50-60 Hanover Road, Florham Park, New Jersey 07 32

ASCO Valves

Page 2 of 4 Form No.V5256R8

Valves with suffix P" in the catalog number must be mounted with

the solenoid vertical and upright.

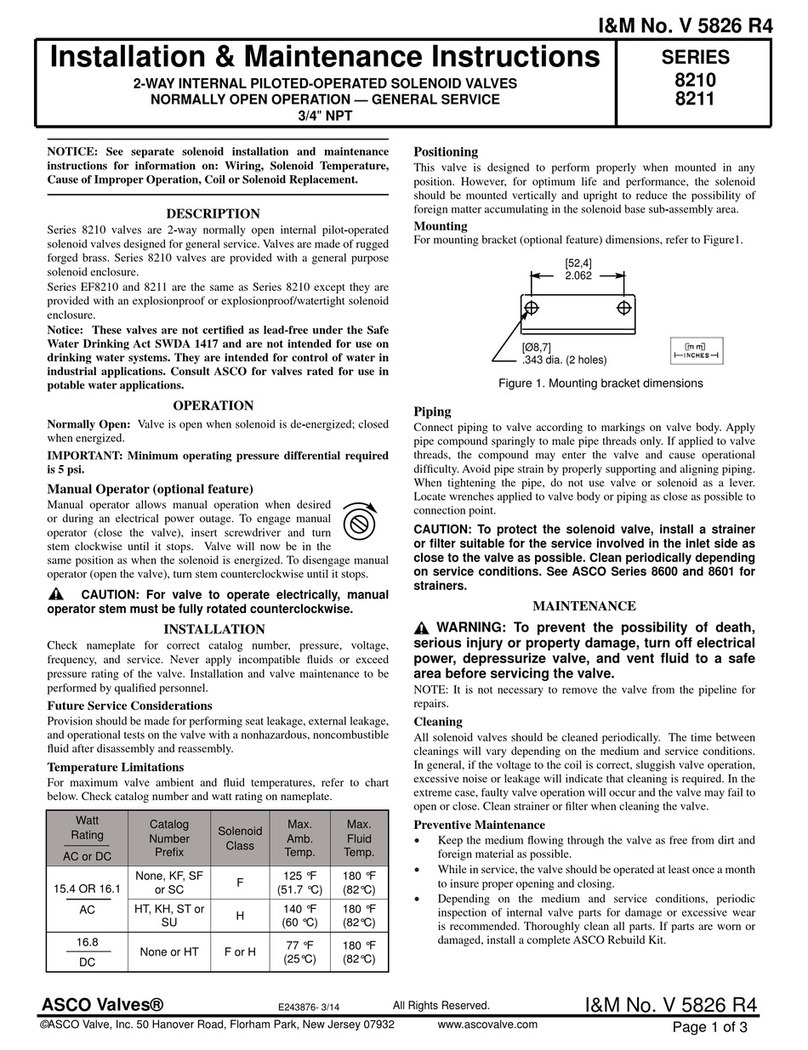

Mounting

Refer to Figure 2 for mounting dimensions.

Piping

Connect piping or tubing to valve according to markings on valve

body. Inlet port will either be marked I" or IN". Outlet port will be

marked 2" or OUT". Wipe the pipe threads clean of cutting oils.

Apply pipe compound sparingly to male pipe threads only. If applied

to valve threads, the compound may enter the valve and cause operaĆ

tional difficulty. Avoid pipe strain by properly supporting and alignĆ

ing piping. When tightening the pipe, do not use valve or solenoid as

a lever. Locate wrenches applied to valve body or piping as close as

possible to connection point.

IMPORTANT: To protect the solenoid valve, install a strainer or filĆ

ter suitable for the service involved, in the inlet side as close to the

valve as possible. Clean periodically depending on service condiĆ

tions. See ASCO Series 8600, 8601 and 8602 for strainers.

MAINTENANCE

WARNING: To prevent the possibility of personal

injury or property damage, turn off electrical power,

depressurize valve, and vent fluid to a safe area before

servicing the valve.

NOTE: It is not necessary to remove the valve from the pipeline for

repairs.

Cleaning

All solenoid valves should be cleaned periodically. The time between

cleanings will vary depending on the medium and service conditions.

In general, if the voltage to the coil is correct,sluggish valve operation,

excessive noise or leakage will indicate that cleaning is required. In

the extreme case, faulty valve operation will occur and the valve may

fail to open or close. Clean strainer or filter when cleaning the valve.

Preventive Maintenance

Keep the medium flowing through the valve as free from dirt and

foreign material as possible.

While in service, the valve should be operated at least once a

month to insure proper opening and closing.

Depending on the medium and service conditions, periodic

inspection of internal valve parts for damage or excessive wear is

recommended. Thoroughly clean all parts. If parts are worn or

damaged, install a complete ASCO Rebuild Kit.

Causes of Improper Operation

Incorrect Pressure: Check valve pressure. Pressure to valve must

be within range specified on nameplate.

Excessive Leakage: Disassemble valve (see Maintenance) and

clean all parts. If parts are worn or damaged, install a complete

ASCO Rebuild Kit.

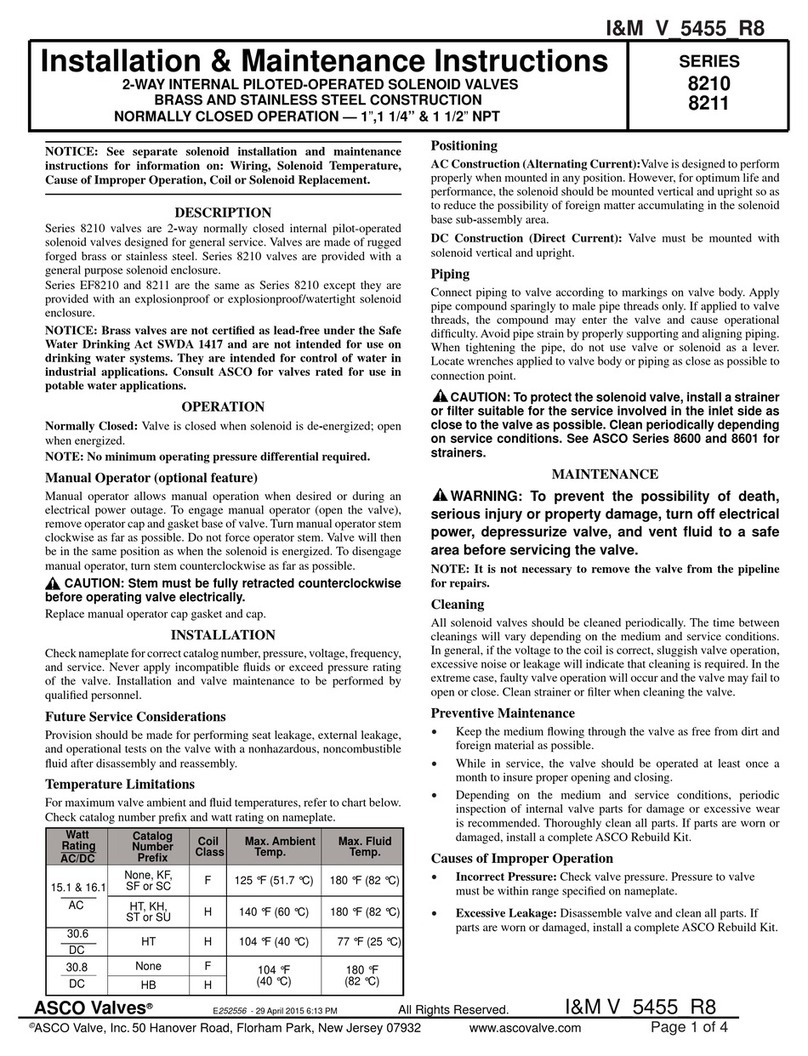

Valve isassembly

1. Disassemble valve using exploded views for identification of parts.

2. Remove solenoid, see separate instructions.

3. Unscrew solenoid base sub-assembly or valve bonnet with

special wrench adapter supplied in ASCO Rebuild Kit. For

wrench adapter only, order No. K218948. Remove core

assembly, core spring, and solenoid base gasket from valve

body. For normal maintenance on Series 8263 valves it is not

necessary to remove valve seat. See Figure 1 for metering or

manual operator constructions.

4. For normally open construction (Figure 3) remove end cap, or

manual operator, (not shown) end cap gasket, disc holder

spring, and disc holder assembly.

5. All parts are now accessible to clean or replace. If parts are worn

or damaged, install a complete ASCO Rebuild Kit.

Valve Reassembly

1. Use exploded views for identification, orientation and placement

of parts.

2. Lubricate all gaskets with DOW CORNING 111 Compound

lubricant or an equivalent high-grade silicone grease.

3. For normally open construction (Figure 3), install disc holder

assembly, disc holder spring, end cap gasket and end cap or

manual operator. For valves with 1/8 NPT, torque end cap or

manual operator to 90ñ 10 in-lbs [10,2 ± 1,1 Nm]. For all othĆ

er valves torque end cap or manual operator to 175 ± 25 in-lbs

[19,8 ± 2,8 Nm].

4. For Series 8263 apply a small amount of LOCTITE PST pipe

sealant to threads of valve seat (if removed). Follow manufacĆ

turers instructions for application of pipe sealant. Then install

valve seat and torque to 75 ± Ă10 in-lbs [8,5 ± 1,1 Nm].

5. Replace solenoid base gasket, core assembly with core spring

and solenoid base sub-assembly or plugnut/core tube sub-asĆ

sembly and valve bonnet. Note: For core assemblies with interĆ

nal type core springs, install wide end of core spring in core asĆ

sembly first, closed end of core springĂ protrudes from top of

core assembly.

6. For 1/8 NPT valve constructions, Torque valve bonnet to 90 ± Ă10

in-lbs [10,2 ± 1,1 Nm]. Torque solenoid base sub-assembly to

175 ± 25 in-lbs [19,8 ± 2,8 Nm].

7. Install solenoid, see separate solenoid instructions. Then make

electrical hookup to solenoid.

WARNING: To prevent the possibility of personal

injury or property damage, check valve for proper opĆ

eration before returning to service. Also perform inĆ

ternal seat and external leakage tests with a nonhazĆ

ardous, noncombustible fluid.

8. Restore line pressure and electrical power supply to valve.

9. After maintenance is completed, operate the valve a few times

to be sure of proper operation. A metallic click signifies the soĆ

lenoid is operating.

OR ERING INFORMATION

FOR ASCO REBUIL KITS

Parts marked with an asterisk (*) in the exploded view are supplied in

Rebuild Kits. When Ordering Rebuild Kits for ASCO valves, order

the Rebuild Kit number stamped on the valve nameplate. If the numĆ

ber of the kit is not visible, order by indicating the number of kits reĆ

quired, and the Catalog Number and Serial Number of the valve(s)

for which they are intended.

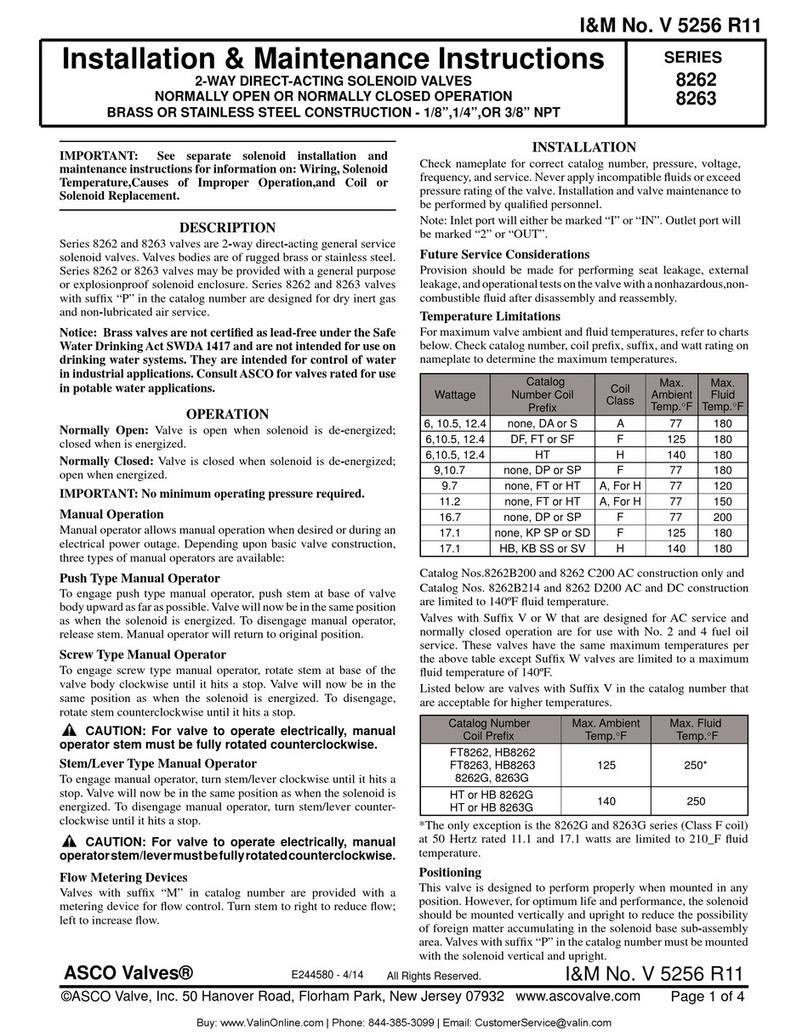

Metering

Device Manual

Operator

body

(1/8 NPT only)

O-ring

stem

retainer

screw

Figure 1. Metering and manual operator constructions.