Norriseal Flow-Lift 7100 Series User manual

Series 7100 Flow-Lift®

Piston Check Valve

Award-Winning Design:

Feature-packed valve provides solutions

for gas, air or liquid systems

Features

No-slam closing

No special tool required

to change seat

Low pressure drop

High Cv values

Smooth opening

Special trims for abrasive and

corrosive services

Built-in lifting device for piston

removal and inspection

PTFE self-lubricating piston seal

Low maintenance costs

Contents

2 Assemblies

2 Operation &

Installation

4 Special Features

5 Materials

6 Flow Characteristics

7 Specifications

8 How to Order

Engineered

Performance

The Norriseal Series 7100 Piston Check Valve*

is designed for the prevention of backflow in gas, air

or liquid systems. Norriseal’s expertise in the design

of piston balanced control valves has introduced new

concepts to the piston check valve industry.

The piston check valve, with its award-winning

design, has been installed in critical services around

the world.

Working Pressures

ANSI Class 150 thru 2,500

API 5,000 and 10,000

Applications

Air and gas compressor service

Gas or liquid pipe lines

Oil and gas production leases

Pulsating flows

Safety systems

* Received the Special Meritorious Award for

engineering innovation at the 1981 Offshore Technology Conference

in Houston, Texas.

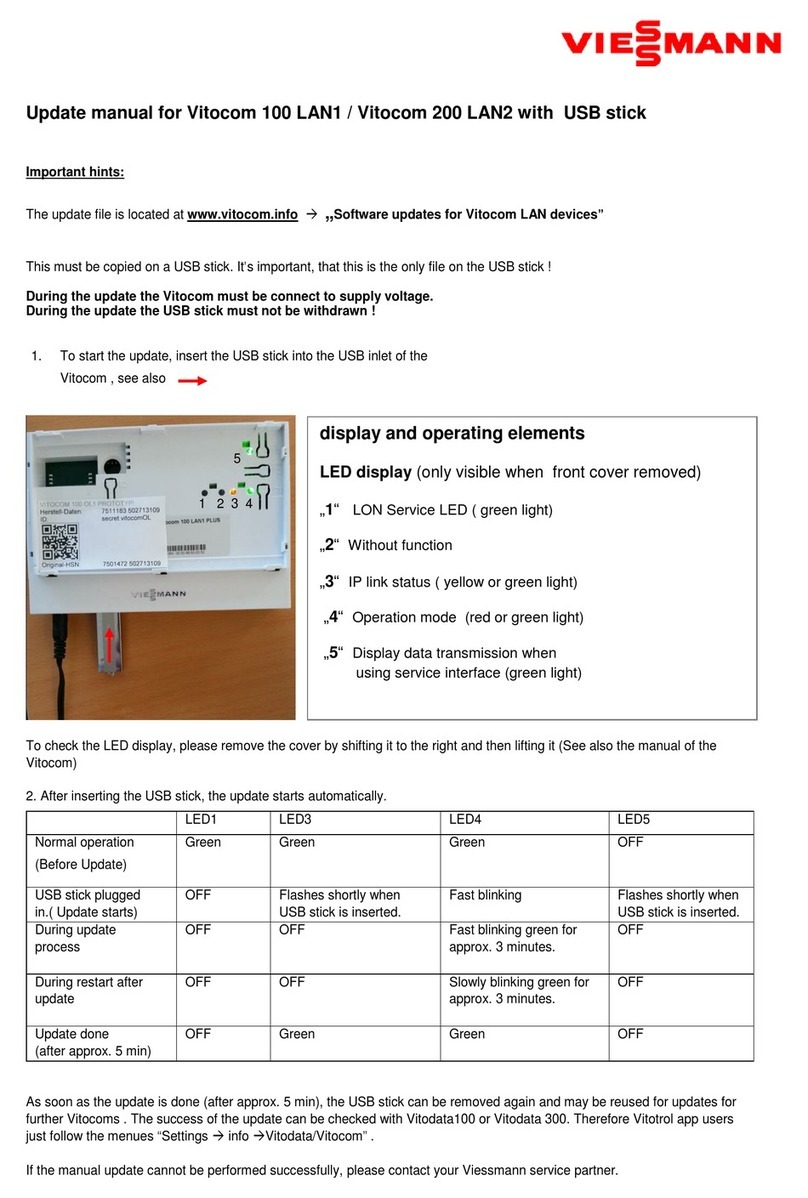

2Assemblies

Valve Assembly

Valve Assembly

3

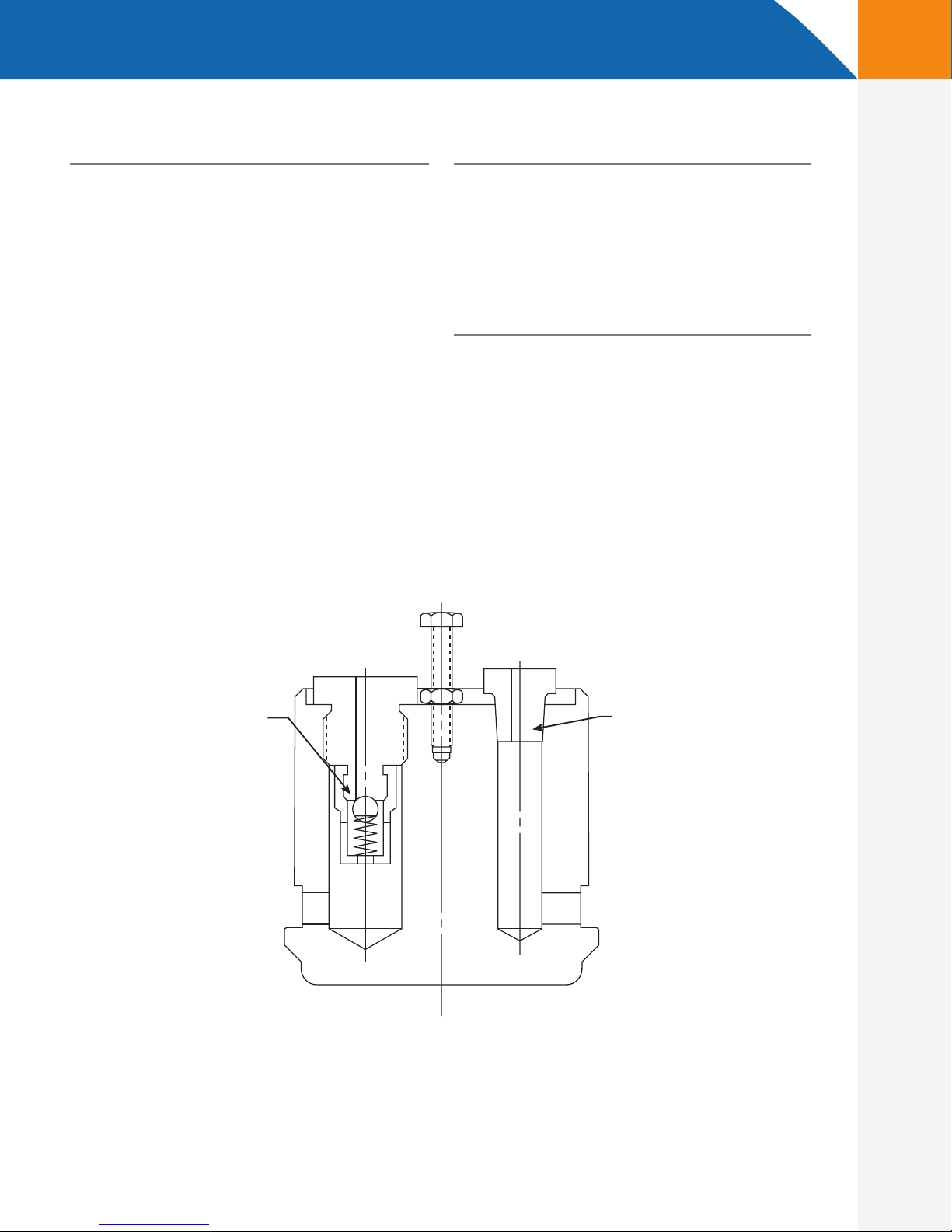

Operation

Normal. Flow is directed under the valve piston

and lifts it upward. When flow is stopped, the

piston descends, closing the valve to prevent

flow reversal.

Stabilized/non-slam piston. Pulsating flow

through the valve, if unrestricted, would cause the

piston to follow the rapidly cycling line pressure,

resulting in vibration, chattering and possibly

slamming of the piston. The ball check and orifice

plug built into the piston are to prevent this from

happening. (Fig. 1)

As the piston rises, the pressure in the PTFE

sealed cavity above the piston increases, forcing

open the ball check. This reduces the cavity pres-

sure and allows the piston to rise smoothly. As

the pressure and flow decrease, the piston moves

downward. The ball check closes, and descent of

the piston is restricted by fluid flowing through the

orifice plug. This equalizes the pressure in the cav-

ity above and below the piston and gives stability

to the valve.

Installation

Valves 4.00” and smaller may be installed in a

vertical position.

Warning: 6.00” and larger valves should NOT

be installed in a vertical plane. If a vertical plane

is required, please consult factory for special

accessories.

Application

Compressible fluids. Valves come with ball-

check and orifice plug in piston.

Non-compressible fluids. Valves furnished

same as for compressible fluids; however, some

applications where heavy, viscous liquids are

present, the ball check should be removed so

piston can stabilize quicker.

Operation & Installation

Figure 1

BALL

CHECK

ORIFICE

PLUG

4

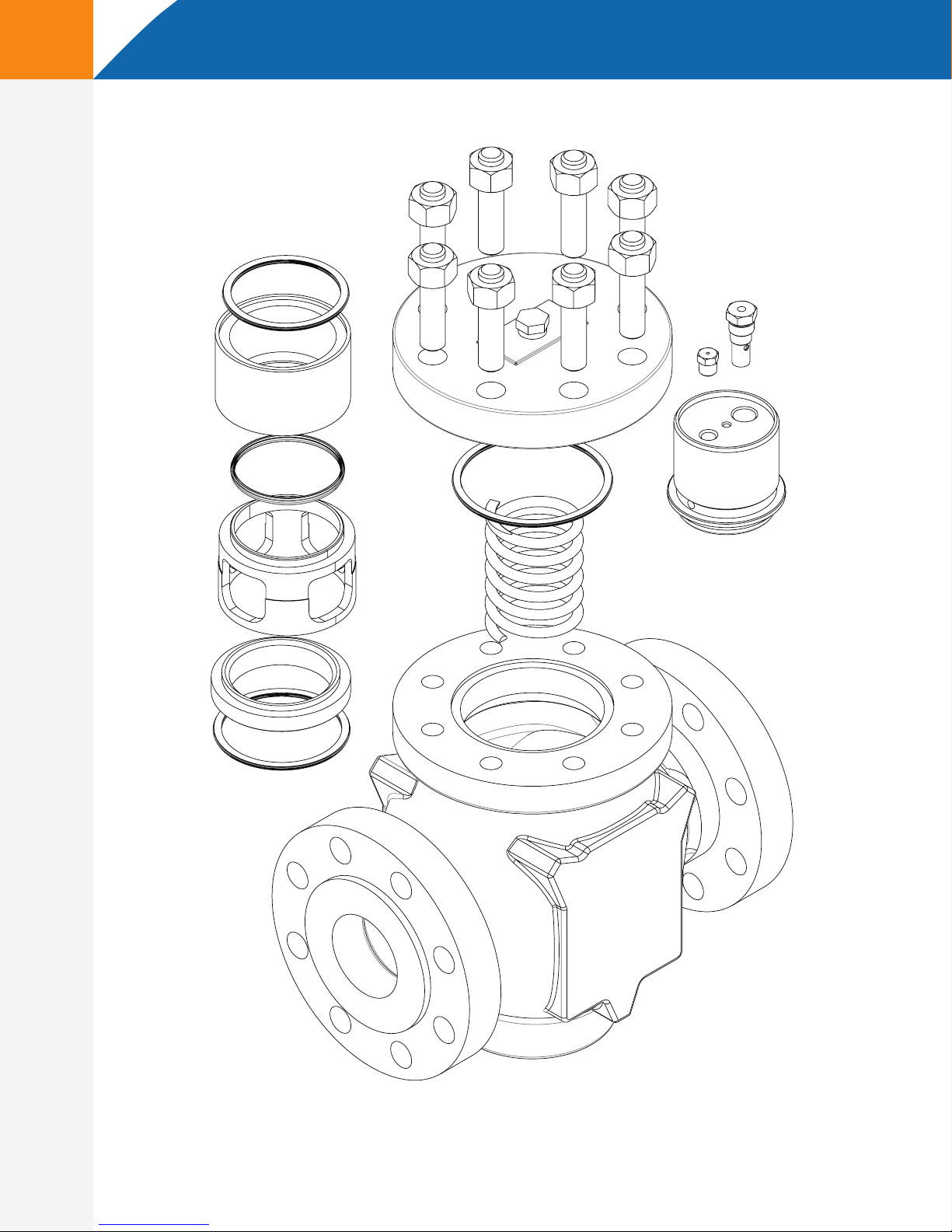

PTFE Piston Seal Ring

Norriseal’s use of a PTFE spring energized seal

ring adds a new dimension to the piston check

valve. By use of a full circle ring, leakage between

piston and guide/cage is zero. Using a low friction,

self-lubricating material allows the piston to move

freely and quietly without seizing to the seal.

Guide/Cage

This feature by Norriseal provides positive piston

and seat alignment which helps prevent piston

vibration and assures stability for proper flow

control.

Valve Spring

Furnished on all valves. This gives an added safety

feature for shut-off in all pressure ranges.

Seat – Cage Retained Type

Held in position by guide/cage requiring no

special tools for removal and can be easily

removed by hand.

Optional Trim

For applications where a positive seal with a zero

leakage is required, composition seating material

is available. This style piston has the feature of a

metal back-up in case of wash-out of the composi-

tion trim. (Fig. 3)

Abrasive resistant metal trim sets are available for

special applications. Please consult factory. (Fig. 3)

NACE

Optional trim available that meets MR0175 recom-

mended practice. (See Materials of Construction)

Easy Maintenance

Norriseal’s valve piston comes with a built-in lift-

ing device. No special fittings or tools are required

to remove the piston from the valve body.

Special Features

Figure 3

2A

2D

2C

2B

2E

12

20

8

13

9

3

18

7

16

4

17

6

15

12

11

5

10

14

19

Figure 2

Note: Figure 3 shows piston with replaceable

inserted material

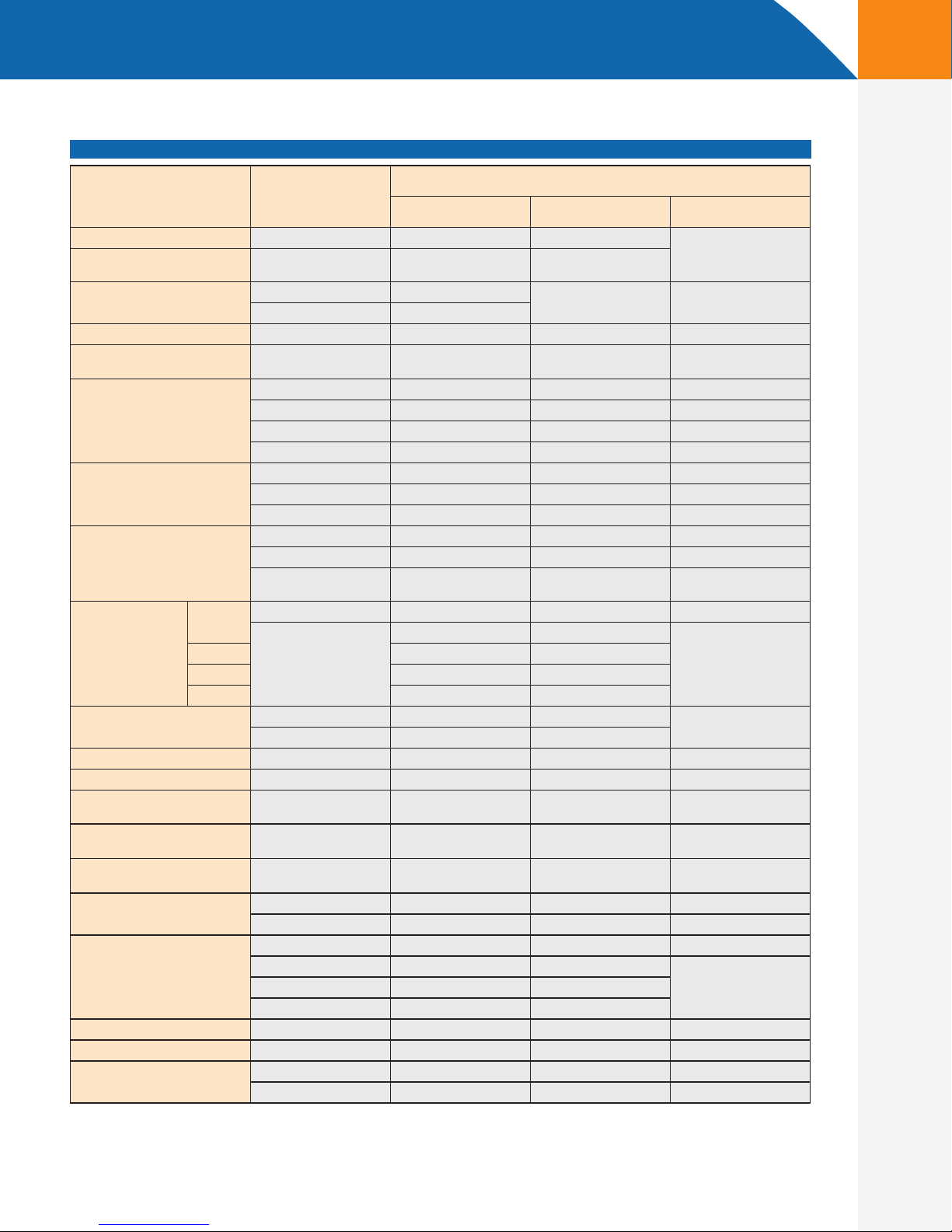

Item No Description

1

2

SEAT Valve

PISTON Valve Solid

2A

2B

BUTT Piston Valve

RETAINER Piston Valve

INSERT Piston Valve

SCREW Retainer Piston

O-Ring Insert

3

4

5

6

7

CAGE Piston Valve

GUIDE Piston Valve

SPRING Valve

PLUG Orifice

SEAT Ball Check

8

9

10

11

12

CAGE Ball Check

SPRING Ball Check

BONNET

GASKET Bonnet

GASKET Guide

13

14

15

16

17

GASKET Seat

STUD Bonnet w/Nut

SCREW Lifting

NUT Hex Ring

SEAL Piston Guide

18

19

20

BALL Check

PLUG Pipe

BODY

5

Materials

Items Valve Size

(inches)

Material

Standard NACE MR0175 Optional

Body 1.00 - 12.00 ASTM A216, GR. WCC ASTM A216, GR. WCC

ASTM A351, GR CF8A

ASTM A352, GR. LCC

Bonnet 1.00 - 12.00 ASTM A516, GR 70 or

ASTM A216, GR. WCC

ASTM A516, GR 70 or

ASTM A216, GR. WCC

Valve Piston 1.00 - 4.00 17-4PH SST/H900 316 SST 316 SST

6.00 - 12.00 17-4PH SST/H1150-M

Valve Seat 1.00 - 12.00 17-4PH SST/H1150-M 316 SST 316 SST

Piston Insert

(Optional) 1.00 - 12.00 Glass-Filled PTFE Glass-Filled PTFE Alloy 6

Valve Cage

1.00, 2.00, 3.00, 4.00 17-4PH SST/H1150-M 17-4PH SST/H1150-M 316 SST

1.50 316 SST 316 SST 17-4PH SST/H1150-M

6.00, 8.00 316 SST 316 SST 17-4PH SST/H1150-M

10.00, 12.00 17-4PH SST/H1150-M 17-4PH SST/H1150-M 316 SST

Piston Guide

1.00 17-4PH SST/H1150-M 17-4PH SST/H1150-M 316 SST

1.50 - 8.00 316 SST 316 SST Consult Factory

10.00, 12.00 N/A N/A N/A

Piston Seal

1.00 None None None

1.50 - 8.00 TFE/ELG Ring TFE/ELG Ring Fluor.-K/ELG Ring

10.00, 12.00 C.G Filled Ring

w/Buna-N O-ring

C.G Filled Ring

w/Viton O-ring Consult Factory

Ball Check

Assembly

Seat 1.00 None None None

1.50 - 12.00

316 SST 316 SST

Consult Factory

Cage 316 SST 316 SST

Ball 302 SST 302 SST

Spring Inconel 600 Inconel 600

Valve Spring 1.00, 5.00 Inconel 600 Inconel 600 Consult Factory

2.00 - 12.00 316 SST Inconel 600

Bonnet Studs 1.00 - 12.00 ASTM A193, GR. B7 ASTM A193, GR. B7 Consult Factory

Hex Nuts 1.00 - 12.00 ASTM A194, GR. 2H ASTM A194, GR. 2H Consult Factory

Spiral Wound Gaskets 1.00 - 12.00 316L SST

w/Graphite Filler

Inconel 600

w/Graphite Filler Consult Factory

Solid Metal Gaskets

(ANSI 2500 and up) 1.00 - 12.00 316 SST 316 SST Consult Factory

Composition Gaskets

(Non-ASB)

10.00

(ANSI 150-600)

Synthetic Fiber

w/Nitrile Binder

Synthetic Fiber

w/Nitrile Binder Graphite/Fiberglass

Orifice Plug 1.00 None None None

1.50 - 12.00 316 SST 316 SST Consult Factory

Piston Lifting

Attachment

1.00 None None None

1.50 - 4.00 304 SST 304 SST

316 SST6.00, 8.00 302/304 SST 302/304 SST

10.00, 12.00 304/316 SST 304/316 SST

Nameplate 1.00 - 12.00 316 SST 316 SST Consult Factory

Bonnet Vent Plug 1.00 - 12.00 CSTL/ASTM A105 CSTL/ASTM A105 316 SST

Lifting Attachments

(Eye Bolts)

1.00 - 2.00 None None None

1.00 - 12.00 Forged Alloy Steel Forged Alloy Steel Consult Factory

MATERIALS OF CONSTRUCTION

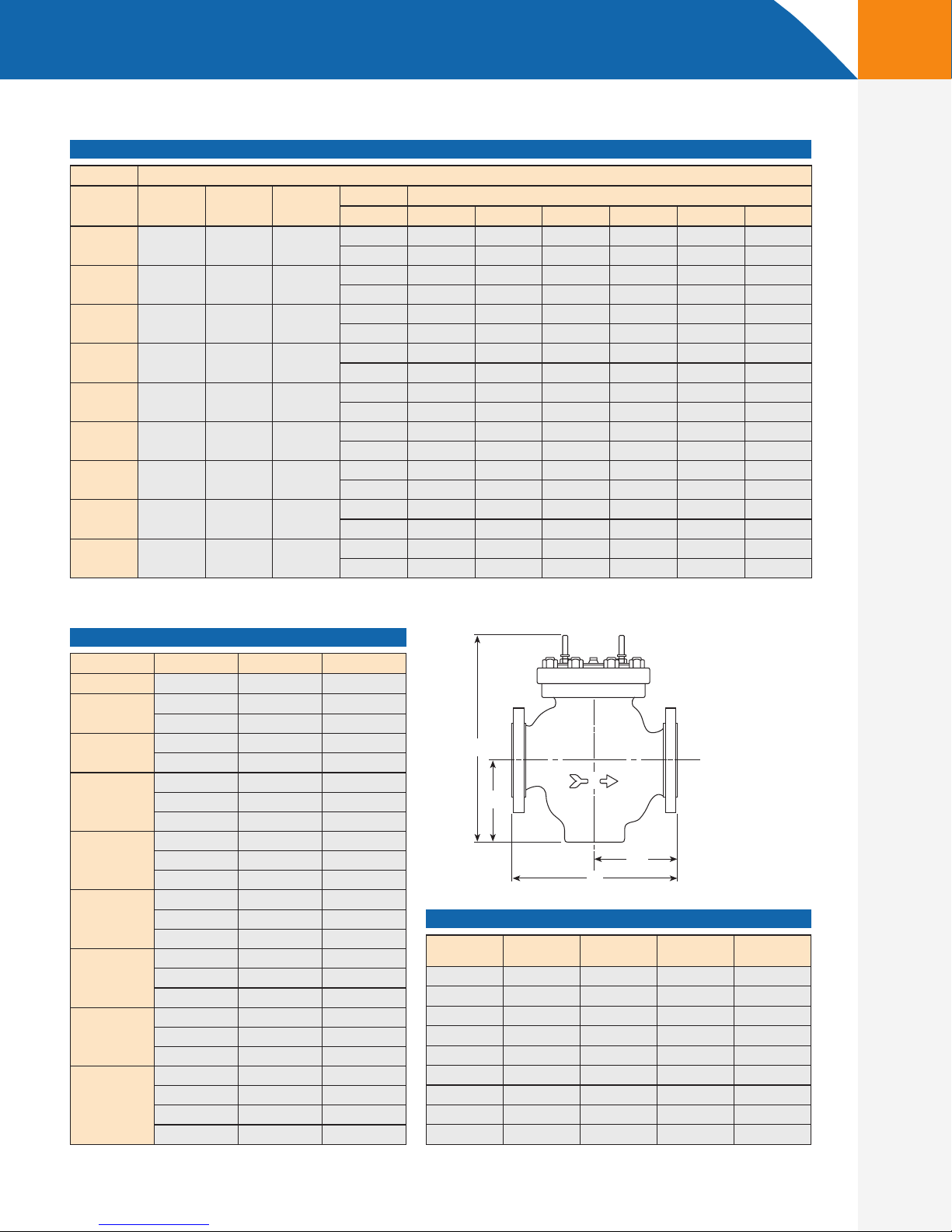

6Flow Characteristics

Pressure Drop vs Flow for Norriseal Series 7100 Piston Check Valves

DIFFERENTIAL PRESSURE (PSI)

WATER FLOW (GPM) AT 60°F

Note: Dotted potion of curves indicates flow with valve spring removed.

1.00” Valve

1.50” Valve

2.00” Valve

3.00” Valve

4.00” Valve

6.00” Valve

8.00” Valve

10.00” Valve

12.00” Valve

10

20

30

40

50

60

70

80

90

100

200

300

400

500

600

700

800

900

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

20000

100

90

80

70

60

50

40

30

20

10

9

8

7

6

5

4

3

2

1

Flow (Water – S.G. = 1.0)

vs.

Pressure Drop (psi)

For liquids other

than water multiply

by 1/ S.G.

For barrels per day

multiply gpm by 34.3

The following formulas may be

used to determine the actual

flow coefficient (Cv) required by

a given condition of flow.

1. Liquid

Cv= Q

Q = Cv

2. Gas

Cv=

Q = 963Cv

Glossary of Terms

Q= Flow Liquids – GPM

Gas – SCFH

Cv= Flow Coefficient

P1= Inlet Pressure (PSIA)

P2= Outlet Pressure (PSIA)

P = P1– P2, Pressure Drop

[Critical flow (gas) use

1⁄2P1for P2if P2is less

than 1⁄2P1]

T= Absolute Temperature

(°F + 460)

G= Specific Gravity

Flow Coefficients (Cv)

for Fully Open Valves

Valve Size Cv

1.00 16

1.50 34

2.00 70

3.00 128

4.00 198

6.00 440

8.00 880

10.00 1200

12.00 1900

G

P

G

P

GT

( P) (P

1+ P2)

Q

963

( P) (P

1+ P2)

GT

7

Specications

End Connection Type

Body

Size NPT+Butt-

Weld+

Socket

-weld+

ANSI Flanged

Flange Type 150 300 600 900 1500 2500

1.00 8.25 8.25 8.25 RF 7.25 7.75 8.25 9.38 9.38 N/A

RTJ 7.75 8.25 8.25 9.38 9.38 N/A

1.50 13.00 13.00 13.00 RF 8.75 9.25 9.88 12.25 12.25 N/A

RTJ 9.25 9.75 9.88 12.25 12.25 N/A

2.00 11.25 11.25 11.25 RF 10.00 10.00 11.25 14.75 14.75 16.88

RTJ 10.50 11.12 11.38 14.88 14.88 17.00

3.00 CF CF RF 11.75 12.50 13.25 15.50 18.12 22.75

RTJ 12.25 13.12 13.38 15.62 18.25 23.00

4.00 CF CF RF 13.38 14.50 15.50 17.00 20.88 26.50

RTJ 14.38 15.12 15.62 17.12 21.00 26.88

6.00 CF RF 17.75 18.62 20.00 24.00 27.75 36.00

RTJ 18.25 19.25 20.12 24.12 28.00 36.50

8.00 CF RF 21.38 22.38 24.00 29.00 32.75 40.25

RTJ 21.88 23.00 24.12 29.12 33.12 40.88

10.00 CF RF 24.50 24.50 31.00 33.00 39.12 C/F

RTJ 25.00 25.12 31.12 33.12 39.38 C/F

12.00 CF RF 29.00 30.50 32.25 40.00 44.50 C/F

RTJ 29.38 31.00 32.38 40.12 45.12 C/F

DIMENSIONS (inches)

Valve Size ANSI Class “D” “E”

1.00 150-1500 7.75 3.06

1.50 150-600 9.75 3.50

900-1500 10.50 4.00

2.00 150-1500 12.12 4.38

2500 15.12 5.25

3.00

150-900 13.50 5.50

1500 16.88 6.25

2500 23.12 7.62

4.00

150-900 18.38 7.00

1500 19.38 7.50

2500 23.12 7.62

6.00

150-600 20.75 7.50

900-1500 25.00 8.62

2500 30.00 10.50

8.00

150-600 26.50 9.00

900 27.88 10.38

1500 & 2500 39.00 12.75

10.00

150-600 34.00 11.63

900 36.25 11.94

1500 39.75 13.00

12.00

150-300 37.12 12.00

600 38.50 12.75

900 40.12 13.50

1500 43.59 14.75

BODY HEIGHT DIMENSIONS

Body Size NPT Butt Weld Socket Weld Flanged

(ANSI Ratings)

1.00 * * * 150-1500

1.50 * * * 150-1500

2.00 * * * 150-2500

3.00 * * 150-2500

4.00 * * 150-2500

6.00 * 150-2500

8.00 * 150-2500

10.00 * 150-2500

12.00 * 150-2500

STANDARD BODY END CONNECTIONS**

* For face-to-face dimensions other than those listed above, ie. API 6D, please consult factory

+ ANSI 1500 C.L. Pressure Rating

* For 10.00” and 12.0” ANSI 2500 Class C/F **For valve body end connections other than those listed and higher

pressure ratings, please consult factory.

D

E

F

4

F/2

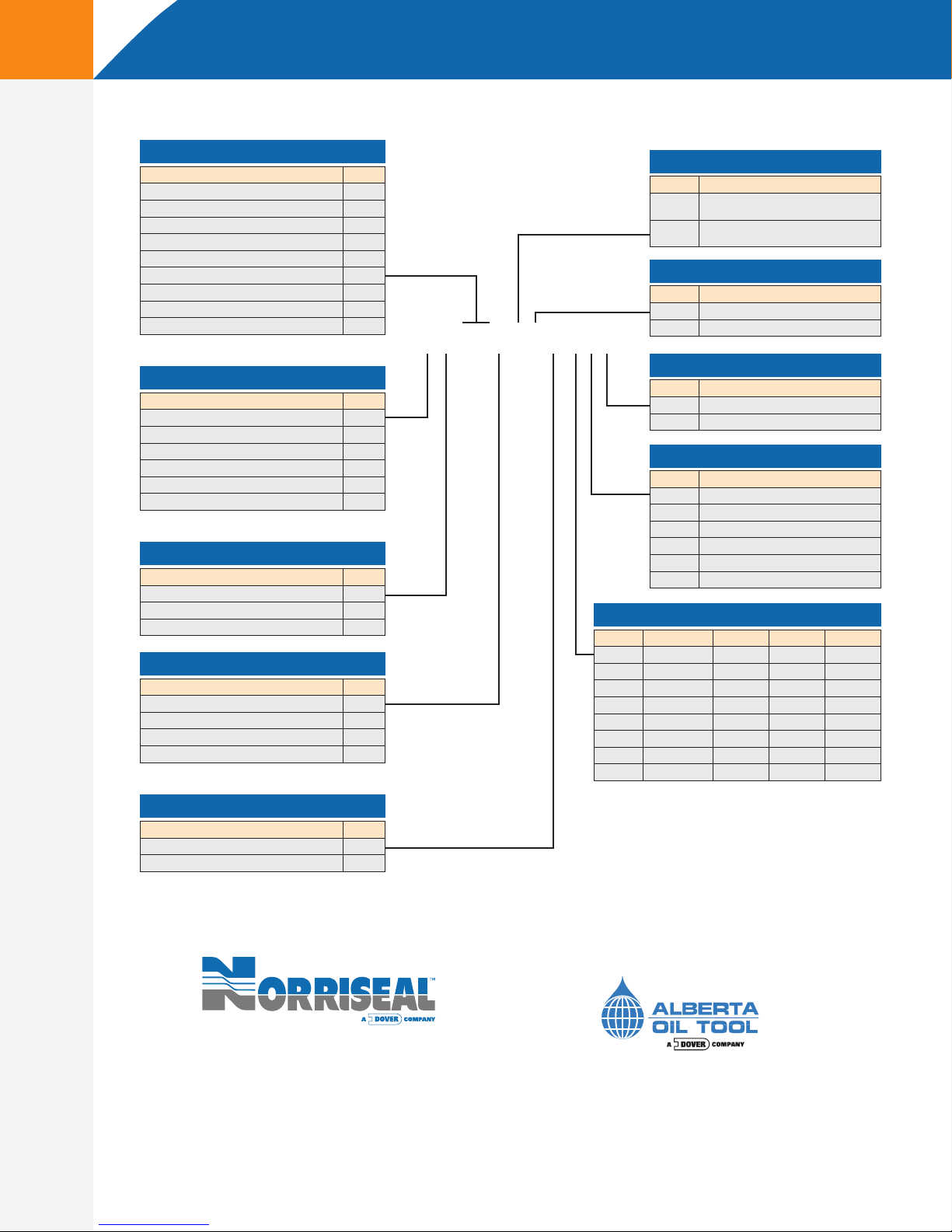

8How to Order

S - 36RGS - AEA

1. Determine required body size.

2. Use model number code below as

illustrated to select proper valve

type to suit operating conditions.

Please note: not all available

options are shown.

1Limited Availability

2Specify schedule

3NACE MR0175 Suitable

4Consult factory for non-standard F-F applications

5NACE MR0175 Suitable

For specific trim combinations per size, refer to Materials of

Construction chart on page 5.

BODY RATING

BODY CONNECTIONS

SERVICE CODE

BODY CONFIGURATION

VALVE SPRING MATERIAL

ANSI Code

150 02

300 07

400 09

600 14

900 21

1500 36

2500 60

5000 501

10,000 1001

Type Code

Screwed (Female) NPT S

ANSI Flanged Raised Face RF

ANSI Flanged Ring Type Joint RJ

Beveled Buttweld B2

Socketweld W2

API Flanged Ring Type Joint AJ

Body, Bonney Code

WCC Standard (General Serv.) -

WCC NACE Spec. (MR0175) N

316 SST S

Configuration Code

Norriseal F-F (ISA) -

Non-Std. F-F (Not ISA or API) C4

Type Code

316 SST (Horizontal) R

Inconel (Horizontal) L3

316 SST (Vertical) V

Inconel (Vertical) W3

BODY STYLE

GASKETS (SPIRAL WOUND)

FLUID TYPE

PISTON SEAL MATERIAL

TRIM MATERIAL

Code Flow Pattern

DGlobe w/Bottom Drain

(Standard 10” and larger)

GGlobe w/o Bottom Drain

(Standard 8” and smaller)

Code Fluid

S 316 SST/Grafoil

N Inconel 600/Grafoil

Code Fluid

A Gas or Air

B Liquid

Code Material

E PTFE/Elgiloy

F Buna w/TFE Rider (>8.00”)

G Viton w/TFE Rider (>8.00”)

K Fluoroloy K (>8.00”)

J Carbon-Graphite

O No Seal (1.00”)

Code Piston Seat Cage Guide

A 17-4PH 17-4PH 17-4PH 316 SST

B5316 SST 17-4PH 17-4PH 316 SST

C5316 SST 316 SST 316 SST 316 SST

E5316/STEL 316/STEL 316 SST 316 SST

J5316/TFE 17-4PH 17-4PH 17-4PH

L5316/TFE 316 SST 316 SST 316 SST

T 17-4/TFE 17-4PH 17-4PH 316 SST

Z 17-4/UHMW 17-4PH 17-4PH 316 SST

Tel: 713·466·3552

Fax: 713·896·7386

www.norriseal.com

Tel: (780) 434-8566

Fax: (780) 434-4267

www.albertaoiltool.com

Engineered Performance

©2015 Dover Corporation/Norriseal and its affiliates. This manual, including all text and

images, is a copyrighted work of Dover Corporation/Norriseal and its affiliates. It may

not be, in whole or in part, photocopied, scanned, or otherwise reproduced, revised,

or publicly displayed, without prior written permission from Norriseal. This manual is

for use only with the new Norriseal valves and/or controllers listed in the manual. It

may not be distributed with, and is not for use with, any remanufactured products.

Due to the continuous improvement program at Norriseal, specifications and/or prices are

subject to change without notice or obligation.

All trademarks contained herein are the property of their respective owners.

7100-0615T

In Canada contact:

Other Norriseal Control Unit manuals

Popular Control Unit manuals by other brands

Emerson

Emerson PACSystems RX3i quick start guide

Calex

Calex LCT-485 Operator's guide

YOODA

YOODA NANO Series quick start guide

ICP DAS USA

ICP DAS USA DS-2200 Series quick start

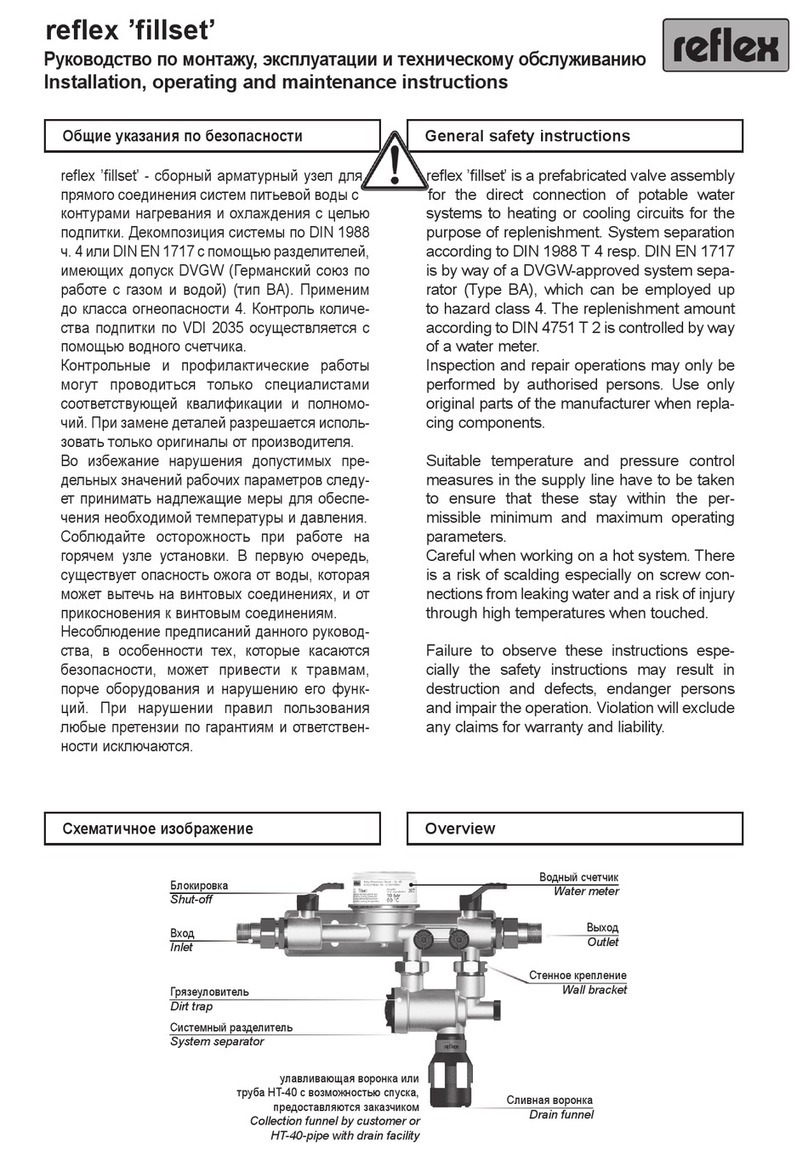

Reflex

Reflex fillset Installation, operating and maintenance instructions

HHV SOLAR

HHV SOLAR HSTXY24xxxZ Series installation manual