NORTHROP GRUMMAN Iklwa II TEM00 User manual

uble Shooting Guid

SVC-UMAN-0007 C

JANUARY 2019

Service Manual

Iklwa II TEM00 Green Laser

Patara II TEM00 Green laser

© 2019 Cutting Edge Optronics, Inc. ii Patara II and Iklwa II Service Manual

Worldwide Technical Support and Product Information

http://www.northropgrumman.com/BusinessVentures/CEO/Pages/Service.aspx

http://www.ngceoservice.com/ (Knowledge Center)

Hours: 8:00 a.m. to 5:00 p.m., Central time*

Technical Support: (636) 916-4900 (follow prompts for department directory)

Cutting Edge Optronics Headquarters

20 Point West Blvd. St. Charles, MO 63301 USA

Sales Support: (636) 916-4900 (follow prompts for department directory)

*After office hours, please leave a voice mail message. Outside North America, contact an NG sales office or distributor; see the NG website

for a list of offices.

© 2019 Cutting Edge Optronics, Inc. iii Patara II and Iklwa II Service Manual

Important Information

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in whole or in part, without the

prior written consent of Northrop Grumman Corporation.

Patents

Northrop Grumman Corporation products are covered by U.S. and foreign patents, issued and pending. Information in this

publication supersedes that in all previously published material. Specifications and price change privileges reserved.

© 2019 Cutting Edge Optronics, Inc. iv Patara II and Iklwa II Service Manual

Safety Information

Product End-of-Life Handling

NG is committed to protecting the environment. In accordance with the Waste Electrical

and Electronic Equipment directive (WEEE) and Restriction of Hazardous Substances in

the European Union (RoHS EU) directives, NG accepts the return of our products for

disposal. When you are ready to reclaim the instrument, you must properly transfer it

according to local regulations concerning WEEE equipment. Contact NG or your local

distributor for shipping instructions. Please package the products as directed for a return

for repair.

ROC ROHS Declaration

In accordance with the Clause 6.2 of Marking for Control of Pollution Caused by

Electronic Information Products (SJ/T11364:2006) for Measures for the

Administration on Pollution Control of Electronic Information Products No. 39,

Order of the Ministry of Information Industry of the Peoples Republic of China,

NG includes the following translation about our products.

© 2019 Cutting Edge Optronics, Inc. v Patara II and Iklwa II Service Manual

Conventions

The following conventions appear in this manual:

This icon denotes a caution or a warning, which advise you of precautions to

take to avoid injury, data loss, or a system crash.

Initial Capped

The first letter in uppercase refers to menu options, e.g., Phase Delay, Pulse

Width.

CAPS

Front-panel buttons, knobs, and connectors appear in all uppercase letters, e.g.,

MENU, CURRENT.

The symbol separates a sequence of button pushes, e.g., MENU

CHANNEL SETUP PULSE WIDTH means that you push the MENU

button, then push the CHANNEL SETUP soft key, and then push the PULSE

WIDTH soft key.

italic

Italic text denotes references to other resources that may be helpful to you or to

bring attention to important information.

This icon denotes a note, which alerts you to important information.

I

O

Power Switch Position Symbols

I = On O = Off

The following conventions may appear on the product:

DANGER

An injury hazard immediately accessible as you read the marking.

WARNING

A hazard not immediately accessible as you read the marking.

CAUTION

A hazard to property including the product.

ESD: Handle Appropriately

© 2019 Cutting Edge Optronics, Inc. vi Patara II and Iklwa II Service Manual

Laser Emission: Use caution.

Shock Hazard: Use caution.

Caution: Risk of danger. Refer to manual.

Chassis Ground

Additional Resources

NG is committed to providing support for all customers. Installation how-to

videos, technical manuals, and descriptions and specifications of products can be

found by visiting http://www.ngceoservice.com.

© 2019 Cutting Edge Optronics, Inc. vii Patara II and Iklwa II Service Manual

Table of Contents

Chapter 1: General Instructions 1

Safety 1

Cleanliness 3

Tools, Equipment, and Materials 3

Alignment Reference, Test Set-up and Laser Layout 4

Fastener Torque and Tack Locations 6

Servicing the Laser 7

Chapter 2: Laser Component Replacement Procedures 12

Align HeNe to Optic 12

Aperture Removal 13

Aperture Replacement 14

Coolant Line Purge 14

Desiccant Replacement 14

Emission Light Replacement 16

Flow Switch Assembly Replacement 16

Fold Mirror / Output Coupler Replacement 17

HM Replacement 17

HR Replacement 18

Install Cover 19

Interlock Replacement 20

Laser Module Alignment 20

Laser Module Replacement 23

© 2019 Cutting Edge Optronics, Inc. viii Patara II and Iklwa II Service Manual

Optics Bonding 24

Output Window Replacement 25

Polarizer Assembly Removal and Replacement 26

Q-Switch Replacement 26

Remove Cover 28

Remove Q-Switch from Beam Path 29

SHG Crystal Replacement and Alignment 30

Shutter Replacement 34

Steering Mirror Replacement 35

Waveplate Replacement 37

Chapter 3: Tuning and Testing Procedures 39

Align for Q-Switch Hold-Off 39

Power the Laser for Alignment 39

Check Hold Off 40

Check for Bullseye 40

Defeating the Cover Interlock 41

HR/HM Alignment 41

Laser Optimization 43

Leak Test 45

Walking the Cavity 46

Appendix A: Customer Service 47

Questions 48

Appendix B: System International Units 50

Appendix C: Acronyms 51

© 2019 Cutting Edge Optronics, Inc. ix Patara II and Iklwa II Service Manual

Table of Figures

Figure 1-1: Laser Alignment and Test Set-up Diagram 5

Figure 1-2: Optical Bench Overview 5

Figure 1-3: Laser Layout and Component Locations 6

Table 1-1: Recommended Torque Values 6

Figure 1-4: Laser Tack Locations 7

Table 1-2: Service Action Table 7

Figure 2-1: Aperture Assembly (AA21) 13

Figure 2-2: 40 Gram Desiccant Cartridge Top 15

Figure 2-3: 40 Gram Desiccant Cartridge Bottom 15

Figure 2-4: 50 Gram Refill and Refill Tool 15

Figure 2-5: Flow Switch Assembly (177594) 16

Figure 2-6: Optical Mount (MM64), Exploded View 17

Figure 2-7: Optical Mount Showing Screw Locations 18

Figure 2-8: Optical Mount Showing Screw Locations 19

Figure 2-9: Shutter Rotated Out of Beam Path 21

Figure 2-10: HeNe Bullseye Pattern 21

Figure 2-11: Pinhole Alignment with Pinless Aperture 22

Figure 2-12: Location of Laser Module (yellow), HR Mirror (green), and Polarizer (red)

23

Figure 2-15: Polarizer Being Removed 26

Figure 2-16: Loosening Hard Plumbing 27

Figure 2-17: Location of Q-Switch Attachment Hardware 27

Figure 2-18: Tightening Hard Plumbing 28

© 2019 Cutting Edge Optronics, Inc. x Patara II and Iklwa II Service Manual

Figure 2-19: Cables Secured Out of Beam Path 28

Figure 2-20: Removal of the Q-Switch Hard Plumbing 29

Figure 2-21: Location of Q-Switch Attachment Hardware 29

Figure 2-22: SHG Mount Location 30

Figure 2-23: Ball Plunger Screw Locations 30

Figure 2-24: Insulators, Crystal and Load Spreader 31

Figure 2-25: Indium Foil Placement 31

Figure 2-26: Ball Plungers for Mount 32

Figure 2-25: Ball Plunger Holding Components in Place 32

Figure 2-26: Finished SHG assembly 33

Figure 2-27 Alignment Process 34

Figure 2-29: Location of 2216 on Mount 36

Figure 2-30: Location of 2216 on Optic 36

Figure 2-31: Steering Mirror Layout 37

Figure 3-1: Location of Q-Switch Attachment Hardware 39

Figure 3-2: HeNe Bullseye Pattern 41

Figure 3-3: The Cover Interlock Switch 41

Figure 3-4: Accessible Holes for HR and HM Cavity Mirror Adjustment 42

Figure 3-5: Example of Laser Performance Dependence on the SHG Temperature 44

Figure 3-6: Example of Laser Performance Dependence on the Operating Current 45

Figure 3-7 Nitrogen Leak Test Layout 45

1

© 2016 Cutting Edge Optronics 1 Patara II and Iklwa II Service Manual

Chapter 1: General Instructions

Safety

Some repair and diagnostic procedures require the opening of the laser while the

system is running. Wear the correct eye protection and also be careful of electrical

hazards. The laser system has been designed to minimize the risk, but still be

cautious and conscious of your and others safety.

Precautions for Safe Operation of Class IV Lasers

Never look directly into the laser beam or at specular reflection, even with

protective eye-wear on.

Always wear laser safety eye-wear that is appropriate for the output power at

the wavelengths of operation (532 nm, 808 nm and 1064 nm).

Set aside a controlled-access area for laser operation; limit access to those

trained in the principles of laser safety.

Post readily readable warning signs in prominent locations near the laser

operation area.

Use safety interlocks on all entryways. All NG system control electronics are

provided with interlock inputs to preclude operation with an open safety door.

NOTE: when multiple interlocks are used, they must be connected in SERIES

for proper function.

Restrict access to laser areas to those who have been instructed in the

necessary safety precautions.

Enclose beam paths wherever possible.

Set up experiments so the laser beam is below eye level.

Work in an area that is well lit to avoid dilation of pupils.

Set up a target for the beam.

Set up shields to prevent reflected beams from escaping the laser operation

area.

The Q-switched output power of the laser emits extremely high peak optical

powers, powers that can severely damage a wide array of optical components

Chapter 1: General Instructions

© 2019 Cutting Edge Optronics 2 Patara II and Iklwa II Service Manual

and detectors. Know the limits of your components before exposing them to

the Q-switched beam.

View an infrared laser beam with a protected image converter at an oblique

angle reflecting from a diffuse surface. Do not use phosphorus cards in the Q-

switched beam.

Insure that all electrical connections are made in a safe manner.

Where possible, position equipment so that electrical connections are shielded

from accidental touch.

No smoking, eating, or drinking should be allowed in laser areas.

Never leave an operating laser unattended.

Caution & Warning Statements

WARNING The NG component when used as a laser oscillator is a Class IV-High

Power Laser whose beam is, by definition, a safety hazard. Avoid eye or skin exposure

to direct or scattered laser radiation. Avoid direct viewing of the beam or its specular

reflection. When energized, a large amount of high power invisible laser radiation is

emitted from the laser module.

Follow instructions contained in this manual for proper installation and safe operation

of your laser. We recommend the use of protective eyewear at all times; selection

depends on the energy and wavelength of the laser beam as well as operating

conditions. Consult ANSI, ACGIH, or OSHA standards for guidance.

WARNING Use of controls, adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

WARNING At all times during installation, operation, maintenance, or service of your

laser, avoid exposure to laser or collateral radiation exceeding the accessible emission

limits listed in “Performance Standards for Laser Products,” United States Code of

Federal Regulations, 21 CFR 1040 10(d).

ESD CAUTION The laser diodes in the Laser Diode Module are sensitive to Electro-

Static Discharge (ESD). Never handle the module without being properly grounded

through the use of properly installed and maintained grounding wrist straps or other

ESD control devices. Subjecting the module to static shock can seriously damage or

destroy the diode bars, and will void the product warranty.

ELECTRICAL WARNING The voltages in this system can be harmful or even lethal.

Whenever handling or servicing the laser, always disconnect the power cord to the

power supplies and drivers. Allow at least five (5) minutes for all electronics to

discharge before touching or grounding of electrical connections.

Chapter 1: General Instructions

© 2019 Cutting Edge Optronics 3 Patara II and Iklwa II Service Manual

WARNING NG recommends that a qualified service technician perform the service on

the laser to avoid any damage.

NOTE: Laser safety goggles for 532nm must be worn during lasing process.

NOTE: Gloves must be worn at all times during service. Service procedures must be

performed in a clean room environment when the cover is removed.

Cleanliness

The laser is a delicate piece of hardware and is susceptible to optical damage due

to contamination. WEAR GLOVES AND OPEN THE LASER IN THE

CLEANEST ENVIRONMENT AVAILABLE. Do not use any unauthorized

epoxy or glue in the laser housing. DO NOT TOUCH THE OPTICAL

SURFACES. Optical surfaces should be inspected using a 10x microscope with

15 W illumination. Optical surfaces should only be cleaned if there is visible

contamination. Only optical grade methanol or acetone should be used with lint

free lens tissue. Failure to keep a clean environment may lead to permanent

damage to optical surfaces.

After performing any procedures contained in this manual, always inspect the

laser for debris before replacing the cover.

Tools, Equipment, and Materials

TechniCloth III™ wipes

Isopropyl alcohol

Streamlight™ Stylus Green LED pen

Allen wrenches

Torque wrench

Spanner wrench

SwageLok Go No Go Gauge

Open ended wrenches

Heat Gun

Chapter 1: General Instructions

© 2019 Cutting Edge Optronics 4 Patara II and Iklwa II Service Manual

Power Meter (minimum 30W rating)

Camera System (Spiricon preferred)

Fused silica 3% wedge

Filter Wheel

0.391 meter focal length lens PLCX-50.8-180.3-UV-1064/532

Fast Photodiode with BNC cable and oscilloscope (100 MHz min)

Neg Lens part number PLCC-25.4-25.8-UV-1064/532

HeNe alignment laser and turn mirrors

Microscope with surface illumination

60-658-1 Alignment Aperture without Alignment Pin

Desiccant cartridge NG part no. 42-228

Desiccant Refill part number 643665

Desiccant Refill tool 980412

McMaster Disposable Tube-Fitting Filter part no. 4795K22

McMaster Female QD part no. 5012K83

McMaster ¼” Hose part no. 52375K32

McMaster 3/16” Hose part no. 52375K31

Male QD O-Rings #011 Black Viton (2 required)

Output Window O-Rings #020 Black Viton (2 required)

8” Nylon clear cable ties

Side cutters

3M 2216 two part epoxy

X-ACTO Knife

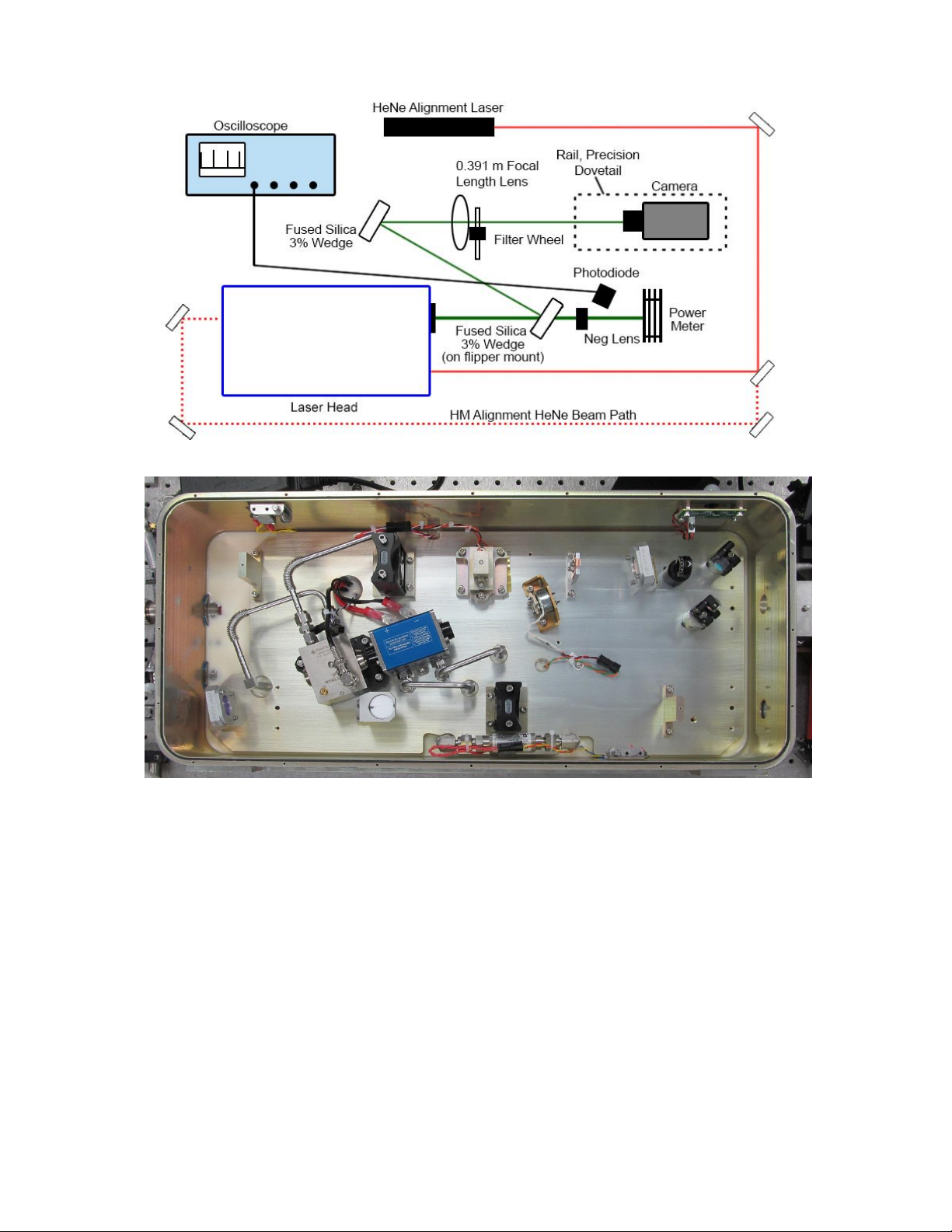

Alignment Reference, Test Set-up and Laser Layout

If possible, the laser should be referenced to a HeNe (or similar alignment laser)

prior to any modifications to the laser. The ideal testing and tuning set-up is

shown in Figure 1-1. The layout and location of the laser components are shown

in Figure 1-2.

Chapter 1: General Instructions

© 2019 Cutting Edge Optronics 5 Patara II and Iklwa II Service Manual

Figure 1-1: Laser Alignment and Test Set-up Diagram

c

Figure 1-2: Optical Bench Overview

Chapter 1: General Instructions

© 2019 Cutting Edge Optronics 6 Patara II and Iklwa II Service Manual

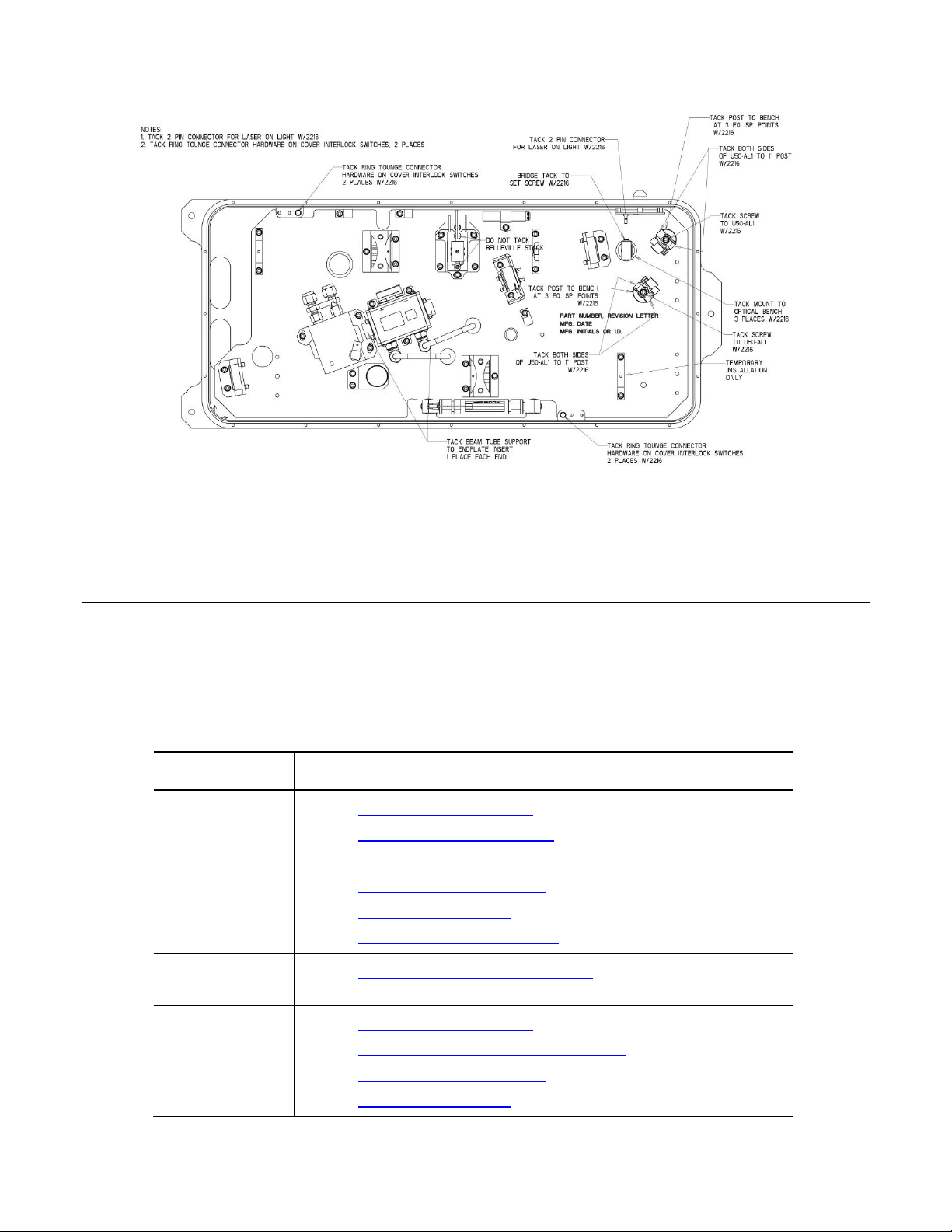

Figure 1-3: Laser Layout and Component Locations

Fastener Torque and Tack Locations

After replacement of laser components, all fasteners should be tightened, unless

otherwise specified, to the recommended torque value contained in Table 1-1,

below

Table 1-1: Recommended Torque Values

Fastener

Size

Recommended

Torque (IN-LBS)

4-40

5.5 +/- 0.5

6-32

14 +/- 1

8-32

25 +/- 1

10-32

40 +/- 2

1/4-20

80 +/- 3

Tack locations are shown in Figure 1-3. NG recommends using 3M 2216 for

tacking components and fasteners as indicated. Allow for a minimum of 12 hours

of curing time before closing the laser housing.

Chapter 1: General Instructions

© 2019 Cutting Edge Optronics 7 Patara II and Iklwa II Service Manual

Figure 1-4: Laser Tack Locations

Servicing the Laser

The following table lists the recommended order of procedures to successfully

perform service operations on the laser. Refer to the sections contained in this

service manual for detailed instructions.

Table 1-2: Service Action Table

Service

Operation

Order of procedures

Replacing the

Aperture

1. Remove Cover (page 28)

2. Aperture Removal (page 13)

3. Aperture Replacement (page 14)

4. Tack Components (page 6)

5. Install Cover (page19)

6. Laser Optimization (page 43)

Replace

Desiccant

1. Desiccant Replacement (page 14)

Replacing the

Emission Light

1. Remove Cover (page 28)

2. Emission Light Replacement (page 16)

3. Tack Components (page 6)

4. Install Cover (page19)

Chapter 1: General Instructions

© 2019 Cutting Edge Optronics 8 Patara II and Iklwa II Service Manual

Service

Operation

Order of procedures

Replacing the

Flow Switch

1. Remove Cover (page 28)

2. Coolant Line Purge (page 14)

3. Flow Switch Assembly Replacement (page 16)

4. Leak Test (page 45)

5. Install Cover (page19)

Replace the Fold

Mirror or OC

Optic

1. Remove Cover (page 28)

2. Fold Mirror / Output Coupler Replacement (page 17)

3. Defeat Cover Interlocks (page 41)

4. Power Laser for Alignment (page 39)

5. Check for Bullseye (page 40)

If concentric go to step 7

6. HR/HM Alignment (page 17-18) (HR first if replacing Fold

Mirror, HM first if replacing OC)

7. Check Hold-Off (page 40)

8. Install Cover (page19)

9. Laser Optimization (page 43)

10. Check Hold-Off (page 40)

Replace the HM

1. Remove Cover (page 28)

2. Align HeNe to Optic (page 12) (reference point)

3. HM Replacement (page 17)

Use HM adjustment screws to align HeNe reflection

back to reference point.

4. Defeat Cover Interlocks (page 41)

5. Power Laser for Alignment (page 39)

6. Check for Bulleye (page 40)

If concentric go to Step 8

7. HR/HM Alignment (page 17-18) (HR alignment may not be

necessary)

8. Check Hold-Off (page 40)

9. Tack Components (page 6)

10. Install Cover (page19)

11. Laser Optimization (page 43)

12. Check Hold-Off (page 40)

Chapter 1: General Instructions

© 2019 Cutting Edge Optronics 9 Patara II and Iklwa II Service Manual

Service

Operation

Order of procedures

Replace the HR

1. Remove Cover (page 28)

2. Align HeNe to Optic (page 12) (reference point)

3. HR Replacement (page 18)

4. Defeat Cover Interlocks (page 41)

5. Power Laser for Alignment (page 39)

6. Check for Bullseye (page 40)

If concentric go to step 8

7. HR/HM Alignment (page 17-18) (HM alignment may not be

necessary)

8. Check Hold-Off (page 40)

9. Tack Components (page 6)

10. Install Cover (page19)

11. Laser Optimization (page 43)

12. Check Hold-Off (page 40)

Replacing the

Interlocks

1. Remove Cover (page 28)

2. Interlock Replacement

3. Install Cover (page19)

Chapter 1: General Instructions

© 2019 Cutting Edge Optronics 10 Patara II and Iklwa II Service Manual

Service

Operation

Order of procedures

Replacing the

Module

1. Coolant Line Purge (page 14)

2. Remove Cover (page 28)

3. Polarizer Removal and Installation (page 26)

Step 1-2

4. HR Replacement (page 18)

Step 1

5. Laser Module Replacement (page 23)

6. Aperture Remove (page 13)

7. HM Replacement (page 17)

Removal Only

1. Remove Q-switch from Beam Path (page 29)

2. SHG Crystal Replacement and Alignment (page 30)

Step 1-2

3. Laser Module Alignment (page 20)

4. Q-Switch Replacement (page 27)

Replacement Steps Only

5. Polarizer Removal and Installation (page 26)

Installation Only

6. Leak Test (page 45)

7. Defeating the Cover Interlocks (page 41)

8. Power the Laser for Alignment (page 39)

9. SHG Replacement and Alignment (Step 15-20)

10. HR/HM Alignment (page 17-18)

11. Align Q-switch for Hold-Off (page 39)

12. Aperture Replacement (page 14)

13. Tack Components (page 6)

14. Install Cover (page19)

15. Laser Optimization (page 43)

16. Check Hold-Off (page 40)

Replacing the

Output Window

1. Output Window Replacement (page 26)

Replacing the

Polarizer

Assembly

1. Remove Cover (page 28)

2. Polarizer Assembly Removal and Replacement (page 26)

3. Tack Components (page 6)

4. Install Cover (page19)

5. Power Laser on for Alignment (page 39)

6. Laser Optimization (page 43)

7. Check Hold-Off (page 40)

This manual suits for next models

1

Table of contents

Other NORTHROP GRUMMAN Measuring Instrument manuals

NORTHROP GRUMMAN

NORTHROP GRUMMAN IKA-012-QTG User manual

NORTHROP GRUMMAN

NORTHROP GRUMMAN Patara EPL-016-QTG User manual

NORTHROP GRUMMAN

NORTHROP GRUMMAN Patara II Manual

NORTHROP GRUMMAN

NORTHROP GRUMMAN Patara I User manual

NORTHROP GRUMMAN

NORTHROP GRUMMAN IR Patara Laser System User manual

NORTHROP GRUMMAN

NORTHROP GRUMMAN NORMARC 7710 NAV User manual

NORTHROP GRUMMAN

NORTHROP GRUMMAN Sperry Marine NAVIGAT X MK 2 User manual