Table of Contents

ii

Part 123456X E2002 Nordson Corporation

Manual XX-XX

Installation 3-1..............................................

Introduction 3-1.............................................

Inspection and Packaging 3-1.................................

Power Supply Installation 3-1.................................

Mounting Guidelines 3-1...................................

Power Supply Electrical Connections 3-3.....................

Power Connections 3-3..................................

Power Supply Balancing 3-4.............................

Network Connections 3-6..................................

Remote I/O Inputs and Outputs 3-6..........................

Machine Stop Interlock 3-8...............................

Remote Power Level Control 3-8.........................

Idle Mode 3-9..........................................

Remote Standby and Lamp On 3-9.......................

Rapid Cycle Using Idle Mode 3-10.........................

DeviceNet Installation 3-10..................................

Chassis Isolation 3-10....................................

BUS Power 3-10.........................................

Hardware Specifications 3-11.............................

Software Specifications 3-11..............................

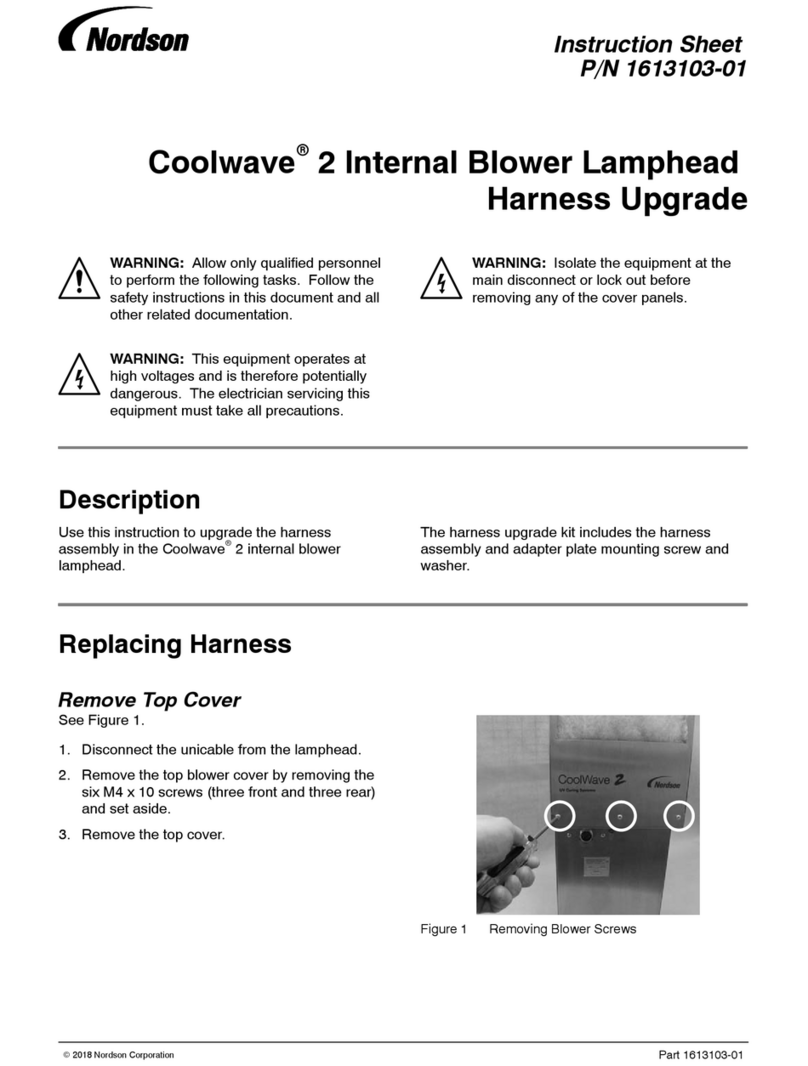

Lamphead Installation 3-11....................................

Mounting Guidelines 3-11...................................

Light Shielding 3-11........................................

Internal Blower 3-12........................................

External Blowers −Cooling Air 3-12..........................

Cooling Exhaust Air −Lamphead/Chamber Cooling Air Removal ....

3-12

Monitoring Static Pressure 3-15..............................

Top/Front Pressure Port 3-15..............................

Bottom Pressure Port 3-15................................

Switching Pressure Ports 3-16.............................

Lamphead Cable Connections 3-17..........................

RF Detector Installation 3-18...................................

Power Supply Configuration 3-19...............................

Operation 4-1...............................................

Introduction 4-1.............................................

Display and Controls 4-1.....................................

Additional Functions 4-3...................................

Temperature 4-3........................................

Light Detector 4-3......................................

Starter Bulb Test 4-3....................................

Panel Lock 4-3.........................................

Display Messages 4-4.......................................

Fault Messages 4-4..........................................

Resetting Faults 4-5.......................................

Startup 4-6.................................................

Locally Operated Units 4-6.................................

Remotely Operated Units 4-8...............................

Shutdown 4-9...............................................