-6-

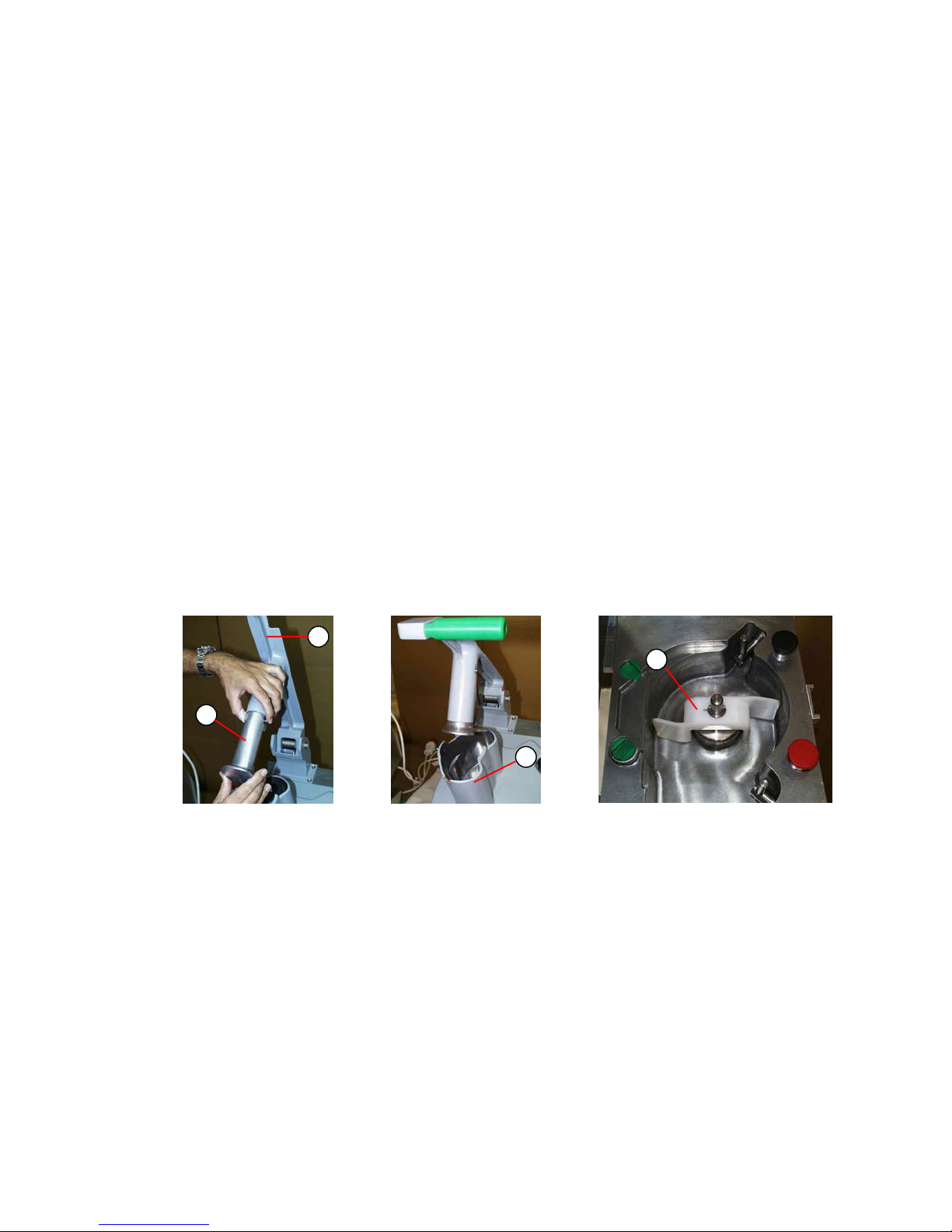

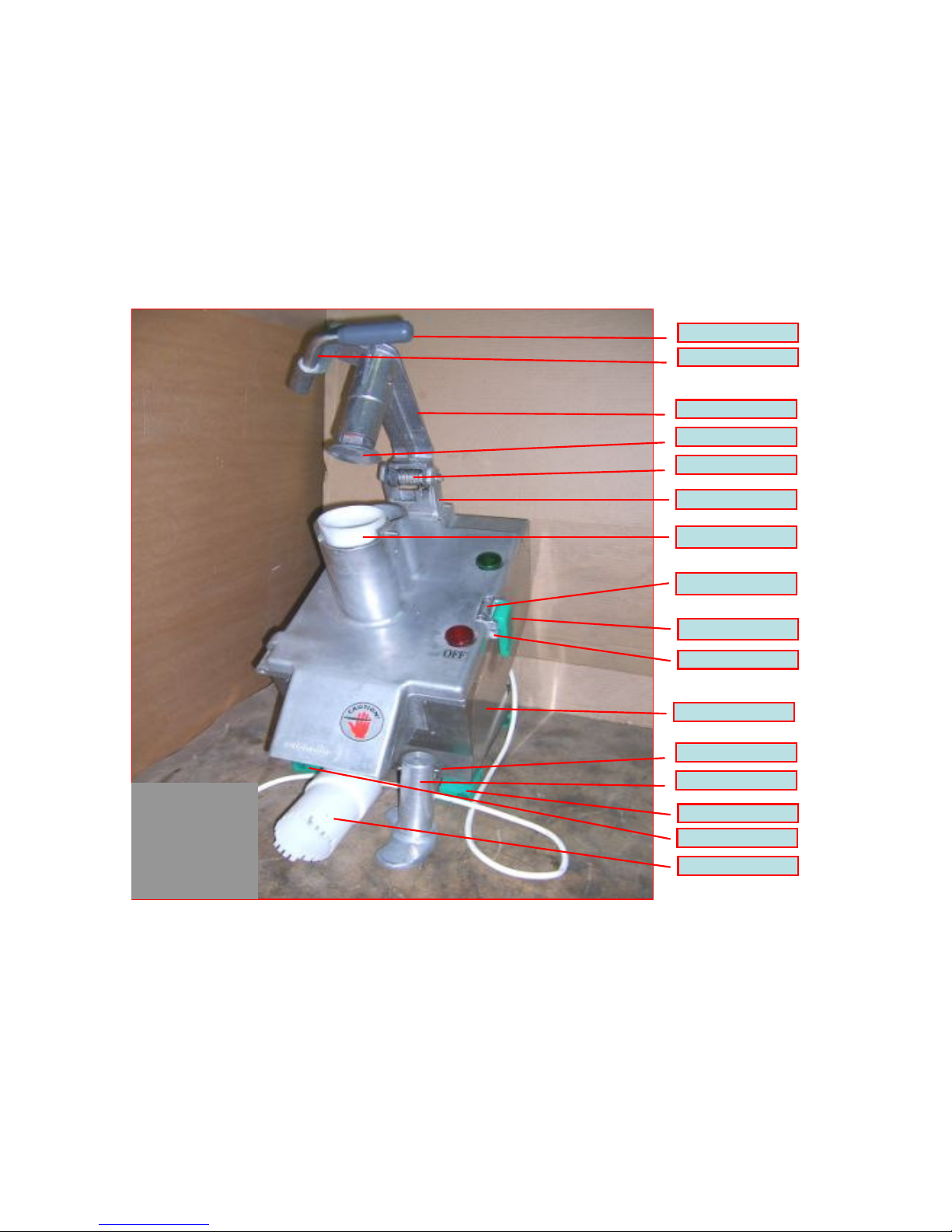

2. Prepare the feed tube. Using this method, the feed tube handle (3), together with the

adapter (9A) become the feed tube. Lower the handle and insert the plastic adapter (9A)

(see picture 4.1).

Make sure the pin set on the feed tube (30) will be inserted, by a ¼ turn, into the slit in the

Stainless Steel ear-shaped adapter (picture 4.2).

Products are inserted using the manual compressor as shown in picture 4.3.

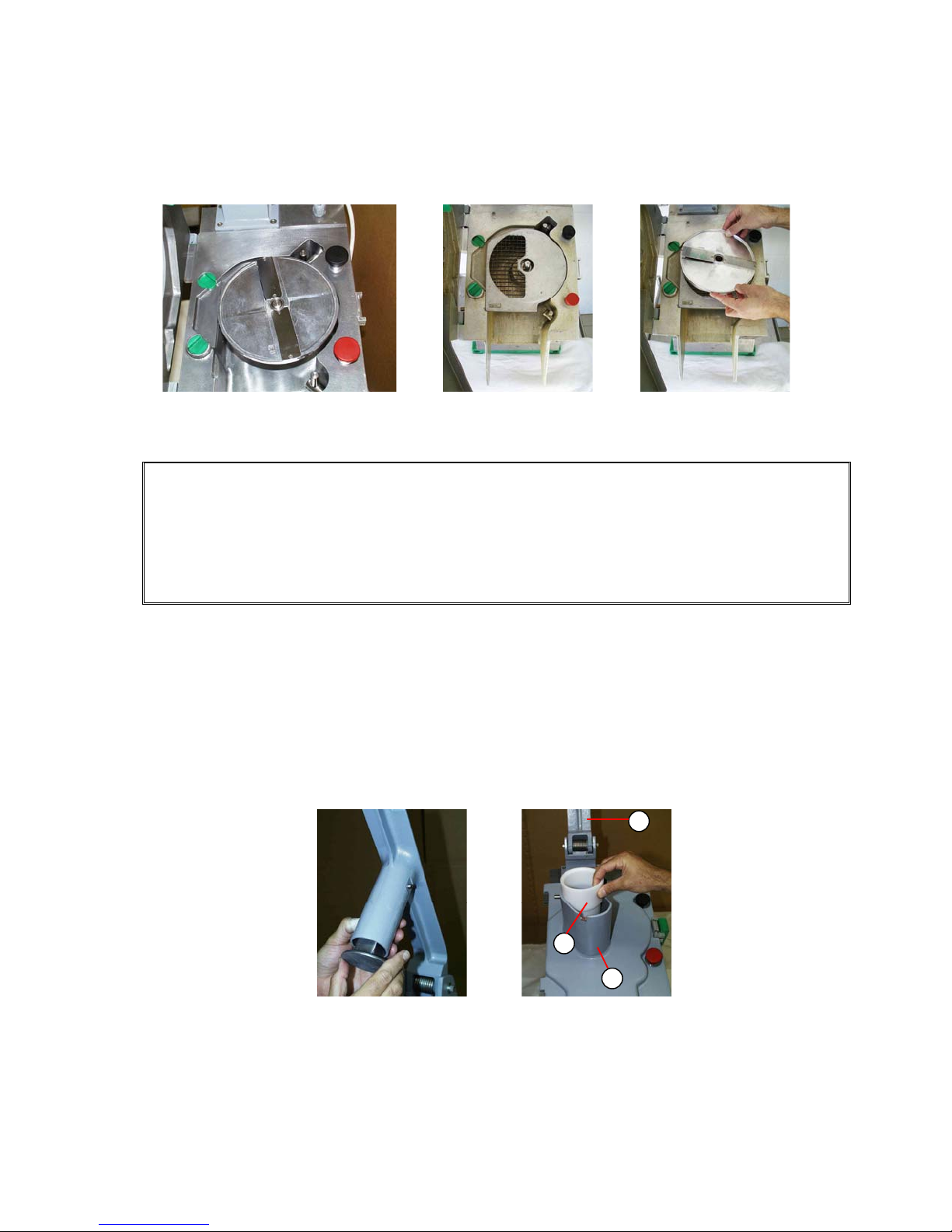

3. Prepare blades: prepare blades by selecting one of the possibilities described earlier.

Usually, one of the slicing blades is selected.

Warning!

Never insert your fingers through the cut product outlet fennel (parts 6 and

7). If any cut vegetables have accumulated it should be cleaned only after the

cover is opened!

Cleaning Operations

1. During work, when transferring between different types of slicing or products, you may

open the cover and, quite easily, manually remove remaining product from the machine

inner spaces into the collecting vessel.

2. Upon completion of work, rinse the inner parts only with running water. The cover,

which can be easily removed, can also be rinsed with running water.

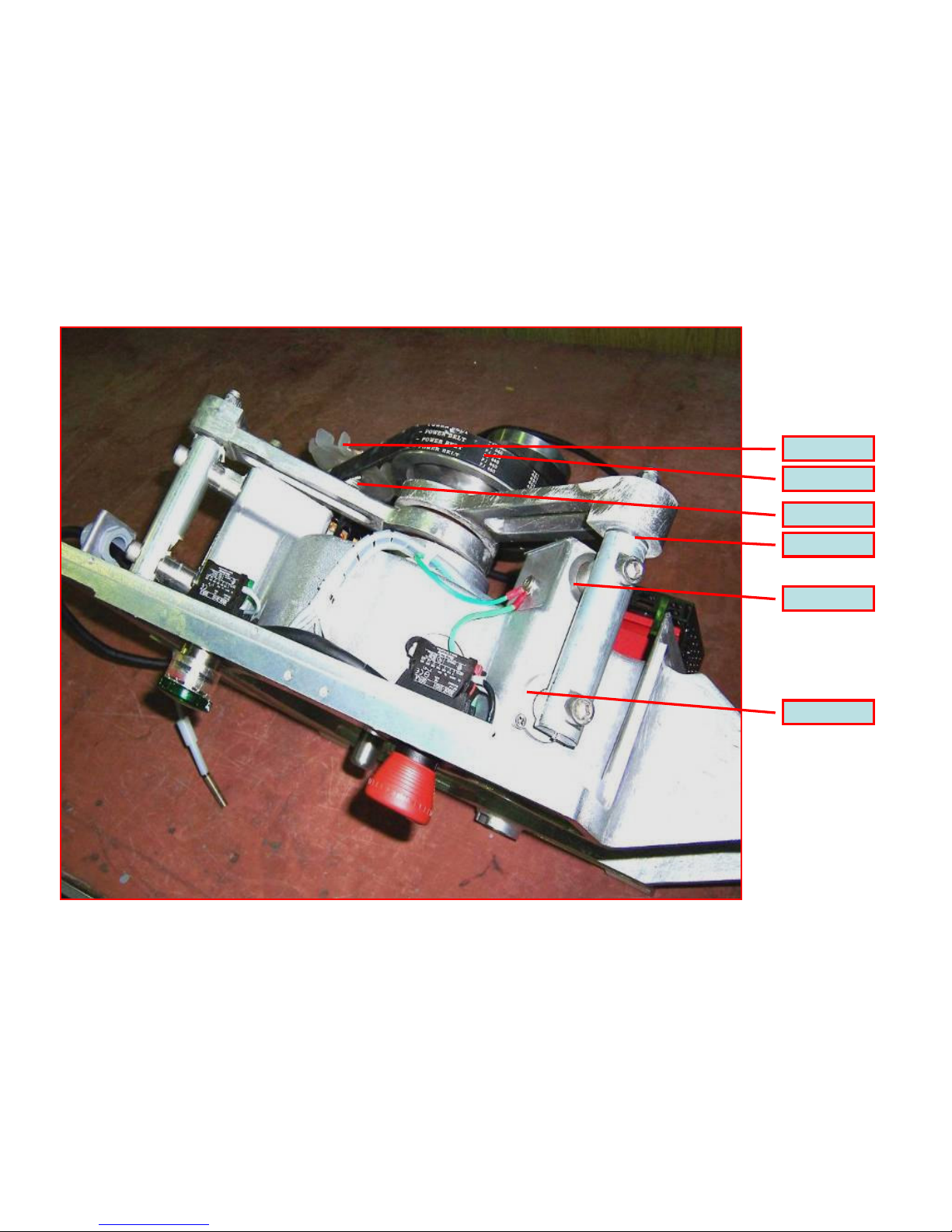

3. Warning! Never let running water come in contact with upper surface of machine

body, (see area 5C in picture 5.1), connecting line to closure (5A in picture 5.1), and

area of connection to handle (5B in picture 5.1).

These surfaces can be wiped with a damp cloth only.

4. All cutting appliances and adapters will be cleaned separately in running water. All these

Fig. 4.1 Fig. 4.3Fig. 4.2

9A

30

9

8

3

9A

5A

Fig. 5.1

5B

5C