Norecs ProboStat How to use

Complementary Material to ProboStat™ Manual

2

ProboStat™ Starting Guide

As we are always learning from feedback from our customers and users, and for giving better understanding of

the ProboStat™ sample holder, we present this note as a complementary material to the ProboStat™ Manual.

The main goal of this document is explanation of the ProboStat™ system design which is not covered in the

Manual.

1. ProboStat™ Gas Supply System

1.1. Recommended reading

First, we recommend familiarizing youself with:

a) ProboStat™ Manual:

Part 2 “Safety first”, pp. 2-1 –2-2,

Part 4.2.4 “Gas connects”, pp. 4-5 –4-7,

Part 4.4 “Support tubes”, pp. 4-12 –4.13,

Part 4.5 “Gas supply tubes”, pp. 4-13 –4-14,

Part 6.3 “Pressures, vacuum, leakage rates, atmosphere purity”, pp. 6-1 –6-2,

Part 7.3 “Gas tightness”, pp. 7-4 –7-5,

Part 9.3 “Over-atmospheric pressure”, pp. 9-3 –9-4,

Part 9.4 “Wet gases with dew-point above room temperature”, p. 9-4,

Part 12.1.4 “Inner gas tubes”, pp. 12-4 –12-6.

b) NorECs web page www.norecs.com :

FAQ –atmosphere control

FAQ –sealing

1.2. Single and dual atmosphere modes

The ProboStat™ is a sample holder designed to perform experiments in single or dual atmosphere modes

at near-atmospheric total pressure, and can be fed with virtually any gas.

1.2.1.

Single atmosphere mode

The term “single atmosphere mode” means that one gas is fed in both inner and outer ProboStat™gas

compartments. The single atmosphere mode is used for:

Complementary Material to ProboStat™ Manual

3

2-point impedance spectroscopy and conductivity measurements on disk sample

2-point conductivity measurements on disk sample with surface guard

4-point conductivity measurement on disk sample (van der Pauw geometry)

4-point conductivity measurement on bar sample

Seebeck coefficient measurements

Annealing and sintering under controlled atmospheres

1.2.2.

Dual atmosphere mode

The term “dual atmosphere mode”means that the inner gas compartment is gas-tight separated from the

outer gas compartment. Achieving this separation is a process we call sealing. Then sealed the inner and

outer compartments can be fed with different gases or gas mixtures.

The dual atmosphere mode is used for:

Transport number measurements

SOFC and SOEC test and characterization

Running electrochemical reactors / electrochemical pumping

Permeability measurements

1.3. Gas connects, stems and stubs

1.3.1.

Gas connects

The gas connects mounted on the base unit hexagon are by default Swagelok quick-connects. In the high-

temperature base units the quick-connects are replaced by Swagelok bulkheads and mounted on the top

part of the splitted hexagon.

The stainless steel (SS) base unit has SS gas lines and SS quick-connects (steel colour). The Ni-coated

brass base unit has copper gas lines, and brass quick-connects (yellow colour).

The inner and outer ProboStat gas compartments are marked “INNER” and “OUTER”. Each compartment

has gas inlet and outlet quick-connects appropriately marked “IN” and “OUT”, resulting in “INNER IN”,

“INNER OUT”, “OUTER IN”, and “OUTER OUT”. The “IN”s are quick-connects with valves that are closed

when matching stems are disconnected. The “OUTER” connectors are always open.

Table 1. Swagelok gas connects.

Part no.

Type

Material

Valve

Function

B-QM2-B1-200

Quick-connect

brass

yes

Gas IN

B-QM2-B1-200MB

Quick-connect

brass

no

Gas OUT

SS-QM2-B1-200

Quick-connect

SS316

yes

Gas IN

SS-QM2-B1-200MB

Quick-connect

SS316

no

Gas OUT

SS-200-61

Bulkhead

SS316

no

Gas IN, Gas OUT

Complementary Material to ProboStat™ Manual

4

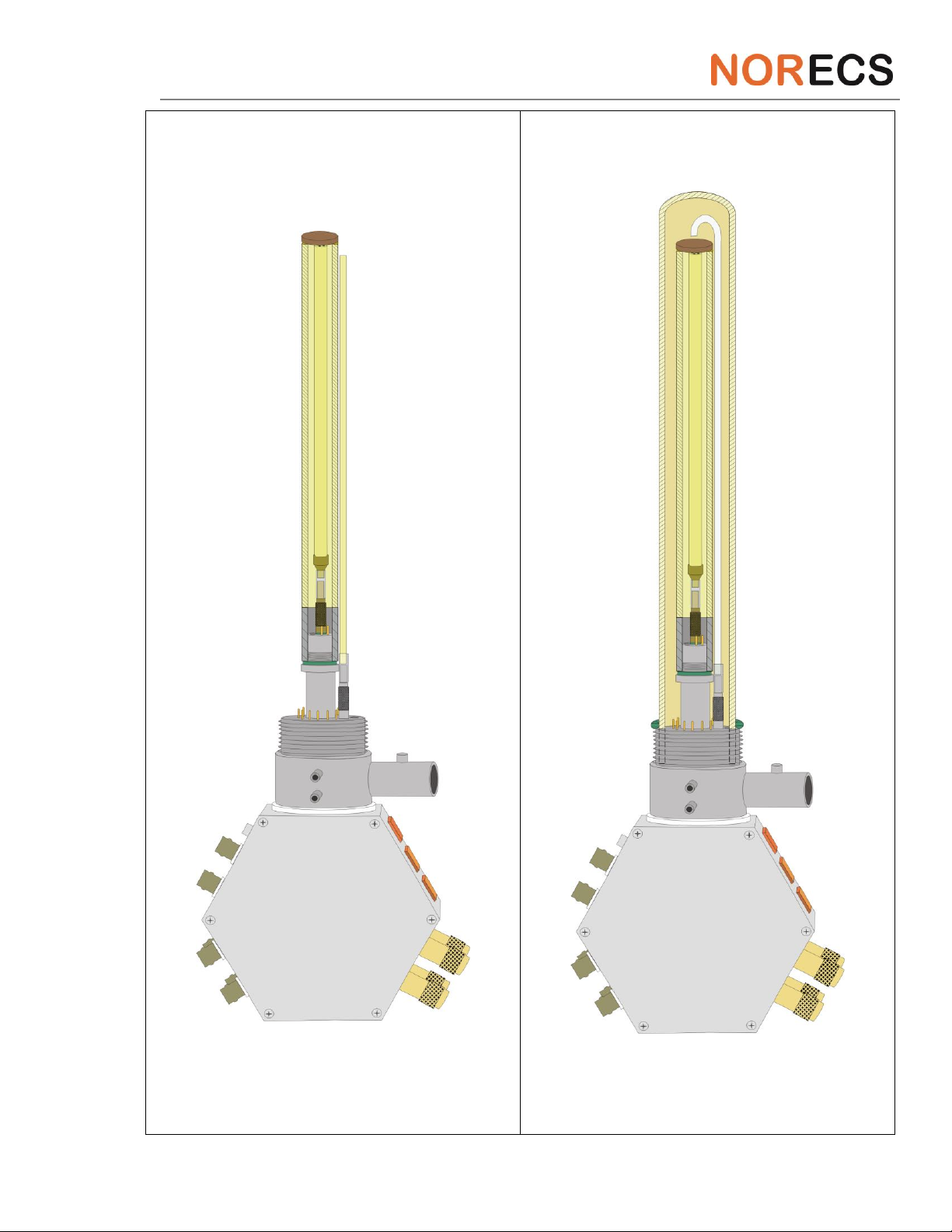

Fig. 1: SS and brass base units.

Fig. 2: IN and OUT quick-

connects for INNER

and OUTER gas

compartments.

Fig. 3: SS bulkheads mounted

on top part of splitted

hexagon.

1.3.2.

Gas stems

As standard, the quick-connects are matched by four quick-connect stems for connecting to 1/8’’ tubing.

The tubing material must be suitable for the gas used, and softer material than the ferrules of the stem.

Fig. 4: Brass quick-connect stem with

valve, for “IN”s.

Fig. 5: Brass quick-connect stem

without valve, for “OUT”s.

The valve on the stems opens only when plugged to a quick-connect with valve. To plug or unplug a stem

pull/push it into the quick-connect while holding back the rasterized collar.

We recommend having some spare parts for gas connectors and stems, namely Swagelok brass and/or SS

ferrule sets, parts no. B-200-SET and SS-200-SET accordingly.

Complementary Material to ProboStat™ Manual

5

Table 2: Swagelok gas stems.

Part no.

Material

Valve

Function

Match to

B-QM2-D-200

Brass

yes

Gas IN

B-QM2-B1-200

B-QM2-S-200

Brass

no

Gas OUT

B-QM2-B1-200MB

SS-QM2-D-200

SS316

yes

Gas IN

SS-QM2-B1-200

SS-QM2-S-200

SS316

no

Gas OUT

SS-QM2-B1-200MB

1.3.3.

Gas stubs

The inner IN and outer IN base unit gas lines are extended to the high temperature zone by various gas

supply tubes mounted on the base unit using gas stubs and piece of silicone hose.

The gas stub for the inner gas compartment is made of PEEK and assembled by a Viton sealing O-ring. The

PEEK gas stub is screwed onto the upper part of base unit body.

The gas stub for the outer gas compartment is made of SS and assembled by two Viton sealing O-ring. The

SS gas stub is set into the lower part of base unit body.

Fig. 6: ProboStat™ PEEK and SS gas stubs

Fig. 7: ProboStat™ base unit with gas stubs

mounted.

Complementary Material to ProboStat™ Manual

6

1.4. Base unit sealing O-rings

The ProboStat base units can be supplied with Viton or Isolast sealing O-rings depending on the base unit

operating temperature. The standard base units are equipped with Viton O-rings, the high-temperature one

–with Isolast version.

Fig. 8: Viton (green) and Isolast (black) O-rings.

Depending on use, the O-rings have four different sizes presented in the table below.

Table 3: Standard ProboStat™ O-rings.

Size, mm

Amount,

pcs

Material

Mounting place

Use

Outer

diameter

thickness

40

3

1

Viton/Isolast

Alumina, quartz or

transport outer

tubes

Outer tube mounting.

Sealing the base unit outer gas

compartment against

environment.

Base unit protection during

transportation.

15.6*

1.78*

1

Viton/Isolast

Upper part of base

unit body

Sealing between inner and outer

gas compartments.

Sample support tube mounting.

4

1

3

Viton

SS and PEEK gas

stubs

Gas stubs mounting

43

2

2

Viton/Isolast

Base unit core

Seal for water cooling system

* Can be replaced by 16.0×1.5 mm O-ring depending on sample support tube socket shape.

Complementary Material to ProboStat™ Manual

7

1.5. Gas supply tubes

The ProboStat™ is supplied with various gas supply tubes. These are to be used inside the cell to supply

gases directly to the sample area.

Table 4: Standard gas supply tubes delivered with the ProboStat™. *

Material

Shape

Diameter,

mm

Length w/o

silicone hose,

mm

Sample support

tube diameter,

mm

Gas

compartment

Working

temperature,

°C

Alumina

Straight

4

480

10 - 20

outer

< 1600

Alumina

Straight

3

480

24

outer

< 1600

Quartz

Bent

4

525

10-20

outer

< 950

Quartz

Bent

3

525

24

outer

< 950

Alumina

Multi-bore

8.5

446

20-24

inner

< 1600

Alumina

Straight

4

470

15-16

inner

< 1600

Alumina

Straight

3

470

10-12

inner

< 1600

*All numbers are for the system with 60 cm outer tube.

1.6. Setting up gas compartments

This part presents a step-by-step description how to create two ProboStat™gas compartments. For simplicity

only the gas supply system is shown. The electrical system, temperature control, spring-load system, and water

cooling system will be described elsewhere.

Complementary Material to ProboStat™ Manual

8

Table 5. Assembling ProboStat™ gas compartments.

Step 1:

Place the ProboStat base unit on the bench,

preferably fix it in a lab stand using a bar for base

unit fixture.

Step 2:

Mount the inner gas supply tube onto the PEEK gas

stub.

Complementary Material to ProboStat™ Manual

9

Step 3: Mount the sample support tube tight.

Step 4: Place an Au sealing ring on top of the

sample support tube. *

*This step is relevant for the gas compartments separation. If you plan to measure using the single

atmosphere mode, skip this step.

Complementary Material to ProboStat™ Manual

10

Step 5: Place a sample on top of the gold ring (or

directly on the sample support tube for the single

atmosphere mode). Check that the gold ring and

sample are centered.

Step 6: Mount outer bent silica (a) or straight

alumina (b) gas tube onto the SS gas stub.

a)

Complementary Material to ProboStat™ Manual

11

Step 6: Mount outer bent silica (a) or straight

alumina (b) gas tube onto the SS gas stub.

Step 7: Mount enclosing quartz or alumina tube

and O-ring.*

*For simplicity the spring load assembly is not

explained or drawn here. In real setup it is always

present and push the sample down on the AU ring.

b)

Complementary Material to ProboStat™ Manual

12

Step 8: Fasten the base unit flange.

Complementary Material to ProboStat™ Manual

13

2. ProboStat™ electrical system

In this part we describe ProboStat™ electrode contact assemblies, base unit electrical wiring, and coaxial

cables.

2.1. Recommended reading

We recommend familiarizing youself with:

a) ProboStat™ Manual:

Part 4.2.6 “Electrical feedthroughs”, pp. 4-7 –4-8,

Part 4.2.7 “Sockets and switches on the connector box”, pp. 4-8 –4-10,

Part 4.2.8 “Wiring Schemes”, pp. 4-10 –4-12,

Part 4.7 “Thermocouple and electrode contacts”, pp. 4-15 –4-19,

Part 6.4 “Electrical specification”, pp. 6-2 –6-3,

Part 7.1 “Electrical wires”, pp. 7-1,

Part 12.4 “Instruction for fabrication of electrode contact assemblies”, pp. 12-13 –12-20.

b) NorECs web page www.norecs.com :

FAQ –How can I repair a Pt electrode contact?

2.2. Electrode contact assemblies

Electrode contact assemblies (hereafter called electrode contacts) are assigned to contact the ProboStat™

base unit with a test sample located in the high-temperature zone.

2.2.1.

Description and denotation

The electrode contacts for electrical measurements come in variety of types. Many of them are issued in 2-

wire pairs; one for current and one for voltage.

Table 6. Electrode contacts denotation

Code

Description

H2N#

Electrode “hand” contact assembly, outer, 2-wire. # - diameter of Pt net disk

H1TN10

Electrode “hand” contact assembly, outer, 1-wire, top

H1BN10

Electrode “hand” contact assembly, outer, 1-wire, bottom

INH2N12

Electrode “hand” contact assembly, inner, 2-wire

IN2

Electrode contact assembly, inner, 2-wire

GP2

Electrode contact assembly, general purpose, 2-wire

GP1

Electrode contact assembly, general purpose, 1-wire

GR#

Guard ring. # - diameter of ring

vdP

Van der Pauw contact assembly

Complementary Material to ProboStat™ Manual

14

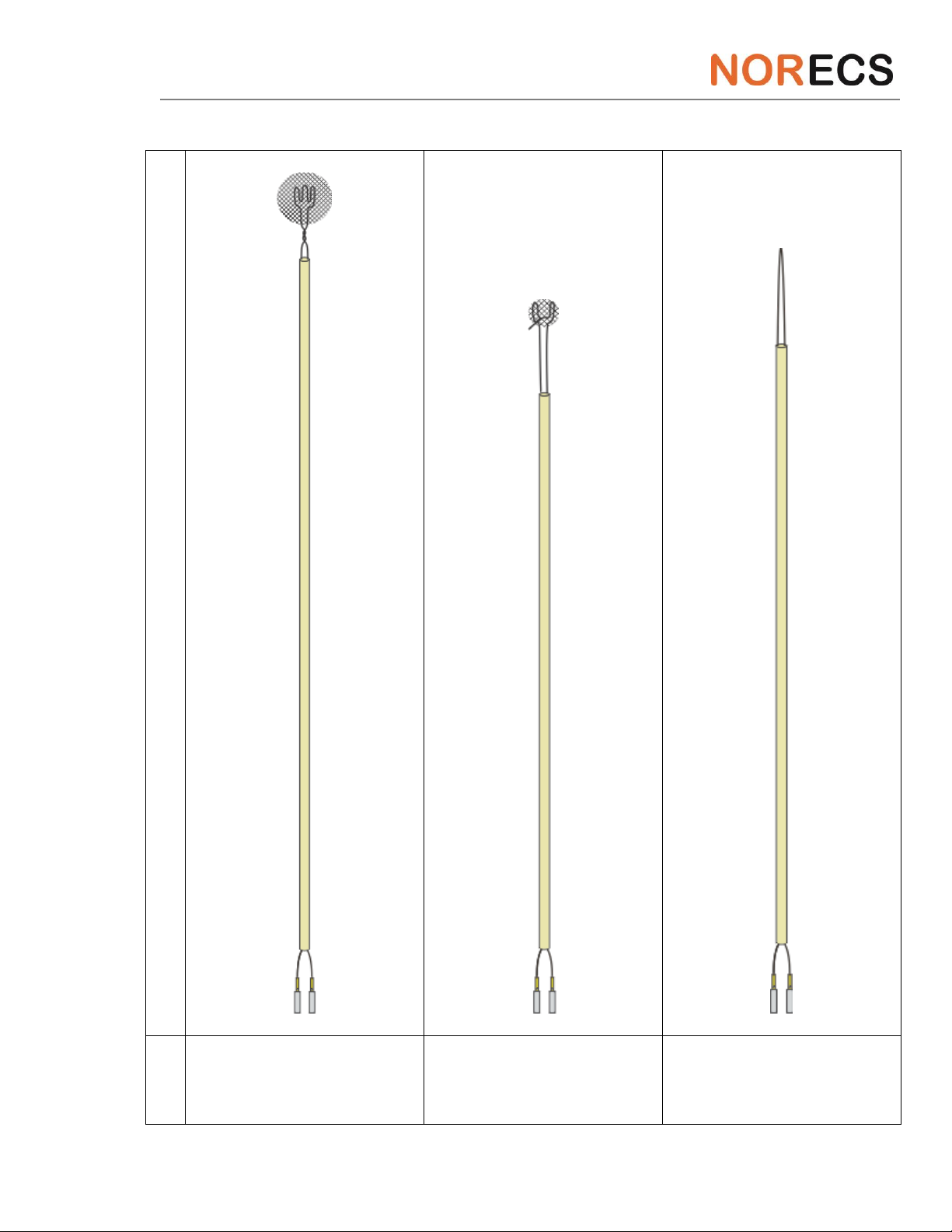

Tabel 7. ProboStat™ electrode contacts.

Electrode contact drawing

Code

H2N#

INH2N12

IN2

Complementary Material to ProboStat™ Manual

15

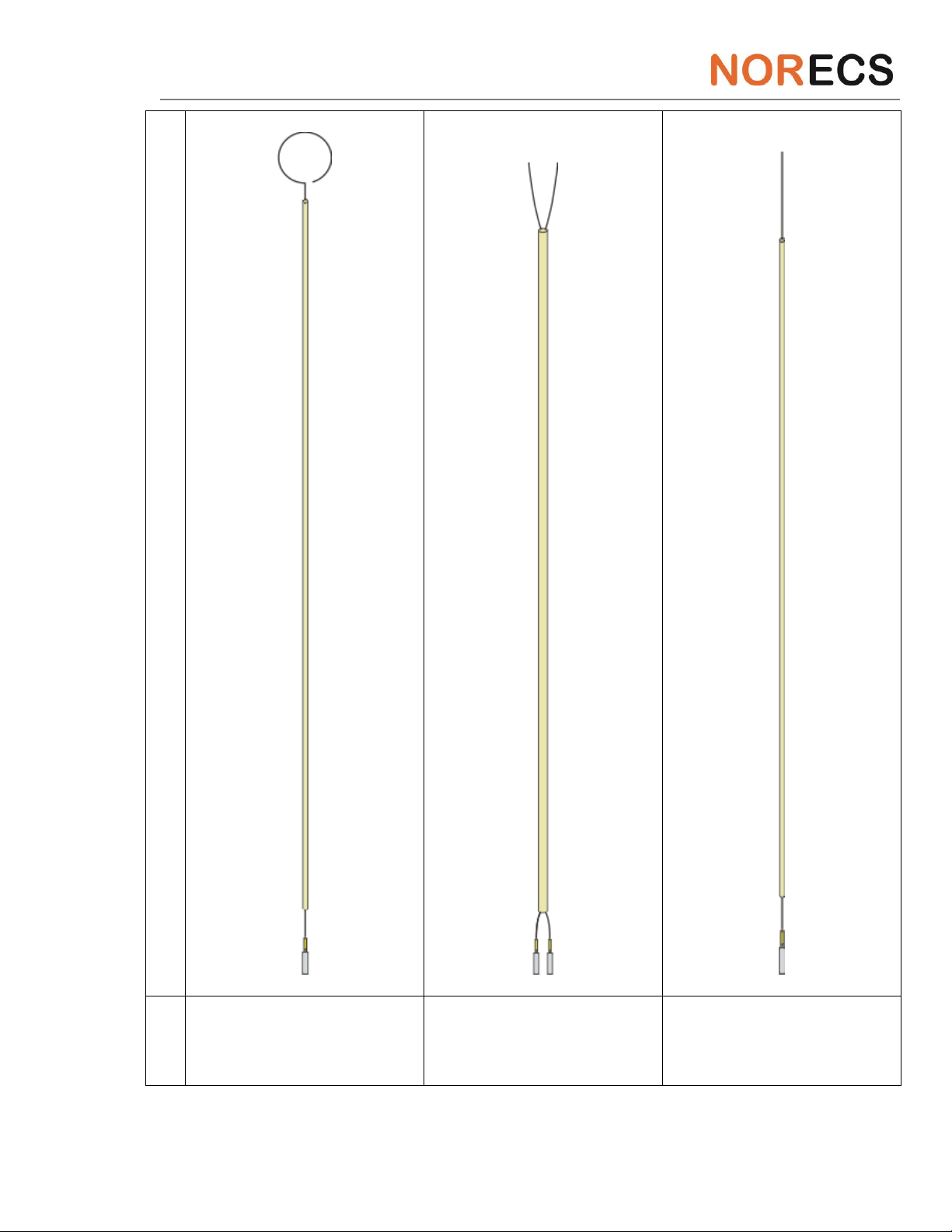

Electrode contact drawing

Code

GR#

GP2

GP1

Complementary Material to ProboStat™ Manual

16

Electrode contact drawing

Code

H1TN10

H1BN10

vdP2

Complementary Material to ProboStat™ Manual

17

2.2.2.

High-voltage electrode contacts

High-voltage (HV) electrode contacts are suitable for connection to special feedthroughs on the HV base

unit. The HV base units are made upon request and usually not a matter for the detailed description.

There are two types of HV electrode contacts:

Electrode “hand” contact assembly, outer, 1-wire, HV-version

(H1N10HV)

Guard ring, HV-version

(GR#HV)

HV electrode contacts are shorter than normal and soldered to bigger mini-contacts.

2.2.3.

Mini-contacts

Supplied electrode contacts and thermocouples (see below) are soldered to female mini-contacts matching

to the base unit feedthroughs. The mini-contacts are made of Au- and Ni-plated brass, and have size

22AWG, HV version –20AWG.

2.2.4.

Soldering of mini-contacts

When soldering insert an appropriate metal wire into the mini-contact, and add solder by tiny portions until

the mini-contact cup is filled. A solder drop should be visible through a small hole into the mini-contact.

Make “shoulders” by pulling out the solder. It is important that solder wets metals.

Correct. The surfaces are wetted.

Wrong. The surfaces are non-wetted.

Fig. 9. Soldering of mini-contacts.

Complementary Material to ProboStat™ Manual

18

2.2.5.

Mounting electrode contacts on the base unit.

In order to connect the electrode contact to the base unit, mount the mini-contacts carefully onto

appropriate feedthroughs. You may use a tweezers.

Fig. 10. The electrode contact connected to the base unit.

2.3. Base unit wiring

2.3.1.

Wiring overview

The Wiring Overview (see next page, example for K-wired base unit) shows the coordinates, numbering

and standard material of the electrical wiring for the base unit feedthroughs (top view, in relation to the

gas inlets (I) and outlets (O)). Also the Phoenix-type chassis multi-connector that was fitted to early

version is shown. The coding and functions are listed in detail in the table below.

We strongly recommend users to print the Wiring Overview (page 14-2 or 14-3 in the ProboStat™ manual)

and hang it on a wall next to the ProboStat™ assembling point.

2.3.2.

Phoenix-type multi-connector

The Phoenix type of multi-connector (Fig. 10) is no longer in use, and will not be described here. In case

you need more information, please contact us.

Complementary Material to ProboStat™ Manual

19

Wiring overview (all figures are top views)/K-Type

Standard electrical wiring of ProboStat versions A-2 and later, using S-type thermocouples.

Base unit feed-through

code

Base unit

feedthrough colour

code

Standard

material

in hot zone

Function

Function code

Phoenix rectangular

multi-connector

(optional) code

BNC code

(S = shield)

Thermocouple contact

codes

1 P

Green

NiCr

Bottom/inner TC+

TCB+

-

-

TCB+

2 N

White

NiAl

Bottom/inner TC-

TCB-

-

-

TCB-

3 G

-

Pt

Inner low current

ILC

a

ILC

-

4 G

-

Pt

Inner low voltage

ILV

c

ILV

-

5 G

-

Pt

Low current shield

LCS

i,j

LCS

-

6 G

-

Pt

Low current/Guard

LC

b

LC

-

7 G

-

Pt

Low voltage shield

LVS

k,l

LVS

-

8 G

-

Pt

Low voltage

LV

d

LV

-

9 P

Green

NiCr

Top TC+

TCT+

-

-

TCT+

10 N

White

NiAl

Top TC-

TCT-

-

-

TCT-

11 P

Green

NiCr

Centre/control TC+

TCC+

-

-

TCC+

12 N

White

NiAl

Centre/control TC-

TCC-

-

-

TCC-

13 G

-

Pt

High voltage

HV

g

HV

-

14 G

-

Pt

High voltage shield

HVS

o

HVS

-

15 G

-

Pt

High current

HC

h

HC

-

16 G

-

Pt

High current shield

HCS

p

HCS

-

Switches: Ch+HCS: Chassis to shield (HCS), LC+HCS: Guard (LC) to shield (HCS), when DOWN.

Shields Br.: Connects all four shields together when DOWN.

The base unit shown here is for A-

3 and higher. For A-2/A-1/B the

outer In and Out gas paths (on the

outer circle) are swapped.

Complementary Material to ProboStat™ Manual

20

Fig. 10. Phoenix-type multi-connector wiring overview.

2.3.3.

Overview of base unit electrical feedthroughs

By electrical feedthrough we mean an assembly where the electrical lead goes through the base unit

chassis from the electrode contacts to BNC contacts mounted on the base unit hexagon. The electrical

feedthrough consists of male mini-contact, sitting in PEEK insulator, and soldered to compensation wire.

The feedthroughs are numbered starting with very top of the base unit and run clockwise from 1 to 4. The

numbering continues on the outer ring from 5 to 16 again clockwise. The feedthroughs no. 1-4 are located

in the inner gas compartment, no. 5-16 –in the outer.

Fig. 11. Feedthrough numbering:

drawing.

Fig. 12. Feedthrough numbering on

base unit.

Fig. 13. Electrical feedthroughs

codes

Complementary Material to ProboStat™ Manual

21

The feedthrough codes, standard materials and functionality are presented in the bottom table of the

Wiring Overview.

2.3.4.

Feedthroughs colour code

The base unit has 16 feedthroughs: 10 electrical and 6 for thermocouples. All feedthroughs are colour

coded.

Table 8. Feedthrough colour code

Colour

Compensation wire to

Function

Red

Pt

Electrical, general

S-type thermocouple, negative

Black

Pt10%Rh

S-type thermocouple, positive

White

NiAl

K-type thermocouple, negative

Green

NiCr

K-type thermocouple, positive

2.3.5.

Signal and shield feedthroughs

The ProboStat™ base unit has 10 electrical feedthroughs, 6 of them lead current or voltage signal, 4 -

shield. The signal feedthroughs are soldered to the center of the BNC contacts, shields –to the plates.

ILC and ILV feedthroughs do not have own shield feedthroughs. However shield is important for some

measurement instruments. For this reason, shield plates of LC and ILC, LV and ILV BNC contacts are

connected pairwise. LCS and LVS act as shields for both, inner and outer, current and voltage probes.

Fig. 14. Signal and shield connection from inside of

the base unit.

Fig. 15. Signal and shield connection from outside

of the base unit.

Other manuals for ProboStat

1

Table of contents