9

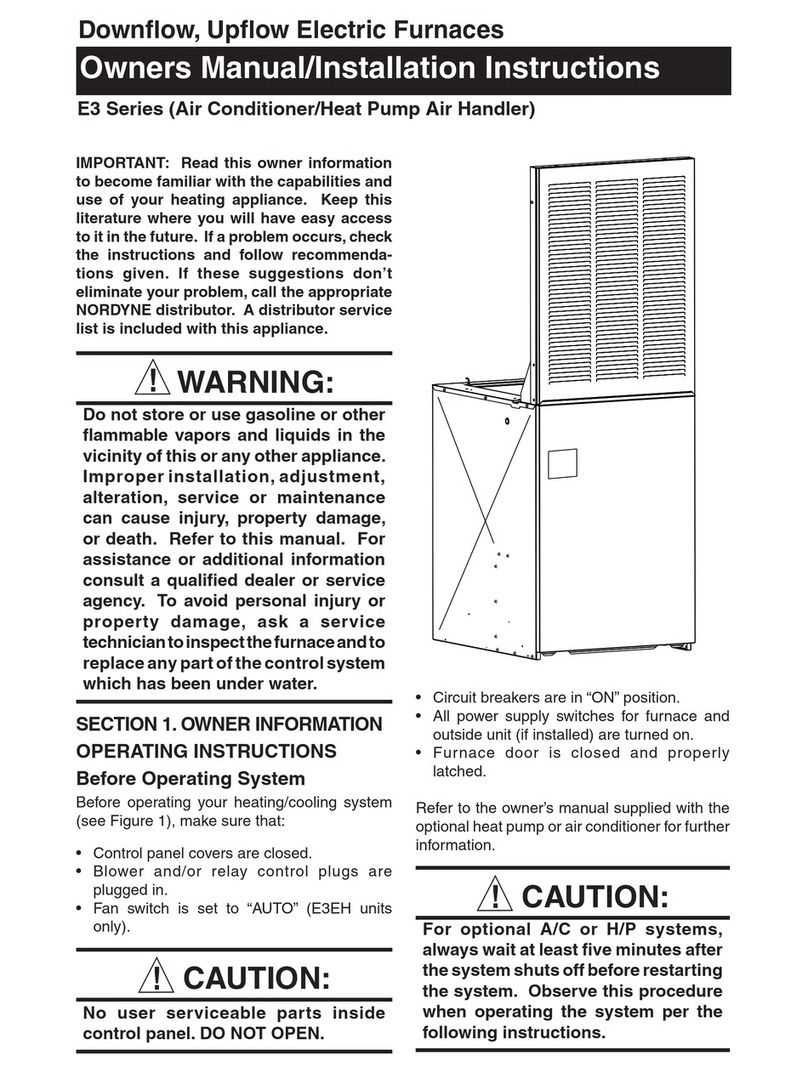

System Heating (optional)

1.Set the thermostat's system mode to HEAT and the

temperature mode above room temperature.

2.Verify the optional heating equipment (furnace or

electric heat) and indoor blower energize. Feel the air

being circulated by the indoor blower and verify that

it is warmer than ambient temperature. Listen for any

unusualnoises.Ifunusualsoundsoccur,determinethe

source of the noise and correct as necessary.

Charging Units in AC mode when Outdoor Temperature

is above 55° F (optimized sub-cooling of 10° F - 12° F)

1.With the system operating at steady-state, measure

the liquid refrigerant pressure (in PSIG) at the outdoor

unit service valve.

2.Measure the liquid refrigerant temperature (in

Fahrenheit) at the service valve.

3.Determinetherequiredliquidrefrigerantpressurefrom

Table 3 &Table 4 (page 15).

• IfthepressuremeasuredinStep1isgreaterthan

therequiredliquidrefrigerantpressuredeterminedin

Step3,thenthereistoo muchchargeinthesystem.

Remove refrigerant and repeat Steps 1 through 3

until the system is correctly charged.

• IfthepressuremeasuredinStep1islessthanthe

required liquid refrigerant pressure determined in

Step 3, there is too little charge in the system. Add

refrigerant and repeat Steps 1 through 3 until the

system is correctly charged.

Refrigerant Charging

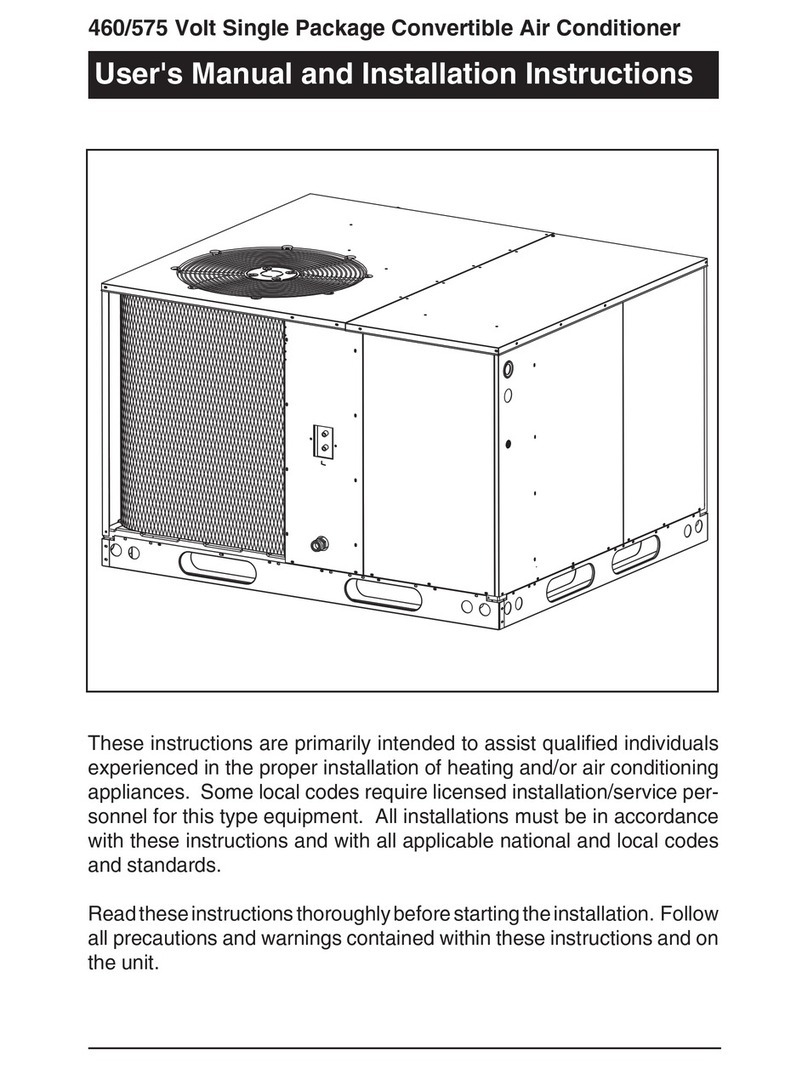

WARNING:

4-5Ton Split System Air Conditioners leave

the factory with a nitrogen holding charge.

Follow these charging instructions for

maximum unit performance and efficiency.

Somelocalcodesrequirelicensedinstallation/

service personnel to service this type of

equipment. Refrigerant charging must be

done by qualified personnel familiar with

safe and environmentally responsible

refrigerant handling procedures.Under no

circumstances should the owner attempt

to install and/or service this equipment.

Failure to comply with this warning could

result in property damage,personal injury,

or death.

After refrigerant line connections are completed, it is

required that you leak check and evacuate the indoor

section and all line connections (using proper methods)

before finalizing the full system refrigerant charge.

• Toachieveratedcapacityandefciencythecompressor

must be exposed to refrigerant for at least 24 hours

prior to running and then the compressor must be run

for a minimum of 12 hours.

• Tables3&4(page15)areapplicableonlytomatched

assembliesofNORDYNEequipmentandlistedairows

for the indoor coil. Outdoor units with indoor coils

not listed are not recommended and deviations from

rated airflows or non-listed combinations may require

modification to the expansion device and refrigerant

charging procedures for proper and efficient system

operation.

• Therefrigerantchargecanbecheckedandadjusted

through the service ports provided external to the

outdoor unit. Use only gage linesets which have a

“Schrader” depression device present to actuate the

valve.

• 4Tonunitsshoulduse0.079oriceintheliquidline

and should be charged with 67 oz.of R-22 refrigerant

as specified in the supplied addendum (7091540).

5 Ton units should use 0.093 orifice in the liquid line

and should be charged with 82 oz.of R-22 refrigerant

as specified in the supplied addendum (7091540).

AIR CONDITIONER MAINTENANCE

WARNING:

Topreventelectrical shock,personal injury,

or death,disconnect all electrical power to

theunit beforeperforming anymaintenance

or service. The unit may have more than

one electrical supply.

Proper maintenance is important to achieve optimum

performancefromtheairconditioner.Theabilitytoproperly

perform maintenance on this equipment requires certain

mechanical skills and tools. If you do not possess these

skills, contact your dealer for maintenance. Consult your

localdealerabouttheavailabilityofmaintenancecontracts.

Routine maintenance should include the following:

• Inspectandcleanorreplaceairltersatthebeginning

ofeachheatingandcoolingseason,ormorefrequently

if required.

• Inspectthecondensatedrainandoutdoorcoilatthe

beginningofeachcoolingseason.Removeanydebris.

Cleantheoutdoorcoilandlouversasnecessaryusing

amilddetergentandwater.Rinsethoroughlywithwater.

• Inspecttheelectricalconnectionsfortightnessatthe

beginningofeachheatingandcoolingseason.Service

as necessary.

CAUTION:

The unit should never be operated without

a filter in the return air system. Replace

disposable filters with the same type and

size.

• Do not attempt to add additional oil to motors un-

equippedwithoiltubes.Thecompressorishermetically

sealed at the factory and does not require lubrication.