Page 6

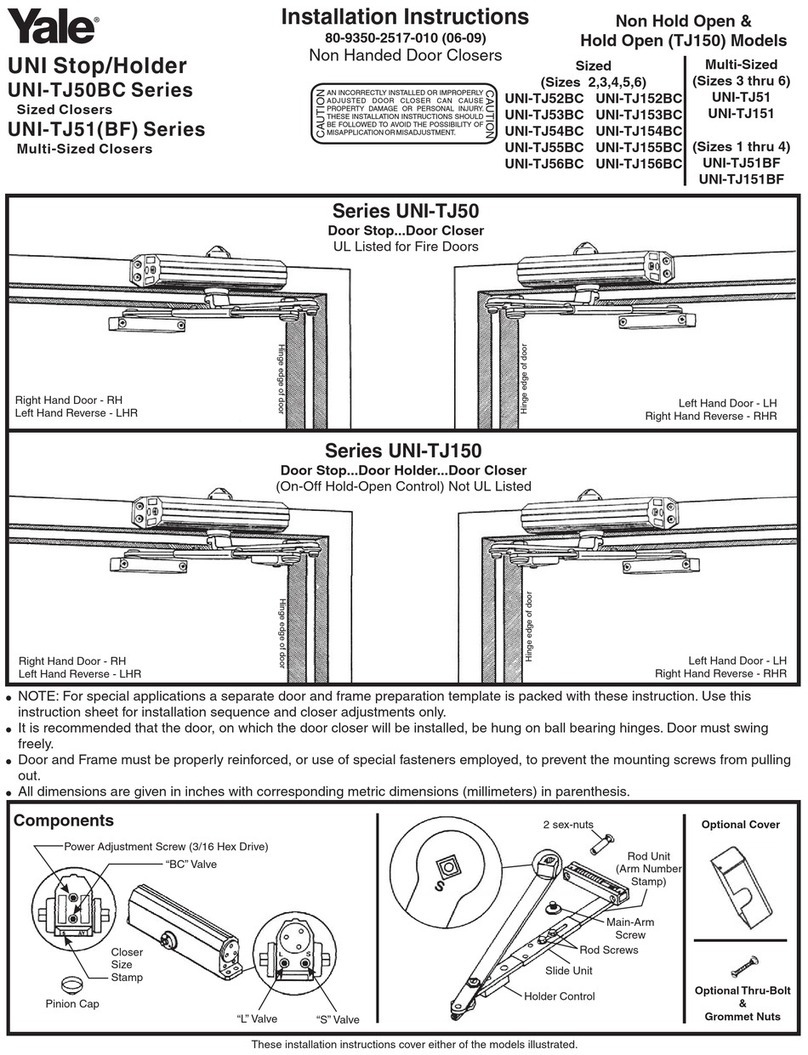

Closing Power Adjustment–

Control Valve Adjustments

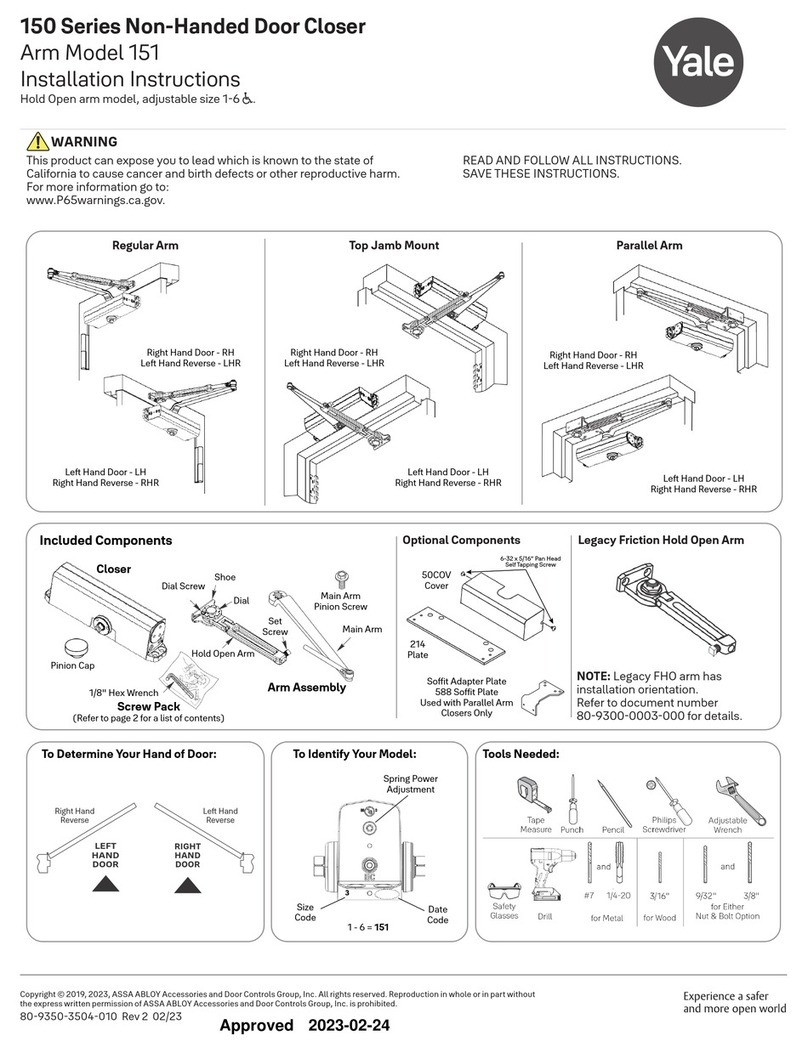

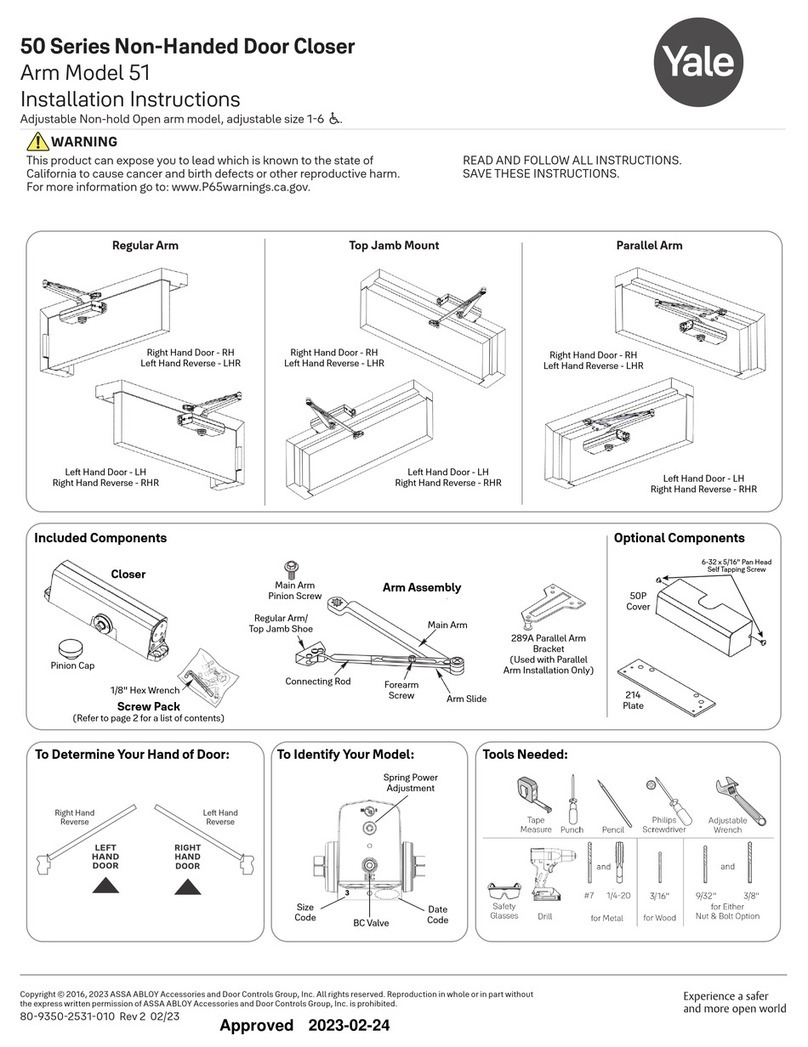

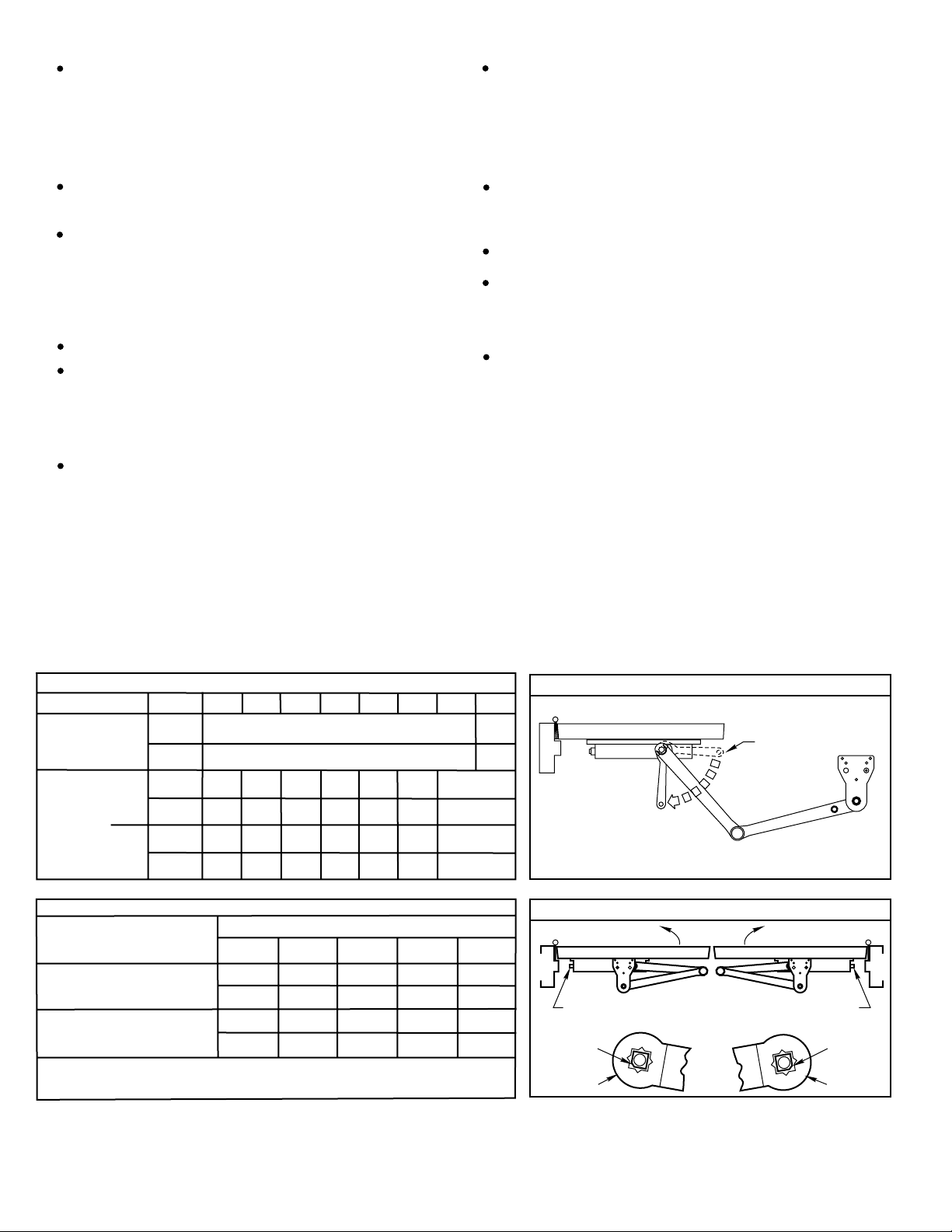

Closing Speed Controls (Figure 1A or 1B and 2.)

Using “Power Adjustment Chart”from Page 3, select the

correct number of turns for power adjustment shaft that

corresponds with the installation. With 1/8”hex-key provided,

rotate adjustment shaft full 360°clockwise turns to desired

setting. After closer has been installed and proper

adjustments made to the sweep and latch, it may be

necessary to readjust spring power for good closing action.

(See Figure 2.)

Valve “S”Controls Sweep Range.

Valve “L”Controls Latch Range.

Valve “D”Controls Delay Range (optional).

Unit Adjustment

L

A

T

C

H

L

A

T

C

H

Delayed Action

Closing Cycle

1B

Closing Speed Controls Figure 1.

S

W

E

E

P

S

W

E

E

P

Attention : Adjust Closing Speed Time

to between 4 to 7 seconds from 90°.

Use of the door by handicapped,

elderly or small children may require

greater closing time.

CLOSED

CLOSED

Standard Closing Cycle

1A

D

E

L

A

Y

R

A

N

G

E

10°

10°

70°

CAUTION:

DO NOT BACK VALVES OUT OF

CLOSER OR A LEAK WILL

RESULT.

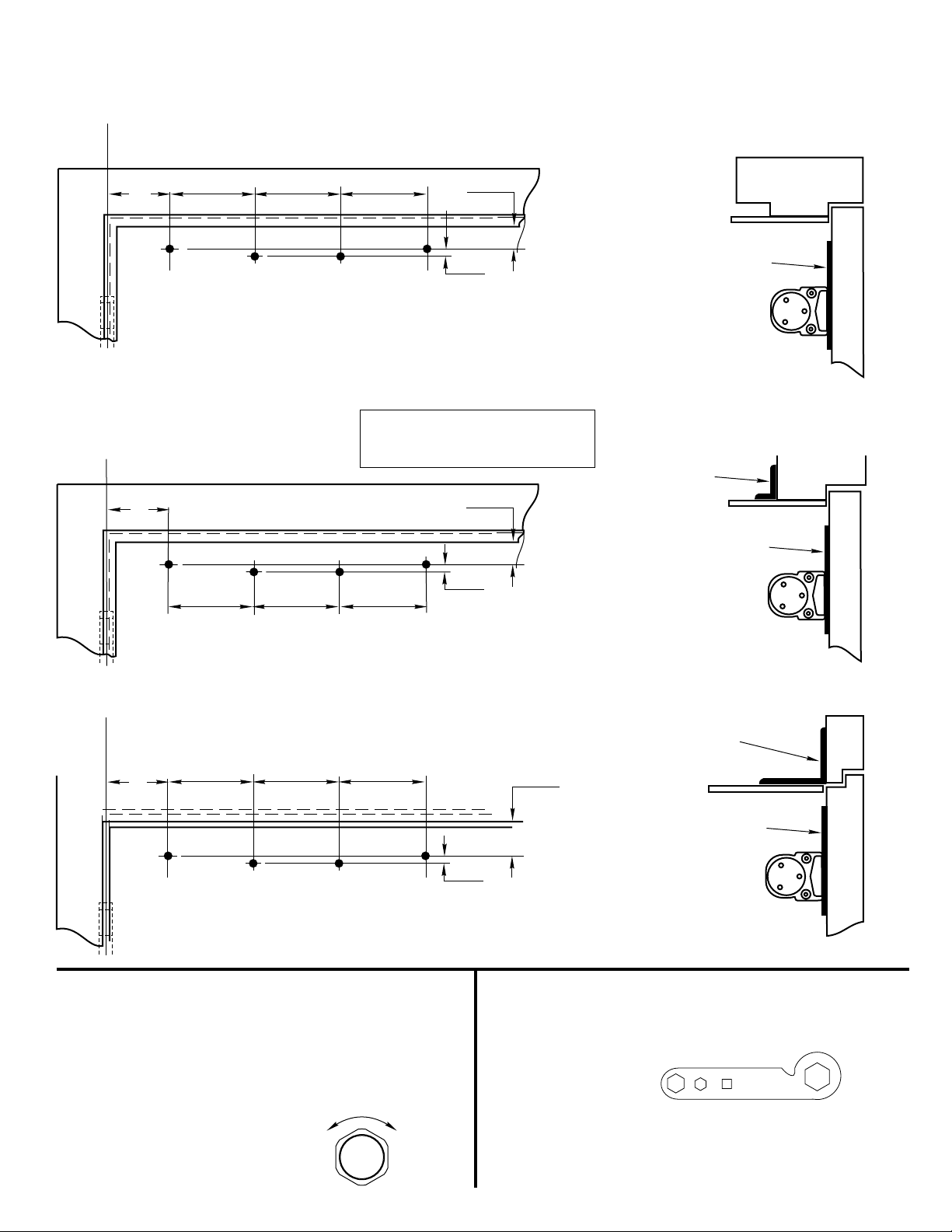

Closing Speed Controls Figure 2.

Slow

1/8”

Hex

Key

Fast

Latch

Valve

Sweep

Valve

Delay Valve

Closing Power Control Figure 3.

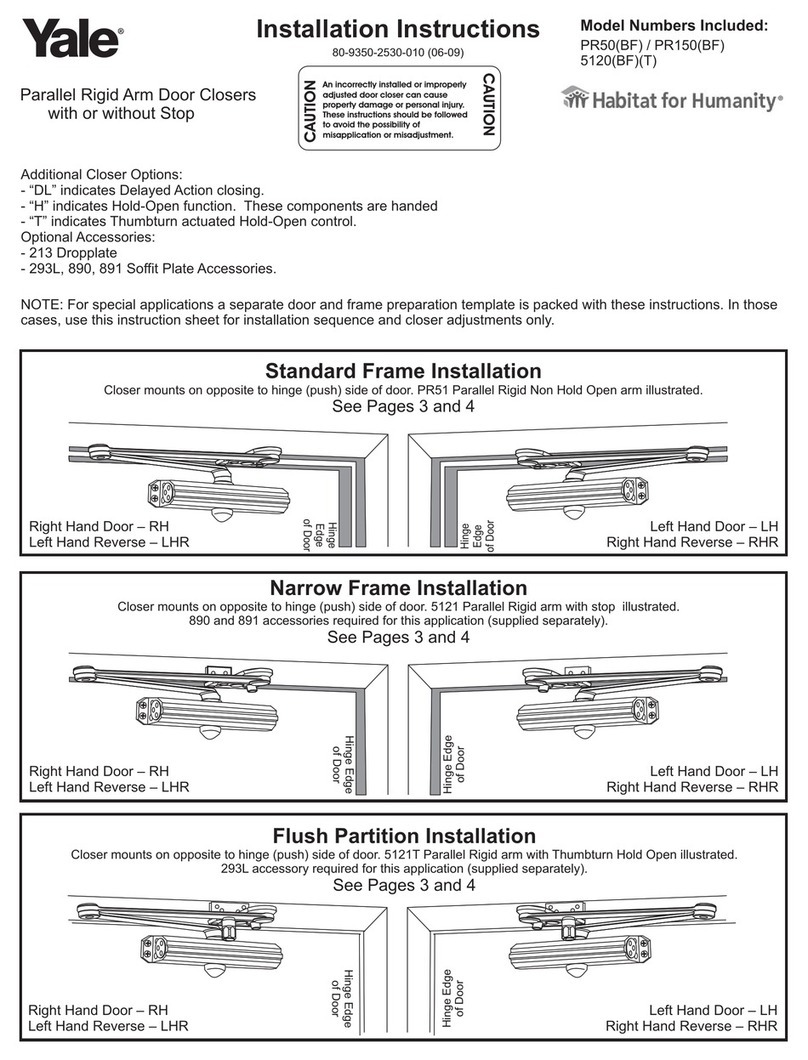

Opening Cycle

Cover–

“Backcheck”valve controls the strength of cushioning in

Backcheck Range. NEVER close this valve completely –it

is not to provide a positive stop. (see Figure 4 and Figure 5).

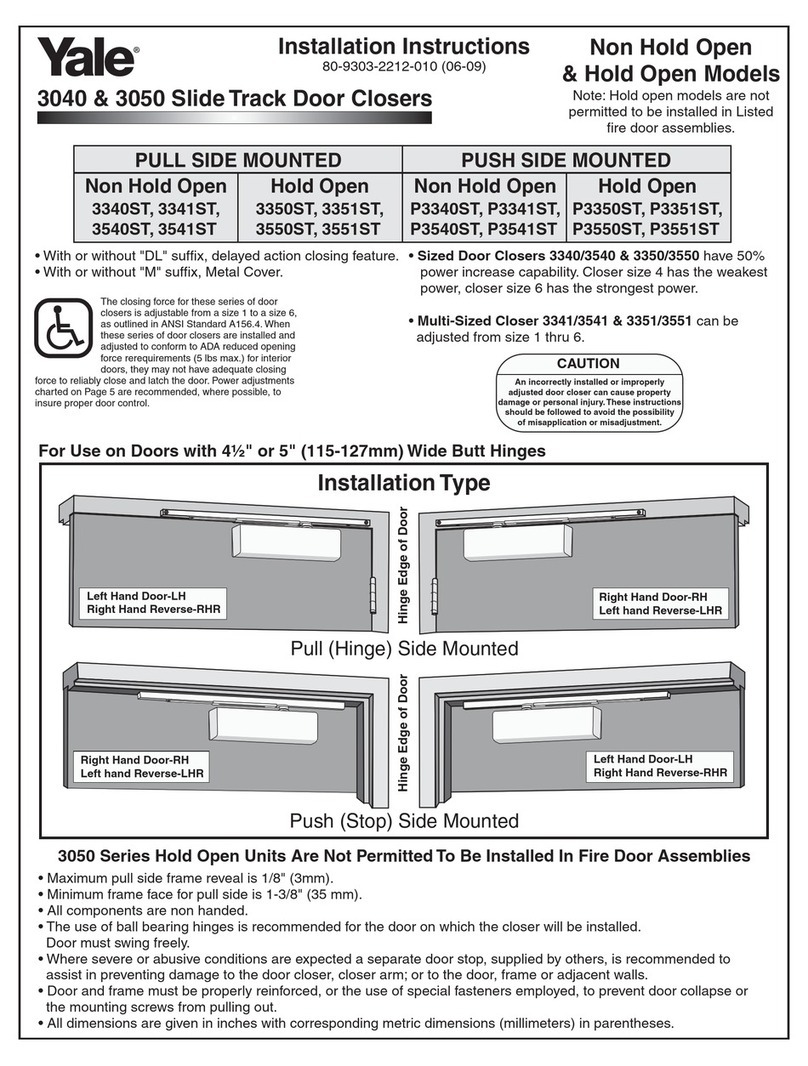

Full cover: Slide cover insert into the un-used cutout

in cover. Install cover using screws provided.

Narrow cover: Install cover using screws provided. Install

pinion cap onto pinion shaft by hand or with a Phillips screw

driver - DO NOT OVER TIGHTEN.

Metal cover: Fasten cover to mounting clips with screws

provided.

Architectural Metal Cover: Remove cover insert where

pinion is located. Install standoffs in ends of closer. Install

cover using screws provided.

Architectural Plastic Cover: Slide cover insert into the un-

used cutout in cover. Install standoffs in ends of closer.

Snap cover over standoffs.

.

Slow

1/8”

Hex

Key

Fast

Slow

1/8”

Hex

Key

Fast

1902 Airport Road, Monroe, NC

Telephone:(800)-438-1951; Fax: (800)-338-0965

www.yalesecurity.com

Security Group

O

P

E

N

I

N

G

Opening Door Control Figure 4.

Opening Cycle

B

A

C

K

C

H

ECK

CAUTION:

DO NOT BACK VALVES OUT OF

CLOSER OR A LEAK WILL

RESULT.

Decrease

Increase

Backcheck Control Figure 5.

Backcheck Valve*

1/8”

Hex

Key

Decrease

Increase

5/16”Socket

or Adjustable Wrench

Power Adjustment Shaft

NOTE: Maximum of 20 360°turns

of Power Adjustment Shaft

NEVER CLOSE VALVES

COMPLETELY - NOT

INTENDED TO PROVIDE

A POSITIVE STOP.

Cover Mounting Figure 6.

An ASSA ABLOY Group Co.