Nortek Sensor Buoy6

© 2018 Nortek

Function description

4

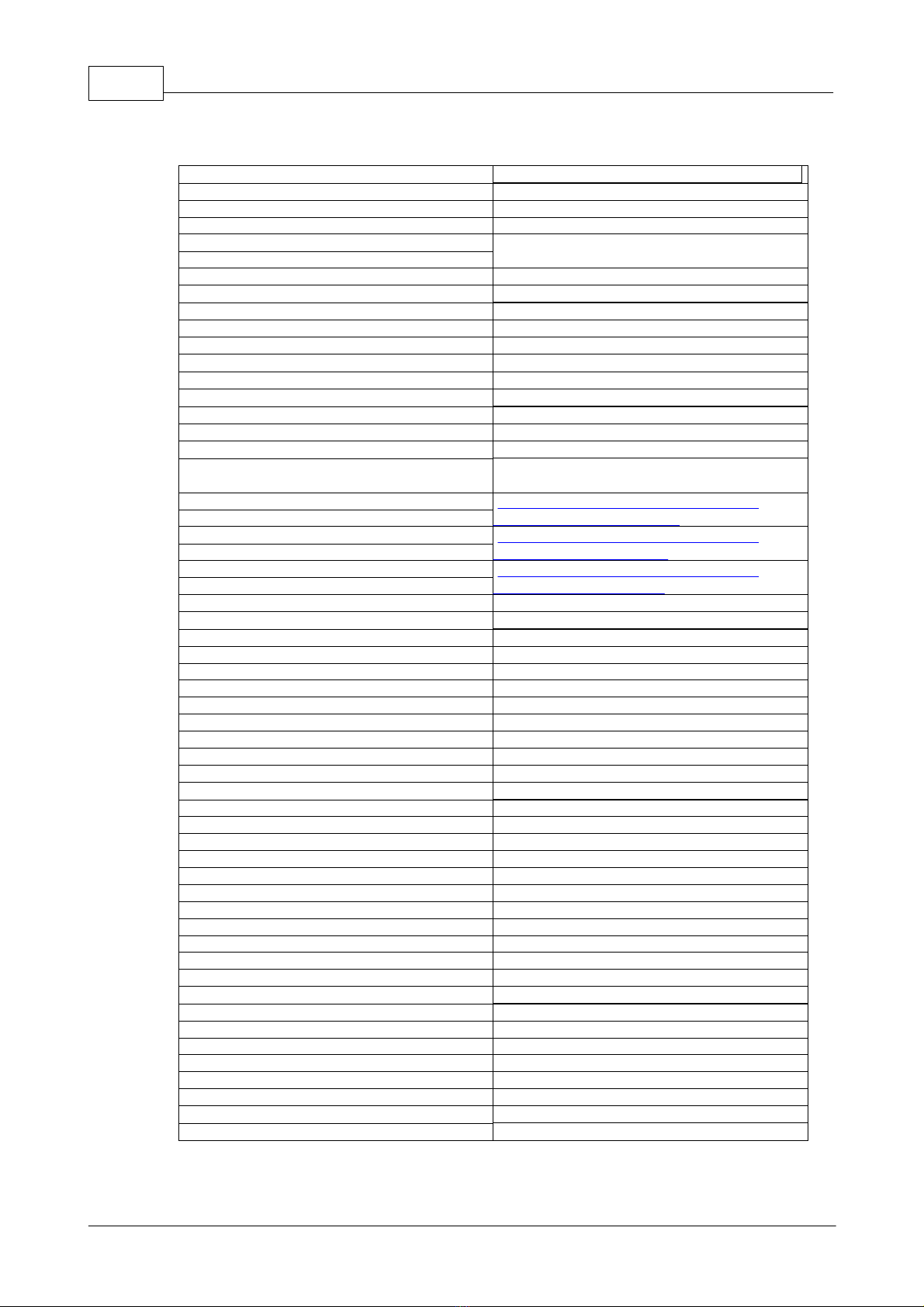

More details about sensors and current measurements are available on Nortek's website (

www.nortekgroup.com), but the summary below may be useful:

Current profiler: To start sampling, simply connect the instrument to the batteries. The

current profiler is configured to measure current speed and direction every 10.minutes, at

three depths: 5 m, 10 m and 15 m (if other is not specified).

Battery tube: Contains 6 * 100 Wh alkaline (not rechargeable) batteries. The batteries are

connected to the battery tube when shipped from Nortek. In other words, there is no need to

connect the batteries to the battery tube first time the AOS buoy is deployed.

The oxygen sensor is an optical sensor that measures percent dissolved oxygen (%

saturation), based on a method called fluorescence. The sensor sends out energy as light,

with very specific wave length (color) that goes through a material that fluoresces. Outside

the fluorescent material there is a membrane that keeps out the water, while letting in

oxygen molecules. The number of oxygen molecules is therefore in equilibrium with the

number of oxygen molecules in the water outside. When the fluorescent light hits an oxygen

molecule, the energy in the light decreases without the wavelength (color) changing.

Oxygen also causes the energy in the light to be absorbed. If there is dissolved oxygen in

the water, the returned light will have reduced energy, and this energy decrease is

proportional to oxygen content.

The salinity / conductivity sensor. Conductivity is the waters ability to conduct an electric

current, and is indicated by the unit mS / cm (milli siemens). Salinity is a measure of salt

content in a given amount of water, and is stated in g / kg (ppt). The sensor measures the

conductivity by generating an electric field in the water using a coil, then measuring this

electric field using another coil. The current measured by coil number two is proportional to

conductivity in the water. Higher salinity leads to higher electrical conductivity. Conductivity

increases at increasing temperature, therefore, the temperature is also measured. Salinity is

calculated using oceanographic tables and standard equations.

The internet webpage indicates the battery status. It is recommended to change batteries

when the indicator turns red. The procedure for change of batteries is described in chapter

8.