Digiway DWPD102S Series User manual

DWPS102S

DWPS102A

DWPS102U

DWPD102SXX

DWPD102AXX

DWPD102UXX

Group Products

DIGIWAY PLUS

Single or double door, inward and outward, automation door

Automatisme pour porte simple ou double, tirante ou poussante

INSTALLATION MANUAL

MANUEL D’INSTALLATION

Range: Door automation / Gamme : Automatismes de portes

EN

G

LI

SH

EN

FRAN

C

AI

S

FR

* Refer to Limited Lifetime Warranty. / Voir conditions de garantie à vie limitée.

DIGIWAY PLUS

INSTALLATION MANUAL EN

General safety precautions

General safety precautions

This manual is intended for professional installers, adequately trained.

This manual is intended for professional installers, adequately trained.

Installation and connections must be carried out in accordance with Good Working Practice and in compliance with the

Installation and connections must be carried out in accordance with Good Working Practice and in compliance with the

current Regulations. Poor installation could be source of a health & safety hazard.

current Regulations. Poor installation could be source of a health & safety hazard.

Read this manual carefully before commencing the installation.

Read this manual carefully before commencing the installation.

First check all of the existing door and frame structure - verify its integrity, stability and strength.

First check all of the existing door and frame structure - verify its integrity, stability and strength.

If necessary modify the structure in order to make it standard, being aware of all the possible

If necessary modify the structure in order to make it standard, being aware of all the possible

problems which could occur during normal use.

problems which could occur during normal use.

Verify that all the zones where there is a risk of crushing, dragging, shearing and other dangers, are protected by electronic

Verify that all the zones where there is a risk of crushing, dragging, shearing and other dangers, are protected by electronic

safety, safety freeboards or barriers.

safety, safety freeboards or barriers.

These devices must be installed in compliance with the current laws and in a perfectly workmanlike way, also in relation to

These devices must be installed in compliance with the current laws and in a perfectly workmanlike way, also in relation to

the place of use, the type of use and the operating logic of the product.

the place of use, the type of use and the operating logic of the product.

The forces developed by the complete system must comply with the current standards and, where this is not possible,

The forces developed by the complete system must comply with the current standards and, where this is not possible,

protect the zones with electronic safety devices.

protect the zones with electronic safety devices.

Apply hazardous area notices required by the applicable regulations.

Apply hazardous area notices required by the applicable regulations.

Before the actuator is connected, make sure that the plate details corresponds to those of the mains power and that there

Before the actuator is connected, make sure that the plate details corresponds to those of the mains power and that there

is a differential circuit-breaker and an adequate protection against overcurrents on the supply side of the system.

is a differential circuit-breaker and an adequate protection against overcurrents on the supply side of the system.

Fit a Dual Pole disconnection switch with contact opening gap of at least of 3 mm.

Fit a Dual Pole disconnection switch with contact opening gap of at least of 3 mm.

Interrupt the power supply before opening the cover of the actuator for any maintenance or repairing intervention.

Interrupt the power supply before opening the cover of the actuator for any maintenance or repairing intervention.

Handling of electronic parts must be carried out wearing grounded antistatic bracelets to avoid any static damage.

Handling of electronic parts must be carried out wearing grounded antistatic bracelets to avoid any static damage.

Servicing the actuator is of fundamental importance if the system is to operate correctly and safely.

Servicing the actuator is of fundamental importance if the system is to operate correctly and safely.

Comply with the manufacturer’s instructions described in this manual.

Comply with the manufacturer’s instructions described in this manual.

Only use genuine spare parts if replacements or repairs are required.

Only use genuine spare parts if replacements or repairs are required.

The motor manufacturer declines any responsability in the event of component parts fitted that are not compatible with the

The motor manufacturer declines any responsability in the event of component parts fitted that are not compatible with the

safe and correct operation.

safe and correct operation.

The actuator must be installed only inside buildings

The actuator must be installed only inside buildings

The manufacturer declines all liability for damage caused by assembly on the outside, without adequate protection.

The manufacturer declines all liability for damage caused by assembly on the outside, without adequate protection.

This product cannot be installed in places with an explosive atmosphere or in the presence of inflammable fumes or

This product cannot be installed in places with an explosive atmosphere or in the presence of inflammable fumes or

gases.

gases.

General safety precautions

General safety precautions

.................................................................................................................................

.................................................................................................................................

2

2

Machinery Directive

Machinery Directive

............................................................................................................................................

............................................................................................................................................

3

3

Instructions of use

Instructions of use

..............................................................................................................................................

..............................................................................................................................................

3

3

Declaration of the Manufacturer

Declaration of the Manufacturer

.........................................................................................................................

.........................................................................................................................

3

3

Identifying product and parts

Identifying product and parts

..............................................................................................................................

..............................................................................................................................

4

4

Accessories

Accessories

.......................................................................................................................................................

.......................................................................................................................................................

5

5

Overall dimensions and mounting guide

Overall dimensions and mounting guide

............................................................................................................

............................................................................................................

6

6

Technical specifications

Technical specifications

......................................................................................................................................

......................................................................................................................................

7

7

Mechanic installation - Sliding arm version

Mechanic installation - Sliding arm version

........................................................................................................

........................................................................................................

8

8

Mechanic installation - Articulated arm version

Mechanic installation - Articulated arm version

..................................................................................................

..................................................................................................

9

9

Wiring diagram and connections

Wiring diagram and connections

........................................................................................................................

........................................................................................................................

11

11

LED messages

LED messages

...................................................................................................................................................

...................................................................................................................................................

12

12

Getting started

Getting started

....................................................................................................................................................

....................................................................................................................................................

12

12

•

•

Step I : Set-up

Step I : Set-up

.............................................................................................................................................

.............................................................................................................................................

13

13

•

•

Step II : Configuration

Step II : Configuration

..................................................................................................................................

..................................................................................................................................

14

14

•

•

Step III : Door calibration

Step III : Door calibration

.............................................................................................................................

.............................................................................................................................

15

15

•

•

Step

Step

IV : Adjustings

IV : Adjustings

......................................................................................................................................

......................................................................................................................................

16

16

•

•

Step

Step

V : Advanced sets

V : Advanced sets

................................................................................................................................

................................................................................................................................

17

17

Disabled persons settings

Disabled persons settings

..................................................................................................................................

..................................................................................................................................

19

19

Radio transmitters management

Radio transmitters management

.......................................................................................................................

.......................................................................................................................

20

20

Reset to factory default & system reset

Reset to factory default & system reset

..............................................................................................................

..............................................................................................................

20

20

Double door installing

Double door installing

.........................................................................................................................................

.........................................................................................................................................

21

21

Warranty

Warranty

............................................................................................................................................................

............................................................................................................................................................

25

25

Summary

Summary

pag.

pag.

2cdvi.com

cdvigroup.com

INSTALLATION MANUAL

DIGIWAY PLUS

3

cdvi.com

cdvigroup.com

EN

Machinery Directive

Machinery Directive

Automatic pedestrian doors fall into the application field of the Machinery Directive (2006/42/CE).

Automatic pedestrian doors fall into the application field of the Machinery Directive (2006/42/CE).

1. Prepare the Technical Construction File (which must contain the documents indicated inAnnex V of the Machinery Directive) and must

1. Prepare the Technical Construction File (which must contain the documents indicated inAnnex V of the Machinery Directive) and must

be kept and placed at the disposal of competent national authorities for at least ten years from the date of manufacture of the motorised

be kept and placed at the disposal of competent national authorities for at least ten years from the date of manufacture of the motorised

door.

door.

2. Draft the EC Declaration of Conformity in accordance with Annex II-Aof the Machinery Directive

2. Draft the EC Declaration of Conformity in accordance with Annex II-Aof the Machinery Directive

3. Affix the CE marking on the power operated door in accordance with point 1.7.3 of Annex I of the Machinery Directive.

3. Affix the CE marking on the power operated door in accordance with point 1.7.3 of Annex I of the Machinery Directive.

The installer must consign to the customer the following documents :

The installer must consign to the customer the following documents :

1. Instructions on how to operate and safely use the system.

1. Instructions on how to operate and safely use the system.

2. Routine maintenance instructions.

2. Routine maintenance instructions.

3. Declaration of conformity.

3. Declaration of conformity.

4. Maintenance register.

4. Maintenance register.

Instructions for use

Instructions for use

The operator DIGIWAY type DWPS102xx, DWPD102XX belongs to the Service Class 5 ( 600 cycles a day for 5 years min).

The operator DIGIWAY type DWPS102xx, DWPD102XX belongs to the Service Class 5 ( 600 cycles a day for 5 years min).

Applications : HEAVY DUTY, for pedestrian accesses to institutional complexes with very intense use.

Applications : HEAVY DUTY, for pedestrian accesses to institutional complexes with very intense use.

Declaration of the Manufacturer

Declaration of the Manufacturer

( according to Directive 98/37/CE, Annex II part B )

( according to Directive 98/37/CE, Annex II part B )

The Manufacturer

The Manufacturer

ELPRO INNOTEK SPA - CDVI Group

ELPRO INNOTEK SPA - CDVI Group

Via Piave,23

Via Piave,23

31020 S.Pietro di Feletto (TV)

31020 S.Pietro di Feletto (TV)

ITALY

ITALY

Herewith declares that the automatic operator for swing doors

Herewith declares that the automatic operator for swing doors

Brand : DIGIWAY

Brand : DIGIWAY

Types : DWPS102Ax, DWPS102Sx, DWPD102Axx, DWDP102Sxx

Types : DWPS102Ax, DWPS102Sx, DWPD102Axx, DWDP102Sxx

- constitutes a “partly completed machinery” and it is intended to be incorpored into machinery or to be

- constitutes a “partly completed machinery” and it is intended to be incorpored into machinery or to be

assembled with other machinery to constitute a machinery covered by Directive

assembled with other machinery to constitute a machinery covered by Directive

2006/42/CE;

2006/42/CE;

- complies with the following Directives :

- complies with the following Directives :

2006/95/CE ( Low Voltage Directive )

2006/95/CE ( Low Voltage Directive )

2004/108/CE ( Electromagnetic Compatibility Directive )

2004/108/CE ( Electromagnetic Compatibility Directive )

99/05/CE ( R&TTE )

99/05/CE ( R&TTE )

89/106/CEE ( Construction Products Directive )

89/106/CEE ( Construction Products Directive )

- it is not allowed to put the machinery into service until the machinery into which it has to be incorporated or

- it is not allowed to put the machinery into service until the machinery into which it has to be incorporated or

of which it has to be a component has been found and declarated to be in compliance with the provisions of the

of which it has to be a component has been found and declarated to be in compliance with the provisions of the

Directive 98/37/EC.

Directive 98/37/EC.

S.Pietro di Feletto, 30/5/2010

S.Pietro di Feletto, 30/5/2010

G. Massimo Dalle Carbonare

G. Massimo Dalle Carbonare

( Product manager )

( Product manager )

DIGIWAY PLUS

INSTALLATION MANUAL EN

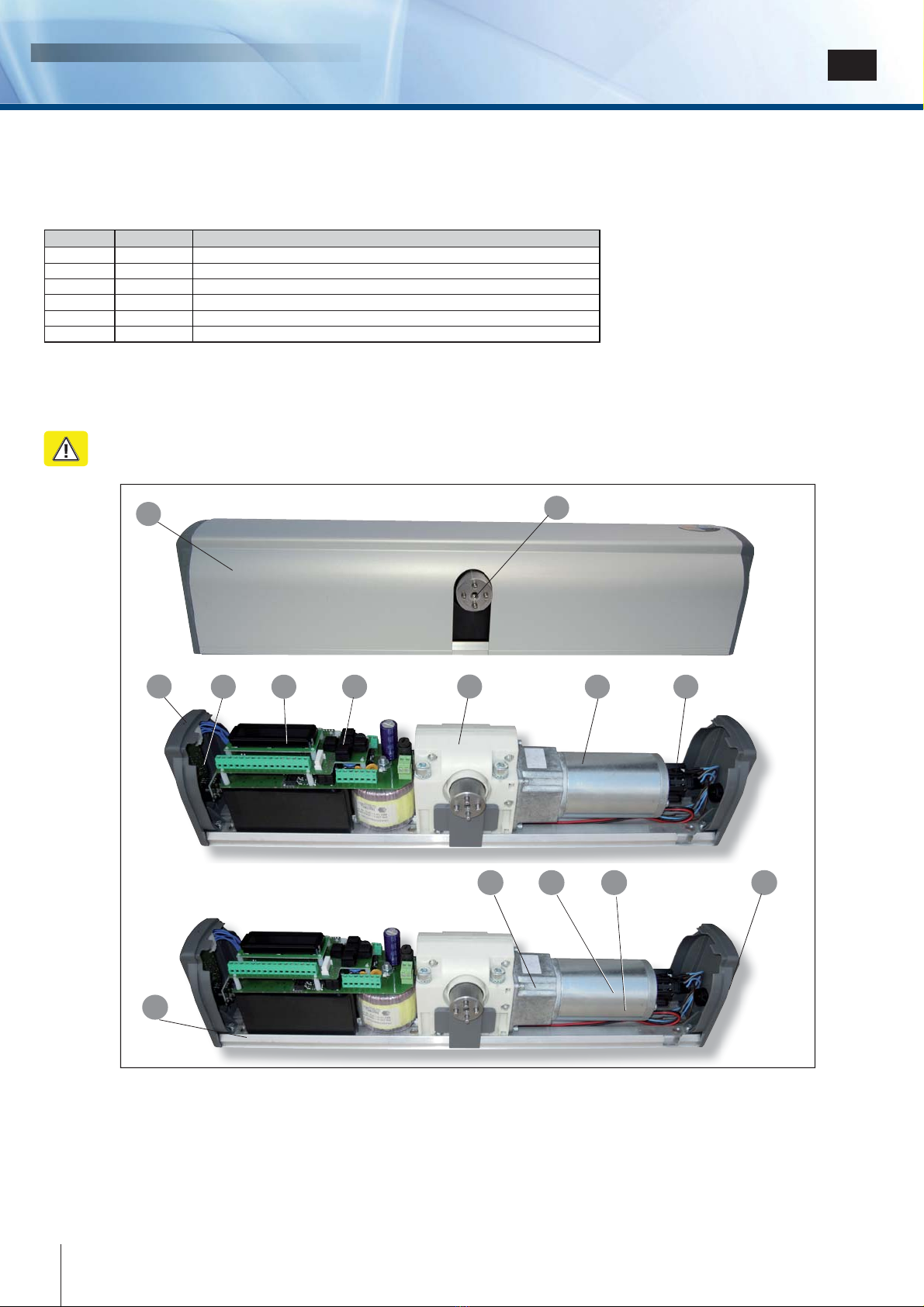

Identifying the product and its parts

Identifying the product and its parts

Digiway type DWPx102xx is a indoor operator for swing doors, with integrated electronic controller and radio receiver.

Digiway type DWPx102xx is a indoor operator for swing doors, with integrated electronic controller and radio receiver.

The opening and closing motion is electromechanical with backup battery which assures the operation in cases of power

The opening and closing motion is electromechanical with backup battery which assures the operation in cases of power

failure. The following versions are available:

failure. The following versions are available:

Legend

Legend

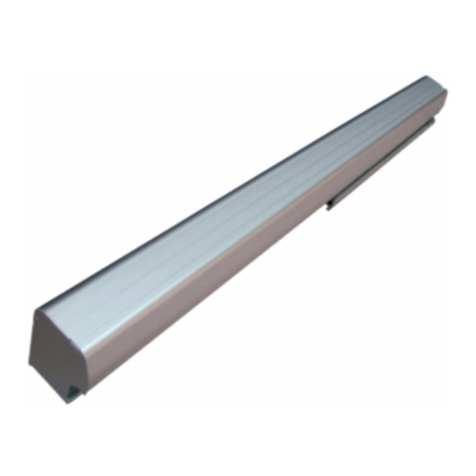

1 - Anodized aluminium cover

1 - Anodized aluminium cover

8 -

8 -

Motoriductor

Motoriductor

2 - Motor shaft

2 - Motor shaft

9 -

9 -

Encoder

Encoder

3 - Status led LP

3 - Status led LP

10 - Slot for coven opening

10 - Slot for coven opening

4 -

4 -

Receiver Card

Receiver Card

11 -

11 -

Toroidal transformer

Toroidal transformer

5 - Display LCD 12 -

5 - Display LCD 12 -

Backup battery

Backup battery

6 - 5-buttons keyboard

6 - 5-buttons keyboard

13 -

13 -

Battery cable with protection fuse

Battery cable with protection fuse

7 -

7 -

Gear box

Gear box

14 -

14 -

Operating mode selector

Operating mode selector

P/N Reference Description

F0543000054

F0543000054 DWPS102SCD

Single door operator for inswing doors with sliding arm

Single door operator for inswing doors with sliding arm

F0543000055

F0543000055 DWPS102ACD

Single door operator for outswing doors with articulated arm

Single door operator for outswing doors with articulated arm

F0543000056 DWPS102UCD

Single door operator for inswing or outswing doors with universal arm

Single door operator for inswing or outswing doors with universal arm

F0543000059

F0543000059 DWPS106SCD

16 Vac single door operator for inswing doors with sliding arm

16 Vac single door operator for inswing doors with sliding arm

F0543000058 DWPS106ACD

16 Vac single door operator for outswing doors with

16 Vac single door operator for outswing doors with

articulated arm

articulated arm

F0543000060

F0543000060 DWPS106UCD

16 Vac single door operator for inswing or outswing doors with universal arm

16 Vac single door operator for inswing or outswing doors with universal arm

11

78 95 6

3

10

12

12 13 14

4

The operator is suitable for swing doors with max width of 1,2 m and max weight of 120 Kg ( Refer to diagram on page 7).

The operator is suitable for swing doors with max width of 1,2 m and max weight of 120 Kg ( Refer to diagram on page 7).

At the max speed the door can open and close within 3 sec. ( 90°), depending on door weight and dimensions .

At the max speed the door can open and close within 3 sec. ( 90°), depending on door weight and dimensions .

See the technical specifications in the following pages of this manual.

See the technical specifications in the following pages of this manual.

4cdvi.com

cdvigroup.com

Warning : the operator is suitable only for top-jamb fixing. Door leaf fixing is not allowed.

Warning : the operator is suitable only for top-jamb fixing. Door leaf fixing is not allowed.

INSTALLATION MANUAL

DIGIWAY PLUS

5

cdvi.com

cdvigroup.com

EN

Accessories

Accessories

Legend

Legend

Mounting kit

Mounting kit

1

5

Kit Articulated Arm

Kit Articulated Arm

Kit Sliding Arm

Kit Sliding Arm

1 - Articulated base arm 5 -

1 - Articulated base arm 5 -

Sliding base lever

Sliding base lever

2 - Arm 6 -

2 - Arm 6 -

Sliding block

Sliding block

3 -

3 -

Forearm

Forearm

7 -

7 -

Aluminium guide

Aluminium guide

4 - Door bracket 8 - Lateral plug

4 - Door bracket 8 - Lateral plug

9 - Junction for articulated base arm

9 - Junction for articulated base arm

3

4

2

6

7

8

Kit Universal

Kit Universal

9

Article

Article

Description Screw for

wallplugs

SX 8

Wallplugs

SX 8

Self

tapping

screws

Screw

M6x14 Mounting

plate Mounting

template

Q.ty

Q.ty

6

6

6

6

4

4

7

7

1

1

1

1

DIGIWAY PLUS

INSTALLATION MANUAL EN

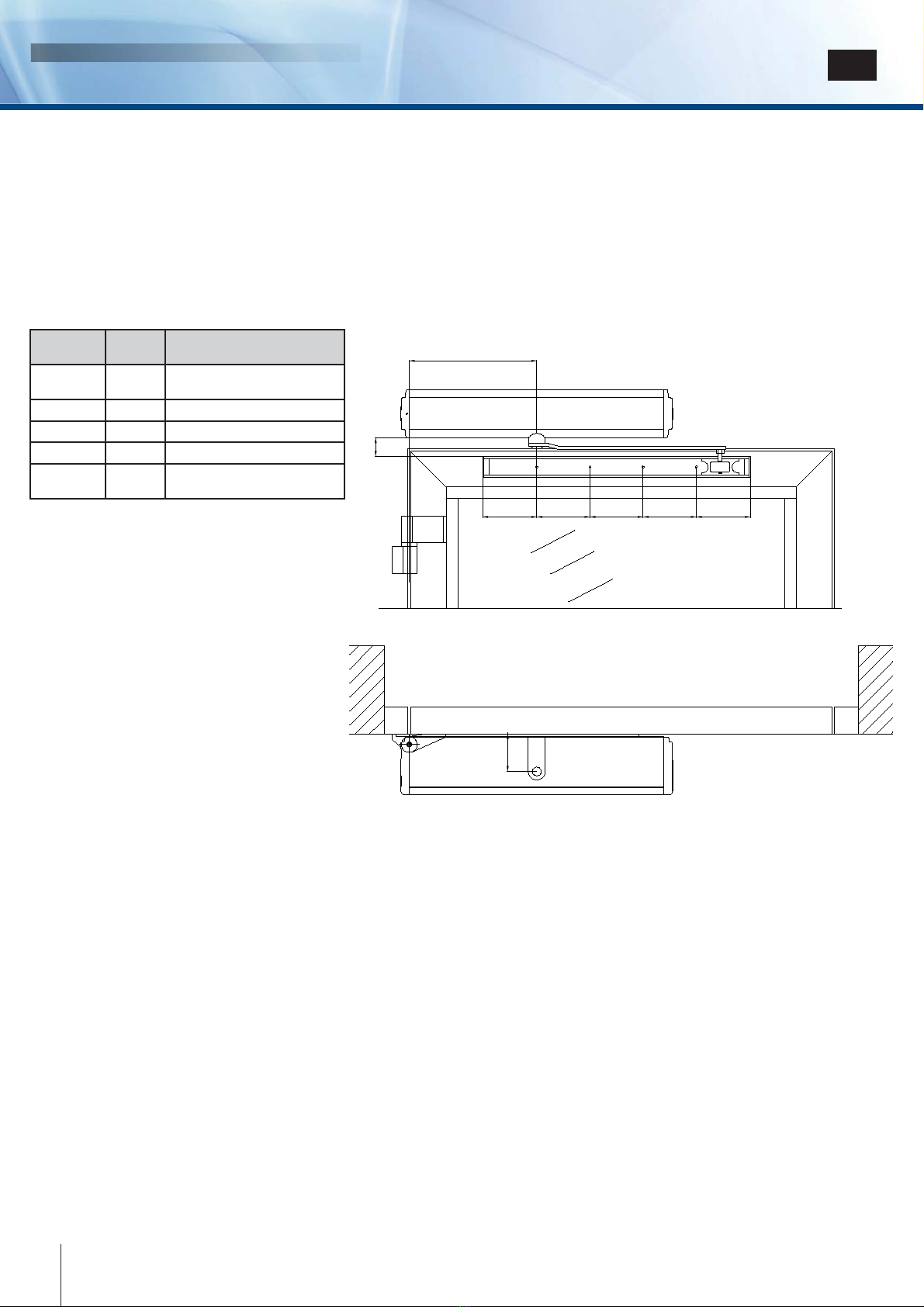

Overall dimensions and mounting quotes

Overall dimensions and mounting quotes

Mounting plate drilling quotes

Mounting plate drilling quotes

Accessories dimensions

Accessories dimensions

55 mm

55 mm

35 mm

35 mm

Optional extension

Optional extension

52

52

40

40

40

40

40

40

40

40

Cover lift point

Cover lift point

Cover lift point

Cover lift point

6cdvi.com

cdvigroup.com

INSTALLATION MANUAL

DIGIWAY PLUS

7

cdvi.com

cdvigroup.com

EN

Technical specifications

Technical specifications

•

•

General specifications

General specifications

Power supply:

Power supply:

.........................................................

.........................................................

230 Vac - 50 Hz

230 Vac - 50 Hz

Motor torque:

Motor torque:

...........................................................

...........................................................

15 Nm

15 Nm

Motor power:

Motor power:

............................................................

............................................................

33 W

33 W

Motor voltage:

Motor voltage:

..........................................................

..........................................................

24 Vdc

24 Vdc

Operating class:

Operating class:

.......................................................

.......................................................

5 ( heavy duty )

5 ( heavy duty )

Battery:

Battery:

....................................................................

....................................................................

12 Vdc 1,3 Ah

12 Vdc 1,3 Ah

Max motor consumption:

Max motor consumption:

........................................

........................................

6A @ 12V

6A @ 12V

Overall dimensions :

Overall dimensions :

................................................

................................................

511 x 90 x 110 mm

511 x 90 x 110 mm

Weight:

Weight:

....................................................................

....................................................................

5 Kg

5 Kg

Operating temperature:

Operating temperature:

...........................................

...........................................

-10

-10

÷

÷

+55°C

+55°C

IP Grade:

IP Grade:

.................................................................

.................................................................

IP22

IP22

Opening / closing time:

Opening / closing time:

............................................

............................................

3 ÷ 15 sec.

3 ÷ 15 sec.

Pause time:

Pause time:

..............................................................

..............................................................

3

3

÷

÷

90 sec.

90 sec.

Power for auxiliary devices:

Power for auxiliary devices:

.....................................

.....................................

13,5 Vdc / 500 mA [ max ]

13,5 Vdc / 500 mA [ max ]

Power for electrolock:

Power for electrolock:

.............................................

.............................................

12 Vdc / 1A

12 Vdc / 1A

[ max ]

[ max ]

Electrolock output relay:

Electrolock output relay:

..........................................

..........................................

( C-NO-NC) 10A / 12V

( C-NO-NC) 10A / 12V

Open door output relay

Open door output relay

............................................

............................................

( C-NO ) - 24 VA

( C-NO ) - 24 VA

Electrolock hold time:

Electrolock hold time:

..............................................

..............................................

Adjustable [ 0,1

Adjustable [ 0,1

÷ 40 Sec. ]

÷ 40 Sec. ]

Power failure autonomy:

Power failure autonomy:

..........................................

..........................................

270 cycles

270 cycles

Transmitters security protocol:

Transmitters security protocol:

................................

................................

Keeloq® Hopping Code

Keeloq® Hopping Code

TX memory:

TX memory:

.............................................................

.............................................................

50 transmitters

50 transmitters

Integrated receiver main specifications:

Integrated receiver main specifications:

..................

..................

433,92 MHz ASK /

433,92 MHz ASK /

-107 dBm

-107 dBm

Fire voltage input:

Fire voltage input:

....................................................

....................................................

12

12

÷ 48

÷ 48

Vac/dc

Vac/dc

•

•

Use conditions

Use conditions

•

•

Electronic card specifications

Electronic card specifications

•

•

Main features

Main features

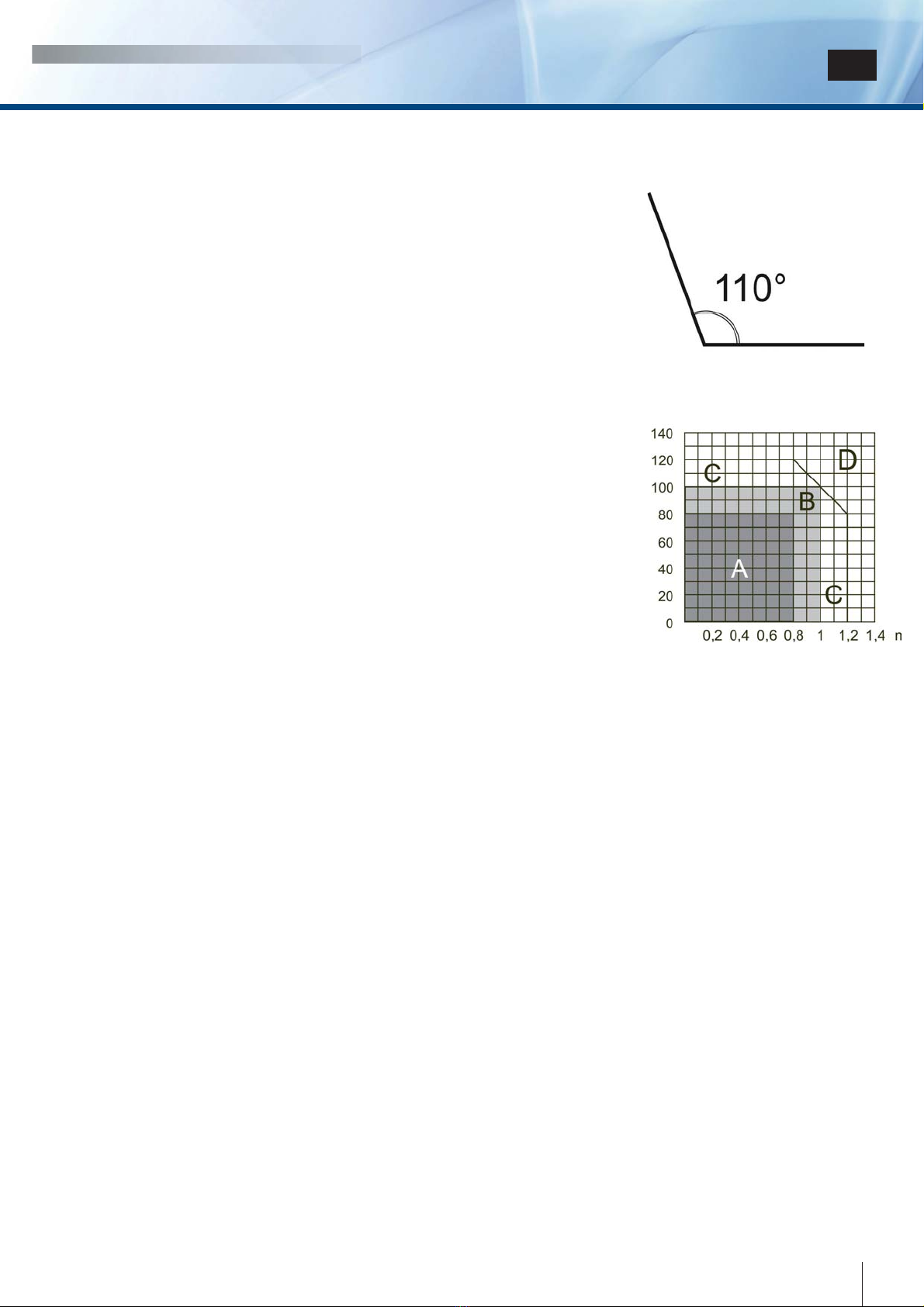

Zone A

Zone A

: Very intense use : 600 cycles / day

: Very intense use : 600 cycles / day

Zone B

Zone B

:

:

Intense use

Intense use

: 200-300

: 200-300

cycles / day

cycles / day

Zone C

Zone C

: Use at reduced speed

: Use at reduced speed

Zone D : Not allowed

Zone D : Not allowed

Operating modes:

Operating modes:

Automatic ( I ) - Door free ( 0 ) - Door always open (II)

Automatic ( I ) - Door free ( 0 ) - Door always open (II)

Inputs: Re-open photocells ( NC)

Inputs: Re-open photocells ( NC)

Stop photocells ( NC )

Stop photocells ( NC )

Door Alway open

Door Alway open

( NO )

( NO )

Door free ( NO )

Door free ( NO )

External Radar ( NO )

External Radar ( NO )

Internal Radar ( NO )

Internal Radar ( NO )

Day / Night selection ( NO )

Day / Night selection ( NO )

Open / Close command ( NO )

Open / Close command ( NO )

Fire alarm voltage ( +V, -V) [optoisolated ]

Fire alarm voltage ( +V, -V) [optoisolated ]

Operating modes: Fully automatic, Always open, Door free;

Operating modes: Fully automatic, Always open, Door free;

Operating with single door, double door, with or without leaf overlapping;

Operating with single door, double door, with or without leaf overlapping;

Guided procedure for door travel limits characterization;

Guided procedure for door travel limits characterization;

Motor torque in opening and closing adjustable;

Motor torque in opening and closing adjustable;

Remote controls memorization and management;

Remote controls memorization and management;

Slow motion approaching the limits;

Slow motion approaching the limits;

Push & Go / Pull & Go function;

Push & Go / Pull & Go function;

Pause Time, Max Speed, Torque, Velocity adjustable;

Pause Time, Max Speed, Torque, Velocity adjustable;

Opening Jolt fully adjustable;

Opening Jolt fully adjustable;

Status bicolor LED;

Status bicolor LED;

Electrolock hold time and torque adjustable;

Electrolock hold time and torque adjustable;

Opening Jolt parameters adjustable;

Opening Jolt parameters adjustable;

Spring mode ( door always free, automatic closing );

Spring mode ( door always free, automatic closing );

Stop photocells range adjustable;

Stop photocells range adjustable;

“Fire mode”;

“Fire mode”;

Night / day mode;

Night / day mode;

Door open output relay.

Door open output relay.

Leaf width

Leaf width

Leaf weight

Leaf weight

Max Door opening angle

Max Door opening angle

Outputs:

Outputs:

Door open contact ( C-NO )

Door open contact ( C-NO )

External devices power 13,5 Vdc / 500 mA

External devices power 13,5 Vdc / 500 mA

Electrolock output contacts ( C-NO-NC )

Electrolock output contacts ( C-NO-NC )

Electrolock power 12 Vdc / 1A

Electrolock power 12 Vdc / 1 A

DIGIWAY PLUS

INSTALLATION MANUAL EN

Sliding arm version

Sliding arm version

First of all, check the stability of the door which has to be motorized, verifying that regularity of the motion in both

First of all, check the stability of the door which has to be motorized, verifying that regularity of the motion in both

directions ( open and close ) is without any friction from the complete close to the complete open status. If this is

directions ( open and close ) is without any friction from the complete close to the complete open status. If this is

not the case, make necessary improvements to the structure. Remove any manually operated lock (eg. requiring a

not the case, make necessary improvements to the structure. Remove any manually operated lock (eg. requiring a

physical lowering of the handle to open the door).

physical lowering of the handle to open the door).

Digiway plus

Digiway plus

does not need a door-stop fitted

does not need a door-stop fitted

to complete the open cycle.

to complete the open cycle.

This type of installation is addressed to inswing doors.

This type of installation is addressed to inswing doors.

1) Identify the dimensions of the motor, locate the fixing position, the holes for the cables and the 6 fixing holes making use

1) Identify the dimensions of the motor, locate the fixing position, the holes for the cables and the 6 fixing holes making use

of the mounting template provided;

of the mounting template provided;

2) Check the feasibility of the guide fixing, respecting the distance to the motor;

2) Check the feasibility of the guide fixing, respecting the distance to the motor;

3) Make 6 holes diameter Ø 8 mm and insert the 6 special plugs provided ;

3) Make 6 holes diameter Ø 8 mm and insert the 6 special plugs provided ;

4) Fix the plate to the wall using the special screws provided;

4) Fix the plate to the wall using the special screws provided;

5) Fix the motor to the mounting plate with the screws M6x14 provided;

5) Fix the motor to the mounting plate with the screws M6x14 provided;

6) Plug-in the sliding arm on the motor shaft and screw the fixing screw M6;

6) Plug-in the sliding arm on the motor shaft and screw the fixing screw M6;

7) Slide-in the sliding block into the guide;

7) Slide-in the sliding block into the guide;

8) Offer the guide to the door and mark the 4 fixing holes;

8) Offer the guide to the door and mark the 4 fixing holes;

9) Remove the sliding block and fix the guide to the door by using the 4 special screws provided;

9) Remove the sliding block and fix the guide to the door by using the 4 special screws provided;

10) Slide-in completely the white strip on the guide;

10) Slide-in completely the white strip on the guide;

11) Slide-in the sliding block into the guide and insert the two lateral plugs;

11) Slide-in the sliding block into the guide and insert the two lateral plugs;

12) Make all the electrical connections;

12) Make all the electrical connections;

13) Apply power;

13) Apply power;

14) Follow the procedure : «Getting started»;

14) Follow the procedure : «Getting started»;

15) Connect the Ground wire to the cover terminal and fix the cover.

15) Connect the Ground wire to the cover terminal and fix the cover.

E

A

B

C D D D C

Parameter Value

(mm) Description

A

A

240

240

(max)

(max)

Door hinge – motor axis

Door hinge – motor axis

distance

distance

B

B

35

35

Motor cover – guide distance

Motor cover – guide distance

C

C

102

102

Motor axis - guide edge

Motor axis - guide edge

D

D

100

100

Guide holes interaxis

Guide holes interaxis

E

E

70,5

70,5

Motor axis - vertical plane

Motor axis - vertical plane

distance

distance

8cdvi.com

cdvigroup.com

INSTALLATION MANUAL

DIGIWAY PLUS

9

cdvi.com

cdvigroup.com

EN

This part is addressed to outward door installations

This part is addressed to outward door installations

1) Identify the dimensions of the motor, locate the fixing position, the holes for the cables and the 6 fixing holes making

1) Identify the dimensions of the motor, locate the fixing position, the holes for the cables and the 6 fixing holes making

use of the mounting template provided;

use of the mounting template provided;

2) Make sure that the bracket of the articulated arm falls in the right position;

2) Make sure that the bracket of the articulated arm falls in the right position;

3) Make 6 holes diameter Ø 8 mm and insert the 6 special plugs provided ;

3) Make 6 holes diameter Ø 8 mm and insert the 6 special plugs provided ;

4) Fix the plate to the wall using the special screws provided;

4) Fix the plate to the wall using the special screws provided;

5) Fix the motor to the mounting plate with the screws M6x14 provided

5) Fix the motor to the mounting plate with the screws M6x14 provided

6) Fix the bracket to the door referring to the distance A of the table below;

6) Fix the bracket to the door referring to the distance A of the table below;

7) Plug in the articulated arm on the motor shaft and screw the fixing screw M6;

7) Plug in the articulated arm on the motor shaft and screw the fixing screw M6;

8) If the distance between the motor and the door is higher than that allowed, use the extension (

8) If the distance between the motor and the door is higher than that allowed, use the extension (

optional

optional

);

);

9) Fix the arm to the motor by using the screw M6x14 or M6x70 provided;

9) Fix the arm to the motor by using the screw M6x14 or M6x70 provided;

10) Make all the electrical connections;

10) Make all the electrical connections;

11) Apply power;

11) Apply power;

12)

12)

Follow the procedure : «Getting started»;

Follow the procedure : «Getting started»;

13) Connect the Ground wire to the cover terminal and fix the cover.

13) Connect the Ground wire to the cover terminal and fix the cover.

L1

L2

L3

A

B

Parameter Speed Power Description

(mm) (mm)

A

A

410

410

430

430

Door hinge – door bracket distance

Door hinge – door bracket distance

B

B

270

270

360

360

Door hinge – motor axis distance

Door hinge – motor axis distance

A - B

A - B

140

140

70

70

Motor axis – door bracket distance

Motor axis – door bracket distance

C

C

40

40

Bracket holes distance

Bracket holes distance

L1

L1

70,5

70,5

Motor axis – wall distance

Motor axis – wall distance

L2

L2

300

300

Base lever

Base lever

L3

L3

130 - 300

130 - 300

Arm extension

Arm extension

DIGIWAY PLUS

INSTALLATION MANUAL EN

Complete wiring diagram

Complete wiring diagram

Differential

Differential

magnetothermic

magnetothermic

circuit-braker

circuit-braker

3 pos. switch

3 pos. switch

autom / door free

autom / door free

/ always open

/ always open

NIght / Day

NIght / Day

Start/Stop

Start/Stop

Door open

Door open

relay

relay

Fire-alarm

Fire-alarm

voltage

voltage

Electrolock

Electrolock

FTC-S [ Stop ]

FTC-S [ Stop ]

FTC [ Re-open ]

FTC [ Re-open ]

Internal

Internal

Radar

Radar

External

External

Radar

Radar

Layout inswing door with sliding arm

Layout inswing door with sliding arm

Layout outswing door with articulated arm

Layout outswing door with articulated arm

Internal

Internal

Radar

Radar

External

External

Radar

Radar

FTC

FTC

FTC-S

FTC-S

Internal

Internal

Radar

Radar

External

External

Radar

Radar

FTC

FTC

FTC-S

FTC-S

Electronic card layout

Electronic card layout

Display LCD

Display LCD

Battery

Battery

connector

Fuse

Fuse

3,15A

3,15A

Programming

Programming

buttons

buttons

GND

GND

connection

connection

Monitor

Monitor

LED’s

LED’s

Terminal

Terminal

blocks A

blocks A

Terminal

Terminal

blocks

blocks

B

B

Serial

Serial

connection

connection

connector

connector

Fuse

Fuse

1A

1A

ESC : Return to upper level

Return to upper levelReturn to upper level

scroll UP / increase value

scroll UP / increase value

scroll DOWN / decrease value

scroll DOWN / decrease value

OK

OK

Not used

Not used

Programming buttons

Programming buttons

External switch

External switch

I 0 II

I 0 II

DOOR ALWAYS OPEN

DOOR ALWAYS OPEN

DOOR FREE

DOOR FREE

FULLY AUTOMATIC

FULLY AUTOMATIC

10 cdvi.com

cdvigroup.com

INSTALLATION MANUAL

DIGIWAY PLUS

11

cdvi.com

cdvigroup.com

EN

Connections detail

Connections detail

Electrical connections

Electrical connections

16-way terminal block

1Output C Open door relay

2Output NO Open door relay

3Input V- Fire alarm voltage

4Input V+ Fire alarm voltage

5Safety Input NC Stop Photocells [FTC-S]

6Safety Input C Photocells

7Safety Input NC Re-open Photocells [FTC]

8Input NO switch pos. I

9Input C switch pos. 0

10 Input NO switch pos. II

11 Input NA Radar external

12 Input C Radar

13 Input NO Radar internal

14 Input NO Day/Night switch

15 Input common

16 Input NO push-button open/close/stop

7-way terminal block

17 Output NO relay electrolock

18 Output C relay electrolock

19 Output NC relay electrolock

20 Output 0V external devices power

21 Output 13,5 Vdc external devices power

22 Output 0V electrolock power

23 Output 12 Vdc electrolock power

2-ways removable terminal block

24 Input Phase 230 Vac

25 Input Neutral 230 Vac

2-ways terminal block

26 Output 230 Vac for internal toroidal transformer

27 Output 230 Vac for internal toroidal transformer

2-ways terminal block

28 Input Motor BLACK cable

29 Input Motor RED cable

2-ways terminal block

30 Input from internal toroidal transformer

31 Input from internal toroidal transformer

Battery

Battery

+

+

-

-

FUSE 5A

FUSE 5A

to toroidal

to toroidal

transformer

transformer

to the motor

to the motor

OUT open

OUT open

door relay (*)

door relay (*)

FTC-S

FTC-S

FTC

FTC

Automatic

Automatic

Door free

Door free

Door open

Door open

RADAR Int.

RADAR Int.

RADAR Ext.

RADAR Ext.

Day/Night

Day/Night

Open/Close

Open/Close

Magnet

Magnet

External

External

magnet

magnet

supply

supply

Supply radars

Supply radars

& photocells

& photocells

Electrolock

Electrolock

Supply

Supply

Electrolock relay

Electrolock relay

from toroidal transformer

from toroidal transformer

or

or

Input 16 V~ [ Ref. DWPx106x ]

Input 16 V~ [ Ref. DWPx106x ]

(*) Open door relay

Door Status Closed Opening/Open/Closing

Relay OFF ON

DIGIWAY PLUS

INSTALLATION MANUAL EN

Meaning of LP LED messages

Meaning of LP LED messages

Function

Function LED GREEN LED ORANGE LED RED

ON

ON

blinking

blinking

ON

ON

blinking

blinking

ON

ON

blinking

blinking

fast blinking

fast blinking

Everything OK

Everything OK

O

O

Battery operated

Battery operated

O

O

Fire alarm

Fire alarm

O (fast)

O (fast)

Night Mode

Night Mode

O

O

Night Mode & battery

Night Mode & battery

operated

operated

O

O

Door free

Door free

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Voltage calculation

Voltage calculation

in progress

in progress

O

O

Selflearning

Selflearning

red/green

red/green

Battery test

Battery test

O

O

Battery unleaded

Battery unleaded

O

O

GETTING STARTED

GETTING STARTED

Digiway Plus is equipped with a 2x16 characters LCD Display and by a 5-keys keyboard. The operating configuration can be set navigating

Digiway Plus is equipped with a 2x16 characters LCD Display and by a 5-keys keyboard. The operating configuration can be set navigating

through several menus. The menu has a tree structure with a main menu and different sub-menus.

through several menus. The menu has a tree structure with a main menu and different sub-menus.

ACCESS to the MAIN MENU

ACCESS to the MAIN MENU

Push simultaneously the keys C + D of a radio

Push simultaneously the keys C + D of a radio

transmitter already memorized

transmitter already memorized

(within Digiway memory).

(within Digiway memory).

Hold the OK button down for

Hold the OK button down for

4 seconds.

4 seconds.

A

A

B

B

C

C

D

D

Main Menu structure

Main Menu structure

The main menu is composed by 9 submenus :

The main menu is composed by 9 submenus :

•

•

LANGUAGES :

LANGUAGES :

Selects the language of the display messages ;

Selects the language of the display messages ;

•

•

CONFIGURATION:

CONFIGURATION:

Operating mode settings (number of doors, electrolock, etc.) ;

Operating mode settings (number of doors, electrolock, etc.) ;

•

•

MAIN FUNCTIONS:

MAIN FUNCTIONS:

Adjustments (speed, force, etc);

Adjustments (speed, force, etc);

•

•

ADVANCED SETTING:

ADVANCED SETTING:

Special settings with more parameters

Special settings with more parameters

;

;

•

•

DOOR CALIBRATION:

DOOR CALIBRATION:

Selflearning of the door parameters;

Selflearning of the door parameters;

•

•

TX MANAGEMENT:

TX MANAGEMENT:

Management of the remote controls (add, remove, etc);

Management of the remote controls (add, remove, etc);

•

•

FACTORY DEFAULTS:

FACTORY DEFAULTS:

Restore to the factory settings;

Restore to the factory settings;

•

•

SYSTEM RESET:

SYSTEM RESET:

System restart;

System restart;

•

•

EXIT MENU:

EXIT MENU:

Exit.

Exit.

Electronic card LED’s

Electronic card LED’s

LED ON LED OFF

L1 Fire voltage OK Fire voltageABSENT

L2 NC contact stop photocells

closed NC contact stop photocells

open

L3 NC contact re-open photo-

cells closed NC contact re-open photo-

cells open

L4 Automatic mode -

L5 Door always open -

L6 External radar active -

L7 Internal radar active -

L8 Night mode Day mode

L9 Open/close command

active -

Main Menu

Configuration

Main Menu

Advanced setting

Main Menu

Door calibration

Main Menu

TX Management

Main Menu

System Reset

Main Menu

Languages

Main Menu

Factory defaults

Main Menu

Main functions

Main Menu

Exit Menu

OR

OR

12 cdvi.com

cdvigroup.com

INSTALLATION MANUAL

DIGIWAY PLUS

13

cdvi.com

cdvigroup.com

EN

Guided configuration

Guided configuration

The operator is supplied with a 4-button transmitter included. On completion of the mechanical fixing and the electric connections, proceed

The operator is supplied with a 4-button transmitter included. On completion of the mechanical fixing and the electric connections, proceed

with the memorization of the transmitter into the internal memory inside Digiway. This transmitter can then set-up of all parameters, without

with the memorization of the transmitter into the internal memory inside Digiway. This transmitter can then set-up of all parameters, without

accessing the 5 buttons

accessing the 5 buttons

onboard

onboard

.

.

The transmitter keys corresponds to the onboard push-button according to the next diagram:

The transmitter keys corresponds to the onboard push-button according to the next diagram:

The set-up of the operator can be divided into 5 steps:

The set-up of the operator can be divided into 5 steps:

•

•

STEP I : INITIAL SETUP

STEP I : INITIAL SETUP

( preliminary actions )

( preliminary actions )

•

•

STEP II : CONFIGURATION

STEP II : CONFIGURATION

( set-up of the basic operating mode )

( set-up of the basic operating mode )

•

•

STEP

STEP

III : DOOR CALIBRATION

III : DOOR CALIBRATION

( automatic detection of the door characteristics )

( automatic detection of the door characteristics )

•

•

STEP

STEP

IV : ADJUSTMENTS

IV : ADJUSTMENTS

( further adjustments and personalization )

( further adjustments and personalization )

•

•

STEP

STEP

V : SPECIAL PARAMETERS

V : SPECIAL PARAMETERS

(

(

set-up of the

set-up of the

advanced parameters )

advanced parameters )

Press the OK button of the keyboard

Press the OK button of the keyboard

for

for

4 sec

4 sec

until the display enters the main menu ;

until the display enters the main menu ;

Select the language by scolling the possibile choices with the UP and DOWN buttons

Select the language by scolling the possibile choices with the UP and DOWN buttons

Press OK to confirm: the display shows the message OK and then displays all messages in the new language;

Press OK to confirm: the display shows the message OK and then displays all messages in the new language;

Exit from the menu with the button ESC.

Exit from the menu with the button ESC.

Scroll through the main menu, select

Scroll through the main menu, select

TX MANAGEMENT

TX MANAGEMENT

submenu and press OK

submenu and press OK

Select the option

Select the option

ADD TX

ADD TX

and press

and press

OK

OK

Press the transmitter key A (top-left button): the display will show the S/N, confirming the memorization

Press the transmitter key A (top-left button): the display will show the S/N, confirming the memorization

Exit from the menu by pressing the ESC button.

Exit from the menu by pressing the ESC button.

Exit from the main menu selecting EXIT MENU.

Exit from the main menu selecting EXIT MENU.

From this time on the remote control is enabled to access the main menu. Enter simply by pressing simultaneously keys

From this time on the remote control is enabled to access the main menu. Enter simply by pressing simultaneously keys

C + D

C + D

.

.

NOTE : ONLY THE FIRST TRANSMITTER MEMORIZED CAN ACCESS THE MAIN MENU! All the next added transmitters can only

NOTE : ONLY THE FIRST TRANSMITTER MEMORIZED CAN ACCESS THE MAIN MENU! All the next added transmitters can only

open the door!

open the door!

The key OK of the transmitter can do multiple functions: OK if you are in the menu, START / STOP in normal operating.

The key OK of the transmitter can do multiple functions: OK if you are in the menu, START / STOP in normal operating.

ESC

ESC

DOWN

DOWN

UP

UP

UP

UP

DOWN

DOWN

ESC

ESC

STEP I: INITIAL SETUP

2

1

3

4

5

6

7

8

9

DIGIWAY PLUS

INSTALLATION MANUAL EN

Parameter Description Option Default

Num. Doors Sets the number of Doors ONE DOOR / TWO DOORS ONE DOOR

Electrolock Enables electrolock NO LOCK / ENABLE NO LOCK

Opening Jolt Enables the opening Jolt : short pulse of closing before

opening. Usefull to unlock the electrolock in windy

situations ENABLE / DISABLE DISABLE

Push & Open Opens automatically the door with a short push. ENABLE / DISABLE ENABLE

Push & Close Closes the door with a short push even in pause status. ENABLE / DISABLE ENABLE

Wind Stop Keeps the door closed in presence of wind which

pushes the door. See Advanced Sets how to set the

level of the closing force used. ENABLE / DISABLE DISABLE

Autoreclosing Enables the automatic reclosing of the door ENABLE / DISABLE ENABLE

Radar ‘I’ Mode Disables the INTERNAL radar input while the door is

closing. NEVER / CLOSING / ALWAYS NEVER

Radar ‘E’ Mode Disables the EXTERNAL radar input while the door is

closing. NEVER / CLOSING / ALWAYS NEVER

Day / Night Set the Night / Day mode. In Night mode the External

radar is disabled. DAY & NIGHT / NIGHT NIGHT

Disabled Mode Disabled access mode ( See paragraph Disabled

access settings) ENABLE / DISABLE DISABLE

Open Command Functions of the main command which can open, close

and stop ( this will be the function assigned to the open

button ( terminals 15-16 ) and to the radio transmitter

OPEN - OPEN/CLOSE -

OPEN-CLOSE/STOP OPEN/CLOSE

Mode Spring Spring function: if the door is closed, it remains free

and can be pushed manually; once open the door will

reclose after the pause time set. ENABLE / DISABLE DISABLE

2 Doors Overlap Overlap of the leaves ( in case of double doors ) ENABLE / DISABLE DISABLE

Door Type Leaf MASTER or leaf SLAVE ( in case of double doors ) MASTER / SLAVE MASTER

Arm Type Articulated or sliding arm. The controller sets automati-

cally the best value of the internal parameters according

to the arm type selected SLIDING / ARTICULATED SLIDING

Fire Signal

Fire signal management. When this option is enabled

the door operates regularly only if the fire power V-/V+

is present. If the fire power falls down ( for a fire alarm in

progress) the door reacts according to the choice set in

the advanced sets options )

ENABLE / DISABLE DISABLE

Step II allows you to set all the basic parameters of the operator, according to the type of door to automate

Step II allows you to set all the basic parameters of the operator, according to the type of door to automate

The submenu CONFIGURATION consists of 18 parameters.

The submenu CONFIGURATION consists of 18 parameters.

Each parameter can have 2 or more values.

Each parameter can have 2 or more values.

For each parameter there is a preset factory value. If the function FACTORY DEFAULT of the main menu is used, all the parameters are

For each parameter there is a preset factory value. If the function FACTORY DEFAULT of the main menu is used, all the parameters are

reset to those values.

reset to those values.

See the description of each parameter in the following table:

See the description of each parameter in the following table:

STEP II: CONFIGURATION

ATTENTION

ATTENTION

: Any change carried out needs a complete cycle ( open, pause, close ) or a system reset

: Any change carried out needs a complete cycle ( open, pause, close ) or a system reset

to be

to be

implemented

implemented

.

.

14 cdvi.com

cdvigroup.com

INSTALLATION MANUAL

DIGIWAY PLUS

15

cdvi.com

cdvigroup.com

EN

DIGIWAY PLUS is equipped with an innovative software which fits the internal parameters to the door characteristics. The calibration sets

DIGIWAY PLUS is equipped with an innovative software which fits the internal parameters to the door characteristics. The calibration sets

the door travel limits and launches a special 5 cycles routine for the automatic detection of the door characteristics.

the door travel limits and launches a special 5 cycles routine for the automatic detection of the door characteristics.

For the calibration follow the next steps:

For the calibration follow the next steps:

Set the EXTERNAL SWITCH in position ‘0’

‘0’ = DOOR FREE (*)

1

1

Action

Action

Display

Display

Select Door Calibration from the Main

Manu and press OK

2

2

CLOSE THE DOOR COMPLETELY and

press OK

OPEN THE DOOR COMPLETELY and

press OK (*)

4

4

Select Autocalibration from the Door Cali-

bration Menu and press OK

5

5

6

6

Press OK: the door begins 5 cycles of

opening and closing until asking for

SAVE

7

7

Press OK. The calibration cycle is over.

The door remains open

Set the EXTERNAL SWITCH in position ‘I’

= AUTOMATIC. The door closes and the

calibration is completed.

8

8

Door Calibration

Door Limits

Close Door

Then Press OK

Open Door

Then Press OK

Thank You

Door Calibration

Autocalibration

Autocalibration

Wizard

Proceed with

Autocalibration?

Closing ...

Measure 1/5...

Tm= XX,X V= XX

Save ?

....C...........................

P=000,0 V=00,0

Door Calibration

Select Door Limits from the submenu of

Door Calibration and press OK

3

3

9

9

Door Calibration

Door Limits

Set Door Limits

Wizard

STEP III: DOOR CALIBRATION [ SINGLE LEAF ]

(*) : It is advisable to open the door 10 cm more of the final position desired

(*) If this set is not followed, the software will give a warning.

NOTE : Before proceeding with the calibration check the connection of the battery red/black cable to the main board and disconnect tem-

porarily the magnetic lock ( when used ).

Warning : whilst the Digiway is

going trough its 5 learning cycles,

as it opens very quickly, it is

dangerous the passage across the

door.

DIGIWAY PLUS

INSTALLATION MANUAL EN

ADJUSTMENTS

ADJUSTMENTS

The maximum speed, the torque and the pause time are automatically calculated by the system during the door calibration.

The maximum speed, the torque and the pause time are automatically calculated by the system during the door calibration.

If you prefer to adjust the parameters manually to tailor the door travel, then it is necessary to access the submenu MAIN FUNCTIONS

If you prefer to adjust the parameters manually to tailor the door travel, then it is necessary to access the submenu MAIN FUNCTIONS

from the main menu. See following table for the explanation of the parameters.

from the main menu. See following table for the explanation of the parameters.

Each parameter can be adjusted using the keyboard buttons or

Each parameter can be adjusted using the keyboard buttons or

transmitter keys.

transmitter keys.

Main Functions Description Values NOTES

Open Speed Sets the maximum speed reached by the

door during opening. 0 - 100%

At the end of the door calibration the systems sets automatically the

max open speed at a special value. By increasing this value, the total

open time can reduce - be aware that in order to respect the end

opening point, the door may slow down before reaching the max speed.

Close Speed Sets the maximum speed reached by the

door during closing. 0 - 100%

At the end of the door calibration the systems sets automatically the

max close speed at a special value. By increasing this value, the total

close time can reduce - be aware that in order to respect the end closing

point, the door may slow down before reaching the max speed.

Pause Time Pause time - this is the time remains

open before automatically closing again 1 - 99 SEC. The preset factory value is 10 sec.

Open Torque Max torque of the door during opening. 0 - 100% The max opening torque is set automatically by the system at the end of

the door calibration to the max value (100 %). In the case of very light or

sensitive doors, it may be necessary to decrease this value.

Close Torque Max torque of the door during closing 0 - 100%

The max closing torque is set automatically by the system, at the end

of the door calibration, to the max value ( 100 %). Decrease this value

in case of very light or sensitive doors, or to respect the regulations for

disabled access.

Velocity Velocity of the door: rapidity of the door

to reach the max speed set, and to

mantain this value along all its travel. 0 - 100%

The default value for this parameter is 70%. The more this value, the

less is the total travel time, because the door maintains a high value of

speed for a longer time. Values too high for this parameter can cause

“door bounce”, especially for heavy doors (see motion diagram).

Open Speed

|||||||||||||||||........................... 45%

To increase the value press the key UP

To increase the value press the key UP

To decrease the value press the key DOWN

To decrease the value press the key DOWN

Press OK to confirm.

Press OK to confirm.

Press ESC to exit without saving.

Press ESC to exit without saving.

A bar will appear on the display, proportional to the value and the numeric value of the parameter .

A bar will appear on the display, proportional to the value and the numeric value of the parameter .

ESC

ESC

DOWN

DOWN

UP

UP

UP

UP

DOWN

DOWN

ESC

ESC

CURRENT CALCULATION CYCLES

CURRENT CALCULATION CYCLES

At the end of the door calibration, the door will operate normally.

At the end of the door calibration, the door will operate normally.

However, to complete the calibration the system needs 2 more complete cycles to calculate the 2 currents ( called “i” and “I”) necessary for

However, to complete the calibration the system needs 2 more complete cycles to calculate the 2 currents ( called “i” and “I”) necessary for

obstacle management.

obstacle management.

Until the 2 cycles are completed, the external LED LP will blink RED.

Until the 2 cycles are completed, the external LED LP will blink RED.

During the 2 cycles, before the completion of

During the 2 cycles, before the completion of

this calculation, if the door knocks meets an obstacle, the obstacle sensitivity used will be the factory value, which may not fit perfectly with

this calculation, if the door knocks meets an obstacle, the obstacle sensitivity used will be the factory value, which may not fit perfectly with

the door characteristics, therefore:

the door characteristics, therefore:

“It is highly recommended to ensure the door completes these 2 cycles without any interruption. When completed,

“It is highly recommended to ensure the door completes these 2 cycles without any interruption. When completed,

the external LED will illuminate Green, and the door calibration is completed.”

the external LED will illuminate Green, and the door calibration is completed.”

Motion

Motion

diagram

diagram

STEPIV : ADJUSTMENTS

Velocity = 0%

Velocity = 0%

Velocity = 100%

Velocity = 100%

t

t

1

1

v

v

t

t

Vmax

Vmax

t

t

2

2

t

t

3

3

16 cdvi.com

cdvigroup.com

INSTALLATION MANUAL

DIGIWAY PLUS

17

cdvi.com

cdvigroup.com

EN

DIGIWAY PLUS is equipped with many further parameters (all adjustable) to fit better to any type of installation. From the main menu select

DIGIWAY PLUS is equipped with many further parameters (all adjustable) to fit better to any type of installation. From the main menu select

ADVANCED SET to enter this submenu, which allows more adjustments.

ADVANCED SET to enter this submenu, which allows more adjustments.

Advanced Setting

Electrolock Time Electrolock Time

|||||||||||||||||...................0,5 SEC.

It is possible to pause the electrolock release time from 0,1 to 40 sec. depending on the

It is possible to pause the electrolock release time from 0,1 to 40 sec. depending on the

lock/door type . Press the UP or DOWN buttons to increase or decrease the pause time

lock/door type . Press the UP or DOWN buttons to increase or decrease the pause time

and confirm with OK.

and confirm with OK.

Default value = 0,5 Sec

Default value = 0,5 Sec

Advanced Setting

Opening Jolt Time Opening Jolt Time

|||||||||||||||||...................0,5 SEC.

The opening jolt, when enabled, is a short closing motion before the operator begins

The opening jolt, when enabled, is a short closing motion before the operator begins

opening - this relieves pressure of “side-load” for some locking devices. It’s possible to

opening - this relieves pressure of “side-load” for some locking devices. It’s possible to

adjust this time from

adjust this time from

0,1 to 40 sec. depending on the type of electrolock and door.

0,1 to 40 sec. depending on the type of electrolock and door.

Press

Press

the UP or DOWN buttons to increase or decrease the time and confirm with OK.

the UP or DOWN buttons to increase or decrease the time and confirm with OK.

Default value = 0,5 Sec

Default value = 0,5 Sec

1)

1)

2)

2)

Advanced Setting

Open Delay Open Delay Time

|||||||||||||||||...................0,5 SEC.

It is possible to add a short delay to the door motion to allow the electrolock bolt to

It is possible to add a short delay to the door motion to allow the electrolock bolt to

exit completely from its keeper, ensuring the door is fully unlocked. This can be useful

exit completely from its keeper, ensuring the door is fully unlocked. This can be useful

when using motorised locks. The open delay is set by pressing

when using motorised locks. The open delay is set by pressing

UP or DOWN buttons to

UP or DOWN buttons to

increase or decrease

increase or decrease

from

from

0,1 to 40 sec

0,1 to 40 sec

and confirm with OK

and confirm with OK

.

.

Default value = 0,5 Sec

Default value = 0,5 Sec

4)

4)

LOCK

LOCK

MOTOR

MOTOR

START

START

Delay

Delay

Advanced Setting

Open Jolt Torque Open Jolt Torque

|||||||||||||||||.....................20%

It is possible to adjust the torque of the motor during the opening jolt pulse.

It is possible to adjust the torque of the motor during the opening jolt pulse.

This is adjusted depending on the mechanical resistance of the door. Press the

This is adjusted depending on the mechanical resistance of the door. Press the

UP or

UP or

DOWN buttons to increase or decrease the value and confirm with OK.

DOWN buttons to increase or decrease the value and confirm with OK.

Default value =

Default value =

20%.

20%.

3)

3)

Advanced Setting

Wind Stop Torque Wind Stop Torque

|||||||||||||||||......................10%

It is possible to adjust the torque of the motor when the wind stop utility is enabled. This

It is possible to adjust the torque of the motor when the wind stop utility is enabled. This

allows changing the value of the force applied by the door related to the wind pressure.

allows changing the value of the force applied by the door related to the wind pressure.

Press the UP or DOWN buttons to increase or decrease the torque and confirm with

Press the UP or DOWN buttons to increase or decrease the torque and confirm with

OK.

OK.

Default value =

Default value =

50%.

50%.

5)

5)

Main Functions Description Value NOTES

O.D. Type Sets the obstacles detection criteria

C1+C2

C1+C2+C3

C1+C2+C4

C1+C2+C3+C4

By default the motor detects an obstacle when the speed becomes

almost zero (C1) and the current increases over a preset threshold (C2).

The criteria C3 intervenes after the speed decreases under 2/3 of the

max speed, and causes the door to stop.

C3 is not active during the current calculus cycles.

The criteria C4 intervenes if the current consumed exceeds 175% of the

current consumed during the preset.

According to the type of door (resistance, balance, weight, width etc) it is

possible to adjust the reaction of the door against an obstacle.

The first 2 criteria are always present. It is possible to add the criteria C3

or C4 or both.

Default value = C1+C2.

O.D. Reactivity Sets the reaction time against an

obstacle 0,1 - 5 sec.

Use the UP or DOWN keys to adjust this time : the higher the value,

the longer will be the contact of the door against the obstacle (less

sensitive).

Default value = 0,1 Sec.

STEP IV: ADJUSTMENTS (continued...)

STEP IV: ADJUSTMENTS (continued...)

STEP V: ADVANCED SETTINGS

Please contact your local office for further infomation regarding Obstacle Detection (O.D.)

DIGIWAY PLUS

INSTALLATION MANUAL EN

STEP V: ADVANCED SETTINGS (Continued...)

STEP V: ADVANCED SETTINGS (Continued...)

Advanced Setting

Ex Power Open Enable / Disable

When enabled, adds one more

When enabled, adds one more

OPENING

OPENING

pulse after the regular

pulse after the regular

OPENING

OPENING

cycle to

cycle to

compensate possible friction or door unbalance.

compensate possible friction or door unbalance.

Enable or disable this function with the UP or DOWN buttons and confirm with OK

Enable or disable this function with the UP or DOWN buttons and confirm with OK

Default value = DISABLE

Default value = DISABLE

8)

8)

Advanced Setting

Ex Power Close Enable / Disable

When enabled, adds one more

When enabled, adds one more

CLOSING

CLOSING

pulse after the regular

pulse after the regular

CLOSING

CLOSING

cycle to

cycle to

compensate possible friction or door unbalance.

compensate possible friction or door unbalance.

Enable or disable this function with the UP or DOWN buttons and confirm with OK

Enable or disable this function with the UP or DOWN buttons and confirm with OK

Default value = DISABLE

Default value = DISABLE

11)

11)

Advanced Setting

Extra Close Time Extra Close Time

|||||||||||||||||......................0 SEC.

This function allows to set the duration

This function allows to set the duration

TIME

TIME

of the

of the

CLOSING

CLOSING

extra pulse

extra pulse

Change the value by pressing the UP or DOWN buttons and confirm with OK.

Change the value by pressing the UP or DOWN buttons and confirm with OK.

Default value = 0 SEC.

Default value = 0 SEC.

13)

13)

Advanced Setting

Fire Release Fire Release

Open/Free/Closed

When the Fire Release function is enabled, it’s possible to set the reaction of the door

When the Fire Release function is enabled, it’s possible to set the reaction of the door

depending on the failure of the Fire power ( V+, V-) :

depending on the failure of the Fire power ( V+, V-) :

•

•

DOOR FREE

DOOR FREE

= In case of

= In case of

Fire Power

Fire Power

failure the door becomes FREE

failure the door becomes FREE

•

•

DOOR OPEN

DOOR OPEN

= In case of

= In case of

Fire Power

Fire Power

failure the door opens and stays OPEN until

failure the door opens and stays OPEN until

the fire power is reset or the function of the

the fire power is reset or the function of the

Menu Configuration

Menu Configuration

is disabled.

is disabled.

•

•

DOOR CLOSED LOCKED

DOOR CLOSED LOCKED

= Door CLOSED and lock active

= Door CLOSED and lock active

•

•

DOOR CLOSED UNLOCKED

DOOR CLOSED UNLOCKED

=

=

Door CLOSED and lock disactive

Door CLOSED and lock disactive

14)

14)

Advanced Setting

Max Obst Cycles Max Obst Cycles

|||||||||||||||||......................000

When the door meets an obstacle during closing, it re-opens immediately. At the end of

When the door meets an obstacle during closing, it re-opens immediately. At the end of

the pause time, it re-closes slowly. If the obstacle is still present the cycle restarts.

the pause time, it re-closes slowly. If the obstacle is still present the cycle restarts.

It is possible to set the max number of re-closing attempts by the door before stopping to

It is possible to set the max number of re-closing attempts by the door before stopping to

await a definitive command. Change this parameter (from

await a definitive command. Change this parameter (from

1

1

to

to

256)

256)

by pressing the

by pressing the

UP

UP

or DOWN

or DOWN

buttons and confirm with OK.

buttons and confirm with OK.

Default value = 4 attempts.

Default value = 4 attempts.

15)

15)

Advanced Setting

Dynamic Pause Enable / Disable

The dynamic pause is a function which automatically adjusts the pause time

The dynamic pause is a function which automatically adjusts the pause time

programmed, avoiding too many closing attempts of the door in high traffic situations.

programmed, avoiding too many closing attempts of the door in high traffic situations.

When enabled, this function increases by 1 sec. the pause time programmed each time

When enabled, this function increases by 1 sec. the pause time programmed each time

it detects

it detects

a passage through the door during the closing phase, and restarts the time

a passage through the door during the closing phase, and restarts the time

when the passage is detected against when the door is open.

when the passage is detected against when the door is open.

Once the door completes its cycle up to the closed status, the pause time is reset to the

Once the door completes its cycle up to the closed status, the pause time is reset to the

programmed value.

programmed value.

Press UP or DOWN buttons to enable or disable the function and confirm with OK

Press UP or DOWN buttons to enable or disable the function and confirm with OK

Default value = DISABLE.

Default value = DISABLE.

6)

6)

Advanced Setting

FTC-S Exclusion FTC-S Exclusion

|||||||||||||||||......................000

If the door is next to a wall and is using a curtain protection device, it may be necessary

If the door is next to a wall and is using a curtain protection device, it may be necessary