Rules for Safe Operation

Training

WARNING:

1. Read the log lift Operator’s Manual the log splitter Operator’s Manual and the engine owner’s manual completely before

attempting to use the log lift. Serious injury or death can result if safety instructions are not followed.

2. Do not allow anyone to operate the log lift who has not read the Operator’s Manual or has not been instructed on the

safe use of the log splitter.

3. Never allow anyone under 16 years old or untrained adults operate the log lift. Children 16 years and older must be

trained and supervised by a trained adult.

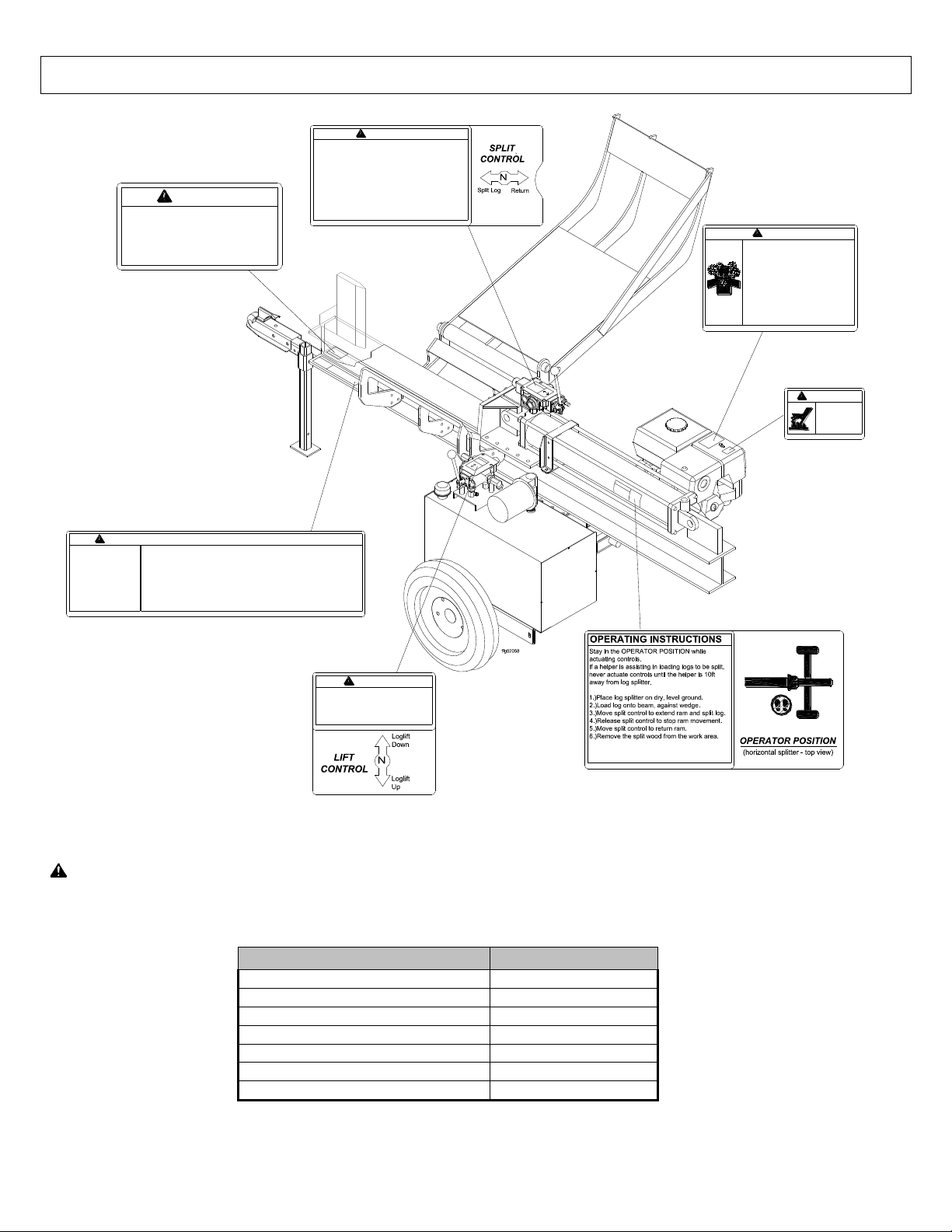

4. CRUSH HAZARD. Moving parts from log lift can crush and cut. Keep hands and feet away. Only one (1) person should

operate this log lift because many accidents occur when more than one (1) person operates the log lift. If a helper is

assisting in loading logs to be split, never operate control valve handle until the helper and bystanders are at least 10ft

from the log lift.

5. MOVING VEHICLE HAZARDS. Review towing safety warnings in your towing vehicle manual. Drive safely. Drive slowly

when you encounter bad driving conditions such as bumpy roads or railroad crossings.

a.) Be aware of the added length of the log splitter.

b.) Make sure the log splitter is securely attached to the towing vehicle before towing.

c.) Never tow this splitter while under the influence of alcohol, drugs, or medication.

d.) Turn off the towing vehicle before leaving the log splitter unattended.

e.) Do not use the log splitter while it is connected to the towing vehicle.

f.) Do not tow this log splitter on any street, highway or public road without checking existing federal, state, or local

requirements. Any licensing or the addition of trailer lights if needed to comply is the sole responsibility of the

purchaser.

g.) Never tow log splitter over 45mph. Faster speeds may result in loss of control of the log splitter.

h.) Make sure all local, state, and federal towing requirements are met. Then, refer to the Towing the Log splitter

section in this manual to make sure the log splitter is towed properly.

i.) Never allow anyone to sit or ride on the log splitter.

j.) Never transport cargo or wood on the log splitter.

6. HYDRAULIC INJECTION HAZARD. High fluid pressures and temperatures are developed in hydraulic log splitters.

Hydraulic fluid escaping through a pin hole opening can burn and cause wounds that result in severe blood poisoning,

infection, disability, gangrene, amputation, or death. Therefore, the following instructions should be heeded at all times.

a.) Do not operate the log splitter with frayed, kinked, cracked or damaged hoses, fittings, or tubing.

b.) Stop the engine, disconnect spark plug, and move all control valve handles back and forth to relieve system

pressures before changing or adjusting fittings, hoses, tubing, or other system components.

c.) Do not adjust the pressure setting of the pump or valve.

d.) Do not check for leaks with your hand. Leaks can be located by holding a piece of cardboard or wood (at least

two feet long) with your hand at one end and passing the other end over the suspected area (wear safety

glasses). Look for discoloration of the cardboard or wood. If injured by escaping fluid, no matter how small the

wound is, see a doctor at once. A typical injection injury may be a small puncture wound that does not look

serious. However, severe blood poisoning, infection, disability, gangrene, amputation, or death can result if

proper medical treatment is not administered immediately by a doctor who is familiar with injection injuries.

e.) Do not remove the hydraulic oil fill cap when engine is running. Hot oil can escape causing severe burns. Allow

log splitter to cool completely before removing hydraulic oil fill cap.

7. FALL HAZARD. Split logs and any other obstructions left in the area around the log splitter are a safety hazard. Please

remove logs as they are split and remove any obstructions so they do not cause you to trip and fall.

8. FIRE HAZARD. If your log splitter is intended for use near any unimproved forest, brush, or grassy covered land, the

engine should be equipped with a spark arrester. See the “Specifications” section to determine if you already have a

spark arrester on your log splitter. Make sure you comply with applicable local, state, and federal codes. Take with you

a fire extinguisher that puts out fires involving ordinary combustibles and flammable liquids.

9. EXPOSURE HAZARD. Engine exhaust, some of its constituents, and certain vehicle components contain or emit

chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

10. Log splitters should be used only for splitting wood. Do not use for other purposes unless the manufacturer provides

attachments and instructions.

11. Log lifts should be used only for lifting wood. Do not use for other purposes.

12. FIRE HAZARD. Do not modify or add to exhaust system. Fire can result.

13. FIRE HAZARD. Do not modify or add fuel tanks or fuel lines. Fire can result.