iDry Inverter Inspection and Installation

6

Part 7790223A E2010 Nordson Corporation

Inverter Replacement (contd)

8. Remove the fasteners securing the inverter assembly from the

enclosure. Save the fasteners for use with the new inverter.

9. Install the new inverter assembly and secure it in place with the

fasteners removed in step 8.

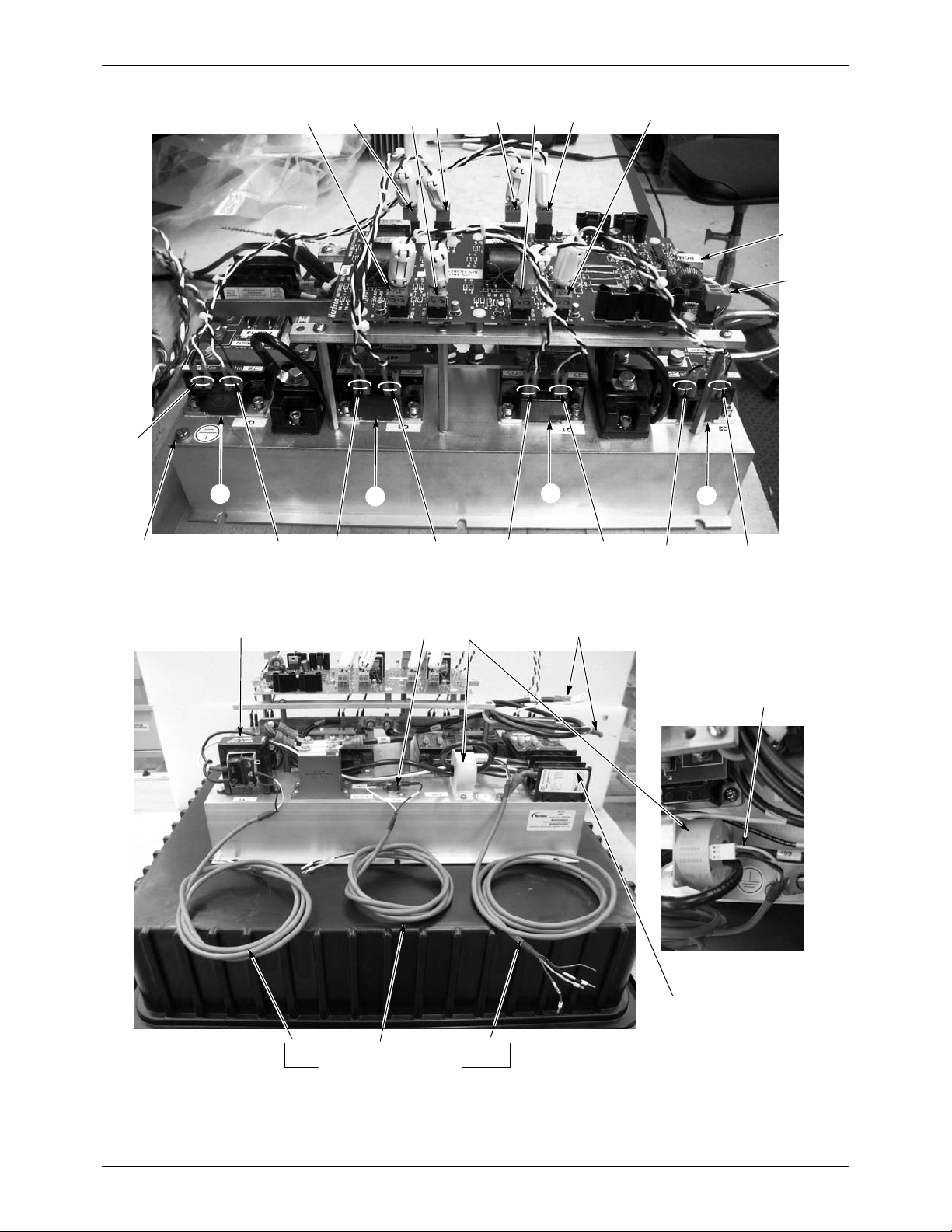

10. See Figure 3. Connect the blue and grey fiber-optic cables to the new

inverter assembly. Push the connectors into the receptacles until they

click.

NOTE: If you connect the fiber-optic cables incorrectly you will get an

Out of Lock fault. Reverse the cables to clear the fault.

11. Connect the blue and white twisted pair 15V power cable to the inverter

assembly driver board terminal J11.

12. See Figure 2. Connect the coil tank capacitor cables 409, 410, and

GND to the terminal block (TBM) on the inverter board. Make sure you

do not connect either the 409 or 410 cables to the ground terminal.

13. See Figure 4. Connect cable 407 to PCB8 (−) and cable 408 to

PCB9 (+).

14. Connect the inverter assembly harnesses to the Distribution Board

terminal block J5 as described in the table on page 4, step 6.

15. See Figure 1. Connect the system ground wire (heavy green and yellow

wire) to the ground screw at the corner of the heat sink.

16. Install the rear panel on the base. Make sure to connect the panel

ground wire to the base.

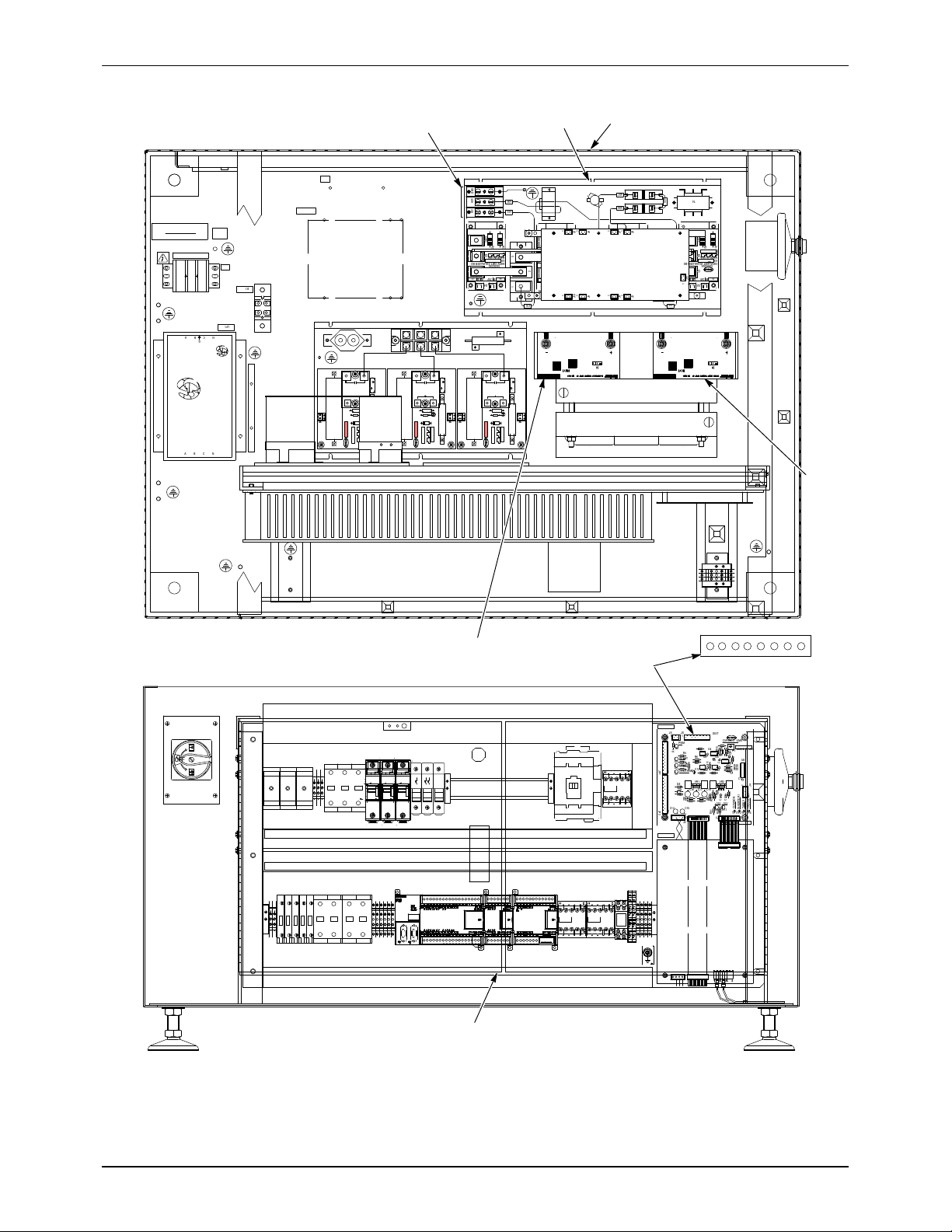

17. See Figure 5. If shipping the old inverter assembly back to Nordson

Corporation:

a. Secure the assembly to the wood panel (1) with the shipping screws,

flat washers, and lock washers (2, 3, 4).

b. Pull the anti-static bag (5) over the assembly.

c. Turn the inverter assembly upside down and place it into the custom

foam insert (6) in the shipping box.

d. Close the anti-static bag and tape the opening shut. If removed,

place the bag of silica gel dessicant (7) in the box.