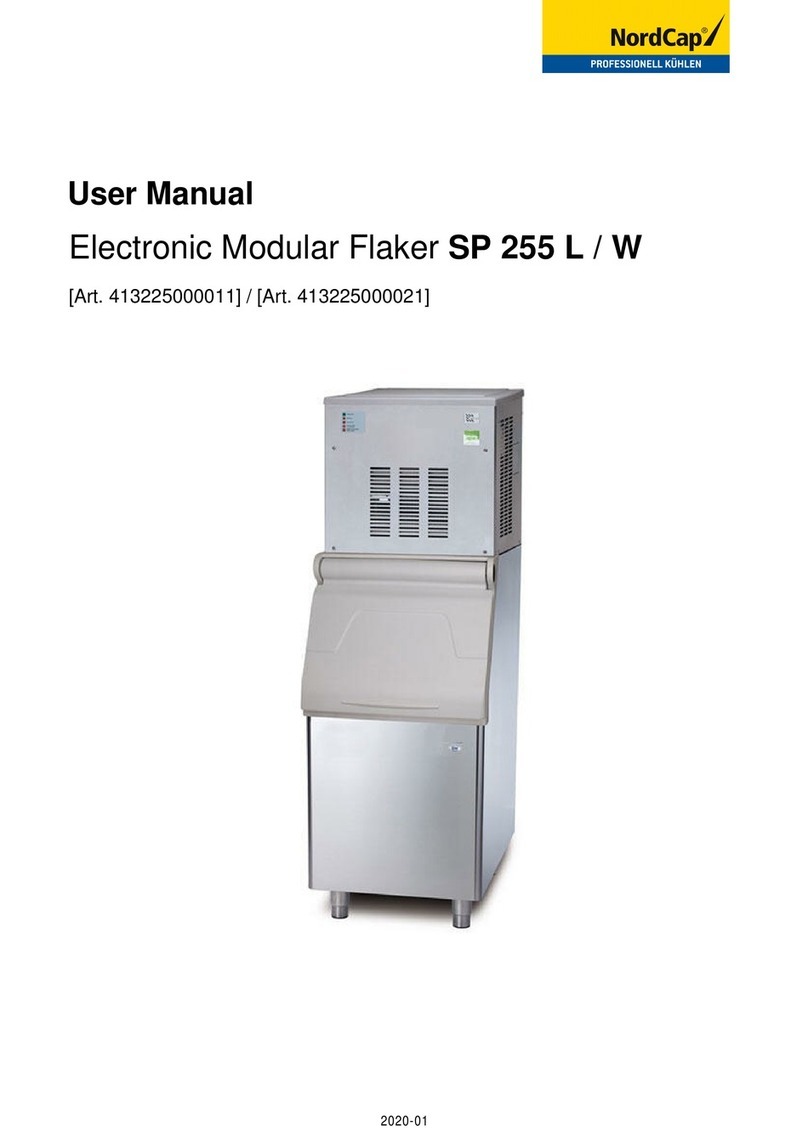

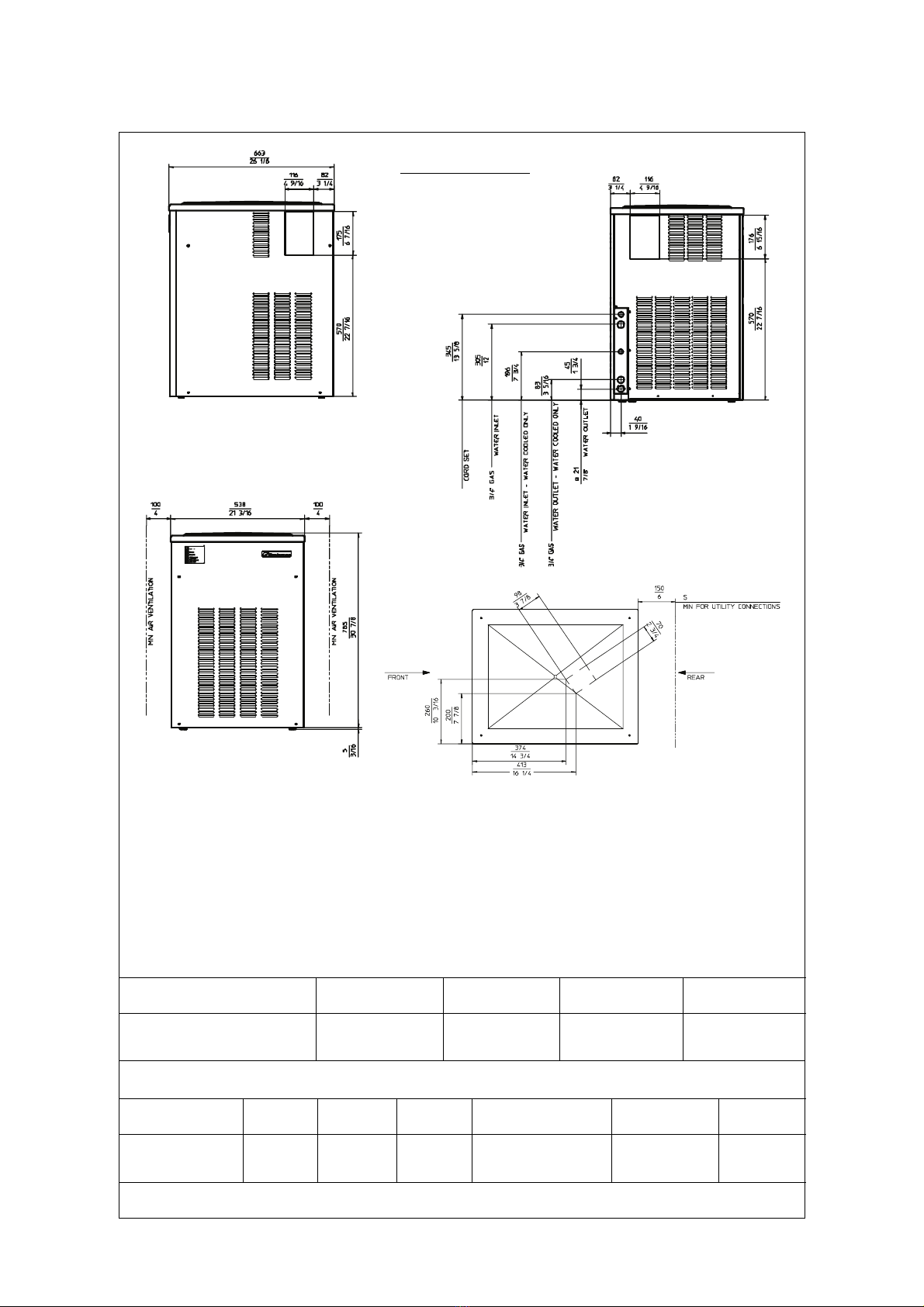

Specifications SPN125

Specifications SPN255

Specifications SPN405

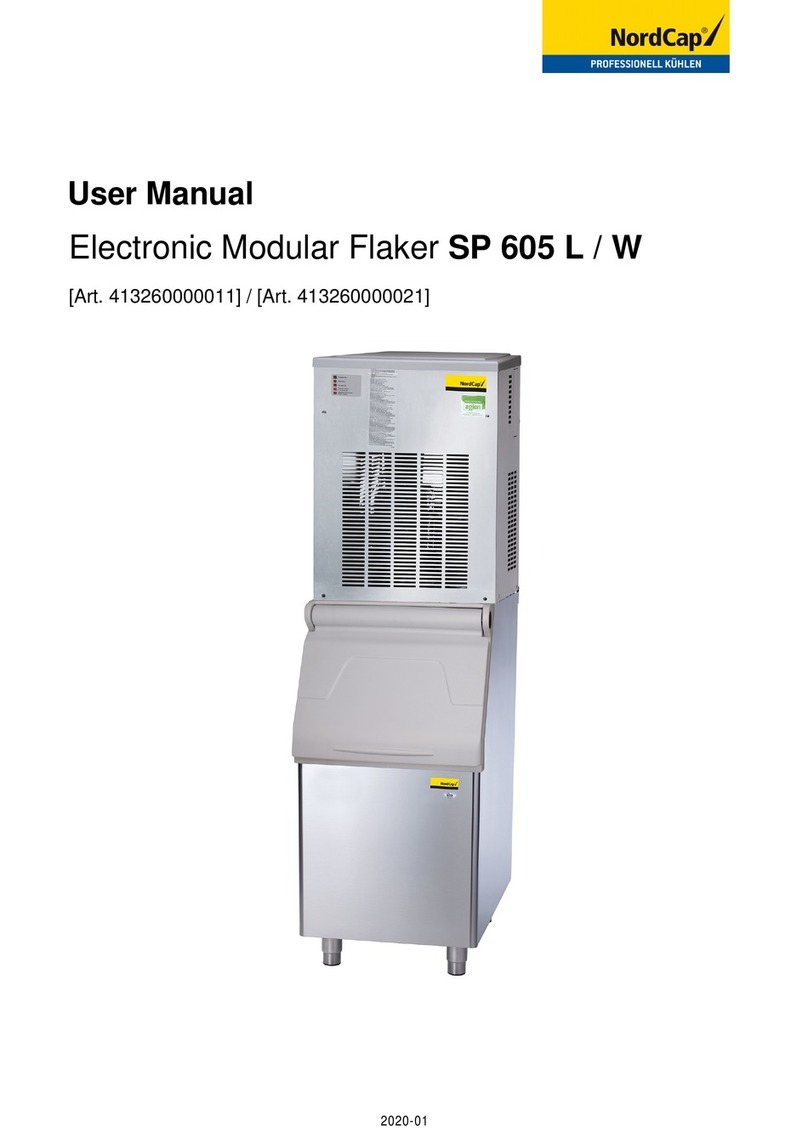

Specifications SPN605

Specifications SPN 1205

GENERAL INFORMATION AND INSTALLATION

Introduction

Unpacking and Inspection - Ice maker

Unpacking and Inspection - Storage bin

Location and levelling

Electrical connections

Water supply and drain connections

Final check list

Installation practice

OPERATING INSTRUCTIONS

Start up

Operational checks

PRINCIPLE OF OPERATION (How it works)

Water circuit

Refrigerant circuit

Mechanical system

Operating pressures

Components description

ADJUSTMENT, REMOVAL AND REPLACEMENT PROCEDURES

Adjustment of the evaporator water level

Replacement of evaporator temperature sensor

Replacement of condenser temperature sensor

Replacement of ice level light control

Replacement of P.C. Board

Replacement of the ice spout

Replacement of the auger, water seal, bearings and coupling

Replacement of the gear motor assy

Replacement of fan motor

Replacement of drier

Replacement of the freezing cylinder

Replacement of air cooled condenser

Replacement of water cooled condenser

Replacement of water regulating valve (water cooled models)

Replacement of compressor

Wiring diagram

Service diagnosis

MAINTENANCE AND CLEANING INSTRUCTIONS

General

Icemaker

Cleaning instructions of water system

16

18

21

22

24

25

26

30

30

30

30

31

31

31

32

32

33

33

33

34

34

34

35

39

12

12

12

13

14

14

14

15

Page 1