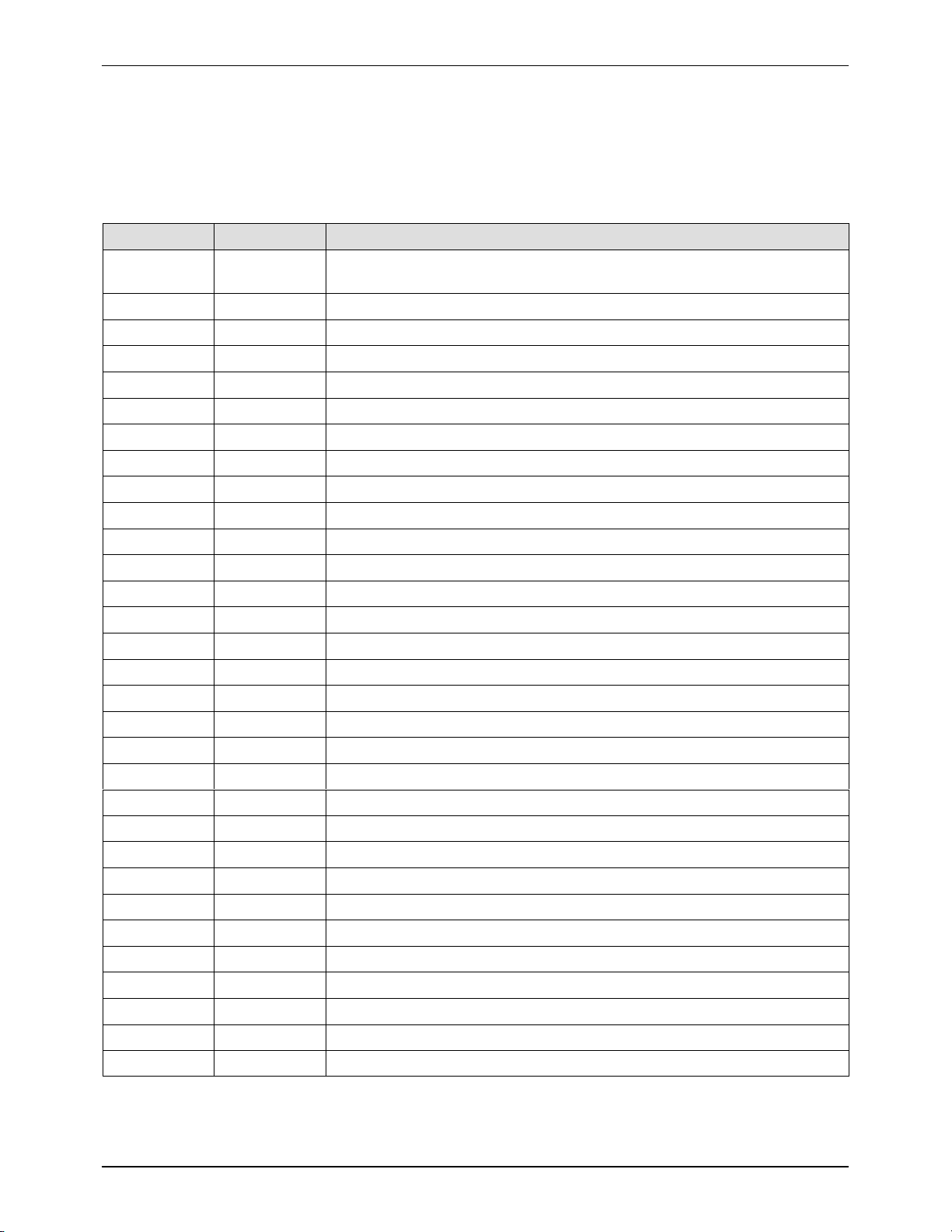

Table of Contents

iv

Part 1105120-03 E2015 Nordson Corporation

Installation 3-1..............................................

Introduction 3-1.............................................

Inspection and Packaging 3-1.................................

System Controller Installation 3-1..............................

Mounting Guidelines 3-1...................................

Power Connections 3-3....................................

Power Load Balancing 3-4...............................

System Connection Diagrams 3-4........................

Network Connections 3-7..................................

Remote Inputs and Outputs 3-7.............................

Machine Stop Interlock 3-9...............................

Remote Power Level Control 3-10.........................

Idle Mode 3-10..........................................

Remote Standby and Lamp On 3-10.......................

Quick Cycle Using Idle Mode 3-11.........................

DeviceNet Installation 3-11..................................

Chassis Isolation 3-11....................................

BUS Power 3-11.........................................

Hardware Specifications 3-12.............................

Software Specifications 3-12..............................

Lamphead Installation 3-12....................................

Mounting Guidelines 3-12...................................

Optional Mounting Kit for Lampheads 3-15....................

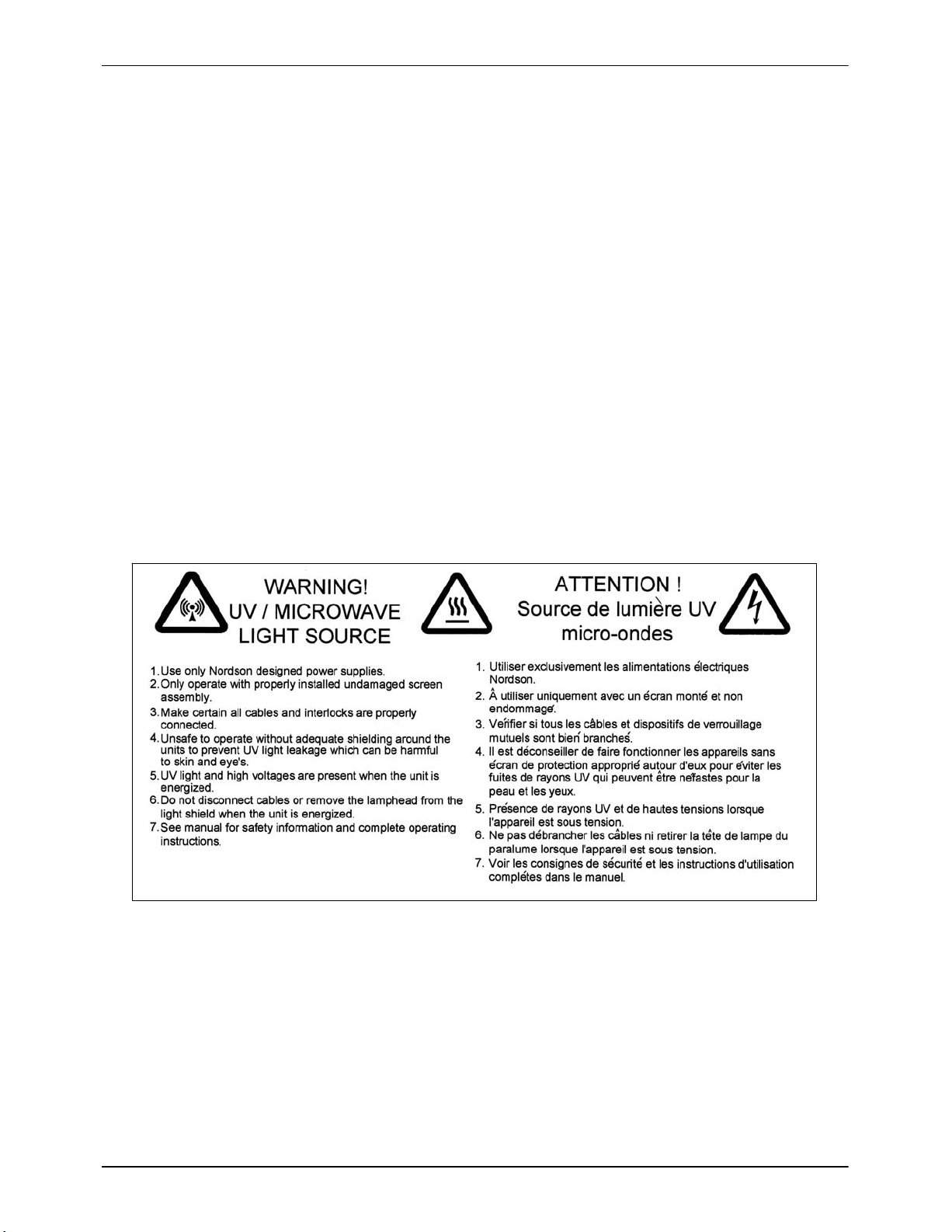

Light Shielding 3-15........................................

Cooling Air Installation 3-15.................................

Internal Blower Lampheads 3-15..........................

External Blower Lampheads 3-16..........................

Exhaust Requirements 3-16.................................

AirShield Ventilation System 3-17............................

Monitoring Lamphead Air Pressure 3-18......................

Top Pressure Port 3-18...................................

Bottom Pressure Port 3-18................................

Switching Pressure Ports 3-18.............................

Lamphead Cable Connections 3-21..........................

RF Detector Installation 3-22...................................

System Controller Configuration 3-23...........................

Operation 4-1...............................................

Introduction 4-1.............................................

Display and Controls 4-1.....................................

Additional Functions 4-3...................................

Temperature 4-3........................................

Light Detector 4-3......................................

Starter Bulb Test 4-3....................................

Panel Lock 4-3.........................................

Operating Messages 4-4.....................................

Fault Messages 4-4..........................................

Resetting Faults 4-5.......................................

System Timing Sequences 4-6................................

Timing Sequence with Idle = Y 4-6..........................

Timing Sequence with Idle = N 4-8..........................

Correcting a Fault Condition 4-9

............................

Startup 4-9.................................................

Locally Operated Units 4-9..................................

Remotely Operated Units 4-12...............................

Shutdown 4-13...............................................