North American Tool 9528 Operating instructions

8809528 06/12

9 GALLON 6.5HP TWIN TANK

GAS AIR COMPRESSOR

DO NOT RETURN TO

STORE. Please CALL

800-348-5004 for parts

and service.

CALIFORNIA PROPOSITION 65

WARNING: You can create dust

when you cut, sand, drill or grind

materials such as wood, paint,

metal, concrete, cement, or other

masonry. This dust often

contains chemicals known to

cause cancer, birth defects, or

other reproductive harm. Wear

protective gear.

WARNING: This product or its

power cord may contain

chemicals, including lead,

known to the State of California

to cause cancer and birth

defects or other reproductive

harm. Wash hands after

handling.

Important!

When using equipment, a few

safety precautions must be

observed to avoid injuries and

damage. Please read the complete

operating manual with due care.

Keep this manual in a safe place,

so that the information

is available at all times. If you

give the equipment to any other

person, give them these

operating instructions as well.

We accept no liability for

damage or accidents which

arise due to non-observance of

these instructions and the

safety information herein.

SPECIFICATIONS

Engine: 6.5 HP OHV

Tank capacity: 9 gallons

Pressure: 115 PSI

Speed: 1150 RPMs

12 CFM @ 90 PSI

CAUTION:

FOR YOUR OWN SAFETY,

READ INSTRUCTION

MANUAL COMPLETELY AND

CAREFULLY BEFORE

OPERATING THIS GAS

COMPRESSOR.

Any failures made in

following the safety

regulations and instructions

may result in an electric

shock, fire and/or serious

injury.

SAFETY INSTRUCTIONS

1) Only persons who are

familiar with these

instructions and warnings

should operate this

compressor.

2) Do not allow children in the

work area and keep visitors

back away from equipment.

3) Use safety glasses and

hearing protection when you

are operating this unit.

4) Do not stand on the unit or

use it as a handhold.

5) Before each use, inspect

the compressor for signs of

damage, deterioration,

weakness or leakage. Repair

or replace damaged items

before use.

6) Check the fasteners at

frequent intervals to ensure

proper tightness.

7) Motors, electrical

equipment and their

Model: 9528,7295

For customer service, call 1-800-348-5004 or email feedback@natitools.com

2

controls can cause electrical

arcs that could ignite flammable

gas or vapors. Do not store any

flammable liquids or gases near

the compressor.

8) Carbon monoxide is

produced when operating this

unit and can cause severe

nausea, fainting or death. Do

not operate this unit in a poorly

ventilated area or while inside a

closed building.

9) Never operate a compressor

without a belt guard. It is

possible for a compressor to

start without warning. Personal

injury or property damage could

occur from coming in contact

with moving parts.

10) Do not wear loose clothing

or jewelry. Keep long hair pulled

back.

11) Compressor parts may be

hot even though the unit may be

stopped.

12) Keep fingers and

appendages away from the

compressor while it is running.

Fast moving and hot parts can

cause injury and/or burns.

13) If any of the equipment

starts to vibrate abnormally,

stop the engine/motor and

inspect the unit immediately for

the cause.

20) Make sure to drain the tank

regularly and inspect it

periodically for unsafe conditions

such as rust and corrosion.

21) Release air slowly when

draining moisture or

depressurizing the air

compressor system. Fast moving

air will stir up dust and debris,

which may be harmful.

22) Stop the engine and make

sure all moving parts have

stopped when leaving the work

area, before cleaning, making

repairs or inspecting the unit.

23) Allow the engine to cool

before storing the unit.

24) Do not spray flammable

materials within the vicinity of an

open flame or near ignition

sources, including the

compressor unit.

25) Do not smoke when spraying

paint, insecticides or other

flammable substances.

26) Use a facemask when

spraying. Spray in a well

ventilated area to prevent health

and fire hazards.

27) Do not direct any sprayed

materials at the compressor.

Keep the compressor as far

away as possible from the

spraying area to minimize the

accumulation on the compressor.

14) Never refuel a running or

hot engine. Fuel is explosive

and can cause fires and severe

burns. Avoid overfilling the fuel

tank.

15) Check the fuel level before

starting the engine. Do not fill

the gas tank while indoors.

Wipe off any spilled gas from

the unit before starting the

engine.

16) Gasoline vapors are highly

flammable. Only refill the tank

outdoors or in a well-ventilated

area. Do not store, use or allow

spills near an open flame or

heat devices that utilize a pilot

light or could create a spark. If

gasoline is spilt, move the unit

away from the spill and avoid

creating any sparks until the

vapors have evaporated.

17) In order to reduce the fire

hazard, keep the engine and

motor exterior free of oil,

solvents or excessive grease.

18) Never remove or attempt to

adjust the safety valve. Keep

the safety valve free from paint

and other accumulations.

19) Never attempt to repair or

modify a tank. Welding, drilling

or any other modifications made

will weaken the tank and result

in damage by rupture or

explosion. Always replace worn

or damaged tanks.

feedback@natitools.com

3

OPERATION

Start Up

1) Add 87 octane (or higher)

unleaded gasoline to the engine

gas tank and SAE 10W-30 oil to

the engine oil tank. A different

viscosity oil may be required if

the compressor is operated at

different ambient temperatures.

Please refer to the engine

manual for more details.

2) Remove the compressor

dipstick breather and fill the

pump to the proper oil level.

Use a single viscosity, ISO 100

(SAE 30) non-detergent

compressor oil. Do not use a

multi viscosity oil such as 10W-

30.

3) Turn the outlet valve or

regulator knob counterclockwise

to open the airflow.

4) Turn the manual unloader

lever to a vertical position in

order to allow the compressor

pump to run without

compressing air.

Starting A Gasoline Engine

1) Move the choke lever to the

CHOKE position and turn the

stop lever towards the ON

position.

2) Pull the start grip lightly until

resistance is felt, then pull on the

start grip briskly to start the

engine.

3) As the engine begins to warm

up, gradually move the choke

lever to the OPEN position.

4) Run the compressor at an

unloaded speed for

approximately 30 minutes in

order to break in the pump.

5) After approximately 30

minutes of run time, move the

unloader lever down to the

loaded position and turn the

regulator knob clockwise. The

compressor will begin to pump

air into the tank at this time.

When the maximum tank

pressure is achieved, the

compressor automatically

unloads, which brings the

engine to idle. The engine

remains at the idle state until the

pressure in the tank falls to a

preset level. The engine will then

accelerate and the compressor

will pump additional air into the

tank.

MAINTENANCE

WARNING: Release all

pressure from the system

before attempting to perform

any maintenance, relocate,

service or install the unit.

Check the air filter, oil level and

gasoline level before each use in

order to maintain efficient

operation of the unit.

The ASME safety valve should

be checked before each use. Pull

the ring on the safety valve and

allow the ring to snap back into

its normal position. This valve

automatically releases air if the

tank pressure exceeds a preset

maximum. If air leaks after the

ring has been released, or if the

valve is stuck and cannot be

actuated by the ring, the ASME

safety valve must be replaced.

Do not attempt to tamper with

the ASME safety valve.

With the engine OFF, clean any

debris from the engine, flywheel,

tank, air lines and pump cooling

fins.

Never attempt to repair or

feedback@natitools.com

4

modify the tank. Welding,

drilling or any other

modifications will weaken the

tank and could result in

damage from rupture or

explosion. Always replace

worn, cracked or damaged

tanks as soon as possible.

Drain liquid from the tank at

the end of each use.

Drive Belt

Belts will stretch as a result of

normal use. When they are

properly adjusted, the belt

deflects about ½inch with 5

pounds of pressure applied

midway between the engine

pulley and pump.

To adjust the drive belt tension:

1) Remove the belt guard and

loosen the engine brace.

2) Loosen the four fasteners

that are holding the motor to the

base plate.

3) Shift the motor in the proper

direction. The belt must be

properly aligned when this

adjustment is made.

4) To align the belt, lay a

straight edge against the face of

the flywheel, touching the rim at

two places.

5) Adjust the flywheel or motor

pulley so that the belt runs

parallel to the straight edge.

6) Use a gear puller to move the

pulley on the shaft and to tighten

the fasteners.

7) Adjust the brace and then

tighten the fasteners, braces and

reinstall the belt guard.

Storage

1) When the unit is not in use,

the air hose and compressor

should be stored in a cool, dry

location.

2) Tanks should be drained of

moisture. The hose should be

disconnected and hung with the

open ends down to allow any

moisture to drain.

Maintenance Schedule

Check Oil: Daily

Drain Tank: Daily

Check Air Filter: Weekly

Check Safety Valve: Weekly

Blow Dirt From Inside Motor:

Weekly

Check Belt Tightness: Monthly

Change Oil: Every 3 Months

feedback@natitools.com

5

feedback@natitools.com

Problem

Possible Cause Possible Solution

Low oil shutdown Fill engine with adequate amount of oil

Cold engine Choke engine to start

No fuel

Add gas to engine. Make sure fuel shutoff

valve is open.

Engine does not turn ON Place ON/OFF switch in the ON position

Spark plug wire not

attached

Attach spark plug wire to spark plug

Air leaks in discharge

piping

Check tubing connections. Tighten joints or

replace as required.

Compressor components

are leaky, broken or

loose

Inspect the components and clear or replace

as required

Flywheel or motor pulley

is loose, excessive end

play in motor shaft or

loose drive belts

Check flywheel, motor pulley or the

crankshaft drive belt tension/alignment.

Replace or repair as required

Clogged or dirty inlet

and/or discharge line

Clean or replace

Defective safety/relief

valve

Replace

Pressure switch unloader

leaks or does not work

Realign stem or replace

Leaking, broken or worn

inlet unloader parts at

check valve

Inspect parts and replace as requried

Compressor viscosity is

too high for the ambient

temperature

Drain the existing lubricant and refill the

tank with the proper lubricant

Belt tension is too tight

or sheaves are not

aligned

Check the tension and/or alignment

Flywheel or motor pulley

is loose, excessive end

play in motor shaft or

loose drive belts

Check flywheel, motor pulley or the

crankshaft drive belt tension/alignment.

Replace or repair as required

Leaking check valve or

check valve seat is blown

out

Replace check valve

High interstage

pressure

High pressure inlet valve

leaking

Inspect, clean or repair as required

Low interstage

pressure

Low pressure inlet valve

leaking

Inspect, clean or repair as required

Engine does not

start

Air delivery drops

off

Compressor does

not come up to

speed

6

feedback@natitools.com

Problem

Possible Cause

Possible

Solution

Compressor viscosity is too high for the

ambient temperature

Drain the

existing

lubricant and

Belt tension is too tight or sheaves are not

aligned

Check the

tension

and/or

alignment

Flywheel or motor pulley is loose, excessive

end play in motor shaft or loose drive belts

Check

flywheel,

motor pulley

Leaking check valve or check valve seat is

blown out

Replace

check valve

Clogged or dirty inlet and/or discharge line

Clean or

replace

Air leaks in discharge piping

Check tubing

connections.

Tighten joins

Clogged or dirty inlet and/or discharge line

Clean or

replace

Pressure switch unloader leaks or does not

work

Realign stem

or replace

Leaking, broken or worn inlet unloader parts

at check valve

Inspect parts

and replace

as requried

Pressure switch unloader leaks or does not

work

Realign stem

or replace

Excessive condensation in receiver tank

Drain receiver

tank

Light duty cycle

Increase duty

cycle

Moisture in crankcase,

milky substance in oil

Detergent lubricant in crankcase

Replace with

proper

lubricant

Oil in discharge air Lubricant level too high

Drain excess

lubricant

Clogged or dirty inlet and/or discharge line

Clean or

replace

Defective safety/relief valve Replace

Pressure switch unloader leaks or does not

work

Realign stem

or replace

Safety/relief valve pops

Compressor is slow to

come up to speed

Compressor will not

unload cycle or will not

unload when stopped

Excessive starting or

stopping

7

feedback@natitools.com

North American Tool Industries (NATI) makes every effort to ensure that this product meets high quality

and durability standards. NATI warrants to the original retail consumer a 1-year limited warranty from

the date the product was purchased at retail and each product is free from defects in materials.

Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents,

repairs or alterations, or a lack of maintenance. This product is intended for personal use. The warranty

will be voided if used in commercial, rental, or industrial applications. NATI shall in no event be liable for

death, injuries to persons or property, or for incidental, special or consequential damages arising from

the use of our products. To receive service under warranty, the original manufacturer part must be

returned for examination by an authorized service center. Shipping and handling charges may apply. If

a defect is found, NATI will either repair or replace the product at its discretion.

DO NOT RETURN TO STORE

For Customer Service:

Email feedback@natitools.com or Call 1-800-348-5004

8909528 12/13

9 GALLON 6.5HP TWIN TANK

GAS AIR COMPRESSOR

8

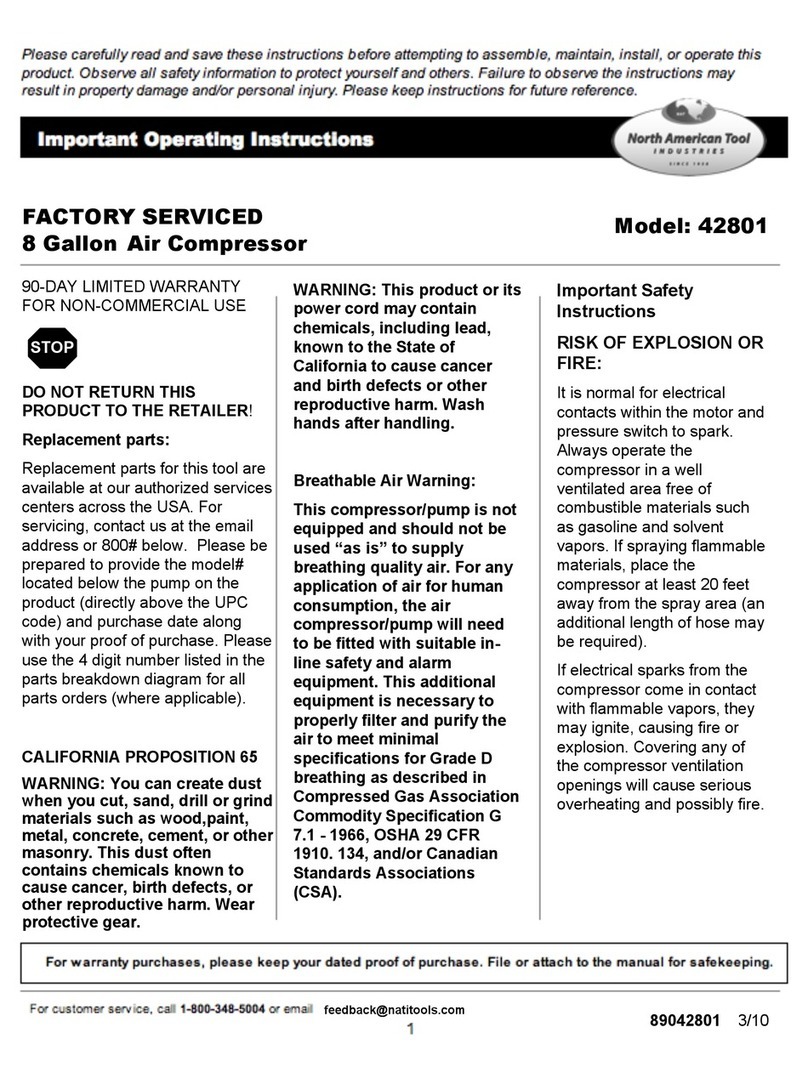

Exploded View

For customer service, call 1-800-348-5004 or email feedback@natitools.com

9

4Spring Washer19

1Tank14

1Bolt15

4Spring Washer16

4Cotter Pin17

4Bolt18

425261Comb Valve13

42525

42524

42530

42523

SKU#

1Pump11

1Discharge Tube12

1Belt Guard10

4Nut9

4Washer8

4Bolt7

4Nut6

4Spring Washer5

4Bolt4

1Bolt3

1Cable2

1Engine1

QTYDescriptionNo.

409422Drain Valve28

425292Quick Connect29

2Bolt30

425311Pressure Gauge31

425321Safety Valve32

425331Regulator33

1Grip34

425341

Plastic Supply

Line

35

1

Quick Connect

Manifold

36

409331Pressure Gauge37

4Washer26

4Bolt27

385274Bumper25

42528

42527

SKU#

4Nut23

4Spring Washer24

1Tire22

4Axle21

4Cotter Pin20

QTYDescriptionNo.

feedback@natitools.com

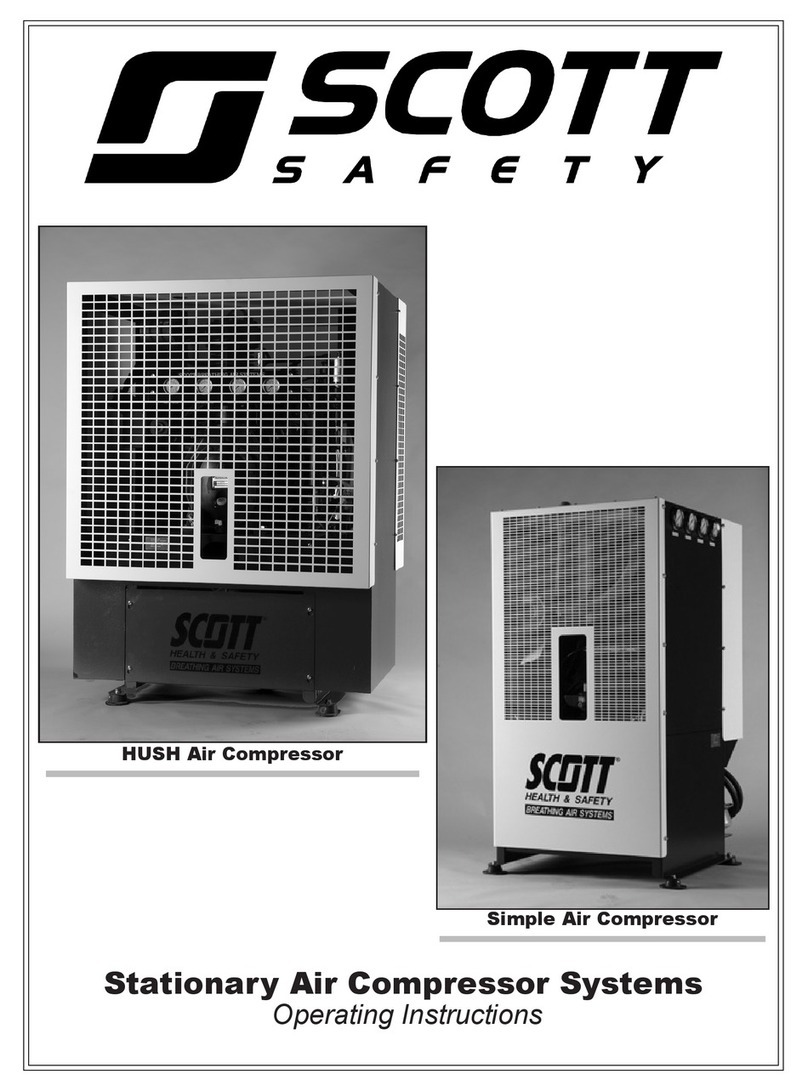

Pump Assembly

10

For customer service, call 1-800-348-5004 or email feedback@natitools.com

11

42551

42550

42549

42548

42547

42546

42545

42544

42543

42542

42541

42540

42539

42538

42537

41020

41002

42536

42535

SKU#

Bolt24

Oil Needle23

Connector Rod22

Piston Pin21

Piston20

Retaining Ring in Hole19

Oil Ring18

Compressor Ring17

Cylinder Down Washer16

Cylinder15

Split Washer14

Bolt13

Cylinder Up Washer12

Valve Plate11

Valve Seat10

Aluminum Washer9

Head Washer8

Aluminum Pipe7

Elbow6

Exhaust Elbow5

Filter4

Head3

Split Washer2

Bolt1

DescriptionNo.

42554

42553

42552

SKU#

Bolt47

M8 Nut46

Split Washer45

Bolt44

Split Washer43

Pulley42

Bolt41

Crankcase Back Cover40

Crankcase Back

Washer

39

O-Ring38

Bearing37

Crank Shaft36

Crankcase35

Oil Drain Plug34

O-Ring33

Oil Window32

Bearing31

Crankcase Washer30

Crankcase Cover29

Bolt28

Split Washer27

Bolt26

Split Washer25

DescriptionNo.

feedback@natitools.com

This manual suits for next models

1

Table of contents

Other North American Tool Air Compressor manuals

Popular Air Compressor manuals by other brands

Scott Safety

Scott Safety Simple operating instructions

hecht

hecht 2360 TRANSLATION OF ORIGINAL INSTRUCTIONS FOR USE

PUMP'IN

PUMP'IN ONE user manual

Danfoss

Danfoss Turbocor TT-300 user manual

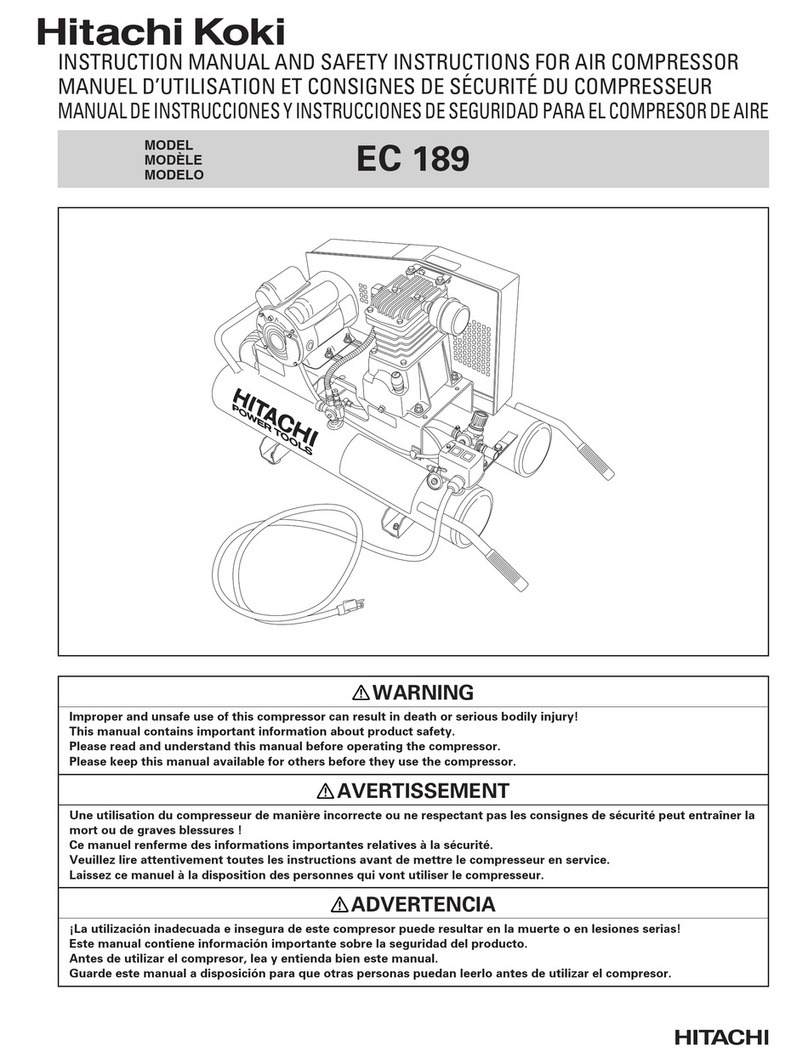

Hitachi Koki

Hitachi Koki EC 189 Instruction manual and safety instructions

Scheppach

Scheppach HC06 Translation of original instruction manual

BE

BE AC708RB Operation manual

Marshalltown Company

Marshalltown Company DUOFLEX HC125A user manual

Parkside

Parkside PKZ 180 B2 Translation of the original instructions

BorMann

BorMann BWR5066 owner's manual

ABB

ABB Aztec ADS430 EZCLEAN operating instructions

Frick

Frick RXB PLUS Installation operation & maintenance