North American Tool Industries 51866 Operating instructions

88051870 08/11

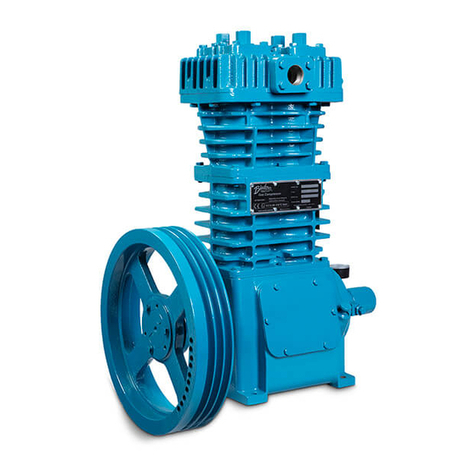

5HP 80 GALLON TWO

STAGE COMPRESSOR

CALIFORNIA PROPOSITION 65

WARNING: You can create dust

when you cut, sand, drill or grind

materials such as wood, paint,

metal, concrete, cement, or other

masonry. This dust often

contains chemicals known to

cause cancer, birth defects, or

other reproductive harm. Wear

protective gear.

WARNING: This product or its

power cord may contain

chemicals, including lead,

known to the State of California

to cause cancer and birth

defects or other reproductive

harm. Wash hands after

handling.

CAUTION:

FOR YOUR OWN SAFETY READ

INSTRUCTION MANUAL

COMPLETELY AND CAREFULLY

BEFORE OPERATING THIS

COMPRESSOR.

Failure to follow all instructions

as listed below may result in

electrical shock, fire, and/or

serious personal injury.

BREATHABLE AIR

WARNING:

This compressor/pump is not

equipped and should not be

used “as is”to supply

breathing quality air. For any

application of air for human

consumption, the air

compressor/pump will need

to be fitted with suitable in-

line safety and alarm

equipment. This additional

equipment is necessary to

properly filter and purify the

air to meet minimal

specifications for Grade D

breathing as described in

Compressed Gas Association

Commodity Specification G

7.1 - 1966, OSHA 29 CFR

1910. 134, and/or Canadian

Standards Associations

(CSA).

SPECIFICATIONS:

Tank Size: 80 gallons

PUMP RPMs: 1050

CFM: 13.0 @ 40PSI; 12.0 @ 90

PSI

Max Pressure: 150 PSI

Thermal overload protection

SAFETY WARNINGS

Disconnect power and

release all pressure from

the system before

attempting to install,

relocate, service or perform

any maintenance on this

compressor.

Never store flammable

liquids or gases near the

compressor. Electric arcs

can be produced by the

electric motor and pressure

switch.

Do not operate the

compressor without the

belt guard in place. Moving

parts can cause serious

injuries.

1) Follow all electrical and

safety codes along with

National Electrical Codes

(NEC) and Occupational

Safety and Health Act

(OSHA).

2) Electric motors and

starters must be securely and

properly grounded.

Models: 51866, 51870

feedback@natitools.com

2

3) Do not allow the cable to

come into contact with oil,

grease, chemicals or sharp

objects. Do not allow kinks to

form in the cable.

4) Do not exceed the pressure

limits for any component in or

connected to the system.

5) Inspect the compressor to

make sure that all the fittings,

bolts, etc., are tight and secure

before starting the compressor.

6) Do not touch the compressor

or motor while it is in operation.

These parts become HOT

during normal operation. Allow

the unit to cool completely

before performing maintenance

or repairs.

7) Do not increase the settings

on control components. These

settings provide safety against

over pressurization. The

pressure switch settings are

preset at the factory for normal

operating conditions and

increasing the settings will

result in compressor and motor

damage.

8) Regularly inspect the hoses,

plugs, fittings, piping, wires,

etc., for signs of damage,

weakness or leakage before

starting and using the

compressor.

9) Fast moving air can stir up

dust and debris, which may be

harmful. Release the air slowly

when draining moisture

or depressurizing the unit.

10) Tanks rust and weaken with

moisture. Ensure the tank is

drained daily to avoid rust

formation.

11) Inspect the air tank for rust,

pin holes, cracks (especially in

rear welds), bulges and other

changes in the tank.

12) Never weld or drill holes in

the air tank.

13) Keep others at a safe

distance from the work area.

SPRAYING

PRECAUTIONS

1) Always wear a respirator and

safety glasses when spraying.

2) Always spray in an open, well-

ventilated area to prevent fumes

from accumulating and causing

fire and health hazards. Fumes

are dangerous.

3) Do not spray materials near

open flames and electrical

equipment.

4) Do not smoke while spraying

insecticides, paint or other

flammable substances.

5) Do not direct paint or other

sprayed material at the

compressor. Make sure the

compressor is as far away from

the spraying area as possible to

minimize overspray accumulation

on the compressor.

6) When spraying solvents or

chemicals, follow the

instructions that are provided

by the manufacturer.

7) Never use air pressurized

accessories or parts in the air

system that are not suitable for

150 PSI.

When high humidity is present

or when a compressor is used

for an extended period of time,

moisture will collect in the tank.

This condensation can cause

water droplets to appear in

paint that is sprayed. To

eliminate this moisture, drain

the tank often to reduce the

buildup. A filter in the air line

can help eliminate this

moisture when it is located as

near to the gun as possible.

INSTALLATION

Location

It is extremely important to

install the compressor in a

clean, well-ventilated area.

Make sure the temperature will

not exceed 100 degrees

Fahrenheit. A minimum

clearance of 12 to 18 inches

between the compressor fly

wheel or fan and walls is

required because objects could

obstruct the air flow.

Do not locate the

compressor air inlet near

steam, paint spray,

sandblast areas or any other

source of contamination.

feedback@natitools.com

3

Tank Mounting

The tank should be bolted on a

concrete floor or on a separate

concrete foundation. Vibration

isolators can be used between

the tank leg and the floor. When

using isolator pads, do not draw

bolts tight. Allow the pads to

absorb vibrations. When

isolators are used, a flexible

coupling should be installed

between the tank and service

piping.

Vertical tanks have three feet

and do not need shimming as

long as the floor or foundation is

level.

Never use wood shipping

skids for mounting the

compressor!

Installing A Shut Off Valve

A shut off valve should be

installed on the discharge port

of the tank to control the air flow

out of the tank. The valve

should e located between the

tank and the piping system.

Do not install a shut off valve

between the compressor

pump and the tank. Personal

injury and/or equipment

damage could occur.

Piping

If a pipe line is used, the line

must be at least ¾inch NPT.

Smaller piping restricts the air

flow. Use 1 inch NPT pipe if the

pipe line is over 100 feet

long in order to prevent

excessive pressure drops.

Bury underground lines below

the frost line and avoid pockets

where condensation can gather

and freeze.

Apply air pressure to the piping

installation and make sure all

joints are free from leaks before

underground lines are covered.

Before using the compressor,

find and repair all leaks in the

piping, connections and fittings.

ELECTRICAL INSTALLATION

All wiring and electrical

connections should be

performed by a qualified

electrician. Installation must

be in accordance with local

and national electrical codes.

Grounding

This unit must be grounded.

Grounding the compressor

reduces the risk of electrical

shock by providing an escape

wire for the electric current if a

short circuit occurs. This product

must be equipped with a power

cord or cable that provides a

grounding wire.

Improperly grounded motors

and starters are shock

hazards. Ensure all equipment

is properly grounded.

Wiring

Have an electrician connect the

feedback@natitools.com

unit to an appropriate line

disconnect service and make

sure that the electric disconnect

and fuse box are large enough

and located within sight distance

of the compressor, the service is

of adequate ampere rating, the

supply line has the same

electrical characteristics (phase,

cycles, voltage) as the motor,

and the line wire is the proper

size and no other equipment is

operated from the same line.

ALWAYS INSURE THE MOTOR

IS ROTATING “Clockwise”when

facing the front of the

compressor.

ASSEMBLY INSTRUCTIONS

Do not operate the compressor

without lubricant or with low

lubricant levels.

1) Check the oil level. Add

additional oil if needed. If using

for the first time, pour 30W non

detergent S.A.E.oil into the pump

crankcase until the oil reaches

the red dot on the oil level sight

glass. Do not over fill.

2) Install oil fill plug before

starting.

3) Close the tank valve on the

bottom of the air tank by turning

the valve clockwise.

4) A shut off valve (ideally ¾”)

should be installed on the

discharge port of the tank. Use

Teflon tape on the threads to

ensure an airtight connection

between the tank and the

plumbing or hose coupler. Do not

over tighten the fittings.

5) Attach the supplied air filter to

4

the air intake port on the pump

head.

6) Attach the air hose and any

desired accessories (not

included). Use Teflon tape on

the threads to ensure an airtight

connection. Do not over tighten

the fittings. Note: Vibration

isolator pads are recommended

prior to bolting to the floor. Only

mount the compressor to a

concrete floor or concrete pad.

OPERATING

INSTRUCTIONS

Start Up

1) Turn the ON/OFF switch to

the off position.

2) Check the air compressor

visually for any damage or

obstruction.

3) Close the drain valve.

4) Turn the ON/OFF switch to

the ON position and the

compressor should start and

build air pressure in the tank to

cut-out pressure and then shut

off automatically.

5) It is recommended that an

inline regulator or FRL is

installed before using this air

compressor. A regulator will

insure the proper recommended

operating pressure (PSI) setting

is used for the air tool or air

accessory being used.

7) The air compressor is ready

for use

.Once started, the compressor

will start and stop

automatically until the power

is disconnected.

ASME Safety Valve

DO NOT REMOVE OR TAMPER

WITH THIS VALVE. This valve

automatically releases air if the

tank pressure exceeds the preset

maximum for this unit (150 PSI).

This valve should be checked

occasionally by pulling the ring

by hand. If air leaks after the ring

has been released, or the valve

cannot be actuated by the ring

and is stuck, the valve MUST be

replaced.

Shut Down

1) Turn the ON/OFF switch to the

OFF position.

2) Unplug the power cord from

the receptacle.

3) Set the outlet pressure to zero

on the regulator.

4) Remove any air tools or

accessories.

5) Open the drain valve allowing

air to bleed from the tank. After

all of the air has bled from the

tank, close the drain valve to

prevent debris buildup in the

valve.

Water that remains in the tank

during storage will corrode and

weaken the air tank which could

cause the tank to rupture. To

avoid serous injury, ensure the

feedback@natitools.com

tank is drained properly after

each use or daily.

Check the tank safety valve and

air filter before each use.

MAINTENANCE

Before starting maintenance,

ensure the air compressor is

turned off, disconnected from the

power source, the tank is drained

and the compressor is cooled

down completely.

Never repair a cracked tank or

personal injury could occur.

Daily:

- Check oil level

- Drain accumulated liquid from

tank

- Check for oil leaks

- Check for unusual noise and/or

vibrations

- Check all fasteners are secure

Weekly:

- Check safety relief valve. DO

NOT DISSASEMBLE THE

VALVE WITH AIR IN TANK.

- Inspect and clean air filter

- Clean breather holes on oil

check dipstick

Monthly:

- Check for air leaks by applying

a solution of soapy water around

joints. Look for air bubbles

around joints when the

compressor reaches the

pressure cut-out limit and pump

turns off.

- Check all nuts and bolts are

tight

5

Six months or 250 operating

hours:

- Change compressor oil (SAE

20 or 30)

Replace oil more frequently

when used in dusty operating

environments.

CHANGING THE OIL

1) Place oil drain pan below the

oil drain plug.

2) Remove oil cap to allow the

air to enter the crankcase.

3) Remove oil drain plug.

4) Allow oil to drain completely.

5) Clean and replace oil drain

plug.

6) Refill crankcase with SAE 20

or SAE 30 weight non-detergent

oil to the red dot on the oil level

sight glass. Be careful not to

overfill the tank.

Do not use multi-grade, ATF,

hydraulic fluid, two-cycle oil or

any other improper oils because

it will void the warranty. Using

automotive engine oils may

cause carbon deposits on

valves and can shorten valve

life.

Changing Filter

Never run the compressor

without an intake air filter or with

a clogged intake air filter. Use

compressed air to blow the filter

clean. If the filter

cannot be blown clean, the filter

should be replaced.

Do not allow intercooler fins to

become clogged with dirt, lint,

dust, paint, etc. If surrounding

air is dirty and is causing the

intercooler to clog, move the

compressor to a cleaner area

or use duct work to bring

clean air into the cooling fan

intake.

feedback@natitools.com

6

feedback@natitools.com

Symptom Possible Cause(s) Possible Solutions

Fuse blown or circuit breaker

tripped

Check for cause of blown

fuse/breaker and replace

Loose electrical connections Check wiring connections

Overheated motor

Turn compressor off, wait until total cool

down. Check to insure the motor is

rotating "clockwise" when facing the

front of the compressor before

restarting

Air leak in safety valve

Check valve manually by pulling

upwards on ring. If condition

persists, replace valve

Defective check valve Replace check valve

Safety valve releasing

Defective pressure switch or

improper adjustment

Check for proper adjustment and if

problem persists, replace pressure

switch

Loose drain valve Tighten drain value

Loose connections at regulator or

pressure switch

Check connections for leaks, seal

with teflon tape

Excessive water in tank Drain tank through drain valve

Humidity too high

Move compressor to an area of less

humidity.

Improper oil viscosity

Replace oil with SAE 20-30 weight

non-detergent oil

Too much oil in crankcase

Drain crankcase and fill to proper

level

Compressor overheated Air pressure regulated too high

Restricted air filter Clean or replace filter

Worn piston rings Replace piston rings

Oil discharge in air

No start condition

Low pressure

Tank pressure drops

when compressor is shut

off

Excessive moisture

coming out of air hose

7

feedback@natitools.com

North American Tool Industries (NATI) makes every effort to ensure that this product meets high quality

and durability standards. NATI warrants to the original retail consumer a 1-year limited warranty from

the date the product was purchased at retail and each product is free from defects in materials.

Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents,

repairs or alterations, or a lack of maintenance. This product is intended for personal use. The warranty

will be voided if used in commercial, rental, or industrial applications. NATI shall in no event be liable for

death, injuries to persons or property, or for incidental, special or consequential damages arising from

the use of our products. To receive service under warranty, the original manufacturer part must be

returned for examination by an authorized service center. Shipping and handling charges may apply. If

a defect is found, NATI will either repair or replace the product at its discretion.

DO NOT RETURN TO STORE

For Customer Service:

Email feedback@natitools.com or Call 1-800-348-5004

89051870 08/11

5HP 80 GALLON TWO STAGE COMPRESSOR

Models: 51866, 51870

feedback@natitools.com

8

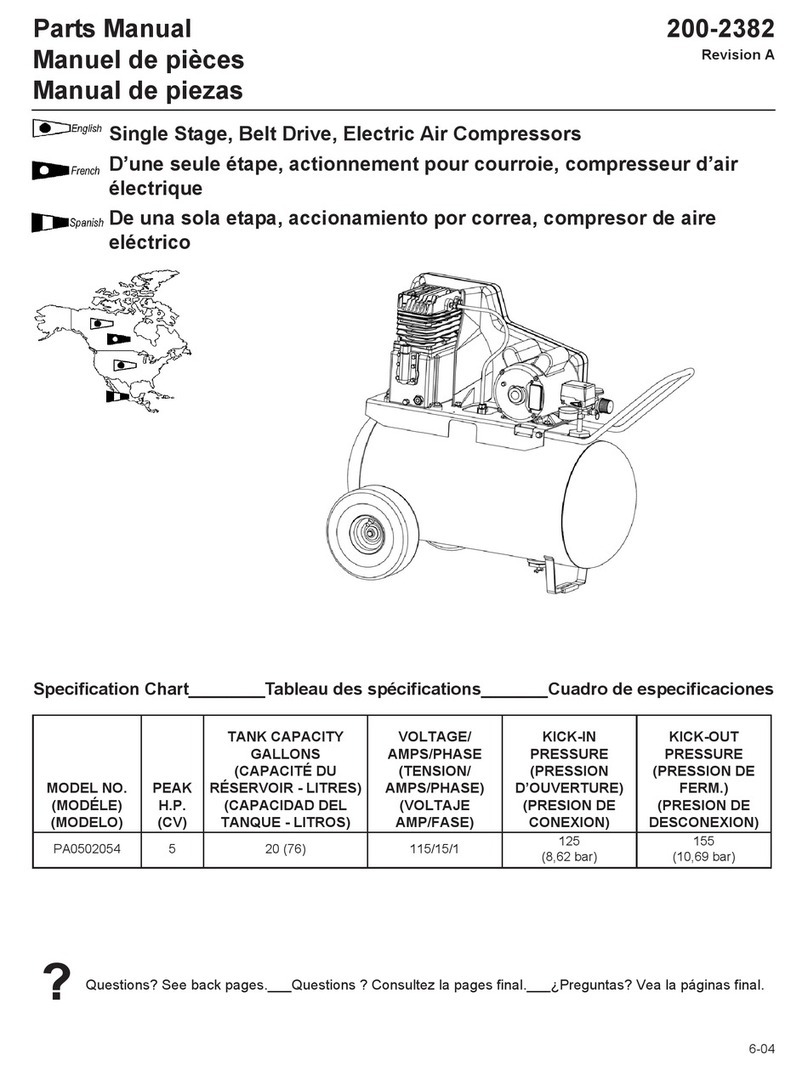

72

2

feedback@natitools.com 9

No. Description Qty No. Description Qty

1 Bolt 4 33 Bolt 4

2 Spring Washer 4 34 Spring Washer 4

3 Cylinder Head 1 35 Cylinder 1

4 Rear Cover Air Filter 1 36 Cylinder Gasket 1

5 Cylinder Head Gasket 1 37 Piston Ring Set 2

6 Valve Plate 2 38 Oil Ring 1

7 Valve Seat 1 39 Spring Washer 2

8 Cylinder Head Gasket 1 40 Piston Pin 1

9 Valve Seat 1 41 Piston 1

10 Cylinder Gasket 1 42 Connecting Rod 1

11 Bolt 4 43 Splasher 1

12 Spring Washer 4 44 Spring Washer 1

13 Cylinder 1 45 Cross Recess Head Screw 1

14 Cylinder Gasket 1 46 Bolt 1

15 Piston Ring Set 2 47 Spring Washer 1

16 Oil Ring 148 Pulley Washer 1

17 Spring Washer 2 49 Pulley 1

18 Piston Pin 1 50 Bolt 4

19 Piston 1 51 Bearing Seat 1

20 Connecting Rod 1 52 Gasket Bearing Seat 1

21 Splasher 1 53 Oil Seal 1

22 Spring Washer 1 54 Bearing 1

23 Cross Recess Head Screw 1 55 Crankshaft 1

24 Bolt 4 56 Oil Filling Plug 1

25 Spring Washer 4 57 Oil Breather 1

26 Exhaust Elbow 1 58 Motor Bolt 4

27 Cylinder Head 1 59 Washer 4

28 Cylinder Head Gasket 1 60 Six Angle Nut 1

29 Valve Seat 1 61 Crankcase 1

30 Cylinder Head Gasket 1 62 Bearing 1

31 Valve Seat 1 63 Oil Leveler Washer 1

32 Cylinder Head Gasket 1 64 Oil Leveler 1

2

feedback@natitools.com 10

No. Description Qty

65 Oil Drain Plug 1

66 Motor 1

67 Woodruff Key 1

68 Motor Pulley 1

69 V-Belt 2

70 Electric Cable 1

72 Valve Plate 2

74 Air Tank 1

79 Drain Valve 1

81 Check Valve 1

82 Unload Elbow 1

83 Unload Pipe 1

84 Unload Nut 1

85 Pressure Gauge 1

86 Safety Valve 1

87 Nipple 1

88 Pressure Switch 1

89 Quick Connector 1

90 Belt Guard 1

91 Spring Washer 1

92 Bolt 1

93

Exhaust Pipe Assembly

1

94 Exhaust Tube Pipe 1

95 Exhaust tube Elbow 1

This manual suits for next models

1

Table of contents

Other North American Tool Industries Air Compressor manuals

Popular Air Compressor manuals by other brands

4tek

4tek ECO Series Operating and maintenance manual

Ryobi

Ryobi R18I-0 Original instructions

Michelin

Michelin MBL 6V2/1100 user guide

Crown

Crown CT36073 Original instructions

BLACKMER

BLACKMER LB161B Installation, operation & maintenance instructions

Euromate

Euromate B-KPS-24/165 Translation of the original instructions