Norriseal 2200 series Operating instructions

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

Series 2220

INIRRIS

PRODUCTION SOLUTIONS

INN

---

N

N=

AEI

elle!

AU

Engineered

11

11N1

WY ink

muaErael

Performance

A

MI

*

CAMPAAV

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

TABLE OF CONTENTS

INTRODUCTION

1

About the Series 2200/ 2220 Valve

1

Identifying the valves

1

1.0 VALVE INSTALLATION AND START-UP 2

2

2.0 VALVE MAINTENANCE

3

2.1 Actuator Disassembly

3

2.2 Actuator Re-Assembly

4

2.3 Valve Disassembly

4

2.4 Trim Inspection

5

2.5 Trim Restoration

6

2.6 Valve Re-Assembly

6

3.0 REPAIR KITS

6

4.0 TROUBLE DIAGNOSIS

7

4.1

Internal Leakage Problems

7

4.2 External Leakage Problems

8

4.3 Valve Performance Problems

9

5.0 VALVE BODY STYLES AND PORT ORIENTATION MARKINGS

11

TABLES

Table 1 — Maintenance Schedule

2

Table 2 — Lapping Compounds

5

Table 3 — Bridge Symbol and Valve Body Port Orientation

1

2200M —02012, August, 2012

Mika

P.O. Box 40525, Houston, Texas USA 77240-0525

--

--

._AINI MIME All

Tel: 713.466.3552 • Fax: 713.896.7386

IMINIIYMIRIO1111MIN www.norriseal.com

10 IMMO

0:0••••

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

INTRODUCTION

CAUTION!

You will see warning boxes like this

throughout the manual. Please read

and strictly observe these warnings to

prevent personal injury or equipment

damage. Before you begin the instal-

lation, operation or repair of equip-

ment, make sure to completely review

and understand the instructions in this

manual.

The information contained in this man-

ual is about the 1.0" and 2.0" Norriseal

Series 2200 and 2220 Control Valves.

Please refer to separate manuals for

all other controllers, positioners and

their optional accessories.

About the Series 2200/2220 Valve

The Series 2200/ 2220 Valve is

designed for general use for either

liquid or gas source that require a

throttle or on/off control. The Series

2200/2220 Valve has one port with

three different types of plugs (or "un-

balanced trim"): quick opening, equal

percent and modified percent. The

pneumatic spring-diaphragm actua-

tor is either open yoke (model 2200)

or close-coupled (model 2220). The

valve has a hammer nut closure.

All Norriseal valves come with spring-

diaphragm pneumatic actuators that

are either reverse-acting (fail-closed)

or direct-acting (fail-open). Both are

available in No. 9 (35 sq. in.) and No.

12 (70 sq. in.).

The Series 2200/ 2220 valves have

non-adjustable, spring-loaded pack-

ing with PTFE V-rings and a spring

below the packing to maintain a tight

stem seal.

WARNING!

Before attempting to disassemble or

repair this valve, please make sure that

all pressure going through the valve

has been relieved. Failure to do this will

cause personal injury and/ or damage

to the device. In addition, the fluid that

projects from the device after failure to

comply with these warnings will cause

injury to people, equipment and the

environment.

Identifying the valves

The nameplate of each valve has the

assembly information you need to

replace the part and can be found on

its upper diaphragm. It is important

to use genuine Norriseal parts when

repairing valves. When calling your

Norriseal representative, make sure

to have the serial and model numbers

found on the nameplate.

WARNING!

When consulting the nameplate please

pay attention and adhere to the maxi-

mum pressures and temperatures for

the valve. Should you need to increase

the limitations of the parts, install relief

valves or other over-pressure protec-

tion devices in the pressure lines.

2200M — 02012. August. 2012

MIME Al

111'%1111YRIFILIOIGMb

CCOMPIIIV

P.O. Box 40525. Houston, Texas USA 77240-0525

Tel: 713.466.3552 • Fax: 713.896.7386

www.norriseal.com

Page 1 of 12

TABLE1 MAINTENANCE SCHEDULE*

ITEM

INSPECTION SCHEDULE

Valve Trim

(Seat, Plug)

Inspect every 6 months, under normal service conditions

(low-pressure drop and no sand or abrasives in fluid).

Or inspect every 2 months, under service conditions, such as

high-pressure drop, corrosion, or fluid with sand.

Stem Packing

Inspect Packing at least once a year.

Actuator

Inspect Diaphragm, Spring and Stem once a year.

Body

The body should last many years under normal conditions.

However, under severe conditions of corrosion or erosion from

sand in the flowing fluid, high-pressure drops, or high-fluid

velocity, body life may be greatly reduced. Inspect the body

each time the bonnet is removed.

Bonnet

Inspect Bonnet once a year or whenever trim inspection is

performed.

Seals

Inspect 0-rings each time valve is disassembled.

'Under certain operating conditions, this suggested maintenance schedule will not be adequate and shorter time intervals

may be required.

Series 2200/2220 - 1.0" & 2.0"

CAUTION!

Your valve configuration and construc-

tion materials were selected to meet

specific pressure, temperature, pres-

sure drop and fluid conditions. Some

combinations of body and trim are

limited in their pressure drop and tem-

perature ranges. Please call the Nor-

riseal sales office or your sales repre-

sentative before subjecting the valve to

conditions outside the specified range.

1.0 Valve Installation and

Start-Up

1.

Inspect the valve for any dam-

age or residue that might have

occurred during packing or ship-

ping. Remove all protection ma-

terial from the parts.

2.

Make sure to blow air into all

the pipelines to rid them of any

foreign material. Threaded and

gasketed surfaces should also

be free from residue.

3.

Be sure to install the valve so

that flow direction is under the

seat for throttling trim. For quick

opening trim, it can be installed

either under the seat or over the

seat. (reference Table 3)

4.

Good piping practice during in-

stallation includes using a suit-

able gasket in between the body

and pipeline flanges. For thread-

ed (NPT) bodies use pipe thread

sealant.

5.

This is a good time to inspect the

nameplate on your valve. Iden-

tify the working pressure limita-

tions of your valve (they are rated

ANSI 150, 300, 600, 900, 1500,

or 2500 class) and DO NOT ex-

ceed the marked pressure.

6.

If you choose to insulate your

valve, DO NOT insulate it above

the hammer nut.

7. Connect the supply pressure

to the actuator or the positioner

connection. (REMINDER: refer to

the nameplate for pressure limi-

tations) Run the actuator through

a couple of cycles to confirm the

proper operation of the valve.

WARNING!

Do not supply pressure that exceeds

the maximum on the nameplate. Under

no circumstances should the actuator

supply pressure exceeding 35 psig for

#12 actuators or 50 psig for #9 actuators.

8. In certain operating conditions

the actuator's springs may need

to be adjusted. To adjust the

springs:

A.

FOR A REVERSE ACTUATOR

Loosen the lock nut on the ad-

justing screw located on the top

of the actuator spring housing.

To achieve a tighter shut off, in-

crease the spring's preload and

plug seating force by turning the

adjusting screw CLOCKWISE.

To reduce the preload, turn the

adjusting screw COUNTER-

CLOCKWISE. Be sure to tighten

the lock nut after making the

needed adjustments.

NOTE: Don't adjust the spring past the

point necessary to achieve shut off and

past the maximum actuator pressure

allowable to fully open the valve.

B.

FOR A DIRECT ACTUATOR

Remove the spring cover by first

loosening the two set screws at

the base of the cover. To increase

the spring's pre-load, turn the ad-

justing nut CLOCKWISE. To re-

duce the pre-load, turn the adjust-

ing nut COUNTERCLOCKWISE.

Be sure to replace the spring

cover and tighten the set screws

after adjusting your springs.

NOTE: Only adjust the spring tension

to the extent necessary to fully open

the valve at operating conditions.

Any additional adjustments will result

in a reduction of plug seating force,

possibly resulting in trim leakage.

IMO

ISIC Ir Al

,

Page 2 of 12

111Novnlilk1W6D411

•

1,01,11

--

i)

moven

P.O. Box 40525, Houston, Texas USA 77240-0525

Tel: 713.466.3552 • Fax: 713.896.7386

www.norriseal.com

2200M — 02012. August. 2012

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

2.0 Valve Maintenance

WARNING!

Before making any repairs to your valve

follow the following four steps:

1.

Isolate the valve from the

process/ system.

2.

Shut off all supply lines to the

actuator.

3.

Release the process pressure

(both upstream and downstream).

4.

Vent the actuator supply pressure.

Be aware that all valve parts are

subject to normal wear and tear,

and as a result, should be inspected

and replaced regularly, as neces-

sary. The frequency of your inspec-

tions will depend on the frequency

and type of usage your parts are put

through. During each inspection, you

will be required to disassemble and

re-assemble the valve. The following

section will describe this process in

detail. Should maintenance be nec-

essary, it can be done while the valve

body is in line as long as:

1)

The line is not in service

2)

The line is isolated from

active process by block valves.

Refer to the parts diagrams during

disassembly and re-assembly. There

you will find a complete list of parts and

configurations.

3.

CLOCKWISE until the spring's

preload is completely removed

(or de-energized). Remove the

adjusting nut, washer, upper

spring retainer and spring.

4.

Remove the nuts and screws

from around the diaphragm

housing flange and remove the

upper diaphragm housing by slid-

ing it carefully upward and off the

stem.

5.

Remove the cotter pin and

unscrew the upper stem from the

lower stem.

6.

Remove the bearing washers,

0-ring, diaphragm, diaphragm

plate and hex nut (2220).

7.

Unscrew the lower housing from

the yoke (2200) or bonnet (2220).

This is the final step in disassem-

bly of the 2220 valve actuator.

8.

Loosen the two jam nuts secur-

ing the valve stem to the actua-

tor stem and unscrew the stems.

Remove the travel indicator from

the valve stem (2200 only).

9.

If repair warrants, unscrew the

yoke (2200) from the bonnet.

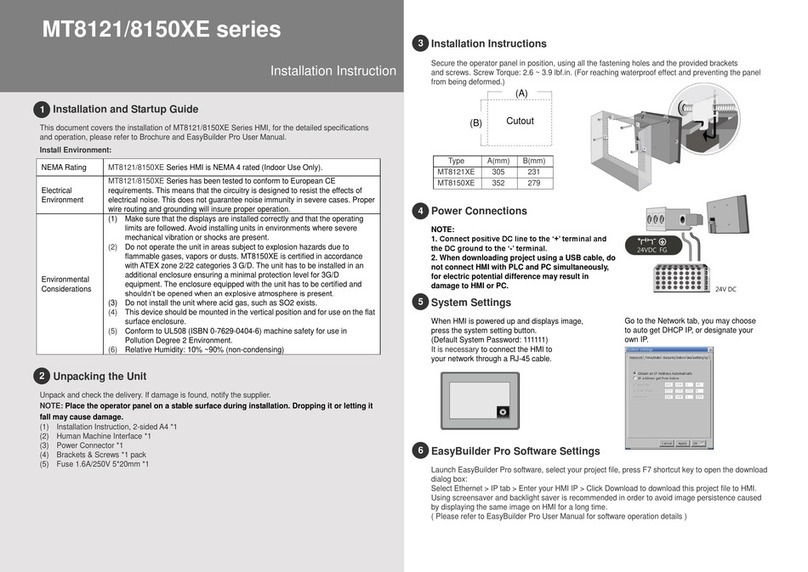

2.1 Actuator Disassembly

A.

Direct (Fail-Open) Actuators

1_1

1.

Vent and disconnect the supply

Series 2200 Yoke-Mounted

pressure from the actuator.

Direct-Acting

2.

Remove the spring cover by first

loosening the set screws at the

base of the cover.

Turn the adjusting nut COUNTER

Series 2220 Close-Coupled

Direct-Acting

P.O. Box 40525, Houston, Texas USA 77240-0525

—.._

mii6

_01k111111er Lir Tel: 713.466.3552 • Fax: 713.896.7386

www.norriseal.corn

OM*

caw,

2200M — 02012, August, 2012

Page 3 of 12

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

A.

Reverse (Fail-Closed)

Actuators

CID

Series 2200 Yoke-Mounted

Reverse-Acting

1.

Vent and disconnect supply pres-

sure from the actuator.

2.

Loosen the lock nut on the adjust-

ing screw on top of the actuator

spring housing. Turn the adjust-

ing screw COUNTERCLOCK-

WISE until the spring's preload

is completely removed (or de-

energized)

3.

Remove the nuts and screws

from around the diaphragm hous-

ing flange and remove the upper

diaphragm housing, spring and

upper retainer.

4.

Remove the nuts from the top of

the stem.

5.

Remove the lock washer,

spring retainer, bearing washers,

0-ring, diaphragm, diaphragm

plate (and hex nut — 2220).

6.

Unscrew the lower housing from

the yoke (2200) or bonnet (2220).

This is the final step in disassem-

bly of 2220 valve actuator.

Series 2220 Close-Coupled

Reverse-Acting

7.

Loosen the two jam nuts secur-

ing the valve stem to the actua-

tor stem and unscrew the stems

(2200 only). Remove the travel

indicator from the valve stem.

8.

If repair warrants, unscrew and

remove the yoke (2220) from the

bonnet

2.2 Actuator Re-Assembly

To re-assemble the actuator, lubri-

cate the 0-rings and simply reverse

the steps of the disassembly proce-

dure in Section 2.1 for the appropri-

ate actuator (direct or reverse).

2.3 Valve Disassembly

A.

With the Actuator Remaining

Attached to the Valve Body

Series 2200/2220 Body

CAUTION!

Use care to avoid damaging 0-ring

sealing surfaces. Assume all of these

parts are in good condition when dis-

assembling the valve and protect

them accordingly. The surface finish

of the valve stem is critical for creat-

ing a reliable packing seal. The bore

of the seat/ cage is critical for smooth

operation of the valve plug. The seat-

ing surfaces of the valve plug and

seat/ cage are critical for tight shutoff.

WARNING!

Before making any repairs to your valve

follow the following four steps:

1.

Isolate the valve from the

process/ system.

2.

Shut off all supply lines to the

actuator.

3.

Release the process pressure

(both upstream and downstream).

4.

Vent the actuator supply pressure.

Page 4 of 12

IMO

-

=

-

-011111111110EA1

Ihir

Inv IMOIGFit

a

*M

01

)....

w

P.O. Box 40525. Houston. Texas USA 77240-0525

Tel: 713-466.3552 • Fax: 713.896.7386

www.norriseal.corn

2200M — 02012. August. 2012

Tungsten

Carbide

9U Heavy

Diamond

TABLE2

LAPPING COMPOUNDS*

TRIM

LAPPING

MATERIAL

MATERIAL

300 Series SST

17-4PH SST

Stellite (Alloy 6)

Clover*

Boron-Carbide

Grade 2A

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

1. Vent and disconnect supply

pressure from the actuator.

2.

Remove all spring

compression.

a.

For A Direct Actuator:

Loosen the two set screws,

remove the spring cover

and turn the adjusting nut

COUNTER CLOCKWISE

until all spring compres-

sion is removed from the

actuator spring.

b.

For A Reverse Actuator:

Loosen the lock nut on the

actuator adjusting screw

and turn the adjusting

screw COUNTERCLOCK-

WISE until all spring com-

pression is removed from

the actuator spring.

3.

Unscrew the hammer nut (turning

COUNTERCLOCKWISE) from the

valve body by striking the lugs

with a hammer.

4. Lift all top workings (bonnet,

actuator, stem and plug) from

the valve body and place on a

suitable work surface.

CAUTION!

When disassembling the plug, provide

adequate support to avoid bending or

damaging the stem or trim. Protect

them by using a solid block as a backup

while removing the pin from the plug.

5.

Using a punch or 1/8 drift pin,

drive the pin from the stem and

unscrew the plug from the stem.

6.

Pull the seat/ cage from the valve

body. In order to remove it, it may

be necessary to hook one of the

cage flow openings and pull it. A

seat/ cage removal tool is avail-

able from Norriseal.

B.

With the Acuator Previously

Removed from the Valve

CAUTION!

Use care to avoid damaging 0-ring

sealing surfaces. Assume all of these

parts are in good condition when dis-

assembling the valve and protect them

accordingly. The surface finish of the

valve stem is critical for creating a reli-

able packing seal. The bore of the seat/

cage is critical for smooth operation

of the valve plug. The seating surfaces

of the valve plug and seat/ cage are

critical for tight shutoff.

1.

Disassemble the actuator by

following the procedure in Sec-

tion 2.1.

2.

Unscrew the hammer nut

(turning COUNTERCLOCKWISE)

from the valve body by striking

the lugs with a hammer, and

remove it from the bonnet.

3.

Remove the bonnet from the

valve body along with the stem

and plug.

CAUTION!

When disassembling the plug, provide

adequate support to avoid bending or

damaging the stem or trim. Protect

them by using a solid block as a backup

while removing the pin from the plug.

4.

Using a punch or 1/8 drift pin,

drive the pin from the stem and

unthread the plug from the stem.

5.

Pull the seat/ cage from the valve

body. In order to remove it, it may

be necessary to hook one of the

cage flow openings and pull it. A

seat/ cage removal tool is avail-

able from Norriseal.

6.

Remove the packaging washer,

spring and retainer from the

packing plug. Pull the valve stem

out of the bonnet.

7.

Use a hook-shaped tool to

remove the packing and 0-ring.

Remove stem bushing.

CAUTION!

Use care to avoid damaging or scratch-

ing the bonnet bore.

2.4 Trim Inspection

1.

While examining the valve plug

and seat, use a magnifying

glass to look for signs of erosion,

pitting, scratches and damage

from corrosion.

2.

Fit the plug and the seat togeth-

er. Lift the seat up to a light and

look through the hole at the bot-

tom. If any light can be seen be-

tween the plug and seat contact

surfaces this is an indication of a

poor fit.

3.

Determine the severity of the

damage. It is likely the plug and

seat contact surfaces can be fully

restored by re-lapping. Replace

any parts that are beyond resto-

ration.

4.

Examine the stem for pitting,

scratches or damage in an area

adjacent to the packing and 0-

ring. If worn, replace the stem.

•

Equivalent products from other manufacturers may be used.

P.O. Box 40525, Houston. Texas USA 77240-0525

ms

ruder

A•

Tel: 713.466.3552 • Fax: 713.896.7386

www.norriseal.com

•

2200M — 02012. August, 2012

Page 5 of 12

_

Page 6 of 12

IllielE A I

111111106141

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

2.5 Trim Restoration

CAUTION!

Trim that has been lapped too much

will widen the lap band and reduce the

force of the plug seating.

Lap the plug to the seat.

NOTE: This

process does not apply to plugs with

soft-seat inserts.

1.

Clean plug and seat in solvent

and wipe dry.

2.

Select the appropriate lapping

compound as shown in Table 2.

3.

Using a stir stick or similar de-

vice, apply lapping compound

sparingly on 3 or 4 places, ap-

proximately equidistant along the

seat surface on the plug.

NOTE:

The use of excess compound

runs the risk of uneven lapping of

the surfaces.

4.

Once the compound has been

applied using the stem. fit the

seat against the plug and begin

lapping the trim by pressing firmly

with your hands while rotating, in

a back and forth motion, against

the stationary plug.

5.

The seat will have a circular unin-

terrupted lap band not exceeding

1/32" in width at the base of the

seating's beveled edge.

6.

The plug will have a definite con-

tinuous lap band that is approxi-

mately the same width as the

plug without being grooved.

7.

You are done when the lap areas

of the seat and plug have a con-

tinuously smooth, close grained,

dull appearance with no skips or

tears.

8.

Once finished, wash the plug

and seat in solvent to remove all

lapping compound and wipe the

parts dry.

9.

Under a bright light, visually in-

spect the lapped contact surfac-

es of the seat and plug.

2.6 Valve Re-Assembly

CAUTION!

If the packing is to be re-used and was

not removed from the bonnet, use care

when re-installing the valve stem to

avoid damaging the packing with the

stem threads.

NOTE: Install and lubricate all new

0-rings prior to re-assembly

Re-assemble the valve by reversing

the order of the disassembly proce-

dure in Section 2.3.

3.0 Repair Kits

Norriseal provides four repair kits for

use in valve maintenance: a valve re-

pair kit, a valve seal kit, a trim repair

kit, and an actuator repair kit. Contact

the Norriseal sales office or your local

sales representative to order one of

these kits.

P.O. Box 40525, Houston, Texas USA 77240-0525

Tel: 713.466.3552 • Fax: 7118967386

www.norriseal.com

2200M

—61)

,

2012. August. 2012

A

COMMAARY

1. In the closed position. the valve leaks

process fluid from inlet to outlet port.

•

Reverse-acting (fail-closed) actuator has

insufficient spring tension

•

Direct-acting (fail-open) actuator has

excessive spring tension or insufficient

actuator supply, or both

•

Slowly increase the spring tension (refer

to 1.8 A) and watch for the leak to stop.

•

Decrease the spring tension (refer to 1.8

B) to the minimum necessary to achieve

full opening at operating conditions and/

or increase actuator supply pressure (re-

fer to 1.7). Watch for the leak to stop.

•

Direct-acting (fail-open) actuator thrust

out-put diminished due to:

1) failed 0-ring around upper stem or, 2)

punctured actuator diaphragm.

•

Apply supply pressure to actuator then

remove the spring cover (refer to 1.8B).

Check for leakage around the: 1) 0-ring

—

where the upper stem enters the up-

per diaphragm house and 2) diaphragm

—

from the opening of the vent plug in-

stalled in lower diaphragm housing. Apply

leak-detector (soapy water) if necessary.

Disassemble actuator (refer to 2.1 A), in-

spect and replace seal component(s) as

necessary.

•

Worn or damaged valve trim (plug and

seat) or failed seat/ cage-to-body 0-ring.

•

Remove the actuator assembly at its

hammer nut (refer to 2.3 A) and the seat/

cage from its body. Inspect the valve trim

(refer to 2.4) and 0-ring seal compo-

nents. Restore (by lapping) trim and/or

replace component(s) as necessary.

•

Differential pressure shut-off require-

ment exceeds the thrust output available

from the actuator.

•

First. record the valve serial number,

model number. flow direction, current

trim size and service conditions. Then

call your Norriseal representative to verify

actuator sizing and shut-off capability.

2. Process fluid leaks into lower diaphragm

housing (Series 2220 only).

•

Bonnet-to-valve stem packing and bon-

net-to-valve stem 0-ring failed. The valve

stem may be worn or damaged. If you

cannot see the leak outside of the pipe.

the bonnet weep hole is plugged.

•

Disassemble the actuator (refer to 2.1)

and valve (refer to 2.3 B). Inspect the 0-

ring and the sealed surfaces of the bonnet

and stem. The packing must have some

installation fit interference with both. Re-

place worn component(s) as necessary.

If the bonnet weep hole is plugged than

clean it out.

OPERATING AND MAINTENANCE MANUAL

=

Series 2200/2220 - 1.0" & 2.0"

4.0 Trouble Diagnosis

WARNING!

Some of the following trouble-shooting techniques require the removal or disassembly of components normally under pressure.

Before beginning any repair, be certain that all pressure(s) have been relieved from the device in accordance with the INTRO-

DUCTION and other section references in this manual.

4.1 Internal Leakage Problems

Symptom

Probable Cause(s)

Corrective Action(s)

2200M —02012. August, 2012

P.O. Box 40525. Houston. Texas USA 77240-0525

0

.

1

,_

--

N-0

1

11111111114e!

Tel: 713.466.3552 • Fax: 713.896.7386

mN0111111LIMIONMIIII

www.norriseal.com

A

soy*

commare

Page 7 of 12

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

4.2 External Leakage Problems

Symptom

Probable Cause(s)

Corrective

Action(s)

1. Process fluid is leaking from the bonnet

weep hole.

•

The bonnet-to-valve stem packing failed

and the valve stem may be worn or

damaged.

•

Disassemble the actuator (refer to 2.1)

and valve (refer to 2.3B).

Inspect bon-

net

and

stem

sealing

surfaces.

The

packing must have some installation fit

interference with both.

Replace the worn

component(s) as necessary.

2. Process

fluid

is

leaking

from

between

the hammer nut and bonnet and/or valve

body.

•

Bonnet-to-valve body 0-ring failed.

•

Remove the actuator assembly at the

hammer

nut

(refer to

2.3

A).

Inspect

the

0-ring and

sealing

surfaces of the

bonnet

and

valve.

Replace

the

worn

component(s) as necessary.

3. In

Reverse-acting

(fail-closed)

Actua-

tors only:

Supply pressure leaks from

around the actuator stem at the top of

the yoke window opening (Series 2200)

or from the bonnet weep hole (Series

2220).

•

The actuator stem-to-yoke 0-ring failed

(Series 2200) or the valve stem-to-bon-

net 0-ring failed (Series 2220)

•

Series 2200:

Disassemble the actuator

(refer to 2.1

B) and inspect the 0-ring,

yoke and actuator stem sealing surfaces.

Series 2220:

Disassemble the actuator

(refer to 2.1B) and valve (refer to 2.38)

and inspect the 0-ring, bonnet and valve

stem sealing surfaces. For either series,

replace any worn components.

4.

Direct-acting (fail-open) actuator only:

Supply pressure leaks from around the

base of the spring cover on top of the

upper diaphragm housing.

•

The actuator stem-to-upper diaphragm

housing 0-ring failed.

•

Disassemble the actuator (refer to 2.1A)

and inspect the 0-ring, back-up ring and

sealing surfaces of the stem and housing

bore. Replace the worn component(s) as

necessary.

4. Supply

pressure

is

leaking

from

the

diaphragm housing vent plug

when the

valve is not moving,

•

The Actuator diaphragm is punctured.

•

Disassemble

the

actuator

(refer

to

2.1)

and

replace

the

diaphragm

and

diaphragm-to-diaphragm plate 0-ring.

4.3 Valve Performance Problems

Symptom

Probable Cause(s)

Corrective Action(s)

1. Tile valve will not open completely (re-

•

Troubleshoot to find an actuator seal leak-

•

See the corrective actions in section 4.2.

verse-acting fail-closed actuator) OR the

age (refer to 4.2, Symptoms 3. 4 and 5)

valve will

not close completely

(direct-

Decrease

spring

tension

(refer

to

1.8)

acting fail-open actuator).

The actuator spring has excessive ten-

until

full

flow is achieved;

increase the

sion or the supply pressure is too weak

actuator supply pressure (refer to 1.7) if

to override the spring (or both).

required.

2. The

valve

is

fully

closed

and

will

not

•

The supply pressure line is connected to

•

Make sure the actuator's supply pressure

open.

the wrong side of the actuator or the re-

source

line

is

connected

to

the

lower

verse-acting (fail-closed) actuator spring

diaphragm housing.

Then decrease the

is

completely

compressed

resulting

in

spring tension (refer to 1.8A) until valve

tile inability to lift the valve plug.

is open far enough to allow full travel.

P.O. Box 40525. Houston, Texas USA 77240-0525

rile AU

Tel: 713-466.3552 • Fax: 713.896.7386

mliournnvourlisi

www.norriseal.com

mow

Page 8 of 12

2200M — 02012, August, 2012

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

4.3 Valve Performance Problems (continued)

Symptom

Probable Cause(s)

Corrective Action(s)

2. The valve is fully closed and will not open.

(Continued)

•

The direct-acting (fail-open) actuator

cannot vent supply pressure due to a

non-relieving pressure source device.

•

Troubleshoot by following section 4.3 -2A

to eliminate those items as problems.

•

In a reverse-acting (fail-closed) actuator,

the supply pressure may be the problem

and in a direct-acting (fail-open) actuator,

the spring tension may be insufficient to

open the valve plug (the tension may not

be enough to overcome the static differ-

ential pressure holding the plug closed).

•

The static differential pressure combined

with the trim size and the direction of the

inlet "flow-over" may exceed the avail-

able thrust of the actuator opening.

•

Replace the supply pressure source

device with one that relieves pressure or

install a 3-way vent valve at the actuator

supply connection.

•

Follow the corrective actions suggested

in Section 4.3 — 2A.

•

If you have a reverse-acting (fail-closed)

actuator, increase the supply pressure. If

you have a direct-acting (fail-open) ac-

tuator, increase the spring tension. For

both, an increase in supply pressure may

be require to re-close the valve.( refer to

1.7)

•

Record the valve's serial number, model

number, current trim size and services

conditions. Contact your Norriseal Rep-

resentative to verify actuator sizing and

shut-off capability.

3. The valve will not close. It is stuck fully

open.

•

In a reverse-acting (fail-closed) actuator,

the supply pressure cannot be vented

due to a non-relieving pressure source

device.

•

The supply pressure line is connected

to the wrong side of the actuator. If it's

a direct-acting (fail-open) actuator, the

spring may be fully compressed and

unable to create valve plug movement.

•

Replace the supply pressure source

device with one that is able to relieve

pressure, or install a 3-way vent valve at

the actuator supply connection.

•

Make sure that the actuator supply pres-

sure source line is connected to the

upper diaphragm housing. Decrease

the spring tension (refer to 1.8B) to the

minimum necessary to achieve full open-

ing at operating conditions.

4. The valve movement is sluggish or

unusually slow.

•

There may be actuator seal leakage (refer

to 4.2, symptoms 3, 4, or 5)

•

The opening of the diaphragm housing

vent plug is partially blocked.

•

If you just installed the valve, the actuator

supply pressure volume may be too low.

If the valve has been in use for a while,

the volume has diminished over time

due to clogged openings and/or filters in

control devices/ regulators.

•

Perform the correlating (3, 4 or 5)

corrective action suggested in 4.2.

•

Remove the vent plug and unclog the

opening

•

Increase the supply pressure line size

and/ or install a volume booster. Clean

the openings and clean/ replace the

filters of the control devices according to

the manufacturers' recommendations.

11

/

4

11

RD. Box 40525, Houston, Texas USA 77240-0525

i

.,„

----—

AIM isle! It 11

-

Tel: 713.466.3552 - Fax: 713-896.7386

MI WIPMLIMOIG11411 www.norriseal.com

A

NW*

0011WARI

2200M — 02012, August, 2012

Page 9 of 12

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

4.3 Valve Performance Problems (continued)

Symptom

Probable Cause(s)

Corrective Action(s)

5.

The inlet flow direction is over the seat

and the trim size is

1

/

2

" or larger (""this

is generally applicable

to

throttling

service only)

On

initial

opening,

the

valve

instanta-

neously travels to full open or near full

open position (there is no valve position

control over travel range).

•

The actuator opening thrust required (by

overcoming

static differential

pressure)

to open the valve plug is greater than the

opposing actuator spring force (tension)

adjustment.

•

The spring force (tension)

requirement

for

the

particular

service

conditions

exceeds the capabilities of the actuator

being used.

•

Slowly

increase

the

spring

tension

(refer to 1.8) and check the movement

of the valve opening.

Slowly

increase

the

tension

until

the

valve

plug

lift

is

controllable. An increase in the actuator

supply pressure (refer to 1.7) may also

be required.

•

Write

down

the

valve

serial

number,

model

number,

current

trip

size

and

service conditions.

Then

contact your

Norriseal

representative

to

verify

the

actuator sizing.

6.

Generally

applicable

to

throttling

•

The

actuator

spring

force

(tension)

•

Record the valve serial number, model

service only:

necessary to achieve a tight shut-off OR

number,

current trim

size

and

service

overcome the static differential pressure

conditions.

Then contact your Norriseal

The closed

valve

is

leaking

or will

not

holding the valve plug closed against the

representative to verify that the actuator

open against static differential pressure

seat is more than the force coming from

has sufficient thrust capability.

You may

even

with

the

actuator

spring

tension

the actuator (3-15 psig) or

the supply

need a valve positioner to:

adjusted to correspond with the control

instrument signal

start

point

(3

psig

if

pressure (6-30 psig).

1)

Achieve

accurate

valve

response

in the 3-15 range. 6 psig if in the 6-30

to the control instrument signal that

range).

(refer to 4.3,

#5 — SYMPTOM

a

simple

spring

tension

adjustment

and PROBABLE CAUSE)

would not fix.

2)

Make use of all available actuator

thrust for shut-off up to the maximum

actuator rating.

P.O. Box 40525, Houston. Texas USA 77240-0525

--

-

-

-

-

-

011111111111ee Al

Tel: 713.466.3552 • Fax: 713.896.7386

Page 10 of 12

illiwynneasous

www.norriseal.com

•

oonn)coranu.

2200M — 02012, August, 2012

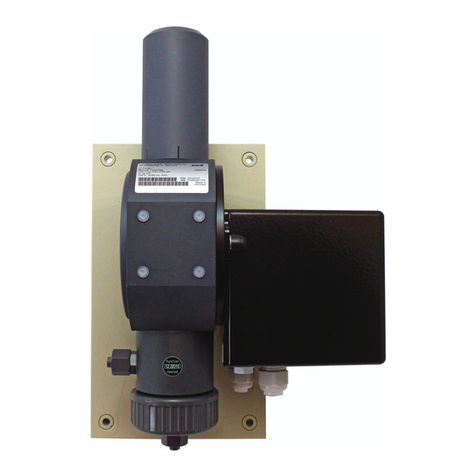

Inlet flow is directed into the upper port

(Flow is over valve seat)

Jr

i

Inlet flow is directed

into the lower port

(Flow is under valve seat)

1-in. Globe and Tee Valve Bodies

Inlet flow is directed into the upper port

(Flow is over valve seat)

Jr

Inlet flow is directed

into the lower port

(Flow is under valve seat)

2-in. Globe Valve Body

OPERATING AND MAINTENANCE MANUAL

Series 2200/2220 - 1.0" & 2.0"

5.0 Valve Body Styles and Port Orientation Markings

The Styles

The Series 2200 and 2220 valves are

available in three valve body styles:

•

THE GLOBE: This style comes in

1" and 2" valve sizes and has two

process piping connections-one on

each side.

•

THE ANGLE: This style is available

in 1" (using a tee style body) and

2" valve sizes and has two process

pipe connections- an upper port

side connection and a lower port

bottom connection.

•

THE TEE: This style is only avail-

able in the 1" valve size.

The female threaded NPT body has

three connections-one on each side

located in-line (like the globe style)

and an additional bottom connection

located in the center (it shares the

lower port passageway) and has a

pipe plug installed to permit field con-

version to either a globe or angle flow

pattern. The tee body is also used for

1" angle pattern flanged, socket-weld

and butt-weld bodies. The unused

side port is permanently plugged and

welded closed.

The Body Markings and Port

Orientation

On the outside of the globe and tee

valve bodies you will find a

BRIDGE

SYMBOL

cast. This image repre-

sents the position of the internal

cast web (or bridge) separating the

lower port-flow passage from the

upper port-flow passage. The Series

2200/2220 valve can be installed

with the

inlet

fluid flow directed into

the body's

lower port ("flow under

seat")

or

upper port ("flow over

seat").

This is the reason a bridge

symbol is used instead of a direction

arrow. Issues regarding your valve's

performance are often because of the

direction fluid is flowing through the

valve body. The illustrations below

define how the bridge symbol geom-

etry and the internal port orientation

of the valve body work together.

TABLE3—BRIDGE SYMBOL AND VALVE BODY PORT ORIENTATION

2200M — 02012. August, 2012

INN

A I

nanow‘rae•

aDovin)co.ram

P.O. Box 40525, Houston, Texas USA 77240-0525

Tel: 713.466.3552 • Fax: 713.896.7386

www.norriseal.com

Page 11 of 12

This manual suits for next models

1

Table of contents

Other Norriseal Control Unit manuals

Popular Control Unit manuals by other brands

DIGITIZE

DIGITIZE RAD-800 instruction manual

Wigersma & Sikkema

Wigersma & Sikkema Moxa MiiNePort E1 Installation and user manual

Lutz-Jesco

Lutz-Jesco C 7700 operating instructions

Texas Instruments

Texas Instruments TAS5514B user guide

Festo

Festo HMP-x-B Series operating instructions

Epson

Epson RTC-72421 A Applications manual